How to Professionally Rebuild and

Modify Kohler Engines to Produce More Power

How to Professionally Rebuild and

Modify Kohler Engines to Produce More Power

How to Professionally Rebuild and

Modify Kohler Engines to Produce More Power

How to Professionally Rebuild and

Modify Kohler Engines to Produce More Power

Educating and Inspiring Small Engine, Lawn & Garden, and Garden

Pulling Tractor Enthusiasts Since 1996. Where Science and Common Sense Come

Together for Safety and Improved Engine/Tractor Performance |

A-1

Miller's Performance Enterprises - Parts & Services

Webstore |  Available Soon - Detailed Illustrated Plans

on How to Construct a Professional Pull-Back and Self-Propelled Garden

Tractor/Small Wheel Mini Rod Pulling Sleds

Available Soon - Detailed Illustrated Plans

on How to Construct a Professional Pull-Back and Self-Propelled Garden

Tractor/Small Wheel Mini Rod Pulling Sleds

Updated 9/9/25. Click

Refresh to see any

changes or updates. Optimized for 1152 x 864 computer screen resolution.

To search for a word or phrase in any of my websites, press the CTRL

and F

and F  keys on

your keyboard simultaneously to open the Find or Search dialog box in your

web browser. And being I have no

apprentice to update and pay for my websites so they'll

continue to be on the Internet, they will be removed forever when I'm no

longer around. Scroll down this website or click/tap the links below to

jump down to...

keys on

your keyboard simultaneously to open the Find or Search dialog box in your

web browser. And being I have no

apprentice to update and pay for my websites so they'll

continue to be on the Internet, they will be removed forever when I'm no

longer around. Scroll down this website or click/tap the links below to

jump down to...

Decoding Kohler K-series and Magnum Engine Model, Specification and Serial Identification Numbers -

The Kohler K-series and Magnum engine

model and serial numbers appear on an adhered metallic vinyl label or a riveted

aluminum plate that's affixed to the flywheel shroud. If there's no plate

or label on the shroud, if the printed ink lettering and numbers on the plate

or label is faded away, or if the shroud was replaced with one from another

engine, then there's no way of knowing exactly which specific parts the engine

requires or the year the engine was manufactured. If the plate or label have

legible wording and numbers, all you'll know is the model, specification

and year of the flywheel shroud itself. Because flywheel shrouds can

be swapped from one engine to another and unlike most automotive engines

with identification numbers stamped directly on the block, there are no

identification numbers on Kohler engine blocks themselves. Only an experienced

and knowledgeable Kohler K-series or Magnum engine mechanic will know exactly

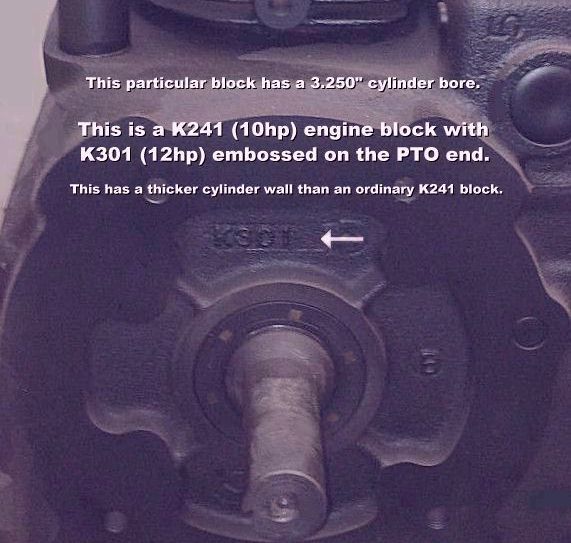

which specific parts the engine requires. Certain Kohler K-series engines

have the model number embossed on the Power Take Off (PTO) end of the block,

but this is rare. Therefore, if the flywheel shroud is missing or if it's

mismatched with the correct engine, the only true way finding for sure the

size and model is to remove the cylinder head and measure the bore and stroke.

Otherwise, they're like the early small and big block Chevy V8's, and the

Chevy 348 and 409 "W" engines

The Kohler K-series and Magnum engine

model and serial numbers appear on an adhered metallic vinyl label or a riveted

aluminum plate that's affixed to the flywheel shroud. If there's no plate

or label on the shroud, if the printed ink lettering and numbers on the plate

or label is faded away, or if the shroud was replaced with one from another

engine, then there's no way of knowing exactly which specific parts the engine

requires or the year the engine was manufactured. If the plate or label have

legible wording and numbers, all you'll know is the model, specification

and year of the flywheel shroud itself. Because flywheel shrouds can

be swapped from one engine to another and unlike most automotive engines

with identification numbers stamped directly on the block, there are no

identification numbers on Kohler engine blocks themselves. Only an experienced

and knowledgeable Kohler K-series or Magnum engine mechanic will know exactly

which specific parts the engine requires. Certain Kohler K-series engines

have the model number embossed on the Power Take Off (PTO) end of the block,

but this is rare. Therefore, if the flywheel shroud is missing or if it's

mismatched with the correct engine, the only true way finding for sure the

size and model is to remove the cylinder head and measure the bore and stroke.

Otherwise, they're like the early small and big block Chevy V8's, and the

Chevy 348 and 409 "W" engines  ,

there's no way of knowing for sure simply by looking at it from the outside.

Because a Kohler K241 or M10 engine block can be bored and stroked to a model

K301, M12, using the K301 or M12 piston, rod and crankshaft, and a K301 or

M12 block can be bored to a model K321 or M14 using the K321 or M14 piston,

rod and crankshaft. But the models K341 or M16 blocks are in a class by

themselves. A K321 or M14 block could be bored for the K341 or M16 piston,

but doing this would make the cylinder wall about 1/8" thick, or the boring

process could break through the cylinder wall without centering the boring

bar according to the outside of the cylinder beforehand. Therefore, this

is NOT recommended.

,

there's no way of knowing for sure simply by looking at it from the outside.

Because a Kohler K241 or M10 engine block can be bored and stroked to a model

K301, M12, using the K301 or M12 piston, rod and crankshaft, and a K301 or

M12 block can be bored to a model K321 or M14 using the K321 or M14 piston,

rod and crankshaft. But the models K341 or M16 blocks are in a class by

themselves. A K321 or M14 block could be bored for the K341 or M16 piston,

but doing this would make the cylinder wall about 1/8" thick, or the boring

process could break through the cylinder wall without centering the boring

bar according to the outside of the cylinder beforehand. Therefore, this

is NOT recommended.

Bore, Stroke and Valve Sizes of Kohler K-series and Magnum engines:

| Engine Model | K90/K91 | K141 (early) | K141 (later) | K160/K161, KV161, L160/L161 (early models) | K160/K161, KV161, L160/L161 (later models) | L181, K181 and M8 | K241 and M10 | K301 and M12 | K330/K331 | K321 and M14 | K341 and M16 | K361 (OHV) | |

| Bore (STD) | 2.375" | 2.875" | 2.938" | 2.875" | 2.938" | 2.938" | 3.250" | 3.375" | 3.625" | 3.500" | 3.750" | 3.750" | |

| Stroke | 2.000" | 2.500" | 2.500" | 2.500" | 2.500" | 2.750" | 2.875" | 3.250" | 3.250" | 3.250" | 3.250" | 3.250" | |

| Cubic Inch Displacement | 8.86 | 16.23 | 16.94 | 16.23 | 16.94 | 18.64 | 23.85 | 29.08 | 33.54 | 31.27 | 35.895 | 35.895 | |

| Minimum Safe Idle Speed | <-1,200 RPM (±75 RPM)-> | ||||||||||||

| Factory-Rated Horsepower at Maximum Safe Operating Speed |

4hp at 4,000 RPM | 6¼hp at 3,200 RPM | 7hp at 3,600 RPM | 6¼hp at 3,200 RPM | 6.6hp at 3,600 RPM | 7hp at 3,600 RPM | 8hp at 3,600 RPM | 10hp at 3,600 RPM | 12hp at 3,600 RPM | 12½hp at 3,200 RPM | 14hp at 3,600 RPM | 16hp at 3,600 RPM | 18hp at 3,600 RPM | |

| Valve Size (Head diameter) | Intake | 1.262" | 1-3/8" | 1-3/8" | 1-3/8" | 1-3/8" | 1-3/8" | 1-3/8" | 1-3/8" | ? | 1-3/8" | 1-3/8" | 1-7/16" |

| Exhaust | 1.262" | 1-1/8" | 1-1/8" | 1-1/8" | 1-1/8" | 1-1/8" | 1-1/8" | 1-1/8" | ? | 1-1/8" (Early K321's) 1-3/8" (Later K321's with specification suffix "D" and later, and all M14's) |

1-3/8" | 1-13/32" | |

How to Decode the Model Numbers of Kohler K-series and Magnum Engines - These determine the size and basic description of the engine.

| Example of Model K161 -> K = K-series engine | 16 = Cubic inch

displacement (approximate) | 1 = One/single cylinder engine

Example of Model KV161 -> K = K-series engine | V = Vertical crankshaft | 16 = Cubic inch displacement (approximate) | 1 = One/single cylinder engine Example of Model L161 -> L = Liquid-cooled engine | 16 = Cubic inch displacement (approximate) | 1 = One/single cylinder engine Example of Model K301AQS -> K = K-series engine | 30 = Cubic inch displacement (approximate) | 1 = One/single cylinder engine | A = Narrow Base Block and/or Special Oil Pan | Q = Quiet Model "Quiet Line" | S = Electric (Gear) Start Example of Model M14PT -> M = Magnum series engine | 14 = Horsepower rating | PT = Pump model/Retractable start Example of Model KT17 -> K = K-series engine | T = Twin cylinder | 17 = Horsepower rating Example of Model M18 -> M = Magnum engine | 18 = Horsepower rating Example of Model K482 -> K = K-series engine | 48 = Cubic inch displacement (approximate) | 2 = Two (twin) cylinder engine By the way - The model numbers corresponding to Kohler engine models K90/K91, K160/K161, K330/K331, and K660/K662 are basically the same engines, respectively. Beginning in 1965, Kohler changed the "0" to "1" or "2" at the end of the model number to indicate that it's a one (1) or two (2) cylinder engine. The History of Kohler Engines | eHow. |

How to Decode the Version Codes for Kohler K-series and Magnum Single- and Opposed Twin-Cylinder Engines - These are the letter(s) immediately following the engine model number, indicating the type of engine.

| A = Narrow

Base Block w/Narrow Oil Pan and/or Special Oil Pan B = Basic Engine C = Clutch (OEM Kohler Mechanical Clutch Unit) |

G = Generator

(Electric Power Plant) P = (Water) Pump Q = Quiet Line Model |

R = Reduction

Gear S = Electric (Gear) Start T = Recoil Start |

ST = Electric (Gear) Start and Recoil

Start EP = Electric Power Plant (Portable or Stationary Stand-By Generator) |

How to Decode the Specification Numbers for Kohler K-series and Magnum Single- and Opposed Twin-Cylinder Engines - The first two numbers of the specification number indicate the engine model. The following three numbers and letter (not shown below) are the specific variation of the engine to meet the original equipment manufacturer's (OEM) specifications. No information is available from Kohler to what these numbers represent. Engine model codes with a 4th digit of 5 or greater denote Magnum engines.

| Specification Number = Model(s) of Engine | Specification Number = Model(s) of Engine | Specification Number = Model(s) of Engine | Specification Number = Model(s) of Engine | Specification Number = Model(s) of Engine |

| 26, 27, 31 = K90 and K91 | 29 = K141 | 28 = K160, K161 and

L160/L161 41, 42 = K160 and K161 (Generator Specs) |

30 = K181, L181 and M8 | 46 = K241 and M10 |

| 47 = K301 and M12 | 60 = K321 and M14 | 71 = K341 and M16 | 23 = K361 | 24 = KT17 (first design), KT17 Series II and M18 |

| 49 = KT19 (first design), KT19 Series II and M20 | 32 = KT21 | 56 = MV16 | 58 = MV18 | 57 = MV20 |

| 35 = K482 | 53 = K532 | 36 = K582 | 37, 38, 43, 44 = K330 and 331 | 29, 30, 33, 39, 45 = K660 and K662 |

How to Decode the Serial Numbers for Kohler K-series and Magnum Single- and Opposed Twin-Cylinder Engines - The letter or the first two or three numbers of the serial number indicates the year the engine was manufactured. The remaining digits of the serial number are factory code (line/shift at the factory when the engine was assembled on that day; these numbers are for warranty purposes only.) FYI - In 1951, Kohler released the model K90 engine (which is actually the K91). The model K160 (which is actually the K161) followed in 1952. No serial numbers are available these early model engines. In 1968, Kohler expanded into the small all terrain vehicle market by beginning to produce 2-cylinder snowmobile engines. In 1984, Kohler revealed new style and improvements through the Magnum series, complete with electronic ignition and "superior" air filtration system.

| Letter code. E 1 7 2 4 5 2 (example) |

If seven numbers, use the first two digits. 9 0 7 6 4 3 0 (example) |

If eight numbers, use the first three digits. 1 0 0 2 6 6 9 2 (example) |

If ten numbers, use the first two digits. 1 5 0 1 8 9 7 5 9 1 (example) |

|

| (See below for models made before 1965) A............1965 B............1966 C............1967 D............1968 E...(early)1969 |

10-19...(late)1969 20-29...........1970 30-39...........1971 40-49...........1972 50-59...........1973 60-69...........1974 70-72...........1975 73-79...........1976 80-89...........1977 90-94...........1978 95-99...........1979 |

100-109.............1980 110-119.............1981 120-129.............1982 130-139.............1983 140-149.............1984 150-159...(early)1985 |

15...(late)1985 16...........1986 17...........1987 18...........1988 19...........1989 20...........1990 21...........1991 22...........1992 23...........1993 24...........1994 25...........1995 26...........1996 27...........1997 28...........1998 |

29...........1999 30...........2000 31...........2001 32...........2002 33...........2003 34...........2004 35...........2005 36...........2006 37...........2007 38...........2008 39...........2009 40...........2010 41...........2011 |

| Before 1965, Kohler did not give any of their engines a serial

number manufacturing date. No information is available from Kohler regarding

the year of manufacture for these early engines, with the exception of the

engine model and specification numbers listed below.

K90P-2667 Carver Pump Co. 1955 | K90T-27191 Canadian Tap & Die 1957 | K91S-31544 Cart Craft Co. 1961 | K91P-3106, 3167 Carver Pump Co. 1958 | K141P-29111 Carver Pump Co. 1962 | K141-29140 Canasco Products 1963 | K160P-2881 Carver Pump Co. 1955 | K161S-28636 Canadian Golf Cars 1961 | K161S-28854 Canadian Golf Cars 1962 | K161CS-28374 Carson Machine 1959 | K161P-28643 Carver Military Pump Co. 1961 | K161T-28711 Carson Machine 1962 | K181S-30204 Canadian Golf Cars 1964 | K181S-30207 Canadian Golf Cars 1964 | K181S-30179 Capri Manufacturing/Golf Car 1963 | K301-4721 Case 1964 | K662P-3333 Carver Pump Co. 1956 | K660P-33177 Carver Pump Co. 1958 | K662P -33278 Carver Pump Co. 1960 | K662CS-33275 Cardox Corporation 1960. |

||||

Kohler Engine Models K330/K331 12-1/2 Horsepower - Sizes and Running Clearances

| PARTS FITTED | SIZE OR CLEARANCE | PARTS FITTED | SIZE OR CLEARANCE | |

| Minimum safe idle speed (RPM) Maximum safe operating speed (RPM) |

1,200 3,200 |

Breaker cam to camshaft pin | .001" - .0025" | |

| Cylinder Bore - STD size | 3.625" | Camshaft end play | .005" - .010" | |

| Closure plate to block | .001" - .005" | Tappet in block | .0008" - .0023" | |

| Crankshaft end play - Models with Oil Pump Crankshaft end play - Models with Splash Lubrication |

.003" - .008" .005" - .010" |

Valve stem in guide - Intake Valve stem in guide - Exhaust |

.002" - .005" .002" - .0035" |

|

| Connecting rod to crankpin running clearance | .0003" - .0023" | Guide in block | .0005" - .002" | |

| Connecting rod side play on crankpin | .007" - .011" | Exhaust valve seat in block | .0025" - .0045" | |

| Crankshaft connecting rod journal size | 1.873" | Transfer bearing to crankshaft, oil clearance | .001" - .0035" | |

| Connecting rod to wrist pin | .0003" - .0008" | Crankshaft gear to crankshaft | .001" - .0015" | |

| Wrist pin to piston boss | .0001" - .0003" | Output shaft seal to closure plate | .001" - .007" | |

| Ring side clearance - top ring | .0025" - .0045" | Governor gear to governor shaft | .0005" - .0015" | |

| Ring side clearance - middle ring | .0025" - .0045" | Piston to cylinder bore clearance (top thrust face) | .0005" - .0015" | |

| Ring side clearance - bottom ring | .002" - .0035" | Valve clearances (cold) - Intake | Exhaust | .008" | .020" | |

| Ring end gap | .007" - .017" | Spark plug gap - Magneto ignition Spark plug gap - Battery ignition |

.025" .035" |

|

| Camshaft pin to camshaft running clearance | .001" - .0025" | Breaker points gap | .020" | |

| Camshaft pin to block | .0015" - .003" | Spark retard (engine start) Spark advance (engine running) |

2º ATDC 15º BTDC |

Kohler K-series Single Cylinder Engine Specifications and Tolerances (All dimensions in inches.)

| Engine Model | K90/K91 | K141, KV161, K160/K161, L160/L161 | L181 and K181 | K241 | K301 | K321 | K341 | K361 (Over Head Valve) |

||||

| General Information | Minimum Safe Idle Speed (See note 11 below) | <-1,200 RPM (±75 RPM)-> | ||||||||||

| Factory-Rated Horsepower at Maximum Safe Operating Speed | 4hp at 4,000 RPM | 6¼hp at 3,200 RPM | 6.6hp at 3,600 RPM | 7hp at 3.600 RPM | 8hp at 3,600 RPM | 10hp at 3,600 RPM | 12hp at 3,600 RPM | 14hp at 3,600 RPM | 16hp at 3,600 RPM | 18hp at 3,600 RPM | ||||

| Bore x Stroke | STD. 2.375" .010" 2.385" .020" 2.395" .030" 2.405" x 2.000" |

6¼ and 6.6hp - STD. 2.875" | 7hp - STD. 2.938" .010" 2.948" .020" 2.958" .030" 2.968" x 2.500" |

STD. 2.938" .010" 2.948" .020" 2.958" .030" 2.968" x 2.750" |

STD. 3.251" .010" 3.261" .020" 3.271" .030" 3.281" x 2.875" |

STD. 3.375" .010" 3.385" .020" 3.395" .030" 3.405" x 3.250" |

STD. 3.500" .010" 3.510" .020" 3.520" .030" 3.530" x 3.250" |

STD. 3.750" .010" 3.760" .020" 3.770" .030" 3.780" x 3.250" |

STD. 3.750" .010" 3.760" .020" 3.770" .030" 3.780" x 3.250" |

||||

| Cubic Inch Displacement (STD Bore) | 8.86 | 16.23 (K141) 16.95 (K161) |

18.64 | 23.85 | 29.07 | 31.27 | 35.90 | 35.90 | ||||

| Compression Ratio | 6.6:1 | 5.93:1 (K141) 6.2:1 (K161) |

6.8:1 | 5:1, 5.4:1 or 7.1:1 (See note 8 below) | 6.2:1, 6.6:1 or 8.6:1 (See note 8 below) | 6.6:1, 7:1 or 9:1 (See note 8 below) | 7.3:1 | 9.2:1 | ||||

| Balance Gears (Not necessarily required for K-series engines, or have rotating assembly precision balanced.) | Shaft O.D. | New | - | - | - | <-.4998"-.5001"-> | ||||||

| Maximum Wear Limit | - | - | - | <-.4996"-> | ||||||||

| Clearance/End-Play | - | - | - | <-.002"-.010"-> | ||||||||

| Camshaft | Clearance/End-Play (See note 10 below) | <-.005"-.010"-> | ||||||||||

| Connecting Rod | Running Clearance (See note 10 below) |

Maximum Big End Diameter | STD. size: .938" / .010" undersize: .928" | <-STD. size: 1.1875" / .010" undersize: 1.1775"-> | <-STD. size: 1.5015" / .010" undersize: 1.4915" / .020" undersize: 1.4815" / .030" undersize: 1.4715"-> | |||||||

| Rod to Crankpin | .001" (min.) .0025" |

<-.001"-.002"-> | ||||||||||

| Maximum Rod to Crankpin Wear Limit | .003" | <-.0025"-> | ||||||||||

| Rod to Piston Pin | .0007" (min.) .0008" |

<-.0006"-.0011"-> | <-.0003"-.0008"-> | |||||||||

| Wrist Pin Hole I.D. | .5630" (min.) .5633" |

<-.6255"-.6258"-> | .8596" (min.) .8599" |

<-.8757"-.8760"-> | ||||||||

| Crankshaft | Main PTO end and Flywheel End O.D. |

New | .9844" | <-1.1814"-> | <-1.5749"-> | |||||||

| Maximum Wear Limit | .9841" | <-1.1811"-> | <-1.5745"-> | |||||||||

| Crankpin | New (max./min.) (See note 10 below) | STD. size: .9360"-.9355" .010" undersize: .9260"-.9255" |

<-STD size: 1.1860"-1.1855", .010" undersize: 1.1760"-1.1755"-> |

STD size: 1.4995"-1.5000", .010" undersize:

1.4895"-1.4900", .020" undersize: 1.4795"-1.4800", .030" undersize: 1.4695"-1.4700" |

||||||||

| Maximum Wear Limit | STD. .9350" .010" .9340" |

<-STD. size: 1.1850" / .010" undersize: 1.1840"-> | <-STD. size: 1.4990" / .010" undersize: 1.4890" / .020" undersize: 1.4790" / .030" undersize: 1.4690"-> | |||||||||

| Maximum Out of Round | <-.0005"-> | |||||||||||

| Maximum Taper | <-.001"-> | |||||||||||

| clearance/end-play (See note 10 below) | .004" (min.) .023" |

<-.002"-.023"-> | <-.003"-.020"-> | |||||||||

| Cylinder Bore | Standard Size Cylinder Bore Diameter | New (See note 10 below) | 2.3745"-2.3755" | <-2.9370"-2.9380"-> | 3.2505"-3.2515" | 3.3745"- 3.3755" |

3.4995"- 3.5005" |

3.7495"-3.7505" | 3.7495"-3.7505" | |||

| Maximum Wear Limit | 2.378" | 2.941" | 2.941" | 3.254" | 3.378" | 3.503" | 3.753" | 3.753" | ||||

| Cylinder Bore Diameter for Oversize Piston/Rings | .010" = 2.385" .020" = 2.285" .030" = 2.405" |

.010" = 2.9475" .020" = 2.9575" .030" = 2.9675" |

.010" = 2.9475" .020" = 2.9575" .030" = 2.9675" |

.010" = 3.260" .020" = 3.270" .030" = 3.280" |

.010" = 3.385" .020" = 3.395" .030" = 3.405" |

.010" = 3.510" .020" = 3.520" .030" = 3.530" |

.010" = 3.760" .020" = 3.770" .030" = 3.780" |

.010" = 3.760" .020" = 3.770" .030" = 3.780" |

||||

| Maximum Out of Round | <-.003"-> | |||||||||||

| Maximum Taper | <-.003"-> | <-.002"-> | ||||||||||

| Cylinder Head | Maximum Out of Flatness | <-.003"-> | ||||||||||

| Ignition | Correct Spark Plug Type and Gap | Type (See note 2 below) | Autolite 255 or Champion 861 (J19LM) | <-Autolite 295 or Champion 841 (J8C)-> | <-Autolite 216 or Champion 884 (H10C)-> | |||||||

| Magneto | <-.025"-> | |||||||||||

| Battery | <-.035"-> | |||||||||||

| LP/Propane | <-.018"-> | |||||||||||

| Point Gap | Magneto | <-If no spark at .020" point gap, set gap between .015"-.018" for a stable spark and so the engine will run-> | ||||||||||

| Battery (See note 12 below) | <-Set point gap at .020" or set timing at 20º BTDC-> | |||||||||||

| All Pistons | Service Replacement Sizes | <-.010", .020", .030"-> | .010", .020", .030" | <-.010", .020", .030", .040" (aftermarket)-> | ||||||||

(K-series Cast Piston) |

Thrust Face O.D. (See note 3 below) | New | 2.371"-2.369" | <-2.866" (K141) 2.9297"-2.9281" (K161, K181, L181)-> |

3.2432"-3.2413" | 3.368"-3.365" | 3.4941"-3.4925" | <-3.7425"-3.7410"-> | ||||

| Maximum Wear Limits | 2.366" | 2.925" | 2.925" | 3.238" | 3.363" | 3.491" | <-3.738"-> | |||||

| Thrust Face to Bore Clearance (max.) (See note 1 below) | .0035"-.006" | <-.007"-.010"-> | ||||||||||

| Ring End Gap (All 3 rings; see note 1 below) | New Bore (See note 10 below) | <-.007"-.017"-> | <-.010"-.020"-> | |||||||||

| Used Bore (Maximum) (See note 6 below) | <-.027"-> | <-.030"-> | ||||||||||

| Maximum Ring Side Clearance | <-.006"-> | |||||||||||

(K-series Cast Piston) |

Thrust Face O.D. (See note 5 below) | New | 3.371"-2.369" | 2.9279"-2.9281" | 2.9279"-2.9281" | 3.2432"-3.2413" | 3.368"-3.365" | 3.4941"-3.4925" | <-3.7425"-3.7410"-> | |||

| Maximum Wear Limits | 2.366" | 2.925" | 2.925" | 3.238" | 3.363" | 3.491" | <-3.738"-> | |||||

| Thrust Face to Bore Clearance (max.) (See note 1 below) | .0035"-.006" | .007"-.010" | .007"-.010" | .007"-.010" | .007"-.010" | .007"-.010" | <-.007"-.010"-> | |||||

| Ring End Gap (All 3 rings.) | New Bore (See note 10 below) | .007"-.017" | .007"-.017" | .007"-.017" | .010"-.020" | .010"-.020" | .010"-.020" | <-.010"-.020"-> | ||||

| Used Bore (Maximum) (See note 6 below) | .027" | .027" | .027" | .030" | .030" | .030" | <-.030"-> | |||||

| Maximum Ring Side Clearance | .006" | .006" | .006" | .006" | .006" | .006" | <-.006"-> | |||||

(Magnum Mahle Piston) |

Thrust Face O.D. (See notes 5, 9 below) | New / Used | - | - | 2.9329"-2.9336" | - | 3.3700"-3.3693" | 3.4945"-3.4938" | <-3.7433"-3.7426"-> | |||

| Maximum Wear Limits | - | - | 2.931" | - | 3.367" | 3.492" | <-3.7406"-> | |||||

| Thrust Face to Bore Clearance (See notes 1, 9 below) | - | - | .0034"-.0051" | - | .0045"-.0062" | .0050"-.0067" | <-.0062"-.0079"-> | |||||

| Ring End Gap (All 3 rings.) | New Bore (See note 10 below) | - | - | .010"-.023" | - | <-.010"-.020"-> | <-.013"-.025"-> | |||||

| Used Bore (Maximum) (See note 6 below) | - | - | .032" | - | <-.030"-> | <-.033"-> | ||||||

| Maximum Ring Side Clearance | - | - | .006" | - | <-.006"-> | <-.004"-> | ||||||

| Wrist Pin Outside Diameter (min.-max.) | .5623"-.5625" | <-.6247"-.6249"-> | .8591"-.8593" | <-.8752"-.8754"-> | ||||||||

| Valves | Valve Head Diameter | Intake: 63/64" Exhaust: 51/64" |

<-Intake: 1-3/8" Exhaust: 1-1/8"-> |

<-Intake: 1-3/8" Exhaust: 1-1/8"-> |

Intake: 1-3/8" Exhaust: 1-1/8" (early) / 1-3/8" (late) |

Intake: 1-3/8" Exhaust: 1-3/8" |

Intake: 1-7/16" Exhaust: 1-13/32" |

|||||

| Guide Reamer Size | .250" | <-.3125"-> | <-.3125"-> | |||||||||

| Tappet Clearance (Cold) (See notes 4, 9 below) | Intake (min.-max.) | .005"-.009" | <-.006"-.008"-> | <-.008"-.010"-> | .005"-.008" | |||||||

| Exhaust (min.-max.) | .011"-.015" | <-.017"-.019"-> | <-.017"-.019"-> | .010"-.012" | ||||||||

| Minimum Lift (Zero Lash) | Intake | .2035" | <-.2718"-> | <-.318"-> | ||||||||

| Exhaust | .1768" | <-.2482"-> | <-.318"-> | |||||||||

| Minimum Stem O.D. | Intake | .2478" | <-.3103"-> | |||||||||

| Exhaust | .2458" | <-.3088"-> | <-.3074"-> | |||||||||

| Minimum Valve Head Margin (Width) | <-.030"-> | |||||||||||

| Face / Seat Angle | <-45º / 46º-> | |||||||||||

| Guide I.D. Maximum Wear Limit (See note 1 below) | Intake | <-.005"-> | <-.006"-> | |||||||||

| Exhaust | <-.007"-> | <-.008"-> | ||||||||||

| Lifter to Bore Clearance | <-.001"-.0015"-> | |||||||||||

NOTES -

| NOTE 1 - Subtract O.D. of inner part from I.D. of outer part.

Use the lesser clearance for a stock engine (up to 4,000± RPM), and

the greater number for a higher RPM engine. Higher RPM creates more heat

due to friction, which cause greater expansion of parts. Also, when boring

or honing for piston clearance, it's important to check the ring end gaps

and gap them according to Kohler's specs. NOTE 2 - For longevity of the coil and to prevent overheating of the coil, use only metal core spark plug wire and copper core/non-resistor spark plugs. NOTE 3 - Measure just below oil ring groove and at right angles to wrist pin. NOTE 4 - 1,800 RPM generator sets at .005"- 007". NOTE 5 - Measure 1/2" above the bottom of the piston skirt. NOTE 6 - Top and center compression rings. NOTE 7 - Measure just below oil ring groove and at right angles to wrist pin. NOTE 8 - Compression ratio depends on which cylinder head is used. |

NOTE 9 - Use the lesser clearance is for a valve that have been

ran for a while, and use the greater clearance for a fresh reground valve

face and seat (As the valve and seat wear into each other, the clearance

will be lessened over time.) NOTE 10 - Use the lesser clearance for up to 3,600 RPM operation, and use the greater clearance for open RPM. NOTE 11 - Idle speed should be set at 1,200 RPM (±75 RPM) so the oil dipper can lubricate the internal moving parts more thoroughly. This speed also allows the flywheel fins to blow adequate amount of air across the cylinder head and around the cylinder fins to cool the engine better. NOTE 12 - For early model engines with the 2-piece camshaft and automatic timing advance, set points so they just begin to open when piston is positioned at top dead center (TDC) on the compression stroke. And for later model engines with the 1-piece camshaft and automatic compression release (ACR), set point gap at .020" with piston positioned at top dead center (TDC) on the compression stroke, or set static ignition timing when points begin to open exactly when S mark on flywheel passes raised line on bearing plate or hole in bearing plate. |

Kohler Magnum Single Cylinder Engine Specifications and Tolerances (All dimensions in inches)

| Engine Model | M8 | M10 | M12 | M14 | M16 | ||

| General Information | Minimum Safe Idle Speed (See note 9 below) | <-1,200 RPM (±75 RPM)-> | |||||

| Factory-Rated Horsepower at Maximum Safe Operating Speed (See note 8 below) | 7hp at 3,200 RPM 8hp at 3,600 RPM |

9hp at 3,200 RPM | 10hp at 3,600 RPM |

10.6hp at 3,200 RPM | 12hp at 3,600 RPM |

12.4hp at 3,200 RPM 14hp at 3,600 RPM |

14.2hp at 3,200 RPM 16hp at 3,600 RPM |

||

| Bore x Stroke | STD. 2.938" .010" 2.948" .020" 2.958" .030" 2.968" x 2.750" |

STD. 3.251" .010" 3.261" .020" 3.271" .030" 3.281" x 2.875" |

STD. 3.375" .010" 3.385" .020" 3.395" .030" 3.405" x 3.250" |

STD. 3.500" .010" 3.510" .020" 3.520" .030" 3.530" x 3.250" |

STD. 3.750" .010" 3.760" .020" 3.770" .030" 3.780" x 3.250" |

||

| Cubic Inch Displacement (STD Bore) | 18.64 | 23.85 | 29.07 | 31.27 | 35.90 | ||

| Balance Gears (These may be required for Magnum engines, or have rotating assembly precision balanced.) | Shaft O.D. | New | - | <-.4998"-.5001"-> | |||

| Maximum Wear Limit | - | <-.4996"-> | |||||

| Clearance/End-Play | - | <-.002"-.010"-> | |||||

| Camshaft | Clearance/End-Play (See note 6 below) | <-.005"-.010"-> | |||||

| Connecting Rod |

Running Clearance | Maximum Big End Diameter | STD. 1.1875" .010" 1.1775" |

<-STD. 1.5015" / .010" 1.4915" / .020" 1.4815" / .030" 1.4715"-> | |||

| Rod to Crankpin (max.) | <-.001"-.002"-> | ||||||

| Rod to Crankpin - Maximum Wear Limit | <-.0025"-> | ||||||

| Rod to Wrist Pin (max.) | .0006"-.0011" | <-.0003"-.0008"-> | |||||

| Small End I.D. (max.) | .6255"-.6258" | .8596"-.8599" | <-.8757"-.8760"-> | ||||

| Crankshaft | Main PTO end and Flywheel End O.D. | New | 1.1811"-1.1814" | <-1.5745"-1.5749"-> | |||

| Maximum Wear Limit | 1.1811" | <-1.5745"-> | |||||

| Crankpin | New - O.D. | STD. 1.186"-1.1855" .010" 1.176"-1.1755" |

<-STD. 1.4995"-1.5000", .010" 1.4895"-1.4900", .020" 1.4795"-1.4800", .030" 1.4695"-1.4700"-> | ||||

| Maximum Wear Limit | STD. 1.1850" .010" 1.1840" |

<-STD. 1.4990", .010" 1.4890", .020" 1.4790", .030" 1.4690"-> | |||||

| Maximum Out of Round | <-.0005"-> | ||||||

| Maximum Taper | <-.001"-> | ||||||

| clearance/end-play (See note 6 below) | .002"-.023" | <-.003"-.020"-> | |||||

| Cylinder Bore | Inside Diameter | New (See note 6 below) | 2.9370"-2.9380" | 3.2505"-3.2515" | 3.3745"-3.3755" | 3.4995"-3.5005" | 3.7495"-3.7505" |

| Maximum Wear Limit | 2.941" | 3.254" | 3.378" | 3.503" | 3.753" | ||

| Maximum Out of Round (I.D.) | <-.005"-> | ||||||

| Maximum Taper (I.D.) | .003" | <-.002"-> | |||||

| Cylinder Head | Maximum Out of Flatness | <-.003"-> | |||||

| Ignition (Solid State) |

Spark Plug | Type (See note 2 below) | Autolite 295 or Champion 841 (J8C) | <-Autolite 316 or Champion 884 (H10C)-> | |||

| Gap | <-.025"-> | ||||||

| Armature Air Gap | <-.010"-.012"-> | ||||||

| Ignition Timing | <-Not Applicable/Fixed Timing (20º BTDC)-> | ||||||

| All Pistons | Service Replacement Sizes | <-.003", .010", .020", .030"-> | <-.003", .010", .020", .030", .040" (aftermarket)-> | ||||

(K-series Cast Piston) |

Thrust Face O.D. (See note 3 below) | New (See note 6 below) | 2.9297"-2.9281 | 3.2432"-3.2413 | 3.368"-3.365 | 3.4941"-3.4925 | - |

| Maximum Wear Limits | 2.925" | 3.238" | 3.363" | 3.491" | - | ||

| Thrust Face to Bore Clearance (max.) (See notes 1, 6 below) | <-.007"-.010"-> | - | |||||

| Ring End Gap (All 3 rings; see note 1 below) | New Bore (See note 7 below) | .007"-.017" | <-.010"-020"-> | - | |||

| Used Bore (Maximum) (See note 5 below) | .027" | <-.030"-> | - | ||||

| Maximum Ring Side Clearance | <-.006"-> | - | |||||

(K-series Cast and Magnum Mahle Pistons) |

Thrust Face O.D. (See note 4 below) | New | - | 3.7465"-3.7455" | |||

| Maximum Wear Limits | - | 3.7435" | |||||

| Thrust Face to Bore Clearance (max.) (See note 1 below) | - | .003"-.005" | |||||

| Ring End Gap (All 3 rings.) | New Bore (See note 7 below) | - | .010"-020" | ||||

| Used Bore (Maximum) (See note 5 below) | - | .030" | |||||

| Maximum Ring Side Clearance | - | .004" | |||||

(Magnum Mahle Piston) |

Thrust Face O.D. (See note 4 below) | New (See note 6 below) | 2.9329"-2.9336" | - | 3.3700"-3.3693" | 3.4945"-3.4938" | 3.7433"-3.7426" |

| Maximum Wear Limits | 2.9312" | - | 3.3673" | 3.4918" | 3.7406" | ||

| Thrust Face to Bore Clearance (max.) (See note 1, 6 below) | .0034"-.0051" | - | .0045"-.0062" | .0050"-0067" | .0062"-.0079" | ||

| Ring End Gap (All 3 rings.) | New Bore (See note 7 below) | .010"-.023" | - | <-.010"-.020"-> | .013"-.025" | ||

| Used Bore (See note 5 below) | .032" | - | <-.030"-> | .033" | |||

| Maximum Ring Side Clearance | .006" | - | <-.006"-> | .004" | |||

| Wrist Pin | Outside Diameter | .6247"-.6249" | .8591"-.8593" | <-.8752"-.8754"-> | |||

| Valves | Valve Head Diameter | <-Intake: 1-3/8" / Exhaust: 1-1/8"-> | <-Intake: 1-3/8" / Exhaust: 1-3/8"-> | ||||

| Guide Reamer Size | <-.3125"-> | ||||||

| Tappet Clearance (Cold) (see note 6 below) | Intake (min.-max.) | .006"-.008" | <-.008"-.010"-> | ||||

| Exhaust (min.-max.) | <-.017"-.019"-> | ||||||

| Minimum Lift (Zero Lash) |

Intake | .2718" | <-.318"-> | ||||

| Exhaust | .2482" | <-.318"-> | |||||

| Minimum Stem O.D. | Intake | <-.3103"-> | |||||

| Exhaust | <-.3074"-> | ||||||

| Face / Seat Angle | <-45º / 46º-> | ||||||

| Guide I.D. Maximum Wear Limit (See note 1 below) |

Intake | <-.006"-> | |||||

| Exhaust | <-.008"-> | ||||||

| Lifter to Bore Clearance | <-.001"-.0015"-> | ||||||

NOTES:

| NOTE 1 - Subtract O.D. of inner part from I.D. of outer part.

Use the lesser clearance for a stock engine (up to 4,000± RPM), and

the greater number for a higher RPM engine. Higher RPM creates more heat

due to friction, which cause greater expansion of parts. NOTE 2 - For longevity of the coil and to prevent overheating of the coil, use only copper core/non-resistor spark plugs. NOTE 3 - Measure just below oil ring and at right angles to wrist pin. NOTE 4 - Measure 1/2" above the bottom of the piston skirt. NOTE 5 - Top and center compression rings. NOTE 6 - Use the lesser clearance is for a valve that have been ran for a while, and use the greater clearance for a fresh reground valve face and seat (As the valve and seat wear into each other, the clearance will be lessened over time.) |

NOTE 7 - Use the lesser clearance for up to 3,600 RPM operation,

and use the greater clearance for open RPM. NOTE 8 - To prevent a lean air/fuel mixture when using a Walbro carburetor with a fixed/non-adjustable high speed main jet, set maximum engine speed at 3,200 RPM. But if using a Carter, Kohler or Walbro carburetor with a fully adjustable high speed main jet, maximum engine speed can be set at 3,600 RPM. NOTE 9 - Idle speed should be set at 1,200 RPM (±75 RPM) so the oil dipper can lubricate the internal moving parts more thoroughly. This speed also allows the flywheel fins to blow adequate amount of air across the cylinder head and around the cylinder fins to cool the engine better. |

Kohler Opposed (Flathead) Twin Cylinder Engine Specifications and Tolerances (All dimensions in inches.)

| Engine Model | MV16 | M18, MV18 | M20, MV20 | KT17 (first design), KT17 Series II | KT19 (first design), KT19 Series II | KT21 | K482 | K532 | K582 | K660/K662 |

| Minimum Safe Idle Speed (See note 11 below) | <-1,200 RPM (±75 RPM)-> | |||||||||

| Factory-Rated Horsepower at Maximum Safe Operating Speed (See note 2 below) | 14.2hp at 3,200 RPM 16hp at 3,600 RPM |

16hp at 3,200 RPM 18hp at 3,600 RPM |

17.8hp at 3,200 RPM 20hp at 3,600 RPM |

17hp at 3,600 RPM | 19hp at 3,600 RPM | 21hp at 3,600 RPM | 18hp at 3,600 RPM | 20hp at 3,600 RPM | 23hp at 3,600 RPM | 24hp at 3,200 RPM |

| Engine Construction | <-Two-Piece Aluminum Crankcase w/Incorporated Cast Iron Barrels/Cylinders/Jugs-> (Use a thin bead of Clear RTV Silicone Adhesive Sealant on crankcase halves and barrels/cylinders/jugs when reassembling these engines.) | <-One-Piece Cast Iron Crankcase w/Integrated Cylinders-> | ||||||||

| Cubic Inch Displacement (STD Bore) | 42.18 | 42.18 | 47.00 | 42.18 | 47.00 | 52.76 | 47.70 | 53.68 | 57.70 | 67.20 |

| Compression Ratio | 5.8:1 | 6:1 | M20 - 6.6:1 MV20 - 6:1 |

6:1 | 6.7:1 | 7.3:1 | 5.8:1 | 6.4:1 | 7:1 | ? |

| Cylinder Bore (New) | <-3.125"-> | 3.312" | 3.250" | 3.375" | 3.500" | 3.625" | ||||

| Cylinder Bore (Worn) | <-3.128"-> | 3.315" | 3.253" | 3.378" | 3.503" | 3.6245" | ||||

| Crankshaft Stroke | <-2.750"-> | 3.062" | 2.750" | 3.062" | 3.062" | 2.875" | 3.000" | 3.000" | 3.250" | |

| Cylinder Taper | <-.0015"-> | .002" | ||||||||

| Cylinder Out of Round |

<-.002"-> | <-.005"-> | ||||||||

| Crankshaft Clearance/End-Play (Engines w/Sleeve Bearing) | <-.002"-.014"-> | <-.004"-.010"-> | .0035"-.0055" | |||||||

| Crankshaft Clearance/End-Play (Engines w/Ball Bearing) | <-.002"-.023"-> | -- | ||||||||

| Crankshaft Main Journals Diameter (Engines w/Sleeve Bearing) | <-STD size: 1.742", .010" undersize: 1.732", .020" undersize: 1.722"-> | <-STD size: 1.750", .010" undersize: 1.740", .020" undersize: 1.730"-> | ||||||||

| Crankshaft Main Journals Diameter (Engines w/Ball Bearing) | <-1.378"-> | <-1.772"-> | ||||||||

| Crankshaft Main Sleeve Bearing Oil Clearance | <-.0013"-.0033"-> | <-.0015"-.004"-> | ? | |||||||

| Crankpin (Rod Journal) New Diameter | <-1.3733"-1.3738"-> | 1.500" | 1.3733"-1.3738" | first design - 1.3733"-1.3738" Series II - 1.4993"-1.4998" |

1.7422"-1.7421" | <-1.625"-> | ? | |||

| Crankpin Out of Round | <-.0005"-> | ? | ||||||||

| Crankpin Maximum Taper |

<-.001"-> | ? | ||||||||

| Camshaft Clearance | <-.001"-.0025"-> | <-.0005"-.0045"-> | ? | |||||||

| Camshaft End Float | <-.003"-.013"-> | <-.017"-.038"-> | ? | |||||||

| Connecting Rod Big End Maximum Diameter | <-1.376"-> | 1.5010"-1.5017" | 1.376" | first design - 1.376" Series II - 1.5025" |

1.5010"-1.5017" | <-1.627"-> | ? | |||

| Connecting Rod Big End to Crank Pin Clearance | <-KT17 (first design), KT19 (first design)

and KT21 Engines: .0015"-.0025"-> <-KT17 Series II, KT19 Series II, All Magnums, K482, K532, K582 and K662 Engines: .0012"-.0024"-> |

|||||||||

| Connecting Rod Small End Pin New Diameter | <-0.62565"-> | 0.7511" | 0.62565" | 0.7511" | .85975" | .8596" | <-0.87585"-> | .8752"-.8754" | ||

| Connecting Rod Small End Clearance | <-.0006"-.0011"-> | <-.0003"-.0008"-> | ? | |||||||

| Piston Thrust Face Maximum Wear Diameter (See note 1 below) | <-3.1165"-> | 3.2375" | 3.3625" | 3.4945" | 3.624"-3.6235" | |||||

| Piston Thrust Face to Bore Clearance | <-.0035"-.0052"-> | .0030"-.0047" (M20) .0035"-.0052" (MV20) |

.006"-.008" | .0065"-.0085" | .0065"-.0085" | <-.007"-.010"-> | ? | |||

| Piston Rings Maximum Side Clearance | <-.004"-> | <-.006"-> | ? | |||||||

| Piston Rings Gap (New) | <-.010"-.020"-> | .010"-.020" | ||||||||

| Piston Rings Gap Maximum (Used) | <-.030"-> | ? | ||||||||

| Intake Valve to Tappet Clearance Cold See note 12 below | <-.003"-.006"-> | <-.008"-.010"-> | .006"-.008" | |||||||

| Exhaust Valve to Tappet Clearance Cold See note 12 below | <-.011"-.014"-> | <-.017"-.020"-> | .017"-.019" | |||||||

| Intake Valve Maximum Lift (Zero Valve-Tappet Clearance) | <-0.280"-> | <-0.324"-> | ? | |||||||

| Exhaust Valve Maximum Lift (Zero Valve-Tappet Clearance) | <-0.280"-> | <-0.324"-> | ? | |||||||

| Intake Valve Stem-Guide Clearance Maximum | <-.0045"-> | ? | ||||||||

| Exhaust Valve Stem-Guide Clearance | <-.0065"-> | ? | ||||||||

| Cam Follower (Lifter/Tappet) Clearance in Guide | <-.0005"-.0024"-> | <-.0012"-.0023"-> | ? | |||||||

| Spark Plug Type (See note 8 below) |

<-Autolite 26 or Champion 25 (RV17YC)-> | <-Autolite 316 or Champion 884 (H10C)-> | <-Autolite 295 or Champion 841 (J8C)-> | |||||||

| Spark Plug Gap Magneto/Solid State Ignition | <-.025"-> | <-N/A-> | <-.025"-> | |||||||

| Spark Plug Gap Battery Ignition | <-N/A-> | <-.025"-> | <-.035"-> | .025" | ||||||

| Spark Plug Gap - Gaseous Fuel (Propane/LP) | <-.018"-> | |||||||||

| Ignition Points Gap | <-N/A-> | <-.017"-023" (See note 6 below)-> | <-.020"-> | |||||||

| Ignition Timing Spark Run | <-N/A-> (Timing fixed at 23º BTDC) |

<-23º BTDC-> | <-22.5º BTDC-> | When Marks Are Aligned in Sight Hole | ||||||

| Spark Plug Torque | <-11-15 ft. lbs.-> | <-18-22 ft. lbs.-> | ||||||||

| Cylinder Head Torque | <-15-20 ft. lbs.-> | <-35 ft. lbs.-> | ? | |||||||

| Connecting Rod Nut/Bolt Torque | <-200 in. lbs.-> | <-200 in. lbs (See note 4 below)-> | ? | |||||||

| Flywheel Nut / Screw Torque See note 5 below) | <-40 ft. lbs.-> | <-115 ft. lbs.-> | 130 ft. lbs. | |||||||

NOTES -

| NOTE 1 - Measure just below oil ring and at right angle

to piston pin. NOTE 2 - To prevent a lean air/fuel mixture when using a Walbro carburetor with a fixed/non-adjustable high speed main jet, set maximum engine speed at 3,200 RPM. But if using a Carter, Kohler or Walbro carburetor with a fully adjustable high speed main jet, maximum engine speed can be set at 3,600 RPM. NOTE 3 - 1,800 RPM Generator Engines .015" Spark Plug Gap and 16º before top dead center (BTDC) Timing. NOTE 4 - 3/8" Screw - 300 in. lb. NOTE 5 - 5/16" Screw - 250 in. lbs. NOTE 6 - Or set static ignition timing when points begin to open exactly when S mark on flywheel passes roll pin on #1 cylinder. |

NOTE 7 - Measure just below oil ring groove and at right angles

to wrist pin. NOTE 8 - Compression ratio depends on which cylinder head is used. NOTE 8 - For longevity of the coil and to prevent overheating of the coil, use only metal core spark plug wires and copper core/non-resistor spark plugs. NOTE 11 - Idle speed should be set at 1,200 RPM (±75 RPM) so the oil dipper can lubricate the internal moving parts more thoroughly. This speed also allows the flywheel fins to blow adequate amount of air across the cylinder head and around the cylinder fins to cool the engine better. NOTE 12 - Use the lesser clearance is for a valve that have been ran for a while, and use the greater clearance for a fresh reground valve face and seat (As the valve and seat wear into each other, the clearance will be lessened over time.) |

| Model (Horsepower) | K90/91 | K141, K160/K161 | K181, L181 and M8 | K241, M10, K301, M12, K321 and M14 | K341 and M16 | K361 (Over Head Valve) |

KT17 (first design), KT17 Series II, KT19 (first design), KT19 Series II, KT21, MV16, M18, MV18, M20, MV20 | |

| Connecting Rod Nuts/Bolts

(See notes 1, 2, 3 and 4 below) |

Posi-Lock (Flange Nut/Stud)  |

- | - | New 140 in. lb. / 12 ft. lb. Used 100 in. lb. / 9 ft. lb. |

<-New 260 in. lb. / 22 ft. lb.->

<-Used 200 in. lb. / 17 ft. lb.-> |

New 140 in. lb. / 12 ft. lb. Used 100 in. lb. / 9 ft. lb. |

||

Capscrew (Bolt) |

140 in. lb. / 12 ft. lb. | <-200 in. lb. / 17 ft. lb.-> | <-285 in. lb. / 24 ft. lb.-> | |||||

| Spark Plug | <-180-240 in. lb. / 15-20 ft. lb.-> | |||||||

| Cylinder Head Torque Sequences

and Torque Values (See note 1 below) |

15 ft. lb. / 200 in. lb. |

15-20 ft. lb. / 180-240 in. lb. |

25-30 ft. lb. / 300-360 in. lb. |

25-30 ft. lb. / 300-360 in. lb. |

25-30 ft. lb. / 300-360 in. lb. |

15-20 ft. lb. / 180-240 in. lb. |

||

| Flywheel Retaining Nut or Bolt (See note 6 below) |

5/8" or 3/4" Nut (See note 1, 6 below) | 45 ft. lb. | 50 ft. lb. (See note 4 below) | <-65 ft. lb.-> | - | |||

| 3/8" Bolt (See note 1, 6 below) | 250 in. lb. | - | <-24-35 ft. lb.-> | |||||

| Governor Bushing | 80 in. lb. | 140 in. lb. | <-110 in. lb.-> | - | ||||

| Grass Screen | Metal | - | 70 - 140 in. lb. | <-70 - 140 in. lb.-> | ||||

| Plastic | - | - | 20-30 in. lb. | |||||

| Oil Pan | Cast Iron or Aluminum (See note 1 below) | 250 in. lb. | Grade 5 - 250 in. lb. Grade 8 - 350 in. lb. |

<-35 ft. lb.-> | - | |||

| Sheet Metal (See note 1 below) | - | - | <-200 in. lb.-> | - | ||||

| Plastic Fuel Pump Mounting Screws |

- | <-40 in. lb.-> | ||||||

NOTES:

| NOTE 1 - Lubricate fastener threads with motor oil. NOTE 2 - DO NOT overtorque - DO NOT loosen and retorque the hex nuts on Posi-Lock connecting rods. NOTE 3 - Overtorque 20%, loosen below torque value and retorque to final torque value. NOTE: Overtorquing rod bolts 20% places stress on the threads in a NEW aluminum rod. This allow for proper tightness so bolts won't loosen later. Used rods: Torque to 285 in. lbs. one time only. |

NOTE 4 - To prevent rod bolts from loosening, install a split

lock washer on each bolt and then torque to specs. Posi-Lock (flange) nuts

doesn't require a lock washer. NOTE 5 - Prior to Serial No. 23209832 - 45-55 ft. lb. NOTE 6 - Flywheel and crankshaft tapers must be clean and dry. |

Kohler Engine Models K482, K532, K582 and K660/K662 Torque Values and Sequences for Fasteners

| Engine Model Maximum HP at 3,600 RPM |

K482 18hp |

K532 20hp |

K582 24hp |

K660/K662 24hp |

| Connecting Rods | 5/16" bolt - 200 in. lb. 3/8" bolt - 300 in. lb. |

35 ft. lb. | ||

| Spark Plugs | 216-264 in. lb. / 18-22 ft. lb. | |||

| Cylinder Head |  |

|

||

| Flywheel Nut | 115 ft. lb. | 139 ft. lb. | ||

| Grass Screen | 70-138 in. lb. | |||

| Oil Pan | Aluminum - 30 ft. lb. Cast Iron - 35 ft. lb. |

45 ft. lb. | ||

| Manifold Screw/Nut | 210 in. lb. | 300 in. lb. | ||

| Camshaft Nut | 40 ft. lb. | 25 ft. lb. | ||

| Closure Plate | 30 ft. lb. | 50 ft. lb. | ||

- Identification of Most Commonly Used Grades of Bolts -

Hardness  |

No Lines = Grade 3 |

3 Lines = Grade 5 |

6 Lines = Grade 8 |

Stainless Steel / Special Alloy |

Bolt Size |

Material: Low Carbon Steel. Tensile Strength: 85,000 P.S.I. (Low Strength) | Material: Medium Carbon Steel, Tempered. Tensile Strength: 120,000 P.S.I. (Medium Strength) | Material: Medium Carbon Alloy Steel, Quenched and Tempered. Tensile Strength: 150,000 P.S.I. (High Strength) | Material: 18-8 [304] Stainless Steel. Tensile Strength: 130,000 P.S.I. |

1/4-20 (C) 1/4-28 (F) 5/16-18 (C) 5/16-24 (F) 3/8-16 (C) 3/8-24 (F) 7/16-14 (C) 7/16-20 (F) 1/2-13 (C) 1/2-20 (F) 9/16-12 (C) 9/16-18 (F) 5/8-11 (C) 5/8-18 (F) 3/4-10 (C) 3/4-16 (F) |

70 in. lb. / 6 ft. lb. 85 in. lb. / 7 ft. lb. 150 in. lb. / 13 ft. lb. 165 in. lb. / 14 ft. lb. 260 in. lb. / 22 ft. lb. 300 in. lb. / 25 ft. lb. ------------- 35 ft. lb. ------------- 45 ft. lb. ------------- 50 ft. lb. ------------- 70 ft. lb. ------------- 75 ft. lb. ------------ 100 ft. lb. ------------ 110 ft. lb. ------------ 140 ft. lb. ------------ 150 ft. lb. ------------ 200 ft. lb. |

115 in. lb. / 10 ft. lb. 140 in. lb. / 12 ft. lb. 250 in. lb. / 21 ft. lb. 270 in. lb. / 23 ft. lb. ------------- 35 ft. lb. ------------- 40 ft. lb. ------------- 55 ft. lb. ------------- 75 ft. lb. ------------- 80 ft. lb. ------------ 105 ft. lb. ------------ 125 ft. lb. ------------ 165 ft. lb. ------------ 180 ft. lb. ------------ 230 ft. lb. ------------ 245 ft. lb. ------------ 325 ft. lb. |

165 in. lb. / 14 ft. lb. 200 in. lb. / 17 ft. lb. 350 in. lb. / 29 ft. lb. ------------ 30 ft. lb. ------------ 50 ft. lb. ------------ 60 ft. lb. ------------ 80 ft. lb. ------------ 105 ft. lb. ------------ 115 ft. lb. ------------ 165 ft. lb. ------------ 175 ft. lb. ------------ 230 ft. lb. ------------ 260 ft. lb. ------------ 330 ft. lb. ------------ 350 ft. lb. ------------ 470 ft. lb. |

165 in. lb. / 14 ft. lb. 200 in. lb. / 17 ft. lb. 350 in. lb. / 29 ft. lb. ------------ 35 ft. lb. ------------ 58 ft. lb. ------------ 69 ft. lb. ------------ 98 ft. lb. ------------ 110 ft. lb. ------------ 145 ft. lb. ------------ 160 ft. lb. ------------ 200 ft. lb. ------------ 220 ft. lb. ------------ 280 ft. lb. ------------ 310 ft. lb. ------------ 490 ft. lb. ------------ 530 ft. lb. |

| Kohler Engine Service and Repair Manuals Contains all the information needed to disassemble, repair and reassemble your Kohler engine. By clicking the links below, a new website will open, containing the manual in PDF file format, which can be saved on your computer and/or printed out. PDF files require Adobe Acrobat Reader. Visit https://pswusers.arinet.com/kohler, scroll to the bottom of website., click on Login as Guest for information concerning Kohler engines. |

|

|

|

Rare, Vintage VERTICAL SHAFT Kohler cast iron block engine models KV161 and KV331 -

For anyone who is interested

in very rare Kohler K-series engines, there's the Kohler cast iron engine

models KV161 and KV331 that came in the

VERTICAL (

For anyone who is interested

in very rare Kohler K-series engines, there's the Kohler cast iron engine

models KV161 and KV331 that came in the

VERTICAL ( ) crankshaft

orientation. The horizontal version of the KV161 is the K160/K161, and the

horizontal version of the KV331 is the K330/K331. Anyway, These vertical

shaft engines were probably manufactured sometime during the early to mid-60's.

The KV161 was used in a small Wheel Horse riding mower and perhaps a water

pump, and the KV331 was probably used in a larger riding mower and maybe

a water pump. Kohler apparently made these vertical shaft engines in competition

with Briggs & Stratton's, (Clinton's?) and Tecumseh's vertical shaft

engines, but perhaps failed to keep up with production or the supply and

demand at the time, or maybe there was a cost overrun. FYI - Unlike the

horizontal shaft engines, which have the flywheel and PTO on the sides

(

) crankshaft

orientation. The horizontal version of the KV161 is the K160/K161, and the

horizontal version of the KV331 is the K330/K331. Anyway, These vertical

shaft engines were probably manufactured sometime during the early to mid-60's.

The KV161 was used in a small Wheel Horse riding mower and perhaps a water

pump, and the KV331 was probably used in a larger riding mower and maybe

a water pump. Kohler apparently made these vertical shaft engines in competition

with Briggs & Stratton's, (Clinton's?) and Tecumseh's vertical shaft

engines, but perhaps failed to keep up with production or the supply and

demand at the time, or maybe there was a cost overrun. FYI - Unlike the

horizontal shaft engines, which have the flywheel and PTO on the sides

( ), the vertical shaft engines have the flywheel

on top and PTO on the bottom (

), the vertical shaft engines have the flywheel

on top and PTO on the bottom ( ). The carburetor

on certain KV161 engines have either a horizontal or vertical throttle shaft.

Click here to see photos

of the KV161 and KV181 engines.

). The carburetor

on certain KV161 engines have either a horizontal or vertical throttle shaft.

Click here to see photos

of the KV161 and KV181 engines.

K-Series Development: In 1948, Kohler began producing its own line of air-cooled engines, expanding from its roots in plumbing and electrical generators.

Vertical Shaft (KV) Purpose: The KV141, KV161, and KV181 were specifically designed with a vertical crankshaft orientation, making them ideal for vertical-axis lawn mowers.

By 1963, Kohler engines were powering approximately half of all lawn and garden tractors produced in the United States.

The KV141, KV161, and KV181 Models -

The Kohler KV141, KV161, and KV181 are vertical-shaft engines belonging to the renowned Kohler K-Series, which revolutionized the small engine market in the mid-20th century. These engines were introduced to meet the growing demand for smaller, reliable power sources for lawn and garden equipment, particularly walk-behind and early riding mowers.

Rare, Vintage LIQUID-COOLED Kohler cast iron block engine models L160/L161 and L181 -

The rare Kohler engine models L160/L161

and L181 are a liquid-cooled version as Kohler's air-cooled engine models

K141, K160/K161 and K181. Just like with most automotive engines, these

liquid-cooled engines have an impeller water pump and radiator, and require

anti-freeze/water mix to maintain the engine's operating temperature. The

L160/L161 and L181 engines were obviously used in extreme heat desert-like

conditions for long periods of time to prevent overheating of the engine.

The Kohler water-cooled L141, L161, and L181 engines are rare, specialized,

liquid-cooled variants of the legendary K-Series single-cylinder cast iron

engines, primarily produced from the early 1960s until 1971. These engines

were designed specifically for industrial, agricultural, and generator

applications operating in extreme heat or, in some cases, marine environments.

Click here to see photos

of the L141, L161 and L181 engines.

The rare Kohler engine models L160/L161

and L181 are a liquid-cooled version as Kohler's air-cooled engine models

K141, K160/K161 and K181. Just like with most automotive engines, these

liquid-cooled engines have an impeller water pump and radiator, and require

anti-freeze/water mix to maintain the engine's operating temperature. The

L160/L161 and L181 engines were obviously used in extreme heat desert-like

conditions for long periods of time to prevent overheating of the engine.

The Kohler water-cooled L141, L161, and L181 engines are rare, specialized,

liquid-cooled variants of the legendary K-Series single-cylinder cast iron

engines, primarily produced from the early 1960s until 1971. These engines

were designed specifically for industrial, agricultural, and generator

applications operating in extreme heat or, in some cases, marine environments.

Click here to see photos

of the L141, L161 and L181 engines.

Key Historical Aspects of Kohler Liquid-Cooled L-Series -

Engine Specifics (L141, L161, L181) -

Relationship to K-Series -

The L-series engines are essentially water-jacketed versions of the K-series. Their specifications, such as bore and stroke, generally align with their air-cooled counterparts (e.g., K181 having a 2.938" bore and 2.750" stroke).

Scarcity -

The L141, L161, and L181 engines are now considered very rare. They were largely superseded by more advanced cooling techniques or replaced by later Magnum and Command series engines, which, while mostly air-cooled, introduced superior efficiency, though liquid-cooled options returned in the 2000s in other forms.

The liquid-cooled Kohler engine model L160/L161 with specification numbers 4149F, 4150F, 4152E, 4166F, 4167F, 4168E, 4168G, 4168H, 4173E, 4192E, 4194F, 4195F, 4199G, 4199H, 41101F, 41109F, 4110F, 41117F, 41131F and 41137F are listed as generator (power plant) engines, and the liquid-cooled Kohler engine model L181 with specification numbers 42583H, 42594H, 42597H, 42626H, 42723H, 42745H, 42746H are also listed as generator (power plant) engines. These are very rare engines. If anyone have information or additional photos regarding these engines that they would like to share in this website, please let me know and I will post it/them in this article with your name for full credit. Click here to see photos of the L141, L161 and L181 engines.

The Rare and Vintage Kohler K330 and K331 Engines -

The Kohler K330 and K331 engines

were reliable, single-cylinder, air-cooled gasoline engines from Kohler's

popular K-Series, starting in the early 1950s, with the K330 around 12.5

HP and the K331 potentially a short-run evolution for higher HP, known for

powering farm equipment like augers, lawn tractors and generators, prized

for their durability and long life, though the K331's specific production

is less documented than the common K330. The model K330 has splash oiling

only, and the model K331 came with an oil pressure gauge and oil pump (that

produced splash/squirt oiling), but no provision for an oil filter.

The Kohler K330 and K331 engines

were reliable, single-cylinder, air-cooled gasoline engines from Kohler's

popular K-Series, starting in the early 1950s, with the K330 around 12.5

HP and the K331 potentially a short-run evolution for higher HP, known for

powering farm equipment like augers, lawn tractors and generators, prized

for their durability and long life, though the K331's specific production

is less documented than the common K330. The model K330 has splash oiling

only, and the model K331 came with an oil pressure gauge and oil pump (that

produced splash/squirt oiling), but no provision for an oil filter.

Shaft Orientation: While the K-series featured many variations, these specific models were commonly utilized in applications requiring horizontal PTO-shafts, though they were sometimes adapted for vertical needs in early mowers.

I contacted Kohler and asked them for any information regarding these vertical

shaft engines, and they said that they have no information or documentation

whatsoever and no records are stored for these engines.

But an older Kohler engine tech

that I spoke with on the phone told me these engines were used to power a

water pump. But they could also have been used on a riding mower.

But an older Kohler engine tech

that I spoke with on the phone told me these engines were used to power a

water pump. But they could also have been used on a riding mower.

Many years ago, I personally seen a VERTICAL shaft KV161 engine block sitting on the counter of a local machine shop. It had the OEM red paint, too. (Obviously for a Wheel Horse.) And I've seen an [undoctored] photo of the VERTICAL shaft KV331 engine on the Internet several years ago, but never seen one in person. These vertical shaft engines was rare back in the day and is extremely hard to find or next to impossible to find nowadays. If anyone have information or photos regarding these engines that they would like to share in this website, please let me know and I will post it/them in this article with your name for full credit.

All of the engines above are considered a key part of the "golden age" of American small engine manufacturing. [Return To Previous Paragraph, Section or Website]

Differences Between the Kohler K-series and Magnum Single Cylinder Engine Blocks -

Unlike the old school small- and big-block Chevy V8 engines

Unlike the old school small- and big-block Chevy V8 engines

, the Kohler K-series

and Magnum engine block models K241, M10, K301, M12, K321, M14, K341 and

M16 are not all the same. There are several variations in bolt patterns and

PTO end flange configurations between these blocks. Before replacing an engine

block and if possible, the best thing to do is have the original engine rebuilt,

then all the original accessories will attach to the original block with

no modifications. But if the original engine block is not rebuildable and

damaged beyond repair, another block of the same type (specification number)

will need to be acquired. If interested in purchasing a bare block, please

email me several detailed, sharp

photos of your original engine block taken at all sides so I match it to

one I may have in stock. Packaged shipping weight for each bare block

is 45 lbs.

, the Kohler K-series

and Magnum engine block models K241, M10, K301, M12, K321, M14, K341 and

M16 are not all the same. There are several variations in bolt patterns and

PTO end flange configurations between these blocks. Before replacing an engine

block and if possible, the best thing to do is have the original engine rebuilt,

then all the original accessories will attach to the original block with

no modifications. But if the original engine block is not rebuildable and

damaged beyond repair, another block of the same type (specification number)

will need to be acquired. If interested in purchasing a bare block, please

email me several detailed, sharp

photos of your original engine block taken at all sides so I match it to

one I may have in stock. Packaged shipping weight for each bare block

is 45 lbs.

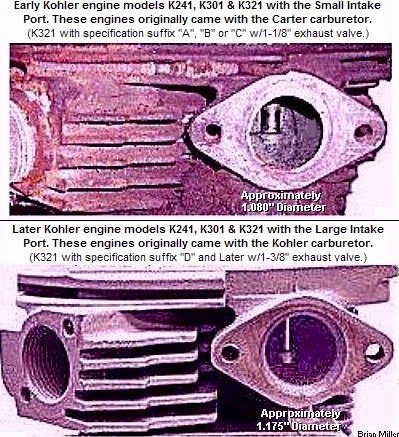

The Major Differences Between the K241, M10, K301, M12, K321, M14, K341 and M16 Kohler Engine and Blocks -

The Major Differences Between the Kohler K-series and Magnum Engine Blocks -

|

|

The Differences Between the Old Kohler K-series and the Newer Kohler Magnum Engines -

The Magnum engines replaced the K-series in later years. The Magnum engines are basically the same engine as the K-series. The main differences are, besides the baffle shields (sheet metal) that covers the block, the Magnum has solid state ignition, a fixed main jet (Walbro) carburetor and the starter motor fastens to the OEM bearing plate instead of the engine block. And there are no provisions for using ignition points. Most of the external and all the internal parts are interchangeable, and most aftermarket (high-performance) parts are interchangeable with either engine.

A Kohler K-series and Magnum M10, M12, M14 and M16 single cylinder engines

will fit in place of a Kohler K241 or M10 engine. These all basically have

the same external dimensions, with the exception of the 16hp, which has a

larger cylinder. Kohler engines are like the old school

small

block or

big

block Chevrolet V8 engines  .

A small block 400 CID engine can be used in place of a 265 CID engine, and

a big block 572 CID [crate] engine can be used in place of a 366 CID [truck]

engine, because they basically have the same external dimensions. The main

difference with Kohler engines is the bolt patterns on the PTO end of the

block. Each block is made specifically for the garden tractor, small motorized

vehicle or lawn and garden equipment it goes in. When replacing an engine

block with another, make sure the bolt pattern matches that of the original

block so the PTO accessories, braces and brackets can be bolted on with no

modifications.

.

A small block 400 CID engine can be used in place of a 265 CID engine, and

a big block 572 CID [crate] engine can be used in place of a 366 CID [truck]

engine, because they basically have the same external dimensions. The main

difference with Kohler engines is the bolt patterns on the PTO end of the

block. Each block is made specifically for the garden tractor, small motorized

vehicle or lawn and garden equipment it goes in. When replacing an engine

block with another, make sure the bolt pattern matches that of the original

block so the PTO accessories, braces and brackets can be bolted on with no

modifications.

The Kohler Magnum engine models M10, M12, M14 and M16 can be used in any Cub Cadet garden tractor. The majority of the Magnum 10-16hp single cylinder engines have flanges at the base. Therefore, the block will need to be converted into a narrow base by cutting off the flanges on each side and then cut new threads in the holes in the block for the narrow oil pan. And the other parts that's needed are: a K-series large OEM bearing plate with an upper mount gear starter (mounting bolts are below the starter motor), or a small K-series OEM bearing plate with a starter/generator; a small or large diameter K-series flywheel with a matching flywheel shroud and baffle shields (sheet metal); and being there's no provisions for ignition points and no points lobe on the Magnum camshaft, Kohler's Breakerless Ignition or crank trigger ignition will need to be used.

Only eight models of the 10-16hp Kohler Magnum single cylinder cast iron block engines was manufactured as a narrow base. The specification numbers for these are as follows: M10, specification #'s 461509, 461534 (Cub Cadet garden tractor model 1050); M12, specification #'s 471512, 471514, 471570 (Cub Cadet garden tractor model 1210); M14, specification #'s 601512, 601513; and M16, specification # 711536. All other 10-16hp Magnum engine block specification numbers are a wide base.

Any Kohler Magnum single cylinder 10-16hp engine

would be excellent to pull with. The only problem is, being these come with

solid state ignition, with no provision for ignition points, if a steel flywheel

is going to be used, a flywheel-triggered

or crank trigger ignition system must be needed, too. Also, if the engine

has counterbalance gears, they will definitely need to be removed because

one or the other could break, destroying the block and other parts. For most

engines, it does absolutely no good to reinstall them. Most Kohler engines

don't come with them and in most engines, they do very little to reduce engine

vibration. When left out, the engine should not vibrate more than usual.

Being balance gears are made of cast iron material and operate [out of balance]

on a single, narrow needle bearing for support, they've been known to break

and destroy the crankshaft, camshaft and engine block. I've seen this happen

to a good engine a few times. Therefore, I highly recommend leaving them

out. But if the engine vibrates excessively with the absence of the balance

gears, the flywheel and/or crankshaft will need to be

dynamically and precision spin-balanced to

reduce engine vibration. Click or tap

here to learn more about flywheel and/or crankshaft balancing.

Any Kohler Magnum single cylinder 10-16hp engine

would be excellent to pull with. The only problem is, being these come with

solid state ignition, with no provision for ignition points, if a steel flywheel

is going to be used, a flywheel-triggered

or crank trigger ignition system must be needed, too. Also, if the engine

has counterbalance gears, they will definitely need to be removed because

one or the other could break, destroying the block and other parts. For most

engines, it does absolutely no good to reinstall them. Most Kohler engines

don't come with them and in most engines, they do very little to reduce engine

vibration. When left out, the engine should not vibrate more than usual.

Being balance gears are made of cast iron material and operate [out of balance]

on a single, narrow needle bearing for support, they've been known to break

and destroy the crankshaft, camshaft and engine block. I've seen this happen

to a good engine a few times. Therefore, I highly recommend leaving them

out. But if the engine vibrates excessively with the absence of the balance

gears, the flywheel and/or crankshaft will need to be

dynamically and precision spin-balanced to

reduce engine vibration. Click or tap

here to learn more about flywheel and/or crankshaft balancing.

How to Convert a Single Cylinder Kohler K-Series Engine into a Magnum Engine -

To convert the Kohler K-series

K241, K301, K321 or K341 engine into a Magnum M10, M12, M14 or M16 engine,

the parts that's needed are: Magnum OEM bearing plate;

starter motor (the

support brackets for the starter are for mounting of the starter solenoid

only. They do not support the starter motor whatsoever); flywheel (w/external

magnet); plastic cooling fan assembly; flywheel shroud; solid state ignition

coil w/mounting screws; plastic inner air baffle; cylinder head (cover) and

cylinder (side) baffles (sheet metal). The only difference in these baffles

is the M10, M12 and M14 all share the same baffles over the cylinder head

and on the cylinder, and the M16 use different (larger) baffles. The Kohler

points pushrod hole will also need to be plugged with a Briggs & Stratton

points plunger plug. And when installing the bearing plate, the cam pin hole

will need to be sealed with

clear RTV silicone adhesive sealant because the

Magnum bearing plate will not cover the hole. By the way - it's best to

use

Clear RTV Silicone Adhesive Sealant for three reasons:

Gaskets don't always seal the imperfections and irregularities between two

mating metals, especially thin metal covers; being

Clear RTV Silicone Adhesive Sealant is an adhesive or glue,

it bonds parts together, forming a leak-proof seal; and being it's clear,

it makes for a clean and professional-looking repair job. When applied sparingly,

it can't be easily seen or noticed between the parts. Also, engine heat has

very little effect on silicone rubber. It can withstand up to 2,500 degrees

heat.

To convert the Kohler K-series

K241, K301, K321 or K341 engine into a Magnum M10, M12, M14 or M16 engine,

the parts that's needed are: Magnum OEM bearing plate;

starter motor (the

support brackets for the starter are for mounting of the starter solenoid

only. They do not support the starter motor whatsoever); flywheel (w/external

magnet); plastic cooling fan assembly; flywheel shroud; solid state ignition

coil w/mounting screws; plastic inner air baffle; cylinder head (cover) and

cylinder (side) baffles (sheet metal). The only difference in these baffles

is the M10, M12 and M14 all share the same baffles over the cylinder head

and on the cylinder, and the M16 use different (larger) baffles. The Kohler

points pushrod hole will also need to be plugged with a Briggs & Stratton

points plunger plug. And when installing the bearing plate, the cam pin hole

will need to be sealed with

clear RTV silicone adhesive sealant because the

Magnum bearing plate will not cover the hole. By the way - it's best to

use

Clear RTV Silicone Adhesive Sealant for three reasons:

Gaskets don't always seal the imperfections and irregularities between two

mating metals, especially thin metal covers; being

Clear RTV Silicone Adhesive Sealant is an adhesive or glue,

it bonds parts together, forming a leak-proof seal; and being it's clear,

it makes for a clean and professional-looking repair job. When applied sparingly,

it can't be easily seen or noticed between the parts. Also, engine heat has

very little effect on silicone rubber. It can withstand up to 2,500 degrees

heat.

FYI - Solid state ignition provides a more stable ignition timing than points ignition. The ignition timing for a K-series engine is less stable because the points operate off the camshaft, which has a tendency to "move around" a few thousandths of an inch while the engine is running, which effects the ignition timing. Flywheel-triggered ignition timing, such as the Magnum solid state ignition, is more stable because it operates off the crankshaft, which doesn't "move around" as much as the camshaft. One thing is lessened and another is gained with either ignition system. [Return To Previous Paragraph, Section or Website]

How to Determine the Condition of an Engine That Smokes A Lot Out the Exhaust -

The best way I found to determine if a small engine needs rebuilding is to remove the cylinder head(s), and look at the condition of the head gasket(s). If there's signs of oil leakage between the pushrod area (OHV models and V-twins), this means the head(s) are warped and needs to be resurfaced on a wide, flat belt- or disc-sander/grinder to remove the any warpage and restore flatness. Resurfacing the cylinder heads on a sander/grinder to remove any warpage and restore flatness works best. Because if only new head gaskets are installed, the possibly of a leaking head gasket still exist. Once the heads are properly resurfaced, new gaskets installed and the head bolts are torqued to specs, the heads should not warp and leak again. Also, look at the top edge of the piston(s). If the carbon deposits is washed off and there's oil on top of the pistons, then this means the piston and rings are worn. And run the piston(s) down in the cylinder and look and feel with your fingers for any scratches or score lines on the cylinder walls. If there are scratches or score lines and they're deep (enough to catch your fingernail on), the cylinder(s) will need to be bored to the next oversize and new matching oversize piston and rings will need to be installed.

BUYER BEWARE! A word of caution before purchasing a used or [supposedly] rebuilt engine: Remove the cylinder head and oil pan (they're easy to remove), and then inspect the internal parts for damage and/or excessive wear. If the seller refuse to allow the engine to be internally examined, then perhaps it'll be best not to purchase it. Because once the seller has your money, all you might have is some scrap metal on your hands.

Detailed Information About the Kohler Engine Models KT17 (first design), KT19 (first design), KT21, and KT17 Series II and KT19 Series II Oiling Systems - Kohler engine models KT17 (first design), KT17 Series II, KT19 (first design), KT19 Series II and KT21 all have a gear-driven gerotor oil pump, and use one of two types of pressurized lubrication systems. NOTE: The KT21 was a short-production engine, and although certain parts off of the other twin cylinder engines will fit this engine, most parts for this engine are no longer available from Kohler. [Top of Page]

The KT17 (first design), KT19

(first design) and KT21 engines use a pressurized SPRAY lubrication system.

The oil pump delivers oil to the main

bearings and camshaft bearings at approximately 5 PSI. The main bearings

are under pressurized oil, but lubrication for the connecting rods and journals

is provided by oil sprayed continuously from two small holes drilled in the

camshaft in alignment with the connecting rods.

The KT17 (first design), KT19

(first design) and KT21 engines use a pressurized SPRAY lubrication system.

The oil pump delivers oil to the main

bearings and camshaft bearings at approximately 5 PSI. The main bearings

are under pressurized oil, but lubrication for the connecting rods and journals

is provided by oil sprayed continuously from two small holes drilled in the

camshaft in alignment with the connecting rods.

On the other hand, the redesigned KT17 Series II and KT19 Series II (including all Magnum opposed twin cylinder engines) have a full pressure lubrication system, much like in a modern-day automobile engine. The Full Pressure Lubrication System delivers oil to the crankshaft bearings, camshaft journals, and connecting rod journals at approximately 25-50 PSI. A spring-loaded pressure relief valve, located in the engine crankcase, behind the closure plate, regulates and limits the maximum oil pressure in the system. The twin cylinder Series II and all twin cylinder Magnum engines have a spring-loaded pressure relief check valve (steel ball with a pressure relief spring) to regulate the oil pressure, and the KT17 (first design), KT19 (first design) and KT21 engines do not. The Series II and Magnum crankshaft is cross-drilled for oil passages from the main journals to the connecting rod journals, and both the main bearings and connecting rod bearing surfaces receive full lubrication from an oil passageway in the block through the crankshaft. Oil does not spray out of the camshaft onto the connecting rods in the KT17 Series II, KT19 Series II and all Magnum opposed twin cylinder engines. If there's no oil filter adapter with no oil filter on a KT17 Series II, KT19 Series II or any Magnum opposed twin cylinder engine (oil filter adapter port blocked-off), it's still important to change the oil on a regular basis with these engines, too. Again, fresh, clean oil cost less than another engine or an engine rebuild.

The crankcase oil in models KT17 (first design), KT19 (first design), KT17 Series II, KT19 Series II, MV16, M18, MV18, M20 and MV20 without an oil filter should be changed every 25 hours of run time. For the average homeowner, this is about once a year. But the oil in models KT17 Series II, KT19 Series II, MV16, M18, MV18, M20 and MV20 with an oil filter adapter and oil filter should be changed every 50 hours of run time, which on the average, is about every two years, and the oil filter can be changed every other oil change.

The Kohler KT17 (first design)

and KT19 (first design) engines are well-designed and well-built engines,

but have gained a bad reputation because the crankcase oil was not changed

on a regular basis or at all, the wrong velocity of oil was used and/or the

engine was ran low on oil on the side of a hill. (Virtually any engine

can have a bad reputation if the oil isn't changed.) There's also a wide-spread

rumor that these engines have the oil pickup strainer housing located off

to one side in the bottom crankcase. This supposedly caused the oil pump

not be able to pick up oil on the side of a hill more than a 30º angle/slope

with the crankcase full of oil, which resulted in insufficient oil

delivery/lubrication to the crankshaft and through the camshaft spray holes

that cause the number one connecting rod to either burn or break. However,

this is NOT true! What cause the rod failure mostly is the

crankcase oil not changed on a regular basis, or at all.

(Any KT17 (first design), KT17 Series II, KT19 (first design), KT19 Series

II, KT21, M18 or M20 without an oil filter with a lot of hours of use that

is still in service today have obviously been well maintained by caring and

responsible person(s) throughout the years.)

The Kohler KT17 (first design)

and KT19 (first design) engines are well-designed and well-built engines,

but have gained a bad reputation because the crankcase oil was not changed

on a regular basis or at all, the wrong velocity of oil was used and/or the

engine was ran low on oil on the side of a hill. (Virtually any engine

can have a bad reputation if the oil isn't changed.) There's also a wide-spread

rumor that these engines have the oil pickup strainer housing located off