A-1 Miller's Performance Enterprises Webstore

of Conventional Ignition Parts and Custom-Made Electronic Ignition Conversion

Kits

A-1 Miller's Performance Enterprises Webstore

of Conventional Ignition Parts and Custom-Made Electronic Ignition Conversion

Kits

A-1 Miller's Performance Enterprises Webstore

of Conventional Ignition Parts and Custom-Made Electronic Ignition Conversion

Kits

A-1 Miller's Performance Enterprises Webstore

of Conventional Ignition Parts and Custom-Made Electronic Ignition Conversion

Kits

Nowadays, prices are subject to change without notice. Click

Refresh to see any

changes or updates. Optimized for 1152 x 864 computer screen resolution.

To search for a word or phrase in any of my websites, press the CTRL

and F

and F  keys on

your keyboard simultaneously to open the Find or Search dialog box in your

web browser. Scroll down this website or click/tap the links below to

jump down to..

keys on

your keyboard simultaneously to open the Find or Search dialog box in your

web browser. Scroll down this website or click/tap the links below to

jump down to..

| FYI - All aftermarket parts offered in this website are of very high quality and come with an unconditional guarantee. As a matter of fact, the aftermarket parts are just as good or better quality than most OEM Kohler parts. However, certain OEM Kohler and aftermarket parts are no longer available, but might still be available from a source in new old stock. | |||||

FYI - Being we haven't had any Onan or Wisconsin engines in our shop for repairs, we have no experience with working on them. Apparently, these engines are rare in our area (mid-Missouri). Therefore, we do not offer a custom-made electronic ignition conversion kit for these engines. If someone is willing to bring their Onan or Wisconsin engine to us, we're sure we can fabricate and install an electronic ignition system on it. |

|||||

Kill Switch and Conventional (Points and Condenser) Ignition Parts -

SAFETY FIRST!

Break-Away / Grounding-Type Safety Kill Switch with

Pull-Pin. Use for competition pulling only; mount on rear of tractor.

When the pin pulled, it grounds the ignition coil from producing spark. If

using with a self-energizing magneto or electronic/solid state ignition systems:

Connect one wire to the chassis ground, and connect the other wire to the

points/condenser wire or to the kill terminal on the solid state ignition

coil/module. If using with a battery-powered ignition system: Connect one

wire to the chassis ground, and connect the other wire to the coil negative

(–) terminal. NOTE: With battery-powered ignition, as soon as pin

is pulled (engine will die), manually shut off ignition switch right away

to prevent possible damage to the ignition coil and electronic ignition module

if equipped with crank trigger ignition. This type of switch does not

disable power to the

electric fuel pump on a pulling tractor. It must be

shut-off manually by the ignition switch or an OFF-ON toggle switch.

[Return to previous section] SAFETY FIRST!

Break-Away / Grounding-Type Safety Kill Switch with

Pull-Pin. Use for competition pulling only; mount on rear of tractor.

When the pin pulled, it grounds the ignition coil from producing spark. If

using with a self-energizing magneto or electronic/solid state ignition systems:

Connect one wire to the chassis ground, and connect the other wire to the

points/condenser wire or to the kill terminal on the solid state ignition

coil/module. If using with a battery-powered ignition system: Connect one

wire to the chassis ground, and connect the other wire to the coil negative

(–) terminal. NOTE: With battery-powered ignition, as soon as pin

is pulled (engine will die), manually shut off ignition switch right away

to prevent possible damage to the ignition coil and electronic ignition module

if equipped with crank trigger ignition. This type of switch does not

disable power to the

electric fuel pump on a pulling tractor. It must be

shut-off manually by the ignition switch or an OFF-ON toggle switch.

[Return to previous section]

|

|

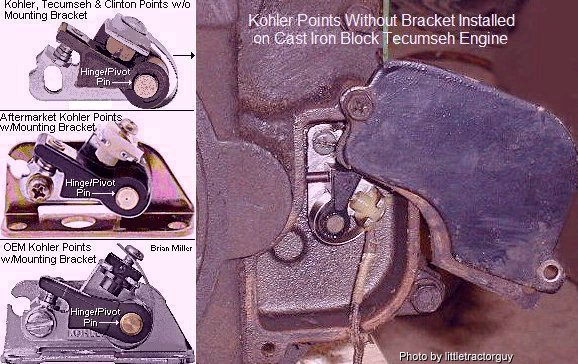

Ignition

Points for Kohler, Tecumseh and Clinton engines. Fits Kohler engine models

K90/K91, K141, K161/K160, KV161,

L160/L161, L181,

K181, K241, K301, K321, K330/K331, K341, K361, KT17 (first design), KT17

Series II, KT19 (first design) KT19 Series II, KT21, K482, K532 and K582

with magneto or 12 volt battery ignition (use with mounting bracket). Also

fits Tecumseh cast iron block engine models HH80, HH100, HH120 with magneto

or 12 volt battery ignition (use without mounting bracket); and Clinton engine

models 414, 418, 420, 422 (use without mounting bracket). Also, use this

part when converting from Breakerless Ignition to points and condenser ignition.

IMPORTANT: Sometimes oxidation will form on new points contacts from sitting

in storage, even when sealed in plastic. This happens A LOT with all types

of ignition points. Therefore, do not use sanding material, such as sandpaper

or emery cloth, to clean any electrical contacts! These will leave a gritty

residue between the contacts, causing a faulty connection. Instead, while

the points is installed and the contacts are closed under pressure, use a

[preferably clean]

ignition points file (professional use) or

metal fingernail file (use in a pinch) to remove any

oxidation/debris between the contacts, then drag a piece of [preferably clean]

lint-free paper through the contacts to remove any left-over residue, and

use

brake parts cleaner,

electrical/electronic contact cleaner,

cleaning solvent or

paint thinner (these leave no oily residue) and then use

150± psi compressed air with an

air blow gun nozzle to clean any remaining debris and metal

filings from the contacts. This will guarantee 100% connection with the points.

Also, lubricate the hinge/pivot pin in the points with clean motor oil to

prevent from wearing due to dry friction, which will eventually effect the

ignition timing. Or improve engine performance and longevity with virtually

any engine and eliminate regular maintenance on conventional ignition components

with an Electronic Ignition Conversion

Kit! Ignition

Points for Kohler, Tecumseh and Clinton engines. Fits Kohler engine models

K90/K91, K141, K161/K160, KV161,

L160/L161, L181,

K181, K241, K301, K321, K330/K331, K341, K361, KT17 (first design), KT17

Series II, KT19 (first design) KT19 Series II, KT21, K482, K532 and K582

with magneto or 12 volt battery ignition (use with mounting bracket). Also

fits Tecumseh cast iron block engine models HH80, HH100, HH120 with magneto

or 12 volt battery ignition (use without mounting bracket); and Clinton engine

models 414, 418, 420, 422 (use without mounting bracket). Also, use this

part when converting from Breakerless Ignition to points and condenser ignition.

IMPORTANT: Sometimes oxidation will form on new points contacts from sitting

in storage, even when sealed in plastic. This happens A LOT with all types

of ignition points. Therefore, do not use sanding material, such as sandpaper

or emery cloth, to clean any electrical contacts! These will leave a gritty

residue between the contacts, causing a faulty connection. Instead, while

the points is installed and the contacts are closed under pressure, use a

[preferably clean]

ignition points file (professional use) or

metal fingernail file (use in a pinch) to remove any

oxidation/debris between the contacts, then drag a piece of [preferably clean]

lint-free paper through the contacts to remove any left-over residue, and

use

brake parts cleaner,

electrical/electronic contact cleaner,

cleaning solvent or

paint thinner (these leave no oily residue) and then use

150± psi compressed air with an

air blow gun nozzle to clean any remaining debris and metal

filings from the contacts. This will guarantee 100% connection with the points.

Also, lubricate the hinge/pivot pin in the points with clean motor oil to

prevent from wearing due to dry friction, which will eventually effect the

ignition timing. Or improve engine performance and longevity with virtually

any engine and eliminate regular maintenance on conventional ignition components

with an Electronic Ignition Conversion

Kit!

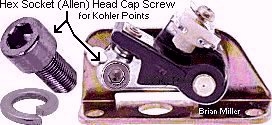

Hex Socket (Allen) Head Cap Screw w/split lock washer and

flat washer. Replaces OEM slotted or aftermarket Phillips head adjustment

screw in points for easier setting of the point gap and/or ignition timing

with a

9/64" hex (Allen) L-wrench. Fits points used on Kohler

engine models K90/K91, K141, K161/K160,

KV161,

L160/L161, L181,

K181, K241, K301, K321, K330/K331, K341, K361, KT17 (first design), KT17

Series II, KT19 (first design) KT19 Series II, KT21, K482, K532 and K582.

Ideal for garden tractors with a

longitudinal engine, such as IH Cub Cadet, Economy Power

King, Ford, hydrostatic-drive John Deere, MTD Farm King model 960, Pennsylvania

Panzer, Meteor, Copar, etc. No need to use this Allen head screw for garden

tractors with a

transverse engine, such as older Bolens, belt-drive John

Deere, Massey Ferguson, Sears Suburban, Wheel Horse, etc. NOTE: Threads for

adjustment screw in aftermarket points may need to be rethreaded with a 8-32

UNF TAPER [preferably]

hand tap. And due to risk of stripping threads in the thin metal points

bracket, do not over-tighten this adjustment screw! Hex Socket (Allen) Head Cap Screw w/split lock washer and

flat washer. Replaces OEM slotted or aftermarket Phillips head adjustment

screw in points for easier setting of the point gap and/or ignition timing

with a

9/64" hex (Allen) L-wrench. Fits points used on Kohler

engine models K90/K91, K141, K161/K160,

KV161,

L160/L161, L181,

K181, K241, K301, K321, K330/K331, K341, K361, KT17 (first design), KT17

Series II, KT19 (first design) KT19 Series II, KT21, K482, K532 and K582.

Ideal for garden tractors with a

longitudinal engine, such as IH Cub Cadet, Economy Power

King, Ford, hydrostatic-drive John Deere, MTD Farm King model 960, Pennsylvania

Panzer, Meteor, Copar, etc. No need to use this Allen head screw for garden

tractors with a

transverse engine, such as older Bolens, belt-drive John

Deere, Massey Ferguson, Sears Suburban, Wheel Horse, etc. NOTE: Threads for

adjustment screw in aftermarket points may need to be rethreaded with a 8-32

UNF TAPER [preferably]

hand tap. And due to risk of stripping threads in the thin metal points

bracket, do not over-tighten this adjustment screw!

Phillips Head

and Hex Socket (Allen) Head Screws with split lock washers to fasten ignition

points and/or points cover on Kohler engines. Fits Kohler engine models

K90/K91, K141, K161/K160, KV161,

L160/L161, L181,

K181, K241, K301, K321, K330/K331, K341, K361, KT17 (first design), KT17

Series II, KT19 (first design) KT19 Series II, KT21, K482, K532 and K582.

These type of screw heads make for easier fastening of points and points

cover to engine block in hard-to-reach places than the OEM slotted head screws

on garden tractors with a

transverse engine as listed above. Each screw replaces

discontinued Kohler part # X-131-1-S. Phillips Head

and Hex Socket (Allen) Head Screws with split lock washers to fasten ignition

points and/or points cover on Kohler engines. Fits Kohler engine models

K90/K91, K141, K161/K160, KV161,

L160/L161, L181,

K181, K241, K301, K321, K330/K331, K341, K361, KT17 (first design), KT17

Series II, KT19 (first design) KT19 Series II, KT21, K482, K532 and K582.

These type of screw heads make for easier fastening of points and points

cover to engine block in hard-to-reach places than the OEM slotted head screws

on garden tractors with a

transverse engine as listed above. Each screw replaces

discontinued Kohler part # X-131-1-S.

High Quality Adjustable Chevy (GM) Ignition Points with Stiff Spring for Quick Reaction at open RPM. Use on Kohler K-series K241, K301, K321, K341, K361 competition pulling engines only. NOTE: Not recommended for use on lawn and garden equipment engines due to long exposure to dust and debris, which can contaminate points contacts and cause a misfire. IMPORTANT: Sometimes oxidation will form on new points contacts from sitting in storage, even when sealed in plastic. This happens A LOT with small engine and automotive ignition points. Therefore, while the points are closed under pressure, use a clean steel fingernail file or ignition points file to remove any oxidation/debris between the contacts, then drag a piece of clean lint-free paper through the contacts to remove any left-over residue, and use brake parts cleaner, electrical/electronic contact cleaner, cleaning solvent or paint thinner (these leave no oily residue) and then use 150± psi compressed air with an air blow gun nozzle to clean any remaining debris and/or metal filings from the contacts. This will guarantee 100% connection with the points. Do not use sanding material, such as sandpaper or emery cloth, to clean any electrical contacts! These will leave a gritty residue between the contacts, causing a faulty connection and possible engine misfire. Or improve engine performance and longevity with virtually any engine and eliminate regular maintenance on conventional ignition components with an Electronic Ignition Conversion Kit! $15.00 each, plus shipping & handling. TIP: To prevent small Phillips- or slotted-head screws from falling out of the screwdriver tip when installing in a hard to reach place, first of all, use the correct size screwdriver that fits the screw head, and for ordinary steel screws, temporarily magnetize the screwdriver by rubbing a magnet several times along the length of the shank, or for stainless steel screws, apply a dab of automotive grease in the head of the screw. |

|

Ignition Points

Pushrods. NOTE: New OEM Kohler K-series engine models points pushrods

are 1.265" in length, and a used pushrod must be no less than 1.205" in length.

Measure yours accurately with a

dial or

digital caliper to determine if it needs replacing. Or

improve engine performance and longevity with A-1 Miller's custom-made

Electronic Ignition Conversion

Kit! Ignition Points

Pushrods. NOTE: New OEM Kohler K-series engine models points pushrods

are 1.265" in length, and a used pushrod must be no less than 1.205" in length.

Measure yours accurately with a

dial or

digital caliper to determine if it needs replacing. Or

improve engine performance and longevity with A-1 Miller's custom-made

Electronic Ignition Conversion

Kit!

Ignition Points Pushrods. NOTE: New OEM Kohler points pushrods are 1.550" in length, and a used pushrod must be no less than 1.500" in length. Measure yours accurately with a dial or digital caliper to determine if it needs replacing. Or improve engine performance and longevity with A-1 Miller's custom-made Electronic Ignition Conversion Kit!

NOTE: If the points lobe on the camshaft is severely worn and the ignition timing cannot be fully advanced to the factory setting of 20º BTDC, and completely disassembling the entire engine to install a threaded-on stainless steel nut on the end of the OEM points pushrod (from inside the crankcase; as shown to the right) or to replace the camshaft with one that's in better condition (if one is available) is out of the question, then the alternative is to convert the engine to A-1 Miller's custom-made flywheel-triggered 12 volt electronic ignition.

|

|

3/16" I.D. Neoprene Rubber O-Ring. Installs on points pushrod

close to engine block, allowing any seepage of crankcase oil to drip down,

staying off points contacts. Fits Kohler engine models K90/K91, K141, K161/K160,

KV161,

L160/L161, L181,

K181, K241, K301, K321, K341, K361, K482, K532 and K582. But if the ignition

points pushrod hole is excessively worn, this will effect the ignition timing

as well, and the block will need to be machined for installation of a bronze

sleeve bushing, or the hole can be plugged, and solid state or a custom-made

flywheel- or

crank-trigger electronic ignition system

can be installed. (The translucent silicone rubber diaphragm seal (part

# 220074-S) is no longer available from Kohler.)

[Return to previous paragraph, section

or website] 3/16" I.D. Neoprene Rubber O-Ring. Installs on points pushrod

close to engine block, allowing any seepage of crankcase oil to drip down,

staying off points contacts. Fits Kohler engine models K90/K91, K141, K161/K160,

KV161,

L160/L161, L181,

K181, K241, K301, K321, K341, K361, K482, K532 and K582. But if the ignition

points pushrod hole is excessively worn, this will effect the ignition timing

as well, and the block will need to be machined for installation of a bronze

sleeve bushing, or the hole can be plugged, and solid state or a custom-made

flywheel- or

crank-trigger electronic ignition system

can be installed. (The translucent silicone rubber diaphragm seal (part

# 220074-S) is no longer available from Kohler.)

[Return to previous paragraph, section

or website]

|

|

Ignition Points

Cover Gaskets. Fits Kohler engine models K90/K91, K141, K160/K161,

KV161,

L160/L161, L181,

K181, K241, K301, K321, K330/K331, K341, K361, KT17 (first design), KT17

Series II, KT19 (first design) KT19 Series II, KT21, K482, K532 and K582.

Protects points contacts from dust, dirt and water contamination. Also, use

this part when converting from Breakerless Ignition to points and condenser

ignition. Ignition Points

Cover Gaskets. Fits Kohler engine models K90/K91, K141, K160/K161,

KV161,

L160/L161, L181,

K181, K241, K301, K321, K330/K331, K341, K361, KT17 (first design), KT17

Series II, KT19 (first design) KT19 Series II, KT21, K482, K532 and K582.

Protects points contacts from dust, dirt and water contamination. Also, use

this part when converting from Breakerless Ignition to points and condenser

ignition.

|

|

Grommet for

Ignition Points Cover/Wire. Fits Kohler engine models K90/K91, K141, K161/K160,

KV161,

L160/L161, L181,

K181, K241, K301, K321, K330/K331, K341, K361, KT17, KT17 Series II, KT19

and KT19 Series II, KT21, K482, K532 and K582. Prevents dust and dirt from

contaminating points contacts, and protects points wire from rubbing/chafing

against points cover or use to convert from Breakerless Ignition to points

and condenser ignition. FYI:

RTV Silicone Adhesive Sealant will serve the same

purpose. Grommet for

Ignition Points Cover/Wire. Fits Kohler engine models K90/K91, K141, K161/K160,

KV161,

L160/L161, L181,

K181, K241, K301, K321, K330/K331, K341, K361, KT17, KT17 Series II, KT19

and KT19 Series II, KT21, K482, K532 and K582. Prevents dust and dirt from

contaminating points contacts, and protects points wire from rubbing/chafing

against points cover or use to convert from Breakerless Ignition to points

and condenser ignition. FYI:

RTV Silicone Adhesive Sealant will serve the same

purpose.

|

|

"Assemble It

Yourself" Points-to-Ignition Coil Wire Kit. Replace OEM wire with

frayed/cracked insulation and/or broken connector(s) to prevent a short circuit

and/or engine misfire. Or use this when converting from Breakerless Ignition

to points and condenser ignition. Fits Kohler engines with battery-powered

ignition, models K90/K91, K141, K161/K160,

KV161,

L160/L161, L181,

K181, K241, K301, K321, K330/K331, K341, K361, KT17 (first design), KT17

Series II, KT19 (first design) KT19 Series II, KT21, K482, K532 and K582.

Includes 22" length (cut to desired length) x #16 gauge (AWG) insulated stranded

copper wire and two uninstalled crimp connectors. Requires use of

electrical connector crimping pliers. High quality A-1

Miller's parts. Replaces Kohler part # A-230371-S. "Assemble It

Yourself" Points-to-Ignition Coil Wire Kit. Replace OEM wire with

frayed/cracked insulation and/or broken connector(s) to prevent a short circuit

and/or engine misfire. Or use this when converting from Breakerless Ignition

to points and condenser ignition. Fits Kohler engines with battery-powered

ignition, models K90/K91, K141, K161/K160,

KV161,

L160/L161, L181,

K181, K241, K301, K321, K330/K331, K341, K361, KT17 (first design), KT17

Series II, KT19 (first design) KT19 Series II, KT21, K482, K532 and K582.

Includes 22" length (cut to desired length) x #16 gauge (AWG) insulated stranded

copper wire and two uninstalled crimp connectors. Requires use of

electrical connector crimping pliers. High quality A-1

Miller's parts. Replaces Kohler part # A-230371-S.

|

|

Ignition Points Covers. Fits Kohler engine models K90/K91,

K141, K161/K160, KV161,

L160/L161, L181,

K181, K241, K301, K321, K330/K331, K341, K361, KT17 (first design), KT17

Series II, KT19 (first design) KT19 Series II, KT21, K482, K532 and K582.

Protects points from dust, dirt and water contamination. Replace damaged

or missing points cover, or use to convert from Breakerless Ignition to points

and condenser ignition. Ignition Points Covers. Fits Kohler engine models K90/K91,

K141, K161/K160, KV161,

L160/L161, L181,

K181, K241, K301, K321, K330/K331, K341, K361, KT17 (first design), KT17

Series II, KT19 (first design) KT19 Series II, KT21, K482, K532 and K582.

Protects points from dust, dirt and water contamination. Replace damaged

or missing points cover, or use to convert from Breakerless Ignition to points

and condenser ignition.

|

|

3/16" Steel Plug for Kohler

Ignition Points Pushrod Hole. Fits Kohler engine models K90/K91,

K141, K160/K161, KV161,

L160/L161, L181,

K181, K241, K301, K321, K341, K361, and K482, K532, K582 (with an unworn

points pushrod hole). Use this part (to prevent eventual oil leakage) when

converting engine to electronic ignition. (Listed in this website.) Remove

points cover, points and OEM pushrod, and install this plug in the pushrod

hole with a medium size hammer. Plug should fit tight in hole, but if it

fits loose, create knurled/raised ridges on the plug with a sharp, flat cold

chisel and hammer, and apply silicone sealant on plug when installing in

the block. No need to reinstall cover and points. NOTE: The alternative

to using this plug is to remove the ignition points and points pushrod, and

place the pushrod on a hard, flat surface, and use a hammer and sharp flat

cold chisel to lightly create knurled raised marks midway on the pushrod.

Then reinstall the knurled pushrod in the engine block with the hammer. Or

a

20 penny common nail cut off to 1/2" length and the end

ground to a bevel will serve the same purpose. The knurled ridges will retain

the pushrod in the hole. Replaces Kohler part # X-702-1 (brass welch

plug). OEM Briggs & Stratton part #'s 231143, 692882. $6.00 each,

plus shipping & handling. [Return

to previous paragraph, section or website] 3/16" Steel Plug for Kohler

Ignition Points Pushrod Hole. Fits Kohler engine models K90/K91,

K141, K160/K161, KV161,

L160/L161, L181,

K181, K241, K301, K321, K341, K361, and K482, K532, K582 (with an unworn

points pushrod hole). Use this part (to prevent eventual oil leakage) when

converting engine to electronic ignition. (Listed in this website.) Remove

points cover, points and OEM pushrod, and install this plug in the pushrod

hole with a medium size hammer. Plug should fit tight in hole, but if it

fits loose, create knurled/raised ridges on the plug with a sharp, flat cold

chisel and hammer, and apply silicone sealant on plug when installing in

the block. No need to reinstall cover and points. NOTE: The alternative

to using this plug is to remove the ignition points and points pushrod, and

place the pushrod on a hard, flat surface, and use a hammer and sharp flat

cold chisel to lightly create knurled raised marks midway on the pushrod.

Then reinstall the knurled pushrod in the engine block with the hammer. Or

a

20 penny common nail cut off to 1/2" length and the end

ground to a bevel will serve the same purpose. The knurled ridges will retain

the pushrod in the hole. Replaces Kohler part # X-702-1 (brass welch

plug). OEM Briggs & Stratton part #'s 231143, 692882. $6.00 each,

plus shipping & handling. [Return

to previous paragraph, section or website]

|

|

| NOTE:

If a small engine idles well, but fails to rev up or runs erratically at

higher speeds (like it hits and misses, pops and backfires), then chances

are, it needs a new condenser/capacitor. And always install a condenser with

the wire or terminal facing downward so rain water and/or when washing off

engine, water will not enter inside condenser, ruining it. With water inside

the condenser, this will cause the engine to run erratically when revved

up.

|

|

High Quality Copper Core/Non-Resistor Spark Plugs. Designed

for Kohler engine models K90/K91, smaller flathead Briggs & Stratton

and Tecumseh engines, most 2-cycle small engines and most chainsaws. Copper

core spark plugs provide a stronger spark that allow the ignition coil to

operate cooler and last longer. For best engine performance and longevity

of the coil, set gap at .025" with a self-energizing magneto or solid state

electronic ignition system, .035" with a full size battery-powered ignition

coil, and .060" with a high-output/performance battery-powered coil. 14mm

threads x 3/8" thread reach, flat washer seat. Replaces Briggs and Stratton

part # 802592S. High Quality Copper Core/Non-Resistor Spark Plugs. Designed

for Kohler engine models K90/K91, smaller flathead Briggs & Stratton

and Tecumseh engines, most 2-cycle small engines and most chainsaws. Copper

core spark plugs provide a stronger spark that allow the ignition coil to

operate cooler and last longer. For best engine performance and longevity

of the coil, set gap at .025" with a self-energizing magneto or solid state

electronic ignition system, .035" with a full size battery-powered ignition

coil, and .060" with a high-output/performance battery-powered coil. 14mm

threads x 3/8" thread reach, flat washer seat. Replaces Briggs and Stratton

part # 802592S.

High Quality Copper

Core/Non-Resistor Spark Plugs. Designed for Kohler opposed twin-cylinder

flathead engine models MV16, KT17, KT17 Series II, KT19 and KT19 Series II,

KT21, M18, MV18, M20 and MV20. Also designed for 1971-1989 Chevrolet and

GMC L4, L6, V6 and V8 engines. Copper core spark plugs provide a stronger

spark that allow the ignition coil to operate cooler and last longer. For

best small engine performance and longevity of the coil, set gap at .025"

with a self-energizing magneto or solid state electronic ignition system,

.035" with a full size battery-powered ignition coil, and .060" with a

high-output/performance battery-powered coil. 14mm threads x 15/32" thread

reach, tapered seat. High Quality Copper

Core/Non-Resistor Spark Plugs. Designed for Kohler opposed twin-cylinder

flathead engine models MV16, KT17, KT17 Series II, KT19 and KT19 Series II,

KT21, M18, MV18, M20 and MV20. Also designed for 1971-1989 Chevrolet and

GMC L4, L6, V6 and V8 engines. Copper core spark plugs provide a stronger

spark that allow the ignition coil to operate cooler and last longer. For

best small engine performance and longevity of the coil, set gap at .025"

with a self-energizing magneto or solid state electronic ignition system,

.035" with a full size battery-powered ignition coil, and .060" with a

high-output/performance battery-powered coil. 14mm threads x 15/32" thread

reach, tapered seat.

High Quality Copper

Core/Non-Resistor Spark Plugs. Designed for most makes and models of

OHV aluminum block single- and V-twin air-cooled small engines. Copper core

spark plugs provide a stronger spark that allow the ignition coil to operate

cooler and last longer. For best engine performance and longevity of the

coil, set gap at .025" with a self-energizing magneto or solid state electronic

ignition system, .035" with a full size battery-powered ignition coil, and

.060" with a high-output/performance battery-powered coil. 14mm threads x

5/8" thread reach, flat washer seat. High Quality Copper

Core/Non-Resistor Spark Plugs. Designed for most makes and models of

OHV aluminum block single- and V-twin air-cooled small engines. Copper core

spark plugs provide a stronger spark that allow the ignition coil to operate

cooler and last longer. For best engine performance and longevity of the

coil, set gap at .025" with a self-energizing magneto or solid state electronic

ignition system, .035" with a full size battery-powered ignition coil, and

.060" with a high-output/performance battery-powered coil. 14mm threads x

5/8" thread reach, flat washer seat.

|

|

Spark Plug

Grommet. Fits Kohler (Quiet Line) engine models K181AQS, M8, K241AQS,

K301AQS, K321AQS and K341AQS. Fastens directly on spark plug in air duct

shield (sheet metal) over cylinder head to help cool the head better. Made

of neoprene rubber. Spark Plug

Grommet. Fits Kohler (Quiet Line) engine models K181AQS, M8, K241AQS,

K301AQS, K321AQS and K341AQS. Fastens directly on spark plug in air duct

shield (sheet metal) over cylinder head to help cool the head better. Made

of neoprene rubber.

|

|

Indexing

Washers for Flat Seat Spark Plugs with 14mm Threads. Positions spark

plug with the open/exposed gap facing the center of the piston in combustion

chamber of flathead engines for up to 10% more horsepower and torque when

using tractor under extreme conditions, such as heavy mowing, garden plowing,

pushing/blowing snow or competition pulling. To know exactly where the open

gap is when the spark plug is installed in the head, place a mark (line)

with a permanent ink marker

(Sharpie,

Magic Marker,

Marks-A-Lot, etc.) on the porcelain in-line with the open

gap at the tip of the spark plug as shown in the photo to the right ->.

Also, leave the original compression washer on the spark plug and add the

indexing washer(s) as required, tighten spark plug with ink mark on

porcelain/open gap facing near center of the piston. Made of hardened steel.

Available in the following thicknesses: .005", .010" and .015".

.75¢ each, plus shipping & handling. Indexing

Washers for Flat Seat Spark Plugs with 14mm Threads. Positions spark

plug with the open/exposed gap facing the center of the piston in combustion

chamber of flathead engines for up to 10% more horsepower and torque when

using tractor under extreme conditions, such as heavy mowing, garden plowing,

pushing/blowing snow or competition pulling. To know exactly where the open

gap is when the spark plug is installed in the head, place a mark (line)

with a permanent ink marker

(Sharpie,

Magic Marker,

Marks-A-Lot, etc.) on the porcelain in-line with the open

gap at the tip of the spark plug as shown in the photo to the right ->.

Also, leave the original compression washer on the spark plug and add the

indexing washer(s) as required, tighten spark plug with ink mark on

porcelain/open gap facing near center of the piston. Made of hardened steel.

Available in the following thicknesses: .005", .010" and .015".

.75¢ each, plus shipping & handling.

|

|

High Quality Universal Switches. Designed for use with

Self-Energizing Magneto Ignition, Solid State Ignition, OEM Solid State

Ignition (SSI) for Tecumseh's Cast Iron Block Engines, or with OEM Kohler

Breakerless Ignition. These can be used on virtually any small engine

installed on lawn and garden equipment, garden tillers, go-karts, chainsaws,

log splitters, portable air compressors, portable generators/welders, portable

water pumps, etc. with a magneto or solid state ignition, and a recoil/rope

starter or a push button starter switch, if engine is equipped with an

electric starter.

Very durable, tough switches. High Quality Universal Switches. Designed for use with

Self-Energizing Magneto Ignition, Solid State Ignition, OEM Solid State

Ignition (SSI) for Tecumseh's Cast Iron Block Engines, or with OEM Kohler

Breakerless Ignition. These can be used on virtually any small engine

installed on lawn and garden equipment, garden tillers, go-karts, chainsaws,

log splitters, portable air compressors, portable generators/welders, portable

water pumps, etc. with a magneto or solid state ignition, and a recoil/rope

starter or a push button starter switch, if engine is equipped with an

electric starter.

Very durable, tough switches.

|

|

High

Quality Universal Switches for Battery-Powered Ignition and Electrical

Accessories. Very durable, tough switches. Either can be used for

ignition, lights,

electric fuel

pump, electric PTO clutch, etc. When used for ignition, use with

push button starter switch (listed below). Terminals or wires on switches

listed below makes contact when in the ON position. Can be used on virtually

anything that have a battery-powered ignition or electrical system, such

as: garden tractors, go-karts, competition pulling tractors, small motorized

vehicles, mini-rods, hot-rods, farm tractors, automobiles, etc. Each can

be mounted in dashboard, instrument panel, engine control panel, etc. High

Quality Universal Switches for Battery-Powered Ignition and Electrical

Accessories. Very durable, tough switches. Either can be used for

ignition, lights,

electric fuel

pump, electric PTO clutch, etc. When used for ignition, use with

push button starter switch (listed below). Terminals or wires on switches

listed below makes contact when in the ON position. Can be used on virtually

anything that have a battery-powered ignition or electrical system, such

as: garden tractors, go-karts, competition pulling tractors, small motorized

vehicles, mini-rods, hot-rods, farm tractors, automobiles, etc. Each can

be mounted in dashboard, instrument panel, engine control panel, etc.

|

|

High

Quality Universal Push Button Switches. Each can be mounted in pedestal,

dashboard, instrument panel, engine control panel, flywheel shroud, etc. High

Quality Universal Push Button Switches. Each can be mounted in pedestal,

dashboard, instrument panel, engine control panel, flywheel shroud, etc.

|

|

High Quality Universal 3-Position OFF-ON-START

MAGNETO Ignition Key Switch. Designed specifically for

Self-Energizing Magneto Ignition, Solid State Ignition, OEM Solid State

Ignition (SSI) for Tecumseh's Cast Iron Block Engines, or with OEM Kohler

Breakerless Ignition. Can be used for various makes and models of riding

mowers, lawn & garden tractors, garden tractors and various small engine

equipment with magneto or solid state ignition. Identification of 5 blade

terminals: B = Battery (+); G = Ground (terminal is grounded

to body of switch); L = Lights (use a separate OFF-ON switch connected

to this terminal to power an electric PTO clutch); M = Magneto (Ignition);

S = Solenoid (small terminal). Key positions: OFF position makes contact

with M+G; IGNITION position makes contact with B+L; START position makes

contact with B+S. Each terminal identified for correct wiring connections.

IMPORTANT: Use with a starter solenoid/relay to crank the engine to prevent

burning out internal contacts in switch. NOTE: If engine is equipped with

an alternator/stator charging system, the center terminal on the voltage

rectifier/regulator connects to the positive (+) battery post. If using an

ammeter/amp gauge, connect the gauge/meter to the positive (+) battery post,

then to the B terminal on the switch. Trace the wires on your tractor/equipment

to see if they match the terminals on this switch. If they don't match, the

plug-in spade connectors/wires can be rearranged in the plastic connector

housing to match the corresponding terminals on the switch. To do this, use

a small flat blade screwdriver to depress the locking tab/tang so the plug-in

connector can be pulled out from the plastic connector housing. Bend the

locking tab/tang up slightly before reinserting it in the plastic connector

so it will be secured in place. Or for a universal application, use #250

slip-on female spade crimp-type wire connectors. Requires 5/8" diameter mounting

hole. High Quality Universal 3-Position OFF-ON-START

MAGNETO Ignition Key Switch. Designed specifically for

Self-Energizing Magneto Ignition, Solid State Ignition, OEM Solid State

Ignition (SSI) for Tecumseh's Cast Iron Block Engines, or with OEM Kohler

Breakerless Ignition. Can be used for various makes and models of riding

mowers, lawn & garden tractors, garden tractors and various small engine

equipment with magneto or solid state ignition. Identification of 5 blade

terminals: B = Battery (+); G = Ground (terminal is grounded

to body of switch); L = Lights (use a separate OFF-ON switch connected

to this terminal to power an electric PTO clutch); M = Magneto (Ignition);

S = Solenoid (small terminal). Key positions: OFF position makes contact

with M+G; IGNITION position makes contact with B+L; START position makes

contact with B+S. Each terminal identified for correct wiring connections.

IMPORTANT: Use with a starter solenoid/relay to crank the engine to prevent

burning out internal contacts in switch. NOTE: If engine is equipped with

an alternator/stator charging system, the center terminal on the voltage

rectifier/regulator connects to the positive (+) battery post. If using an

ammeter/amp gauge, connect the gauge/meter to the positive (+) battery post,

then to the B terminal on the switch. Trace the wires on your tractor/equipment

to see if they match the terminals on this switch. If they don't match, the

plug-in spade connectors/wires can be rearranged in the plastic connector

housing to match the corresponding terminals on the switch. To do this, use

a small flat blade screwdriver to depress the locking tab/tang so the plug-in

connector can be pulled out from the plastic connector housing. Bend the

locking tab/tang up slightly before reinserting it in the plastic connector

so it will be secured in place. Or for a universal application, use #250

slip-on female spade crimp-type wire connectors. Requires 5/8" diameter mounting

hole.

|

|

Universal Wiring Harness with Plastic Connector Housing

and Slide-On Connectors. Replace damaged entire connector, terminals

and wiring, use as new wiring harness on a custom-made project, or use this

part when converting from Breakerless Ignition to battery-powered

points/condenser ignition. Fits universal OFF-ON-START key switches listed

above and other key switches with same terminal configuration. Three terminals

in this part will also fit the OEM Cub Cadet garden tractor OFF-ON-START

key switch listed above. 18" length color-coded wires for easy identification.

$13.00 each, plus shipping & handling. Universal Wiring Harness with Plastic Connector Housing

and Slide-On Connectors. Replace damaged entire connector, terminals

and wiring, use as new wiring harness on a custom-made project, or use this

part when converting from Breakerless Ignition to battery-powered

points/condenser ignition. Fits universal OFF-ON-START key switches listed

above and other key switches with same terminal configuration. Three terminals

in this part will also fit the OEM Cub Cadet garden tractor OFF-ON-START

key switch listed above. 18" length color-coded wires for easy identification.

$13.00 each, plus shipping & handling.

Electrical Plastic Connector Housing Only. Replace damaged connector housing when the brass slide-on spade crimp wire connectors (listed below) are in good condition. Fits universal OFF-ON-START key switches listed above and other key switches with same terminal configuration. Three slots in this part will also fit the OEM Cub Cadet garden tractor OFF-ON-START key switch listed above. Requires 1/4" width slide-on brass spade crimp wire connectors with locking tab/tang below. $8.00 each, plus shipping & handling.

|

|

FYI - Magneto Coils - To test for

continually of an ignition coil (to see if it's in good condition), use a

multimeter set on the ohm ( ) resistance. To test

the secondary winding (this is the one that usually burns out), insert one

of the multimeter's probes into the spark plug terminal of the coil, contacting

the metal inside the terminal. And touch the second probe of the meter to

the ignition coil's negative (–) terminal. (This is the one not connected

to the primary winding and resistor.) Depending on the type of coil (magneto,

compact, standard size or high output/performance), the meter should read

6,000 to 15,000 ohms. If it does not, the secondary winding is faulty and

the coil needs to be replaced. ) resistance. To test

the secondary winding (this is the one that usually burns out), insert one

of the multimeter's probes into the spark plug terminal of the coil, contacting

the metal inside the terminal. And touch the second probe of the meter to

the ignition coil's negative (–) terminal. (This is the one not connected

to the primary winding and resistor.) Depending on the type of coil (magneto,

compact, standard size or high output/performance), the meter should read

6,000 to 15,000 ohms. If it does not, the secondary winding is faulty and

the coil needs to be replaced. |

|

Magneto Armature

Ignition Coil. Fits Kohler engine model K91 with self-energizing magneto

ignition. May not fit model K90 with magneto ignition. Spark plug wire (not

included) inserts into front/outward curvature of coil. Reuse OEM spark plug

wire. 1.0 ohm internal primary resistor. NOTE: This coil should produce

a stronger spark when used with the Universal

Solid State Electronic Ignition Module. Or the engine can be

converted to battery-powered

ignition. Dimensions: 1.700" O.D. x 1.080" length x 1/2" x 1/2" square

hole. How

magneto coils generate a spark. IMPORTANT: Use a new copper

core/non-resistor AC Delco, Autolite or Champion spark plug of the correct

type gapped at .025" for longer coil life. Use of a

resistor type spark plug

will void warranty. New Old Stock. Discontinued OEM Kohler part # 220435-S.

$144.00 each, plus shipping & handling. Magneto Armature

Ignition Coil. Fits Kohler engine model K91 with self-energizing magneto

ignition. May not fit model K90 with magneto ignition. Spark plug wire (not

included) inserts into front/outward curvature of coil. Reuse OEM spark plug

wire. 1.0 ohm internal primary resistor. NOTE: This coil should produce

a stronger spark when used with the Universal

Solid State Electronic Ignition Module. Or the engine can be

converted to battery-powered

ignition. Dimensions: 1.700" O.D. x 1.080" length x 1/2" x 1/2" square

hole. How

magneto coils generate a spark. IMPORTANT: Use a new copper

core/non-resistor AC Delco, Autolite or Champion spark plug of the correct

type gapped at .025" for longer coil life. Use of a

resistor type spark plug

will void warranty. New Old Stock. Discontinued OEM Kohler part # 220435-S.

$144.00 each, plus shipping & handling. |

|

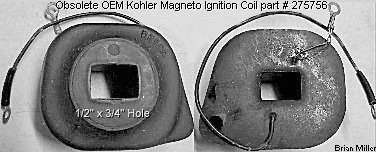

Magneto Armature

Ignition Coils. Fits various Kohler K-series engine models

KV161,

L160/L161, L181,

K181, K241, K301, K321, K330/K331 and K341 with points, condenser/capacitor

and coil under flywheel. Common with Kohler engines mounted to a generator

or welder. Also fits most small- and medium-frame aluminum block Tecumseh

engines with points, condenser and coil under flywheel. NOTES: These coils

should produce a stronger spark when used with the

Universal Solid State Electronic Ignition

Module. Also, each coil listed below can be substituted for the obsolete

OEM Kohler part # 275756 coil by grinding down the laminations on the armature

to .405" x .405" square. Do not grind out inside of coil! To secure coil

on the armature, bend one lamination over end of coil. Or engine could be

converted to the more reliable

battery-powered ignition system. 1.0 ohm internal primary resistor.

Dimensions of each coil: 1.700" O.D. x 1.080" length x .405" square hole.

How

magneto coils generate a spark. IMPORTANT: Use a new copper

core/non-resistor AC Delco, Autolite or Champion spark plug of the correct

type gapped at .025" for longer coil life. Use of a

resistor type spark plug

will void warranty. And being all older magneto coil spark plug wires

have a metal core, save it off your old coil. With a 12 volt battery coil

tower terminal and boot installed, it can be used for battery ignition. Magneto Armature

Ignition Coils. Fits various Kohler K-series engine models

KV161,

L160/L161, L181,

K181, K241, K301, K321, K330/K331 and K341 with points, condenser/capacitor

and coil under flywheel. Common with Kohler engines mounted to a generator

or welder. Also fits most small- and medium-frame aluminum block Tecumseh

engines with points, condenser and coil under flywheel. NOTES: These coils

should produce a stronger spark when used with the

Universal Solid State Electronic Ignition

Module. Also, each coil listed below can be substituted for the obsolete

OEM Kohler part # 275756 coil by grinding down the laminations on the armature

to .405" x .405" square. Do not grind out inside of coil! To secure coil

on the armature, bend one lamination over end of coil. Or engine could be

converted to the more reliable

battery-powered ignition system. 1.0 ohm internal primary resistor.

Dimensions of each coil: 1.700" O.D. x 1.080" length x .405" square hole.

How

magneto coils generate a spark. IMPORTANT: Use a new copper

core/non-resistor AC Delco, Autolite or Champion spark plug of the correct

type gapped at .025" for longer coil life. Use of a

resistor type spark plug

will void warranty. And being all older magneto coil spark plug wires

have a metal core, save it off your old coil. With a 12 volt battery coil

tower terminal and boot installed, it can be used for battery ignition.

|

|

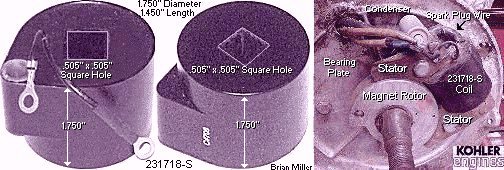

Magneto Armature

Ignition Stator/Coil with Small Charging Coil. Fits various Kohler engines

with stator/coil mounted on bearing plate underneath flywheel with two magnets

inside flywheel. Common with various generator engines. Coil has 1.0 ohm

internal primary resistor. NOTE: This coil should produce a stronger spark

when used with the Universal Solid State Electronic

Ignition Module. Or the engine could be

converted to battery-powered

ignition.

How

magneto coils generate a spark. IMPORTANT: Use a new copper

core/non-resistor AC Delco, Autolite or Champion spark plug of the correct

type gapped at .025" for longer coil life. Use of a

resistor type spark plug

will void warranty. Magneto Armature

Ignition Stator/Coil with Small Charging Coil. Fits various Kohler engines

with stator/coil mounted on bearing plate underneath flywheel with two magnets

inside flywheel. Common with various generator engines. Coil has 1.0 ohm

internal primary resistor. NOTE: This coil should produce a stronger spark

when used with the Universal Solid State Electronic

Ignition Module. Or the engine could be

converted to battery-powered

ignition.

How

magneto coils generate a spark. IMPORTANT: Use a new copper

core/non-resistor AC Delco, Autolite or Champion spark plug of the correct

type gapped at .025" for longer coil life. Use of a

resistor type spark plug

will void warranty.

|

|

Magneto Armature

Ignition Coil. Fits various Kohler engine models K90, K141, K161,

KV161,

L160/L161, L181

and K181 with coil mounted on U-shaped armature on bearing plate underneath

flywheel with magnet rotor on crankshaft. Also fits various larger cast iron

block Clinton engines with coil/armature mounted on cylinder, above flywheel.

Common with various generator engines. Spark plug wire not included. 1.0

ohm internal primary resistor. NOTE: This coil should produce a stronger

spark when used with the Universal Solid State

Electronic Ignition Module. Or the engine could be

converted to battery-powered

ignition. Dimensions: 1.750" diameter x 1.450" length x .505" square

hole. How

magneto coils generate a spark. IMPORTANT: Use a new copper

core/non-resistor AC Delco, Autolite or Champion spark plug of the correct

type gapped at .025" for longer coil life. Use of a

resistor type spark plug

will void warranty. Magneto Armature

Ignition Coil. Fits various Kohler engine models K90, K141, K161,

KV161,

L160/L161, L181

and K181 with coil mounted on U-shaped armature on bearing plate underneath

flywheel with magnet rotor on crankshaft. Also fits various larger cast iron

block Clinton engines with coil/armature mounted on cylinder, above flywheel.

Common with various generator engines. Spark plug wire not included. 1.0

ohm internal primary resistor. NOTE: This coil should produce a stronger

spark when used with the Universal Solid State

Electronic Ignition Module. Or the engine could be

converted to battery-powered

ignition. Dimensions: 1.750" diameter x 1.450" length x .505" square

hole. How

magneto coils generate a spark. IMPORTANT: Use a new copper

core/non-resistor AC Delco, Autolite or Champion spark plug of the correct

type gapped at .025" for longer coil life. Use of a

resistor type spark plug

will void warranty.

|

|

Armature Ignition

Coil with Molded-In Solid State Electronic Module. Fits Kohler Magnum

engine model M8. NOTE: Install this coil with spark plug wire facing engine

block as shown in photo to the right ->. Set the air gap/clearance between

the magnet in the flywheel and armature laminations with a business card

or a .010" or .25mm brass

feeler gauge. The .010" or .25mm gap produces a stronger

magnetic field through the coil to generate more electricity for a stronger

spark, and so the engine won't misfire. IMPORTANT: Use a new copper

core/non-resistor AC Delco, Autolite or Champion spark plug of the correct

type gapped at .025" for longer coil life. Use of a

resistor type spark plug

will void warranty. And being all older magneto coil spark plug wires have

a metal core, save it off your old coil. With a 12 volt battery coil tower

terminal and boot installed, it can be used for battery ignition. Armature Ignition

Coil with Molded-In Solid State Electronic Module. Fits Kohler Magnum

engine model M8. NOTE: Install this coil with spark plug wire facing engine

block as shown in photo to the right ->. Set the air gap/clearance between

the magnet in the flywheel and armature laminations with a business card

or a .010" or .25mm brass

feeler gauge. The .010" or .25mm gap produces a stronger

magnetic field through the coil to generate more electricity for a stronger

spark, and so the engine won't misfire. IMPORTANT: Use a new copper

core/non-resistor AC Delco, Autolite or Champion spark plug of the correct

type gapped at .025" for longer coil life. Use of a

resistor type spark plug

will void warranty. And being all older magneto coil spark plug wires have

a metal core, save it off your old coil. With a 12 volt battery coil tower

terminal and boot installed, it can be used for battery ignition.

|

|

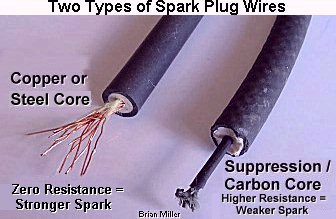

| IMPORTANT:

Most failures of a battery-powered ignition coils and/or electronic ignition

control modules are caused by either the use of suppression/carbon-core spark

plug wire(s), resistor-type spark plug(s) [NGK spark plugs], or overcharging

of the electrical system due to a defective voltage rectifier/regulator or

defective [automotive] battery. Therefore, if it's not already equipped,

it's best to install an ammeter/amp gauge to monitor the charging system.

Also, any coil will burn up if the ignition switch is left on with the points

closed for more than a few minutes with the engine not running. To prevent

this from possibly happening and/or for security reasons, use an OFF-ON key

switch and/or a master disconnect switch with a removable key instead of

just a toggle switch to power the ignition system. Also, the coil could burn

up if the charging system continually overcharge due to a defective voltage

rectifier/regulator or a defective [automotive] battery.

|

|

High Quality,

High-Performance Copper or Metal Core 7mm Spark Plug Wire Assemblies Listed

Below. Universal design for many applications. Along with a copper core

spark plug, metal core spark wires provide a stronger spark that allow the

ignition coil to operate cooler, last longer and provide the highest possible

energy to ensure maximum ignition potential. Replace defective coil-to-spark

plug wire or use either of the parts listed below when converting from

Breakerless Ignition or magneto ignition to battery-powered points/condenser

ignition. Suitable for general lawn & garden equipment, small motorized

vehicles or competition garden pulling tractor engines. Fits Kohler engine

models K141, K160/K161,

KV161,

L160/L161, L181, K181,

K241, K301, K321, K330/K331, K341, K361, KT17 (first design), KT17 Series

II, KT19 (first design) KT19 Series II, KT21, K482, K532, K582 and K660/K662

(with wires cut to desired length) and other makes and models of small engines

with a battery-powered ignition system. Don't be fooled by the dark color,

these wires have a metal core that provide 100% voltage to the spark plug

for a strong spark to extend the life of the coil. Copper or metal wire delivers

maximum energy with zero ohm resistance to the spark plug. (FYI - Most OEM

automotive or brightly-colored coil-to-spark plug wires have a suppression/carbon

core that deliver about 40%-50% voltage to the spark plug at peak demand,

which is at open RPM, they've been known to burn up a good coil.) Solid metal

terminals for maximum conductivity and corrosion resistance. Snug-fitting

quality rubber boots keep out dirt and moisture for reliable engine start

up. Engineered for reliability and long life. Spring-lock terminals insure

positive and secure connection through the toughest conditions and multiple

spark plug changes. High Quality,

High-Performance Copper or Metal Core 7mm Spark Plug Wire Assemblies Listed

Below. Universal design for many applications. Along with a copper core

spark plug, metal core spark wires provide a stronger spark that allow the

ignition coil to operate cooler, last longer and provide the highest possible

energy to ensure maximum ignition potential. Replace defective coil-to-spark

plug wire or use either of the parts listed below when converting from

Breakerless Ignition or magneto ignition to battery-powered points/condenser

ignition. Suitable for general lawn & garden equipment, small motorized

vehicles or competition garden pulling tractor engines. Fits Kohler engine

models K141, K160/K161,

KV161,

L160/L161, L181, K181,

K241, K301, K321, K330/K331, K341, K361, KT17 (first design), KT17 Series

II, KT19 (first design) KT19 Series II, KT21, K482, K532, K582 and K660/K662

(with wires cut to desired length) and other makes and models of small engines

with a battery-powered ignition system. Don't be fooled by the dark color,

these wires have a metal core that provide 100% voltage to the spark plug

for a strong spark to extend the life of the coil. Copper or metal wire delivers

maximum energy with zero ohm resistance to the spark plug. (FYI - Most OEM

automotive or brightly-colored coil-to-spark plug wires have a suppression/carbon

core that deliver about 40%-50% voltage to the spark plug at peak demand,

which is at open RPM, they've been known to burn up a good coil.) Solid metal

terminals for maximum conductivity and corrosion resistance. Snug-fitting

quality rubber boots keep out dirt and moisture for reliable engine start

up. Engineered for reliability and long life. Spring-lock terminals insure

positive and secure connection through the toughest conditions and multiple

spark plug changes.

Please specify if you need the rubber neoprene

boot for a 3/4" coil tower (fits most standard-output coils), or 5/8" coil

tower (fits most twin cylinder dual-wire coils and high-output/performance

or OEM automotive electronic ignition coils). Please specify if you need the rubber neoprene

boot for a 3/4" coil tower (fits most standard-output coils), or 5/8" coil

tower (fits most twin cylinder dual-wire coils and high-output/performance

or OEM automotive electronic ignition coils).

|

|

Complete

Battery-Powered Ignition Conversion Kits Listed Below - When

Kohler's OEM magneto or Breakerless Ignition fails, the engine can be converted

to a battery-powered ignition system. battery-powered ignition systems last

longer, produce a stronger spark, and when a part goes bad, it doesn't cost

much to replace. It's a reliable, simple design and there's no guesswork

about it. FYI: battery-powered ignition conversion kits are intended mainly

for various older engines when the OEM magneto or Breakerless Ignition no

longer produce a spark, replacement parts are not available, are very expensive

or cost prohibitive. (Sometimes one must improvise when certain parts are

obsolete.) Also, the most hassle when using battery-powered ignition without

an integrated charging system with the engine to recharge the battery is

the use of a  battery charger. For a battery to power the ignition, a

small, lightweight and rechargeable

12 volt sealed lead acid (SLA) battery with a minimum 4Ah

(Amp Hour) rating or a small

motorcycle battery can be used.

battery charger. For a battery to power the ignition, a

small, lightweight and rechargeable

12 volt sealed lead acid (SLA) battery with a minimum 4Ah

(Amp Hour) rating or a small

motorcycle battery can be used.

FYI - Kohler's Breakerless Ignition and Tecumseh's Solid State Ignition (SSI) systems use a key switch that's also made for a self-energizing magneto or magneto-type solid state ignition system. Unlike the OFF-ON-START key switch for a battery-powered ignition system, just like the magneto or solid state ignition systems, with the Breakerless Ignition is self-energizing, and to kill the engine, the key switch grounds out or shorts the [low voltage] circuit between the energizing coil and ignition module. But the battery type OFF-ON-START key switch opens the circuit to kill the engine. So with the battery-powered points and condenser ignition system (along with a 12 volt coil), you will need to use a battery type OFF-ON-START key switch, or an OFF-ON toggle switch or an OFF-ON (security) key switch to power the ignition with a momentary push button starter switch to crank the engine. If swapping out the OEM Breakerless Ignition, magneto or solid state (grounding type) OFF-ON-START ignition key switch for a battery type OFF-ON-START key switch, the wire connectors in the wiring connector will need to be rearranged to match the terminals on the battery type key switch to crank the engine, power the ignition and electrical accessories, and recharge the battery. I've performed this before on some of my customer's ordinary garden tractors and garden pulling tractors, and it works great. Click/tap here for battery-powered ignition wiring diagrams. |

|

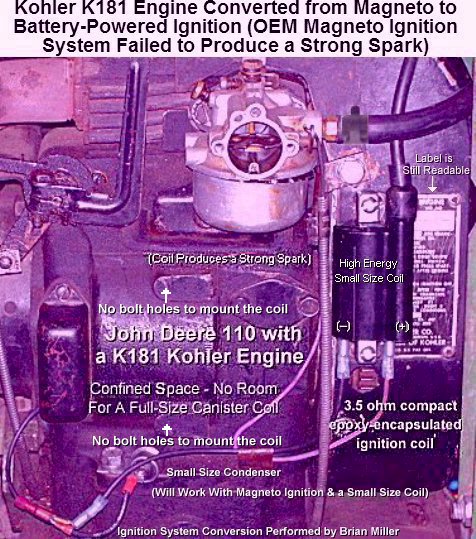

Several years

ago, an out of town customer brought his John Deere model 110 to our shop

for repairs. This tractor has a Kohler engine model K181 with self-energizing

magneto ignition and a 10 amp alternator charging system. (The ignition coil

and charging coils are mounted on the same armature/stator frame under the

flywheel.) My customer told me that he had another reputable small engine

repair shop in his hometown install a new spark plug, points, condenser and

an entirely new armature/stator assembly, but they could not get the engine

to rev up. Several years

ago, an out of town customer brought his John Deere model 110 to our shop

for repairs. This tractor has a Kohler engine model K181 with self-energizing

magneto ignition and a 10 amp alternator charging system. (The ignition coil

and charging coils are mounted on the same armature/stator frame under the

flywheel.) My customer told me that he had another reputable small engine

repair shop in his hometown install a new spark plug, points, condenser and

an entirely new armature/stator assembly, but they could not get the engine

to rev up.

Anyway, I put the tractor on the sturdy

platform table that I

built to make it easier to work on. The engine would start right up and idle

well, but failed to rev up. It would just die out when throttled up. So I

cleaned and inspected the entire carburetor, including clearing out anything

that may have been lodged in the main jet; tried a new Autolite 295 copper

core spark plug gapped at .030"; cleaned and reset the points gap; tried

another new condenser; So after some thoughtful consideration, I came to the conclusion that the OEM Kohler part # 237876 self-energizing magneto ignition/charging system armature/stator assembly is obviously a notorious, bad design. Although this system is still available new from Kohler, Kohler discontinued installing this on certain engines only after a short time. (Apparently, for an obvious reason.)

If you have a similar ignition problem like this and if you're interested, I offer all the parts, including a new compact epoxy-encapsulated 12 volt armature ignition coil kit, that can be used to convert the self-energizing magneto ignition to battery-powered ignition for your tractor. See the complete ignition conversion kit(s) below. I can also convert your tractor from a faulty magneto ignition to the more reliable battery-powered ignition if you don't mind bringing your tractor to my shop. Click here to contact A-1 Miller's for FREE honest and accurate technical support and/or for ordering information and payment options. Please contact A-1 Miller's if you need part(s) and/or service(s) performed that's not listed or mentioned in this website. [Top of Page]

Convert virtually any single cylinder, air-cooled cast iron or various aluminum block small gas engine, such as Kohler, Tecumseh, Briggs & Stratton, Clinton, etc., with a failed self-energizing magneto ignition system to the battery-powered ignition system. NOTE: Must use a universal automotive off/ignition/start key switch, or an OFF-ON toggle ignition switch or a [security] ignition key switch with a push button starter switch. Reuse same type of spark plug and existing ignition points (if in good condition), but set the point gap at .020" or set ignition timing at 20º BTDC. See ignition kits and wiring diagram below Ê.

NOTE: A small, fully charged 12 volt battery is required for this ignition

system. A

High Quality Ignition Kit to Convert from Kohler Magneto Ignition to the More Reliable Battery-Powered Ignition System for an Unconfined Engine Compartment with Unlimited Space to mount a full size canister coil. Designed for Kohler engine models K90/K91, K141, K161/K160, KV161, L160/L161, L181, K181, K241, K301, K321, K330/K331 and K341.

When ordering, please indicate make and model of engine. Ignition parts kit include:

NOTE: A small, fully charged 12 volt battery is required for this ignition

system. A

|

|

| New points, condensers/capacitors, coils and spark plugs for other makes and models of engines are also available. Please call or email A-1 Miller's for your needs. Click here to contact A-1 Miller's for FREE honest and accurate technical support and/or for ordering information and payment options. Please contact A-1 Miller's if you need part(s) and/or service(s) performed that's not listed or mentioned in this website. [Top of Page] | |

Get that

old, antique small gas engine for general lawn & garden equipment, go-karts,

King Midget micro car, all terrain vehicles, snowmobiles,

industrial/commercial, etc., running again with 21st century technology using

100% reliable digital electronic ignition, even when new replacement parts

are cost-prohibited or obsolete. Electronic ignition can be installed on

virtually any small gas engine, regardless of the make and model. Where there's

a will, there's a way. It's mind over matter.

Click here

to contact A-1 Miller's for FREE honest and accurate technical support and/or

for ordering information and payment options. Please contact A-1

Miller's

if you need part(s) and/or

service(s) performed that's not listed or mentioned in this

website. [Top of Page]

[Return to previous paragraph, section

or website]

Get that

old, antique small gas engine for general lawn & garden equipment, go-karts,

King Midget micro car, all terrain vehicles, snowmobiles,

industrial/commercial, etc., running again with 21st century technology using

100% reliable digital electronic ignition, even when new replacement parts

are cost-prohibited or obsolete. Electronic ignition can be installed on

virtually any small gas engine, regardless of the make and model. Where there's

a will, there's a way. It's mind over matter.

Click here

to contact A-1 Miller's for FREE honest and accurate technical support and/or

for ordering information and payment options. Please contact A-1

Miller's

if you need part(s) and/or

service(s) performed that's not listed or mentioned in this

website. [Top of Page]

[Return to previous paragraph, section

or website]

This is the era of modern wonders, where everything is electronic, transistorized, digitized and miniaturized. Yet even today, many competition garden pulling tractors with an older engine still use the old-fashioned breaker point ignition systems. For other people, the frustration of attempting to keep a breaker point-fired tractor in peak running condition has been enough of a reason to join the electronic/solid state electronic ignition era. Breaker point systems do have some positives, though. ignition points are cheap and somewhat easy to install. And many people are comfortable with installing their own ignition points. The bad side of using ignition points is, besides the ignition points contacts burning, pitting and wearing out, if or when the ignition points lobe on the (Kohler) camshaft and/or the ignition points pushrod become worn, this will narrow the gap on the ignition points, and retard the ignition timing. The ignition points lobe can wear so much that resetting the ignition points at the factory setting of .020" or setting the ignition timing at 20º BTDC becomes impossible. As the point gap gets too narrow, the ignition timing will become retarded (less than the factory setting of 20º BTDC), which will cause the engine to run sluggish and lose power, and when it gets too wide, the timing will become too advanced (more than the factory setting of 20º BTDC), which will cause the engine to run hotter than normal, which could cause premature engine wear and oil burning, eventually resulting in an engine rebuild. There's also less chance of a dangerous fire due to non-existence of ignition points.

Self-energizing small engine magneto armature

ignition coils and battery-powered coils with either points and condenser

or electronic ignition must be used with a metal core spark plug wire and

a copper core/non-resistor spark plug. Most automobiles with electronic ignition

have

suppression/carbon core spark plug wires only to prevent

interference of sensitive electronic components and [AM/FM] radio static.

However, if a suppression/carbon core spark plug wire and/or a

resistor type spark plug

is used with a magneto or battery-powered ignition coil, the coil may operate

at a much higher than normal temperature (too hot to the touch), and either

the coil will fail or the engine will idle well, but hesitate to rev up at

high RPM due to the high resistance in the suppression/carbon core spark

plug wire and/or a resistor

type spark plug. And avoid using a

suppression/carbon core spark plug wire with an electronic

ignition system on a small engine! The reason being is if the suppression/carbon

core spark plug wire becomes extremely weak and deteriorated with very high

resistance, this can cause the ignition coil and possibly the electronic

ignition control module to burn up.

Self-energizing small engine magneto armature

ignition coils and battery-powered coils with either points and condenser

or electronic ignition must be used with a metal core spark plug wire and

a copper core/non-resistor spark plug. Most automobiles with electronic ignition

have

suppression/carbon core spark plug wires only to prevent

interference of sensitive electronic components and [AM/FM] radio static.

However, if a suppression/carbon core spark plug wire and/or a

resistor type spark plug

is used with a magneto or battery-powered ignition coil, the coil may operate

at a much higher than normal temperature (too hot to the touch), and either

the coil will fail or the engine will idle well, but hesitate to rev up at

high RPM due to the high resistance in the suppression/carbon core spark

plug wire and/or a resistor

type spark plug. And avoid using a

suppression/carbon core spark plug wire with an electronic

ignition system on a small engine! The reason being is if the suppression/carbon

core spark plug wire becomes extremely weak and deteriorated with very high

resistance, this can cause the ignition coil and possibly the electronic

ignition control module to burn up.

NOTE: With my Universal Solid State Electronic Ignition Module and crank-trigger/flywheel-triggered ignition systems (all listed below), when installed accordingly, the ignition timing is ALWAYS advanced. If it's set or installed retarded, it will NOT automatically advance as soon as the engine starts. If the timing is set retarded, the only way to advance it is by rotating an ignition plate or ignition distributor manually by hand, or automatically by a vacuum canister with intake manifold, or by centrifugal force with flyweights.

When the timing is retarded, the engine may start with no problems, but not idle or rev up too well, and it'll lack sufficient horsepower. Also, with retarded timing, all of the fuel in the combustion chamber will not be burned. Part of the raw fuel will exit out of the exhaust, while the rest will remain in the chamber combustion and cling to the cylinder wall, causing the crankcase lubricating oil to become diluted or thin-out. When this happens, "cylinder wash down" will result. Cylinder wash down is when the gas (or diesel fuel) dilutes the light coating of oil on the cylinder wall, and the piston rings will no longer be adequately lubricated, causing direct metal to metal contact, which will cause them to wear excessively, and cause the cylinder wall have a protruding ridge towards the top, resulting in a smoky, oil burning engine overtime. Cylinder wash down can also happen to a diesel engine when the fuel injectors are purposely "turned up" to increase the fuel delivery so the engine will produce more horsepower. This will cause a lot of black smoke be blown out the exhaust all the time (at idle and especially upon acceleration), which will result in shorter engine life, and eventually, gray exhaust smoke (crankcase oil ash) will be mixed with the black exhaust smoke (resembles partially burnt diesel fuel ash exhaust). It'll run good for a while!

But when the ignition timing is too advanced, this will cause the engine to run too hot, which will likely cause the piston(s) to swell larger than normal, allowing it/them to make metal to metal contact against the cylinder wall, resulting in excessive wear. When the piston wears, it will be too loose in the cylinder, causing a rattling sound. Plus, due to the worn piston, the rings will loose their square edge against the cylinder wall, and become rounded, which will allow oil to be moved to the top of the piston instead of being scraped back into the crankcase. (This is the how the 2nd or middle ring works.) Plus, the rings will lose their expansion against the cylinder wall as well. Eventually, the engine will blow blue or gray smoke out the exhaust, and it will ultimately need to be rebuilt.

If electronic ignition is installed correctly, when the ignition is triggered by the flywheel, this stabilizes the timing, so you won't ever have to worry about it changing. The engine will produce more horsepower and you will have more confidence that the engine will last longer. (As long as an air filter is used, the carburetor is adjusted correctly and the crankcase oil is changed regularly.) So for the utmost precision ignition timing and maintenance-free convenience, flywheel-triggered electronic ignition is the way to go! The high-performance electronic ignition systems offered in this website produce a stable and a very strong spark with the use of microelectronics. They will help the engine to start quicker, idle smoothly and rev up to full RPM with no hesitation whatsoever. Allows a stock coil to perform like a high-performance coil without shortening the life of the coil.

As a matter of fact, electronic ignition works so well, this is why most small engine manufacturers dropped their points and condenser ignition and went to the more dependable and reliable electronic ignition in 1982. And most automotive manufacturers started installing the more dependable and reliable electronic ignition in their vehicles since 1972 (Chrysler products) and 1974 (GM and Ford products).

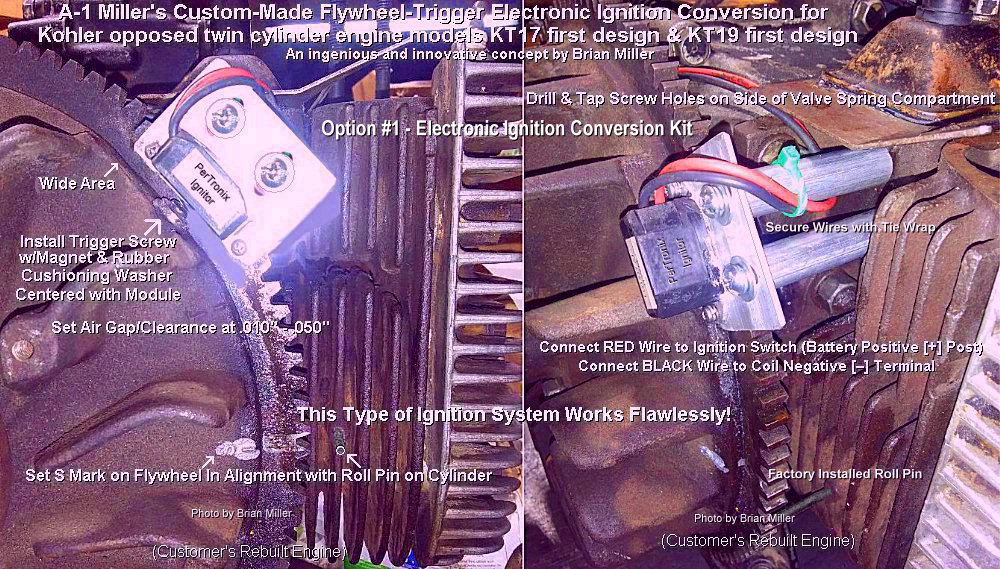

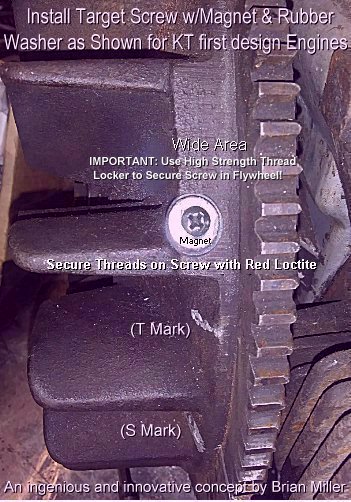

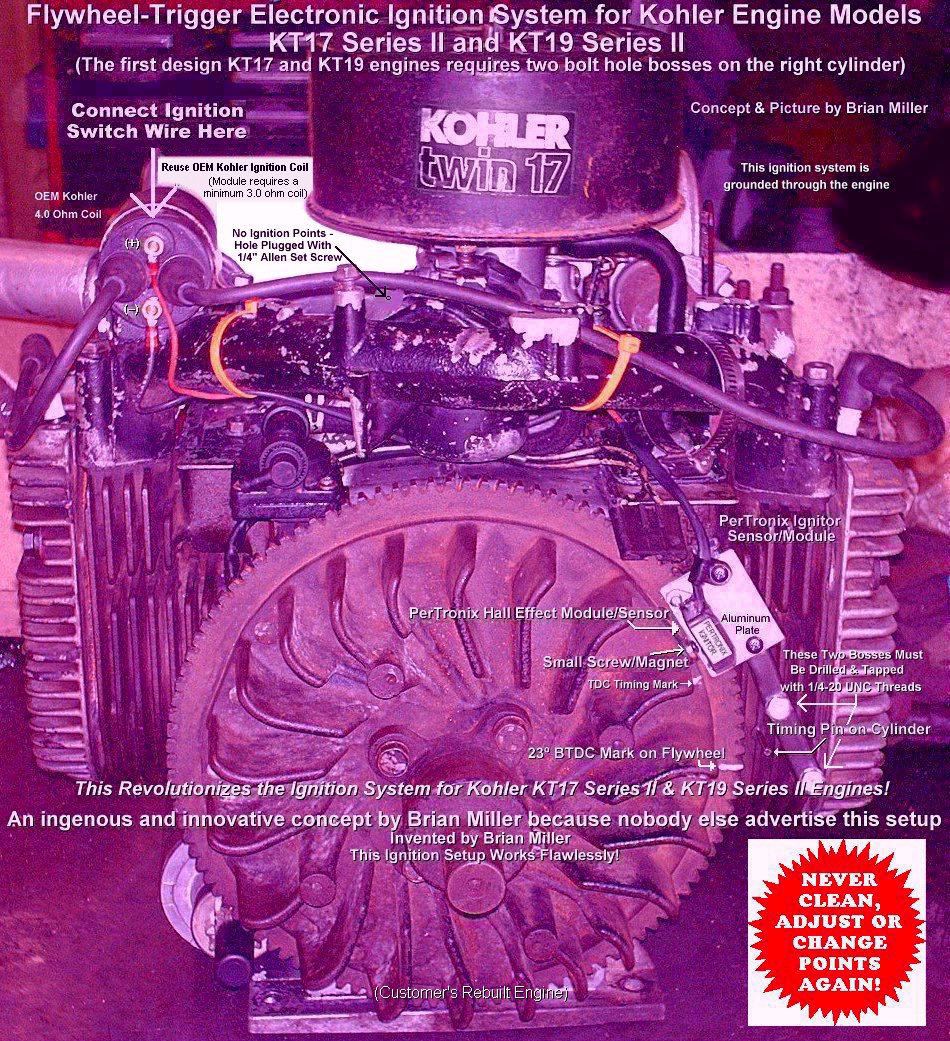

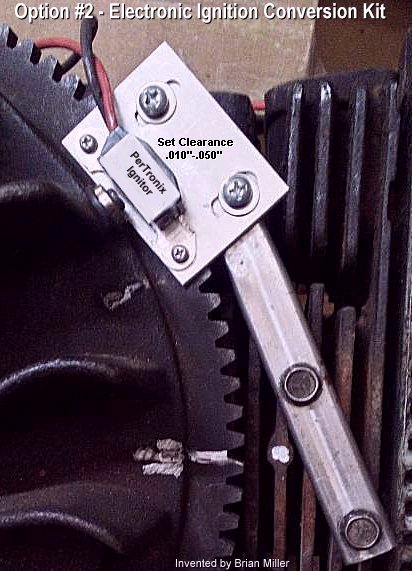

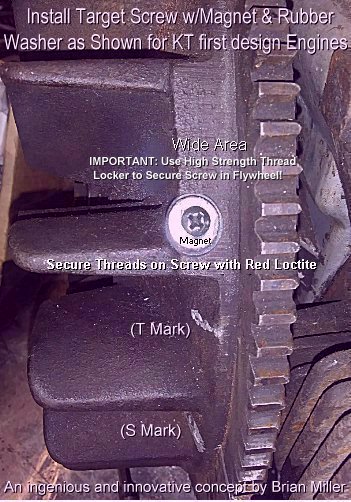

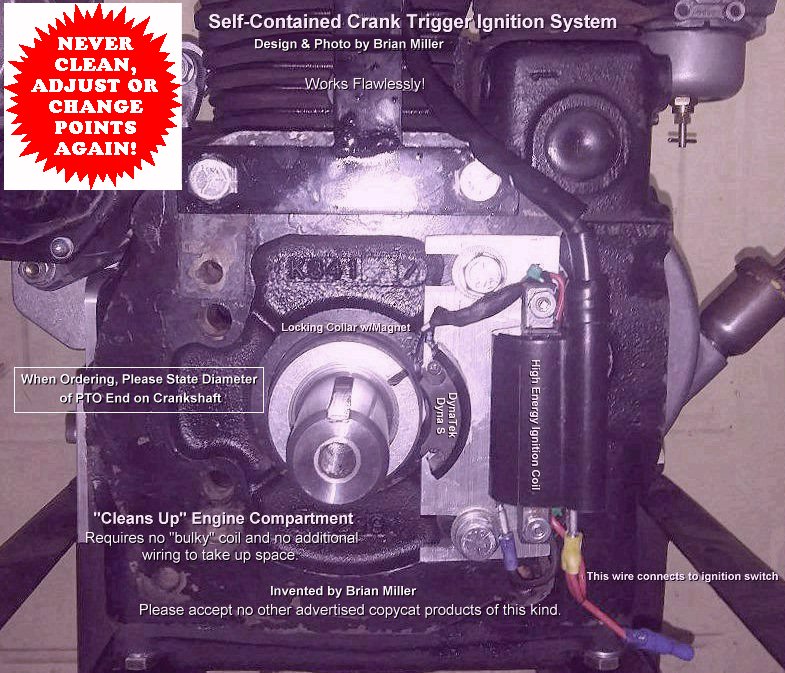

Tired of cleaning, changing or constantly readjusting the ignition points, and replacing the condenser? Well, upgrade/convert the engine with an A-1 Miller's custom-made, maintenance-free and weather-proof 100% digitized flywheel-triggered electronic ignition system! Shock and moisture resistant, and all it takes is a few simple hand tools to install. In my opinion, getting rid of the points and condenser/capacitor have been the best advance ever in engine technology. FYI - I've designed and sold many various custom-made electronic ignition systems to customers for the past several years and haven't received one complaint about the performance of their engine. Because I use technology that I learned from experiences with my competitive competition pulling tractors (engines) to help factory stock lawn & garden engines perform better. And as a matter of fact, other people have emailed or called me to complain to me about my competitor's replacement electronic ignition systems for Tecumseh engines. They said their technical customer service assistance to resolve the problem was of no help. No joke. Apparently, my competitors haven't quite figured it out yet.