Electrical Solutions for Various

Older Small Engines and Competition Garden Pulling Tractors

Electrical Solutions for Various

Older Small Engines and Competition Garden Pulling Tractors

Electrical Solutions for Various

Older Small Engines and Competition Garden Pulling Tractors

Electrical Solutions for Various

Older Small Engines and Competition Garden Pulling Tractors

Educating and Inspiring Small Engine, Lawn & Garden, and Garden

Pulling Tractor Enthusiasts Since 1996. Where Science and Common Sense Come

Together for Safety and Improved Engine/Tractor Performance |

A-1

Miller's Performance Enterprises - Parts & Services

Webstore |  Available Soon - Detailed Illustrated Plans

on How to Construct a Professional Pull-Back and Self-Propelled Garden

Tractor/Small Wheel Mini Rod Pulling Sleds

Available Soon - Detailed Illustrated Plans

on How to Construct a Professional Pull-Back and Self-Propelled Garden

Tractor/Small Wheel Mini Rod Pulling Sleds

Nowadays, prices are subject to change without notice. Click

Refresh to see any

changes or updates. Optimized for 1152 x 864 computer screen resolution.

To search for a word or phrase in any of my websites, press the CTRL

and F

and F  keys on

your keyboard simultaneously to open the Find or Search dialog box in your

web browser. And being I have no

apprentice to update and pay for my websites so they'll

continue to be on the Internet, they will be removed forever when I'm no

longer around. Scroll down this website or click/tap the links below to

jump down to...

keys on

your keyboard simultaneously to open the Find or Search dialog box in your

web browser. And being I have no

apprentice to update and pay for my websites so they'll

continue to be on the Internet, they will be removed forever when I'm no

longer around. Scroll down this website or click/tap the links below to

jump down to...

Be Professional With Your Tractor's or Equipment's Wiring!

First of all, an engine's ignition system is completely separate from its electrical charging system. One has absolutely nothing to do with the other. The power for a battery-powered ignition system comes from the battery while cranking the engine to start it. Once it starts, the charging system takes over, and while the engine is running at full governed speed, the charging system recharges the battery, powers all electrical accessories, and powers the battery-powered ignition system. A self-energizing magneto or electronic/solid state ignition system do not depend on power from the battery or charging system whatsoever.

When connecting the wires for an electrical system, don't just

make a connection by twisting bare wires together by hand and taping them

up. All this does is allow moisture between the wires and in time, lets corrosion

set in, causing a faulty connection. An older, experienced electrical engineer

once said: "Sometimes electrical problems are mechanical." Meaning a loose

or poor connection, or a faulty switch. Therefore, it's better to solder

the wires together, then tape them up with electrical tape or use appropriate

size

heat shrinkable tubing. Or for a "clean" and professional

look, use "crimp" style wire connectors to connect two wires together, or

connect a wire to a coil stud terminal or switch terminal. Use a

wire stripper / crimp connector tool to secure the crimp

connectors to the wire. Use a bench vise to crimp heavy connectors to battery

cables. Route the wiring along the inside of the frame in a safe and secure

manner, away from the spinning flywheel and clutch/driveshaft, moving levers,

and hot exhaust areas.

When connecting the wires for an electrical system, don't just

make a connection by twisting bare wires together by hand and taping them

up. All this does is allow moisture between the wires and in time, lets corrosion

set in, causing a faulty connection. An older, experienced electrical engineer

once said: "Sometimes electrical problems are mechanical." Meaning a loose

or poor connection, or a faulty switch. Therefore, it's better to solder

the wires together, then tape them up with electrical tape or use appropriate

size

heat shrinkable tubing. Or for a "clean" and professional

look, use "crimp" style wire connectors to connect two wires together, or

connect a wire to a coil stud terminal or switch terminal. Use a

wire stripper / crimp connector tool to secure the crimp

connectors to the wire. Use a bench vise to crimp heavy connectors to battery

cables. Route the wiring along the inside of the frame in a safe and secure

manner, away from the spinning flywheel and clutch/driveshaft, moving levers,

and hot exhaust areas.

When removing and installing the engine in and out of a competition garden pulling tractor (or any vehicle as far as this subject is concerned), for whatever reason, install male and female bullet or spade quick disconnect electrical connectors (or any type of quick disconnect electrical connectors as long as they're insulated from the engine and tractor/vehicle frame) in the wiring circuit that's connected to the points, ignition module, coil, charging system, or anything else that's wired to the engine, except for the heavy battery cable that connects to the starter motor. The use of quick disconnect electrical connectors allows for much easier and quicker disconnection of the wires. Example: Before removing engine, the points cover will need to be removed, then the wire needs to be disconnected from the points terminal screw; and then remove the nuts from the ignition coil and then take a chance on losing one of the small nuts. No tools are required for use with quick disconnect electrical connectors either. No need to unscrew this, unbolt that, just unplug the connectors by hand to remove the engine, and plug them back together after reinstalling the engine. It's that simple. Many professional race cars, funny cars, dragsters and NASCAR use this method to speed up the quick engine rebuild or swap process in the pit area at the track on race day. And most electronic appliances, such as computers, TVs, etc., used this method for many years to simplify removing and installing circuit boards and various components. Makes life a lot easier.

Always install either an in-line round- or blade-type fuse holder, panel-mount fuse holder, blade-type automatic reset circuit breaker, or a stud-type automatic reset circuit breaker in the primary wire that's connected directly to the battery positive (+) post. (The small wire that provides power to all electrical components.) An important thing to remember is if using a universal automatic reset circuit breaker in a competition garden pulling tractor, don't fasten it to any part of the tractor! Instead, allow it to dangle free by the wires (hide it inside the steering pedestal assembly), and wrap electrical tape around it so the terminals won't short out against any bare metal part of the tractor. The reason the circuit breaker shouldn't be mounted solid to any part of the tractor is because at high RPM or wide open throttle, normal engine vibration, that's transferred throughout the entire tractor, will cause the bimetallic strip (contact spring or "flapper") inside the circuit breaker to vibrate (a lot) and become momentarily and erratically disconnected, causing the engine to misfire badly and misfire or "cut out" while going down the track. Having a fuse or circuit breaker installed (and amp gauge or volt meter; if the engine has a charging system) is very important to prevent failure of electrical components. Because by the time you smell something burning or see smoke, it may be too late.

Install an

amp gauge or

volt meter to monitor exactly what the charging system

on your engine is doing. Having an amp gauge or volt meter installed is very

important in monitoring the charging system to prevent premature failure

of electrical components. As battery becomes fully charged, needle slowly

moves from positive side (+) to zero (0). Needle will stay on negative side

(–) if no charge goes to the battery. Or gauge will not show any charge

at all if charging system is not working. With a working amp gauge or volt

meter, if the charging system continues to charge on the plus (+) side with

no gradual moving back of the needle to zero while the engine is running

at full governed speed, due to a faulty voltage rectifier/regulator, this

will send too much voltage to or overcharge the battery, which could eventually

burn up the cells in the battery, or burn up the primary windings in a [battery]

ignition coil, burn up an electric PTO clutch, burn out light bulbs, the

[battery powered] electronic ignition control module

(crank-trigger and flywheel-trigger), and

other electrical accessories.

Install an

amp gauge or

volt meter to monitor exactly what the charging system

on your engine is doing. Having an amp gauge or volt meter installed is very

important in monitoring the charging system to prevent premature failure

of electrical components. As battery becomes fully charged, needle slowly

moves from positive side (+) to zero (0). Needle will stay on negative side

(–) if no charge goes to the battery. Or gauge will not show any charge

at all if charging system is not working. With a working amp gauge or volt

meter, if the charging system continues to charge on the plus (+) side with

no gradual moving back of the needle to zero while the engine is running

at full governed speed, due to a faulty voltage rectifier/regulator, this

will send too much voltage to or overcharge the battery, which could eventually

burn up the cells in the battery, or burn up the primary windings in a [battery]

ignition coil, burn up an electric PTO clutch, burn out light bulbs, the

[battery powered] electronic ignition control module

(crank-trigger and flywheel-trigger), and

other electrical accessories.

To determine the size of fuse or circuit breaker, figure how many amps all the connected electrical accessories draw, then use a fuse or circuit breaker with an amp rating slightly higher to prevent the fuse from burning out or the circuit breaker from overloading and popping. If a short occurs, the fuse will need to be replaced and the circuit breaker will automatically reset itself.

Also, it's a good idea to install

a main disconnect/cutoff switch to kill electric

power to everything on the equipment. This is useful when equipment is not

used for a period of time to prevent a slow drain on the battery, prevent

short circuits when performing electrical service on equipment, or for a

pulling tractor to prevent accidental starts or to prevent sabotage at the

pull sites from disgruntled pullers.

Also, it's a good idea to install

a main disconnect/cutoff switch to kill electric

power to everything on the equipment. This is useful when equipment is not

used for a period of time to prevent a slow drain on the battery, prevent

short circuits when performing electrical service on equipment, or for a

pulling tractor to prevent accidental starts or to prevent sabotage at the

pull sites from disgruntled pullers.

How Lead-Acid Batteries Go Bad - (Added 2/6/21) Top of Page

In a lead-acid automotive battery, as the battery ages, the lead (the soft, heavy, toxic, malleable metallic element) on the plates of one cell falls off and builds up on the bottom of the battery (this always happen with a cell on the positive (+) post), it will short-out that cell, causing a dead cell. There is no fix for this whatsoever. The only solution is to replace it with a new battery and keep it fully charged. Or when a battery sits too long with no charge, the activity of the acid will become neutralized and become water-like. If you're lucky, the battery MIGHT be able to be reactivated with a trickle charger. A trickle charger provides low amperage and will slowly reactivate the chemical reaction of the acid/water to the cells. Otherwise, if it won;t recharge, then the battery is bad and needs to be replaced with a new one. Or, the acid/water can be drained and replaced with fresh acid/water, and "maybe" the battery can be fully charged at a low rate for activation again. Or, if the charging system on the engine continually charge the battery at full amperage due to a faulty voltage regulator or voltage rectifier/regulator, this will "burn up" the acid/water and the lead plates, causing a bad battery. The only solution for this is install a new voltage regulator or voltage rectifier/regulator and replace the battery with a new one. Does battery acid contain water? Is it okay to add water or acid to a lead acid battery? Is it okay to add water to a lead acid battery?

Testing the Starting Circuit -

To test the starting circuit

on virtually any lawn, garden or larger tractor, first, make sure that the

battery is fully charged and in good condition, and the cables have a good

connection. Use a

Battery Load Tester to determine the condition of the battery.

If the battery is satisfactory and the connections are good, using either

a screwdriver, metal rod or jumper wire, energize the starter solenoid/relay

by connecting the large terminal on the solenoid/relay where the heavy battery

wire connects, to the small "S" terminal on the solenoid/relay where the

starter switch connects. The starter should spin and crank the engine. If

it doesn't, then the solenoid/relay is defective.

To test the starting circuit

on virtually any lawn, garden or larger tractor, first, make sure that the

battery is fully charged and in good condition, and the cables have a good

connection. Use a

Battery Load Tester to determine the condition of the battery.

If the battery is satisfactory and the connections are good, using either

a screwdriver, metal rod or jumper wire, energize the starter solenoid/relay

by connecting the large terminal on the solenoid/relay where the heavy battery

wire connects, to the small "S" terminal on the solenoid/relay where the

starter switch connects. The starter should spin and crank the engine. If

it doesn't, then the solenoid/relay is defective.

If the starter switch will not crank the engine, to test the starting

circuit, use a fully charged

portable battery booster/jumper or a 12 volt automotive

battery with minimum 6 gauge x 2 foot length jumper wires and heavy duty

clamps. Clamp the battery positive (+) lead directly to the terminal on the

starter motor, and temporarily touch the battery negative (–) lead to

the engine/chassis ground. If the engine cranks over with no hesitation,

then the starter motor is in good condition, and the problem is either the

solenoid/relay, starter switch or wiring. But if it just spins without engaging

into the flywheel, then the gear teeth are worn or the gear is binding on

the spiral of the armature shaft. But if the starter motor does nothing at

all or turns slow, then either the brushes are worn, the commutator is dirty

and needs cleaning, and/or the armature shaft bushings also needs cleaning

and lubricating, or the windings are burned up. Or, the engine itself could

be causing drag on the starter (turn slow) due to either too heavy/thick

(wrong viscosity) crankcase oil in cold weather, damage inside the engine,

or a parasitic accessory (PTO clutch, etc.) may be too tight, binding or

worn, preventing the engine from cranking normally. And never assume that

a starter motor is in good condition. When in doubt, it should be disassembled

to verify that the windings are in fact burned up, the brushes are worn,

or if the magnet(s) are broken. Because like the old saying goes: "Assumption

is the mother of all foul ups."

How A Starter Solenoid/Relay Becomes Defective -

When the engine that uses a

starter solenoid/relay cranks over right away upon the turn of the ignition

key or the push of the start button (and the engine starts right up), but

every now and then when the key is turned or the button is pushed, either

nothing happens or there's a constant clicking sound. What's happening is,

as the round brass contact disc inside the solenoid rotates slightly upon

each activation (magnetic engagement) of the solenoid/relay, the edge of

the disc is either burned away, or the brass contact lug on one or the other

big terminal (where the battery cable and starter motor cable connects) is

burned away. When the metal gets burned away on either part (which is

inevitable), neither will make contact to complete the circuit. If the disc

and/or lugs aren't totally burned away, when attempting to crank the engine

(turning the key back and forth, or push the button again and again), eventually,

a good spot on the disc makes contact with the lugs, and the starter spins.

When the engine that uses a

starter solenoid/relay cranks over right away upon the turn of the ignition

key or the push of the start button (and the engine starts right up), but

every now and then when the key is turned or the button is pushed, either

nothing happens or there's a constant clicking sound. What's happening is,

as the round brass contact disc inside the solenoid rotates slightly upon

each activation (magnetic engagement) of the solenoid/relay, the edge of

the disc is either burned away, or the brass contact lug on one or the other

big terminal (where the battery cable and starter motor cable connects) is

burned away. When the metal gets burned away on either part (which is

inevitable), neither will make contact to complete the circuit. If the disc

and/or lugs aren't totally burned away, when attempting to crank the engine

(turning the key back and forth, or push the button again and again), eventually,

a good spot on the disc makes contact with the lugs, and the starter spins.

How to Test a Starter Solenoid/Relay -

Tools needed are - analog or digital multimeter, fully charged 12 volt battery and four jumper wires with clips. The test is performed as follows -

To connect the wires on a starter solenoid/relay to energize a starter motor -

How to Connect the Wires on the Starter Solenoid/Relay -

If a solenoid/relay have just

one 3/16" terminal, the solenoid/relay is grounded internally through the

mounting bracket. But if a solenoid/relay has two unmarked 3/16" terminals,

the solenoid/relay is grounded externally through one of the 3/16" terminals.

It doesn't matter which terminal is used. Connect one small terminal to the

starter switch and the other to the engine/chassis ground (negative (–)

battery post). When electric current is applied, the two small terminals

energizes a magnetic field within the solenoid/relay so the plunger that's

connected to a brass disc within can make contact across the two larger terminals

to complete the circuit from the battery positive (+) post to the starter

motor. On most larger solenoid/relays having two marked 3/16" terminals,

the one that's marked with an "S" [Start] connects to the starter

switch. It energizes the solenoid/relay so power can be connected from the

battery through the solenoid/relay to the starter. With points and

condenser/capacitor ignition, the "I" [Ignition] terminal on the

solenoid/relay (not present on all solenoids/relays) by-pass the ballast

resistor or resistor wire for points/condenser ignition, or connects to the

Chrysler or Ford electronic ignition control module to give the coil a stronger

spark for faster engine start up. There's no need to use the "I" if

the coil has an internal resistor or with crank trigger ignition. The

solenoid/relay is grounded through the mounting bracket.

If a solenoid/relay have just

one 3/16" terminal, the solenoid/relay is grounded internally through the

mounting bracket. But if a solenoid/relay has two unmarked 3/16" terminals,

the solenoid/relay is grounded externally through one of the 3/16" terminals.

It doesn't matter which terminal is used. Connect one small terminal to the

starter switch and the other to the engine/chassis ground (negative (–)

battery post). When electric current is applied, the two small terminals

energizes a magnetic field within the solenoid/relay so the plunger that's

connected to a brass disc within can make contact across the two larger terminals

to complete the circuit from the battery positive (+) post to the starter

motor. On most larger solenoid/relays having two marked 3/16" terminals,

the one that's marked with an "S" [Start] connects to the starter

switch. It energizes the solenoid/relay so power can be connected from the

battery through the solenoid/relay to the starter. With points and

condenser/capacitor ignition, the "I" [Ignition] terminal on the

solenoid/relay (not present on all solenoids/relays) by-pass the ballast

resistor or resistor wire for points/condenser ignition, or connects to the

Chrysler or Ford electronic ignition control module to give the coil a stronger

spark for faster engine start up. There's no need to use the "I" if

the coil has an internal resistor or with crank trigger ignition. The

solenoid/relay is grounded through the mounting bracket.

FYI - Solenoids and relays are used in a starting circuit or any electrical component that draws a lot of amps, as well as horn and blower motor circuits, to prevent excessive current from flowing through a low amperage switch, which can cause it to burn out. A solenoid/relay (sometimes referred to as an "electric switch" or "relay") eliminates the use of a high amperage momentary push button starter switch and heavy wiring throughout the starting circuit.

In some cases, it's not the starter motor who is the culprit of not being able to crank a big cubic inch or high compression engine. Sometimes the ignition timing can be so advanced, the starter tries to crank the engine to start it, but the advanced spark causes the crankshaft to "kick back." Sometimes if the kick-back is severe enough, the armature in a direct-drive starter motor will bend or break. To fix this problem and prevent damage to the starter, use the same starting technique as the Tecumseh cast iron engine with the crank trigger ignition. Install two separate switches - one being a momentary push button to crank the engine and the other being an ordinary Grounded OFF/ON Toggle Switch. To make this work, first crank the engine over with the momentary push button switch, choke it, then flip the [ignition] switch to "put the spark to it" (power up the ignition). This should allow it to start easily and effortlessly every time.

If an engine is slow at cranking over or will barely crank over, then the first thing to check is the condition of the engine. If it cranks over somewhat easy by hand, then it's probably OK. The next thing to check is the condition of the battery. Use a Battery Load Tester to determine the condition of the battery. If it tests good, then check the wire connections and start solenoid/relay (if equipped). If they're OK, then the lat thing to check is the condition of the starter motor. Disassemble it and observe the condition of the wire windings on the armature. If they're dark brown in color and have a burnt smell, then the motor is burned up. But if the windings are light brown or "bronze" in color, then they're in good condition. Clean the commutator (the part on the armature where the brushes make contact) and shaft where the bushings make contact with emery cloth in a metal lathe. IMPORTANT - If you don't feel comfortable using a metal lathe, please consult a professional and experienced machinist with a lathe. Before reassembling the starter, lightly lubricate the bushings with motor oil. If the engine still won't crank over easy, then either the ignition timing is too advanced or the compression release isn't working. Too much valve clearances could also cause hard cranking.

Some starter motors are American made, some are imported. But most nowadays are made of excellent quality and manufactured to exceed OEM specifications. As a matter of fact, virtually all OEM Kohler starters are made in China, so are most of their other engine parts. Kohler owns two factories in China.

Be gentle when handling a starter motor, especially

one with permanent magnets. Never abuse it by dropping it on the floor or

striking it with a heavy metal object, such as a hammer! Doing this could,

or most likely will, break the fragile

ceramic magnets inside the starter and render it totally

useless. Personally, I've

seen some people strike a starter motor with a hammer, thinking this will

fix it when it fails to operate. No joke.

Be gentle when handling a starter motor, especially

one with permanent magnets. Never abuse it by dropping it on the floor or

striking it with a heavy metal object, such as a hammer! Doing this could,

or most likely will, break the fragile

ceramic magnets inside the starter and render it totally

useless. Personally, I've

seen some people strike a starter motor with a hammer, thinking this will

fix it when it fails to operate. No joke.

Most quality-made starter motors

are designed to last the life of the engine. Therefore, if a good starter

burns up prematurely, then this means that it has cranked the engine for

too long at one time. All 12 volt starters are actually 6 volt motors operating

on 12 volts of power. This is what gives them so much torque to crank the

engine so fast and with no effort. So if a starter motor is spun too long

(longer than 2 minutes), the excess voltage will burn up the wire windings

in the starter. The longer it's spun, the hotter it will get, which causes

the windings to get very hot, which causes the insulating/separating varnish

coating on the windings to melt. When the coating melts, the windings make

contact with each other and become shorted out, and you have a burned up

starter on your hands. That's why most owner's and repair manuals say to

never crank an engine longer than 2 minutes at a time without allowing adequate

time for the starter to cool before cranking it again. (If an engine won't

start within 2 minutes of cranking, then it obviously needs a major tune-up

or repair!) And unlike most automotive starters, which are in

big demand, nobody rebuilds (rewinds) Kohler starter motors.

Most quality-made starter motors

are designed to last the life of the engine. Therefore, if a good starter

burns up prematurely, then this means that it has cranked the engine for

too long at one time. All 12 volt starters are actually 6 volt motors operating

on 12 volts of power. This is what gives them so much torque to crank the

engine so fast and with no effort. So if a starter motor is spun too long

(longer than 2 minutes), the excess voltage will burn up the wire windings

in the starter. The longer it's spun, the hotter it will get, which causes

the windings to get very hot, which causes the insulating/separating varnish

coating on the windings to melt. When the coating melts, the windings make

contact with each other and become shorted out, and you have a burned up

starter on your hands. That's why most owner's and repair manuals say to

never crank an engine longer than 2 minutes at a time without allowing adequate

time for the starter to cool before cranking it again. (If an engine won't

start within 2 minutes of cranking, then it obviously needs a major tune-up

or repair!) And unlike most automotive starters, which are in

big demand, nobody rebuilds (rewinds) Kohler starter motors.

There's three things that can cause a good starter motor to burn up -

If you

would like to have a starter motor to crank your engine without hesitation,

you'd be better off purchasing a new one or one that's been professionally

rebuilt. Never put full trust in a used electric starter to crank your engine

unless your receive an unconditional guarantee that it's good. Otherwise,

there's a chance that it's either 90% wore out, burned up or the magnets

are broken, and the owner is just trying to sell "junk" to another person.

A starter may look nice and clean on the outside, but it's what's on the

inside that matters. Some of these questionable starters are sold "AS IS"

on places like eBay. So remember these words... "BUYER BEWARE!" By the way

- I'm not trying to sell you a new starter here, I'm only informing you of

the facts.

If you

would like to have a starter motor to crank your engine without hesitation,

you'd be better off purchasing a new one or one that's been professionally

rebuilt. Never put full trust in a used electric starter to crank your engine

unless your receive an unconditional guarantee that it's good. Otherwise,

there's a chance that it's either 90% wore out, burned up or the magnets

are broken, and the owner is just trying to sell "junk" to another person.

A starter may look nice and clean on the outside, but it's what's on the

inside that matters. Some of these questionable starters are sold "AS IS"

on places like eBay. So remember these words... "BUYER BEWARE!" By the way

- I'm not trying to sell you a new starter here, I'm only informing you of

the facts.

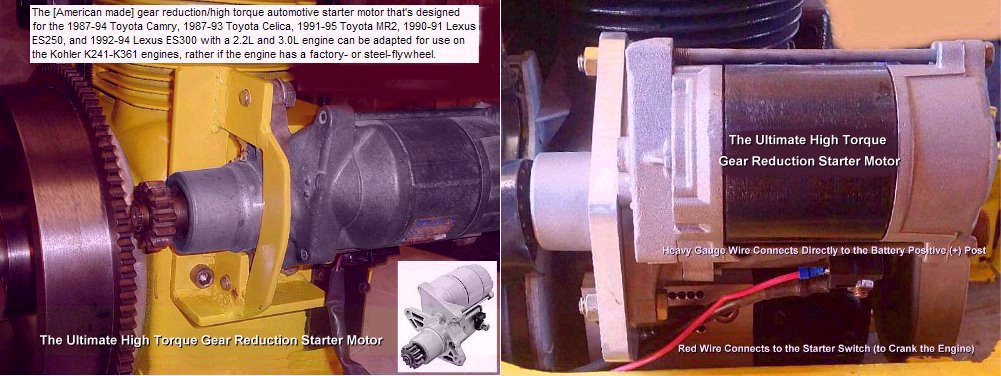

The Ultimate High Torque Gear Reduction Starter Motor and Bracket Assembly!

Suitable for Kohler 10hp, 12hp,

14hp, 16hp and 18hp OHV Competition Pulling Engines. 12 volt negative ground.

This is an extremely powerful starter! It will not hesitate whatsoever

to crank over most Kohler K-series (or Magnum) single cylinder engines with

a machined high compression billet cylinder head and without an automatic

compression release (ACR) on the camshaft. Ideal for Hot-Stock, Stock-Altered,

30 c.i., 37c.i./16hp Missouri Super-Stock, and 50.5 c.i. Modified-Class single

cylinder competition pulling engines. Will also crank over an ordinary lawn

and garden Kohler engine with a non-working automatic compression release.

No need to use this starter on an engine with a working automatic compression

release (ACR). The starter gear will fit inside the OEM Kohler K-series flywheel

shroud. This starter has a built-in solenoid/relay; no need for a separate

solenoid.

Suitable for Kohler 10hp, 12hp,

14hp, 16hp and 18hp OHV Competition Pulling Engines. 12 volt negative ground.

This is an extremely powerful starter! It will not hesitate whatsoever

to crank over most Kohler K-series (or Magnum) single cylinder engines with

a machined high compression billet cylinder head and without an automatic

compression release (ACR) on the camshaft. Ideal for Hot-Stock, Stock-Altered,

30 c.i., 37c.i./16hp Missouri Super-Stock, and 50.5 c.i. Modified-Class single

cylinder competition pulling engines. Will also crank over an ordinary lawn

and garden Kohler engine with a non-working automatic compression release.

No need to use this starter on an engine with a working automatic compression

release (ACR). The starter gear will fit inside the OEM Kohler K-series flywheel

shroud. This starter has a built-in solenoid/relay; no need for a separate

solenoid.

The correct Toyota gear reduction starter motor to use are: 1986-1993 Toyota Celica, 1987-1994 Toyota Camry, 1989-1995 Toyota MR2, 1990-1991 Lexus ES250, and 1992-1994 Lexus ES300.

Requires a heavy duty CNC-machined billet aluminum adapter/mounting bracket, which is available on eBay. When engaged, if the starter gear teeth doesn't fully align with the flywheel gear teeth, the starter can be relocated by rearranging the two Allen screws in the aluminum billet starter bracket.

And due to the extreme outward pressure this high torque starter places on the side of the block of a high compression competition pulling engine to crank it over, it's recommended to fabricate and install a sturdy reinforcement support brace to prevent the possibility of block cracking or breakage. NOTES: Best to use a long reach hex bit (Allen) socket to fasten socket (Allen) head bolts to engine block. And due to the design of certain starter motors (listed below), part of the crankcase next to the lower cylinder may need to be ground away about 1/8" for clearance of the battery cable terminal.

How to Reassemble a Kohler Starter Motor -

Before reassembling a Kohler

starter motor, first, a brush holder tool must be fabricated from sheet metal

to depress and retain the brushes in their cavities before the end cap can

be reinstalled onto the starter housing. Without this tool, it is nearly

impossible to install the end cap with the brushes depressed.

Before reassembling a Kohler

starter motor, first, a brush holder tool must be fabricated from sheet metal

to depress and retain the brushes in their cavities before the end cap can

be reinstalled onto the starter housing. Without this tool, it is nearly

impossible to install the end cap with the brushes depressed.

To properly install the end cap on the housing, align the projected tang inside the housing with the notch inside the end cap so the bolt holes will be aligned and so the terminal will be in the correct position. Install the bolts, then the brush holder tool can be pulled out and the brushes will snap against the commutator, and then tighten the bolts to 15 in. lb.

Always Use a High Quality and Fully Charged Battery to Crank a Competition Pulling Engine!

First of all, to test the condition

of a battery, use a professional

Battery Load Tester as shown to the right ->. Avoid

purchasing a "cheapie" made-in-China load tester. These do not work at all!

Anyway, to use a load tester, remember that when testing a [high-amperage]

automotive battery, use the higher amp scale on the display/meter, and when

testing a low-amperage battery, such as for a riding mower, lawn & garden

tractor, small motorized vehicle, ATV/UTV, motorcycle, etc., use the lower

amp scale on the display/meter. And if possible, fully charge the battery

(preferably overnight) with a

battery charger. When the battery is fully charged, disconnect

the battery charger, and connect the clamps on the load tester to the respective

battery posts (RED –> positive

(+), BLACK –> negative (–)),

hold the Load Switch ON for 10 seconds while observing the display/meter.

If the display needle is in the

GREEN (GOOD/OK) area,

the battery is in usable condition. But if the display is in the

YELLOW or

RED (BAD/WEAK) area, then

the battery is defective.

First of all, to test the condition

of a battery, use a professional

Battery Load Tester as shown to the right ->. Avoid

purchasing a "cheapie" made-in-China load tester. These do not work at all!

Anyway, to use a load tester, remember that when testing a [high-amperage]

automotive battery, use the higher amp scale on the display/meter, and when

testing a low-amperage battery, such as for a riding mower, lawn & garden

tractor, small motorized vehicle, ATV/UTV, motorcycle, etc., use the lower

amp scale on the display/meter. And if possible, fully charge the battery

(preferably overnight) with a

battery charger. When the battery is fully charged, disconnect

the battery charger, and connect the clamps on the load tester to the respective

battery posts (RED –> positive

(+), BLACK –> negative (–)),

hold the Load Switch ON for 10 seconds while observing the display/meter.

If the display needle is in the

GREEN (GOOD/OK) area,

the battery is in usable condition. But if the display is in the

YELLOW or

RED (BAD/WEAK) area, then

the battery is defective.

Most [stock] single cylinder pulling engines with the automatic compression release (ACR) in working condition with a high torque starter motor and a minimum 350 CCA lawn & garden battery should crank over and start with no problems. But a pulling engine without the ACR may hesitate when the piston comes up on the compression while being cranked. Therefore, it'll be a good ideal to use a high torque starter motor along with a high amp battery, such as a small 12 volt 35AH (Amp Hour) sealed lead acid (SLA) battery, a minimum 350 CCA lawn & garden battery, or better yet, a small 12 volt automotive battery (if it will fit in the battery box). The 12 volt 35AH battery packs a lot of punch (cranking power) and it's vibration-resistant, making ideal for use in a competition garden pulling tractor.

No professional puller that I know of have a charging system incorporated with the engine on their pulling tractor. A charging system will rob the running engine of valuable power while it's recharging the battery. Therefore, to maintain a fully charged battery, a battery charger will need to be used when the tractor is not in use or in storage.

Widening the Frame/Chassis on a Narrow-Frame Cub Cadet Garden Tractor for use with a Large Flywheel and Gear Starter Motor - Top of Page

|

The upper mount gear starter (mounting bolts are below the starter motor)can't be installed on the very early K241 engine blocks because there's no indentation in the block just above the starter's mounting holes. These blocks were designed for the starter/generator only. |

Parts needed to convert a Kohler K-series engine with a starter/generator to a gear starter -

|

|

Parts needed to convert virtually any small gas engine to electric gear start -

|

|

Parts needed to convert a stand-alone Kohler K-series [welder or generator] engine models K241, K301, K321 or K341 with a manual recoil or rope starter to an electric gear starter system - (Added 9/13/18) [Top of Page]

| Parts off of a Kohler Magnum engine model M10, M12, M14 or M16 can be used. Parts needed are - flywheel w/plastic fan, starter motor, bearing plate, solid state ignition coil/module w/mounting screws and inner air baffle. These parts will interchange between the K241, K301, K321 and K341 engines. Also, these parts are hard to find nowadays because Kohler didn't make many Magnum single cylinder engines. The best to find these parts is on eBay, local small engine repair shops/salvage yards, Craigslist, visit antique/vintage swap meets/shows or search Google. |

Depending on battery drainage and need for recharging, to be precise, and with the engine running at 3,600 RPM, the generator part of the starter/generator unit or alternator stator uses about 3/8hp (of engine power) when it recharges a fully discharged battery at full 15 amps; about 5/8hp at full 20 amps; and about 7/8hp at full 30 amps. But if the battery doesn't need much recharging, the charging system draws less hp from the engine. I know this small amount isn't much, but every hp counts in competitive pulling. So to reserve this power for pulling, disconnect the generator or alternator from charging the battery (and powering other electrical accessories as well) simply by splitting the wire that connects to the FIELD terminal (the smaller wire and terminal) on a starter/generator unit and splitting the wire that connects to the center terminal on the voltage rectifier/regular of an alternator system. Then connect an ordinary Grounded OFF/ON Toggle Switch in that wire or circuit to turn off and on the charging current. And it'll be best not to spin the starter/generator when pulling. Being it has ball bearings, the excessive spinning won't hurt it. But being the V-belt causes drag, depending on belt tension, it can use up to 2hp of engine power just to spin it. This is also power that can be put to the rear tires for pulling. Besides, wouldn't it be better to spin the tires than the starter/generator? So to disengage the starter/generator belt, install threaded studs with locknuts on the starter/generator bracket and install a heavy spring on the starter/generator so it'll remain close to the engine. To crank the engine, install the belt on the pulleys, then pull out on the starter/generator with a fabricated handle to tighten the belt. After the engine starts, release the starter/generator and flip the belt off. But use caution doing this for an obvious reason!

Advertisement:

| Click here to contact A-1 Miller's Performance Enterprises to place an order, send your parts for repairing, and/or for FREE professional and honest technical customer service assistance and support and payment options. Please contact A-1 Miller's if you need a part or parts, or service(s) performed that's not listed or mentioned in this website. Prices are subject to change without notice. | |

Universal Electric Fuel Level Gauge Kit. 2" gauge can

be mounted in dash of tractor, vehicle or in control panel of equipment.

Use a 2"

hole saw and power drill or

annular cutter to cut hole in dash or panel. Fuel level

reading on gauge can be adjusted or corrected for shallow to deep tanks to

13-1/2" by shortening float rod. Includes wiring harness and instructions.

Operates with 9-36 volts DC. Wire Connections - 1-> Ignition Switch (Battery

Positive (+) Post); 2-> Negative Ground (Battery Negative (—) Post);

3-> Signal Input (Fuel Gauge); 5-> Illuminated Backlight (Connect to

Instrument Cluster or Dash Lights). Complete Kit. $45.00 each, plus

shipping & handling. Universal Electric Fuel Level Gauge Kit. 2" gauge can

be mounted in dash of tractor, vehicle or in control panel of equipment.

Use a 2"

hole saw and power drill or

annular cutter to cut hole in dash or panel. Fuel level

reading on gauge can be adjusted or corrected for shallow to deep tanks to

13-1/2" by shortening float rod. Includes wiring harness and instructions.

Operates with 9-36 volts DC. Wire Connections - 1-> Ignition Switch (Battery

Positive (+) Post); 2-> Negative Ground (Battery Negative (—) Post);

3-> Signal Input (Fuel Gauge); 5-> Illuminated Backlight (Connect to

Instrument Cluster or Dash Lights). Complete Kit. $45.00 each, plus

shipping & handling. |

|

High

Quality Small Engine Inductive Tachometer/Hour Meter with Replaceable

Battery. A tachometer is required for monitoring and/or setting the

maximum speed of a small engine, which is normally 3,200 or 3,600 RPM (depending

on type of carburetor), to prevent from over-revving and possible damage

to the engine or dangerous flywheel explosion. Very accurate, vibration-proof

and weatherproof construction. Can be surface-mounted and secured with two

screws to monitor engine RPM, or hand-held to set engine RPM. Large 3/8 inch

LCD display. Works with magneto or battery-powered ignition systems by selecting

engine type by programming S1 and S2 buttons. If tachometer does not turn

on automatically as soon as engine starts, press and hold the two buttons

at the same time. Instructions included. Reads up to 99,999 RPM. Hour

meter reads up to 9999:59 hours/minutes. Programmable maintenance hour setting

with service icon, a service reminder when to change oil or other maintenance.

Can be manually reset to Zero hours. Easy installation: Single wire wraps

around spark plug wire and secured with two supplied nylon zip-ties. No wire

terminal connections required. Includes replaceable CR2450 battery. Dimensions:

2" wide x 1-3/4" depth x 3/4" height. $25.00 each, plus shipping &

handling. Click here to print

out instructions. Please let me know if you're

interested in purchasing this item and I'll give you the total amount with

shipping and payment options. High

Quality Small Engine Inductive Tachometer/Hour Meter with Replaceable

Battery. A tachometer is required for monitoring and/or setting the

maximum speed of a small engine, which is normally 3,200 or 3,600 RPM (depending

on type of carburetor), to prevent from over-revving and possible damage

to the engine or dangerous flywheel explosion. Very accurate, vibration-proof

and weatherproof construction. Can be surface-mounted and secured with two

screws to monitor engine RPM, or hand-held to set engine RPM. Large 3/8 inch

LCD display. Works with magneto or battery-powered ignition systems by selecting

engine type by programming S1 and S2 buttons. If tachometer does not turn

on automatically as soon as engine starts, press and hold the two buttons

at the same time. Instructions included. Reads up to 99,999 RPM. Hour

meter reads up to 9999:59 hours/minutes. Programmable maintenance hour setting

with service icon, a service reminder when to change oil or other maintenance.

Can be manually reset to Zero hours. Easy installation: Single wire wraps

around spark plug wire and secured with two supplied nylon zip-ties. No wire

terminal connections required. Includes replaceable CR2450 battery. Dimensions:

2" wide x 1-3/4" depth x 3/4" height. $25.00 each, plus shipping &

handling. Click here to print

out instructions. Please let me know if you're

interested in purchasing this item and I'll give you the total amount with

shipping and payment options.

Wiring Instructions:

Wiring is the same for the hall effect and inductive proximity sensors. Certain proximity sensors have an LED (Light Emitting Diode), which flashes when in close proximity of target. If the proximity sensor is wired incorrectly, the LED will illuminate at all times. Click or tap here for YouTube videos to see how well this tachometer works.

|

|

Superior Quality, High Velocity 12 Volt Auxiliary Engine Cooling Fan. Use an electric fan to cool a competition garden tractor pulling engine with a steel flywheel and no cooling fins. Unlike fan blades that's fastened to the flywheel, an electric fan will not produce drag and rob power from the engine. Install fan with motor forward of blades (for maximum velocity) aimed toward exhaust area of engine. Fasten fan housing on a sturdy angle steel support brace with 1/4" bolts, flat washers, lock washers and nuts, in front of engine or behind grille in a garden tractor. See photos to the right and below. No need to mount fan housing on rubber grommets; these will serve no purpose whatsoever. Fan motor is 100% secured and reinforced to plastic housing to withstand severe engine vibration to prevent fan motor from loosening and become inoperable when pulling. Distinctive feature by A-1 Miller's. NOTE: These fans are designed to be run for a short while only. If they are ran continuously, they may burn up. Draws 2.6 amps, produces 145 CFM. Measures 3" diameter and 5" length. IMPORTANT: It's recommended that the fan not be run while pulling because due to normal engine vibration, the brush holders inside motor could break. Turn fan on ONLY between pull-offs or when tuning engine. $40.00 each, plus shipping & handling.

|

|

Break-Away / Grounding-Type Safety Kill Switch with

Pull-Pin. Use for competition pulling only; mount on rear of tractor.

When the pin pulled, it grounds the ignition coil from producing spark. If

using with a self-energizing magneto or electronic/solid state ignition systems:

Connect one wire to the chassis ground, and connect the other wire to the

points/condenser wire or to the kill terminal on the solid state ignition

coil/module. If using with a battery-powered ignition system: Connect one

wire to the chassis ground, and connect the other wire to the coil negative

(–) terminal. NOTE: With battery-powered ignition, as soon as pin

is pulled (engine will die), manually shut off ignition switch right away

to prevent possible damage to the ignition coil and electronic ignition module

if equipped with crank trigger ignition. This type of switch does not

disable power to the

electric fuel pump on a pulling tractor. It must be

shut-off manually by the ignition switch or an OFF-ON toggle switch. Break-Away / Grounding-Type Safety Kill Switch with

Pull-Pin. Use for competition pulling only; mount on rear of tractor.

When the pin pulled, it grounds the ignition coil from producing spark. If

using with a self-energizing magneto or electronic/solid state ignition systems:

Connect one wire to the chassis ground, and connect the other wire to the

points/condenser wire or to the kill terminal on the solid state ignition

coil/module. If using with a battery-powered ignition system: Connect one

wire to the chassis ground, and connect the other wire to the coil negative

(–) terminal. NOTE: With battery-powered ignition, as soon as pin

is pulled (engine will die), manually shut off ignition switch right away

to prevent possible damage to the ignition coil and electronic ignition module

if equipped with crank trigger ignition. This type of switch does not

disable power to the

electric fuel pump on a pulling tractor. It must be

shut-off manually by the ignition switch or an OFF-ON toggle switch.

|

|

High Quality

Universal Self-Grounding OFF/ON Switches. Designed for use with

Self-Energizing Magneto Ignition, Solid State Ignition, OEM Solid State

Ignition (SSI) for Tecumseh's Cast Iron Block Engines, or with OEM Kohler

Breakerless Ignition. These can be used on virtually any small engine

installed on lawn and garden equipment, garden tillers, go-karts, chainsaws,

log splitters, portable air compressors, portable generators/welders, portable

water pumps, etc. with a magneto or solid state ignition, and a recoil/rope

starter or a push-button switch with an electric starter motor to crank the

engine. Very durable, tough switches. High Quality

Universal Self-Grounding OFF/ON Switches. Designed for use with

Self-Energizing Magneto Ignition, Solid State Ignition, OEM Solid State

Ignition (SSI) for Tecumseh's Cast Iron Block Engines, or with OEM Kohler

Breakerless Ignition. These can be used on virtually any small engine

installed on lawn and garden equipment, garden tillers, go-karts, chainsaws,

log splitters, portable air compressors, portable generators/welders, portable

water pumps, etc. with a magneto or solid state ignition, and a recoil/rope

starter or a push-button switch with an electric starter motor to crank the

engine. Very durable, tough switches.

|

|

High Quality Universal OFF/ON Switches for Battery-Powered

Ignition and Electrical Accessories. Very durable, tough switches. Either

can be used for ignition, lights,

electric fuel

pump, electric PTO clutch, etc. When used for ignition, use with

push button starter switch (listed below). Terminals or wires on switches

listed below makes contact when in the ON position. Can be used on virtually

anything that have a battery-powered ignition or electrical system, such

as: garden tractors, go-karts, small motorized vehicles, competition pulling

tractors, mini-rods, hot-rods, farm tractors, automobiles, etc. Each can

be mounted in dashboard, instrument panel, engine control panel, etc. High Quality Universal OFF/ON Switches for Battery-Powered

Ignition and Electrical Accessories. Very durable, tough switches. Either

can be used for ignition, lights,

electric fuel

pump, electric PTO clutch, etc. When used for ignition, use with

push button starter switch (listed below). Terminals or wires on switches

listed below makes contact when in the ON position. Can be used on virtually

anything that have a battery-powered ignition or electrical system, such

as: garden tractors, go-karts, small motorized vehicles, competition pulling

tractors, mini-rods, hot-rods, farm tractors, automobiles, etc. Each can

be mounted in dashboard, instrument panel, engine control panel, etc.

|

|

High

Quality Universal Push Button Switches. Each can be mounted in pedestal,

dashboard, instrument panel, engine control panel, flywheel shroud, etc. High

Quality Universal Push Button Switches. Each can be mounted in pedestal,

dashboard, instrument panel, engine control panel, flywheel shroud, etc.

|

|

High Quality Universal 3-Position OFF-ON-START MAGNETO Ignition

Key Switch. Designed specifically for Self-Energizing Magneto Ignition,

Solid State Ignition, OEM Solid State Ignition (SSI) for Tecumseh's Cast

Iron Block Engines, or with OEM Kohler Breakerless Ignition. Can be used

for various makes and models of riding mowers, lawn & garden tractors,

garden tractors and various small engine equipment with magneto or solid

state ignition. Identification of 5 blade terminals: B = Battery (+);

G = Ground (terminal is grounded to body of switch); L = Lights

(use a separate OFF-ON switch connected to this terminal to power an electric

PTO clutch); M = Magneto (Ignition); S = Solenoid (small terminal).

Key positions: OFF position makes contact with M+G; IGNITION position makes

contact with B+L; START position makes contact with B+S. Each terminal identified

for correct wiring connections. IMPORTANT: Use with a starter solenoid/relay

to crank the engine to prevent burning out internal contacts in switch. NOTE:

If engine is equipped with an alternator/stator charging system, the center

terminal on the voltage rectifier/regulator connects to the positive (+)

battery post. If using an ammeter/amp gauge, connect the gauge/meter to the

positive (+) battery post, then to the B terminal on the switch. Trace the

wires on your tractor/equipment to see if they match the terminals on this

switch. If they don't match, the plug-in spade connectors/wires can be rearranged

in the plastic connector housing to match the corresponding terminals on

the switch. To do this, use a small flat blade screwdriver to depress the

locking tab/tang so the plug-in connector can be pulled out from the plastic

connector housing. Bend the locking tab/tang up slightly before reinserting

it in the plastic connector so it will be secured in place. Or for a universal

application, use #250

slip-on female spade crimp-type wire connectors. Requires

5/8" diameter mounting hole. High Quality Universal 3-Position OFF-ON-START MAGNETO Ignition

Key Switch. Designed specifically for Self-Energizing Magneto Ignition,

Solid State Ignition, OEM Solid State Ignition (SSI) for Tecumseh's Cast

Iron Block Engines, or with OEM Kohler Breakerless Ignition. Can be used

for various makes and models of riding mowers, lawn & garden tractors,

garden tractors and various small engine equipment with magneto or solid

state ignition. Identification of 5 blade terminals: B = Battery (+);

G = Ground (terminal is grounded to body of switch); L = Lights

(use a separate OFF-ON switch connected to this terminal to power an electric

PTO clutch); M = Magneto (Ignition); S = Solenoid (small terminal).

Key positions: OFF position makes contact with M+G; IGNITION position makes

contact with B+L; START position makes contact with B+S. Each terminal identified

for correct wiring connections. IMPORTANT: Use with a starter solenoid/relay

to crank the engine to prevent burning out internal contacts in switch. NOTE:

If engine is equipped with an alternator/stator charging system, the center

terminal on the voltage rectifier/regulator connects to the positive (+)

battery post. If using an ammeter/amp gauge, connect the gauge/meter to the

positive (+) battery post, then to the B terminal on the switch. Trace the

wires on your tractor/equipment to see if they match the terminals on this

switch. If they don't match, the plug-in spade connectors/wires can be rearranged

in the plastic connector housing to match the corresponding terminals on

the switch. To do this, use a small flat blade screwdriver to depress the

locking tab/tang so the plug-in connector can be pulled out from the plastic

connector housing. Bend the locking tab/tang up slightly before reinserting

it in the plastic connector so it will be secured in place. Or for a universal

application, use #250

slip-on female spade crimp-type wire connectors. Requires

5/8" diameter mounting hole.

|

|

Universal Wiring Harness with Plastic Connector Housing

and Slide-On Connectors. Replace damaged entire connector, terminals

and wiring, use as new wiring harness on a custom-made project, or use this

part when converting from Breakerless Ignition to battery-powered

points/condenser ignition. Fits universal OFF-ON-START key switches listed

above and other key switches with same terminal configuration. Three terminals

in this part will also fit the OEM Cub Cadet garden tractor OFF-ON-START

key switch listed above. 18" length color-coded wires for easy identification.

$13.00 each, plus shipping & handling. Universal Wiring Harness with Plastic Connector Housing

and Slide-On Connectors. Replace damaged entire connector, terminals

and wiring, use as new wiring harness on a custom-made project, or use this

part when converting from Breakerless Ignition to battery-powered

points/condenser ignition. Fits universal OFF-ON-START key switches listed

above and other key switches with same terminal configuration. Three terminals

in this part will also fit the OEM Cub Cadet garden tractor OFF-ON-START

key switch listed above. 18" length color-coded wires for easy identification.

$13.00 each, plus shipping & handling.

Electrical Plastic Connector Housing Only. Replace damaged connector housing when the brass slide-on spade crimp wire connectors (listed below) are in good condition. Fits universal OFF-ON-START key switches listed above and other key switches with same terminal configuration. Three slots in this part will also fit the OEM Cub Cadet garden tractor OFF-ON-START key switch listed above. Requires 1/4" width slide-on brass spade crimp wire connectors with locking tab/tang below. $8.00 each, plus shipping & handling.

|

|

Loop-Type Cable/Wire/Hose Clamps. Use to secure throttle or

choke cables, or for safe routing of electrical wire(s), battery cable, small

remote fuel primer hose or bundle of wires along frame. Each require a 3/16"

mounting screw. Loop-Type Cable/Wire/Hose Clamps. Use to secure throttle or

choke cables, or for safe routing of electrical wire(s), battery cable, small

remote fuel primer hose or bundle of wires along frame. Each require a 3/16"

mounting screw.

|

How to Fix a Briggs & Stratton Opposed Twin Cylinder Engine Starter Motor When the Gear Teeth Will Not Fully Engage in the Flywheel Ring Gear Teeth -

Information on the Kohler (Including Most Other Makes and Models of Small Engines) Charging Systems - [Top of Page]

First of all, the battery's only purpose in virtually any vehicle is to provide power to the starter motor to crank the engine and power electrical accessories when the engine isn't running. When the engine is running, and while the battery is being recharged, the alternator/stator or generator then powers the electrical accessories through the electronic/solid state voltage rectifier/regulator. With the engine running, and with a good working charging system, the battery has nothing to do with powering the electrical accessories. The ignition system also have nothing to do with the charging system. It's only purpose is to provide spark to the engine. The charging system and ignition system are two totally separate systems. One has nothing to do with the other, other than the charging system provides power to the battery-powered ignition system. A magneto or electronic/solid state ignition is a stand-alone system. It does not depend on the battery or charging system whatsoever.

The Generator/Starter Charging System -

The voltage-producing

generating part of a starter/generator (or just the generator unit in an

older automobile or heavy equipment machinery) produces DC (direct current)

electricity. These are belt-driven and require a mechanical voltage regulator

to regulate the charge to the battery and power electrical accessories (such

as lights, electric PTO clutch, etc.) at the same time. The faster the engine

runs, the more voltage and amperage the generator produces. And unlike a

belt-driven automotive-type alternator, the generator is self-energizing.

It will produce its own electricity when spun fast enough. A charged battery

is not required.

The voltage-producing

generating part of a starter/generator (or just the generator unit in an

older automobile or heavy equipment machinery) produces DC (direct current)

electricity. These are belt-driven and require a mechanical voltage regulator

to regulate the charge to the battery and power electrical accessories (such

as lights, electric PTO clutch, etc.) at the same time. The faster the engine

runs, the more voltage and amperage the generator produces. And unlike a

belt-driven automotive-type alternator, the generator is self-energizing.

It will produce its own electricity when spun fast enough. A charged battery

is not required.

Although bulky, heavy and uses more space next to the engine, this system is reliable, but produce little- to no-charge at low idle speeds and are considered obsolete by today's standards. Also, this system require more horsepower from the engine than the alternator/stator system while recharging the battery and/or under a heavy electrical load.

I don't rebuild starter/generators. A business that specializes in rebuilding automotive starters, alternators and generators can also rebuild starter/generators. Or, you can purchase a new or used starter/generator off of eBay.

On certain starter/generators and for identification purposes only, the "A" (Armature) terminal may be bigger (#12) than the "F" (Field) terminal (#10). IMPORTANT - If the wires for the Armature and Field are connected to the wrong terminals on the starter/generator (reversed connection), the field windings inside will burn up instantly (lots of smoke) upon engine start up! Anyway, the correct wiring connections for the starter/generator is as follows...

Two wires connects to the "A"

terminal on the starter/generator:

Two wires connects to the "A"

terminal on the starter/generator:

A starter/generator can be adapted to virtually any horizontal shaft or vertical shaft small engine with a fabricated mounting bracket and a slotted adjusting brace to tighten the belt. The starter/generator will need to be installed opposite the carburetor side of the block. They come in two rotations: clockwise and counter-clockwise. Starter/generators that spin clockwise came on older Wheel Horse, Sears Suburban, Bolens, or any engine that's started from the flywheel end. A counter-clockwise starter/generator came mostly on older Cub Cadets, or any engine that's started from the PTO end. A clockwise rotation starter/generator will need to be used if it's driven from the flywheel end. But if it's driven from the PTO end, it will need to be a counter-clockwise rotation starter/generator. If the wrong starter/generator is used, it'll crank the engine opposite of normal rotation, and not recharge the battery.

If a starter/generator is belt-driven by an engine and used only as a generator to charge up a vehicle's battery and/or power 12 volt appliances or lights, the heavy battery cable won't need to be used. And there's about a 3:1 ratio between the starter/generator and engine. This means the starter/generator spins about 3 times faster than the engine. So the pulley on the engine will need to be about 3 times bigger than the pulley on the starter/generator to adequately recharge a battery and/or power 12 volt electrical appliances or lights. A starter/generator require a minimum 7/16hp engine running at a governed 3,600 RPM for it to produce a regulated 15 amps @ 13.5 volts. (15 amps x 13.5 volts = 202.5 watts x 2 = 405 = .4hp engine.) Read on the back label of the appliance you plan to use for how many amps it draws, then you'll know if the generator will be able to handle the load.

But on a pulling tractor, if the engine isn't going to have a charging system, a voltage regulator and wiring isn't required as long as the battery is fully charged with a battery charger before the engine is ran again. Plus, the battery will need to be in a secure place, and route the wiring in a safe manner. Go here to learn how to repair a Delco-Remy starter/generator: Delco-Remy SG Repair.pdf. (require Adobe Acrobat Reader and use Google Chrome web browser for a faster download of web sites with large files.)

The Small Engine Alternator/Stator Charging Systems -

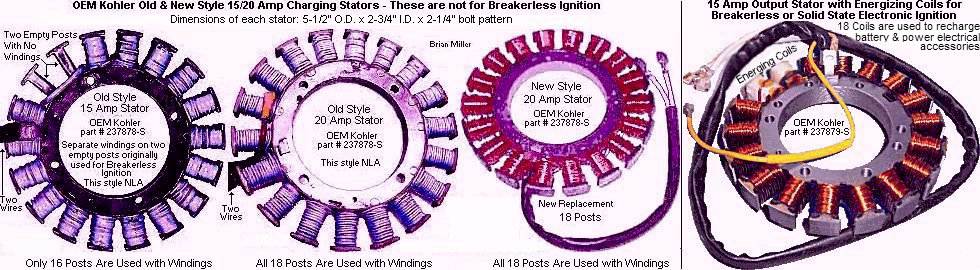

Kohler used six different models of stators on their engines. They are rated at 1.25 amp, which is used only to charge the battery; 3 amp, which is used to charge the battery and supply power for lights and/or an electric PTO clutch; and the 10, 15, 25 and 30 amp output stators, which are used to charge the battery and power heavier electrical loads. And all electric PTO clutches draw 3 amps of power, so the 3 amp output stator is required for these.

The 1.25 and 3 amp stators doesn't

require an electronic/solid state voltage rectifier/regulator to regulate

the power to recharge the battery because for normal use, an average lawn

and garden engine don't run long enough for the 1.25 and 3 amp stators to

over-charge the battery, or over-power (burn out) the lights and/or an electric

PTO clutch. Instead, these use a rectifier diode to convert alternating current

(AC) to direct current (DC). The low 1.25 and 3 amp output stators require

a rectifier diode to convert the electrical Alternating

Current (AC) to Direct Current (DC) only to recharge the battery.

Filament lights and electric PTO clutches don't require direct current, so

they can operate without a diode.

The 1.25 and 3 amp stators doesn't

require an electronic/solid state voltage rectifier/regulator to regulate

the power to recharge the battery because for normal use, an average lawn

and garden engine don't run long enough for the 1.25 and 3 amp stators to

over-charge the battery, or over-power (burn out) the lights and/or an electric

PTO clutch. Instead, these use a rectifier diode to convert alternating current

(AC) to direct current (DC). The low 1.25 and 3 amp output stators require

a rectifier diode to convert the electrical Alternating

Current (AC) to Direct Current (DC) only to recharge the battery.

Filament lights and electric PTO clutches don't require direct current, so

they can operate without a diode.

Troubleshooting a 3 Amp Battery Charging System with the 70 Watt Lighting/Electric PTO Clutch Stator -

Certain Kohler engines with the 1.25 or 3 amp stator use a diode and not a voltage rectifier/regulator. To find out why one of these charging systems isn't generating any power, remove the flywheel and see if any of the magnets inside the flywheel are cracked, loose or missing. Next, check to see if the windings on the stator are burned up or damaged. If they are not burned up or damaged, then they should be in good condition. But to make sure, use a multimeter set on the Ohms resistance, connect the black wire on the meter to engine ground. and connect the red wire on the meter to the BLACK wire coming from the stator, then connect the YELLOW wire. If the meter shows continuity for either wire, then the windings are in good condition. But if there's no continuity, then there's a break (open circuit) in either windings to ground . The windings either needs to be repaired or the stator needs to be replaced. If all of this looks good, and either charging system still will not generate a charge to the battery, then chances are, the diode was overloaded and got burned up, and needs replacing. The diode is part of the BLACK wire coming from the stator, and there should be a "lump" in the BLACK wire. This is where the diode is located. It's probably covered with the plastic sheath and/or heat shrinkable tubing. You can replace it with a 3 amp/12 volt diode. Be sure to install the diode with the silver stripe toward the stator.

But the high-output stators (10, 15, 25, 30 amp or more), rather it's a charging stator under the flywheel on a small engine or belt-driven automotive-type alternator, require an electronic/solid state voltage "rectifier/regulator" to convert the alternating current (AC) to direct current (DC) and to regulate the amount of charge into the battery and limit the amount of voltage throughout the entire electrical system while powering electrical accessories at the same time. The faster the engine runs, the more voltage and amperage the stator produces.

Although very reliable, weather-proof and virtually maintenance-free, this system produces an adequate charge at low idle speeds.

This system is the standard of today's charging systems used on virtually all small engines, motorcycles, snowmobiles, automotive engines, heavy equipment machinery, etc.

And unlike the belt-driven automotive-type alternator, an alternator/stator under the flywheel is self-energizing. It will produce electricity when the flywheel is spun fast enough.

How to Identify the Three Wires Coming from an Engine -

Use a digital or analog multimeter set on the ohms (d) resistance to test each wire coming from the engine. With the engine not running, ground one test lead to the engine, and connect the other lead to each wire one at a time. If one wire shows resistance, this is the ignition kill wire. If the engine has points, the crankshaft may need to be rotated by hand until the wire shows resistance. (This is when the points close.) And if the other two wires show no resistance, these are the charging stator lead wires. When the test leads are connected to the two wires with no resistance, they should show 100% resistance. These two wires connect to the voltage regulator/rectifier. Be sure to mark each wire with masking tape or something to identify them.

How to Test the Condition of a Small Engine Alternator Charging Stator - [Top of Page]

First of all, all charging stators produce alternating current (AC) voltage and there's a diode built into the electronic/solid state voltage rectifier/regulator. (Rectifier = converts alternating current (AC) to direct current (DC); Regulator = regulates voltage to recharge the battery and limits power to electrical accessories, such as lights, electric PTO clutch, etc.) If the diode is shorted, it'll drain the battery and may burn up the stator windings. The wire windings on the stator are not grounded, they're isolated from the engine block. And debris/dirt on the stator or on the magnets in the flywheel do not weaken the magnetism to the stator whatsoever. Stators rarely become defective, unless the two wires are connected to each other while the engine is running, causing a short.

To test the condition of a stator with the engine not running, or with the stator removed from the engine (check to see of there's any wire windings on the stator that's damaged or broken from being mishandled), use an analog or digital multimeter set on ohms (d) resistance. Disconnect the two wires from the voltage rectifier/regulator, connect one stator wire to one test lead and connect the other test lead to the metal frame of the stator or engine block (installed stator). Notice the reading, and then do the same for the other stator wire. The meter should show no resistance with either wire. Then connect the two wires on the stator to the test leads on the meter. If the meter shows full resistance, the stator is likely in good condition. This testing procedure applies to all makes and models of small engines, including motorcycles and snowmobiles, foreign or domestic, with the charging stator located under the flywheel.

To test the voltage output of a stator with the engine running, use an analog or digital multimeter set at more than 36 volts in the AC setting. With the engine running at full governed speed set at 3,600 RPM, for a (4-5/8" O.D.) 10 amp stator, the reading should be in the range of 20 volts. For a (5-1/2" O.D.) 15 amp stator, the reading should be in the range of 28 volts. For a (5-1/2" O.D.) 20 amp stator, the reading should be in the range of 36 volts. If it's less than 20, 28 or 36 volts (according to the amperage of the stator), the stator may be defective and should either be repaired (if possible) or replaced. Or maybe a ceramic magnet inside the flywheel is cracked, or on a rare occasion, magnet(s) may be missing (wrong type of flywheel installed on the engine). A magnet with a chip should work fine, as long as it's not cracked or broken in two. Anyway, when testing the voltage output of a stator, if the reading is more than 20, 28 or 36 volts, the windings may be shorted (making contact with each other), resulting in the excessive increase of voltage, which would likely cause the voltage rectifier/regulator go bad, and possibly also burn up the acid in the battery, primary windings in the ignition coil and/or overpower electrical accessories. This test procedure applies to all makes and models of small engines, gas or diesel, including motorcycles and snowmobiles, foreign or domestic, with the charging stator located under the flywheel.

Do not touch the

two wire terminals or the energizing coils wire on the stator with your bare

hands while the engine is running! Electrical shock or electrocution could

result!

Do not touch the

two wire terminals or the energizing coils wire on the stator with your bare

hands while the engine is running! Electrical shock or electrocution could

result!

How to Test an Electronic/Solid State Voltage Rectifier/Regulator -

The easiest and most accurate way to test an electronic/solid state voltage rectifier/regulator is with an analog or digital multimeter set in the DC setting above 12 volts, and with a known good charging stator installed in an engine while the engine is running. With the engine off, connect the stator's two wires to the rectifier/regulator's two outer terminals (being it's AC, it doesn't matter which wire connects to which terminal). With the engine running at 3,200 RPM (when the engine has a fixed/non-adjustable main jet carburetor) or 3,600 RPM (when the engine has an adjustable main jet carburetor), check the voltage output at the center terminal on the rectifier/regulator. If the voltmeter displays or reads 14.5 volts, the rectifier/regulator is good. If less than 14.5 volts or no voltage, the rectifier/regulator is defective. By the way - the older rectifier/regulator with fins works the same as the newer ones with no fins. Also, the small size voltage rectifier/regulator is to be mounted in the opening of the flywheel shroud of a Kohler AQS (Quiet Line) engine so cool incoming air from the flywheel will keep the regulator unit from overheating while in operation. If it's mounted elsewhere with no cool air blowing over it, it could burn up prematurely.

Make sure the slip-on spade crimp connectors on the stator's wires are in good condition and fit snug on the terminals of the electronic/solid state voltage rectifier/regulator. If the scrimp connectors fit loose or have a faulty connection due to rust, they could arc during heavy charging and burn out the terminal(s) on the voltage rectifier/regulator, and/or heat from the arcing could travel inside the voltage rectifier/regulator and burn it out.

Go here for more information:

The rectifier-regulator must match

the amperage output of the stator it's connected to. If a 15 amp

rectifier/regulator is used with a 25 or 30 amp stator, the rectifier/regulator

will burn up. A 32 amp electronic/solid state voltage rectifier/regulator

that's designed for Harley-Davidson motorcycles will work with the Kohler

30 amp stator. The starter/generators and voltage regulators used on all

garden tractors are rated at 15 amps. And an analog voltage regulator can't

be used with an AC alternator stator, nor the electronic voltage

rectifier/regulator can't be used with a DC generator.

The rectifier-regulator must match

the amperage output of the stator it's connected to. If a 15 amp

rectifier/regulator is used with a 25 or 30 amp stator, the rectifier/regulator

will burn up. A 32 amp electronic/solid state voltage rectifier/regulator

that's designed for Harley-Davidson motorcycles will work with the Kohler

30 amp stator. The starter/generators and voltage regulators used on all

garden tractors are rated at 15 amps. And an analog voltage regulator can't

be used with an AC alternator stator, nor the electronic voltage

rectifier/regulator can't be used with a DC generator.