A-1 Miller's Performance Enterprises

Professional Automotive Services Available in Central Missouri!

Professional Automotive Air Conditioning (A/C)

Services (Posted 7/5/24.) [Top of Page]

-

Vacuum and recharge automotive

a/c system: $50.00 - $100.00 labor only, depending on year, make,

model and size of vehicle. Extra charge for compressor lubricating oil and

refrigerant (Freon).

Vacuum and recharge automotive

a/c system: $50.00 - $100.00 labor only, depending on year, make,

model and size of vehicle. Extra charge for compressor lubricating oil and

refrigerant (Freon).

-

Repair leaking automotive a/c system: $150.00 - $500.00 labor only,

depending on year, make, model and size of vehicle. Extra charge for installation

of new parts.

-

Prices are subject to change without notice. And remember - Perfection takes

time. If it's worth having, it's worth waiting for. It'll be money well spent.

If interested, please contact below.

Professional Old School Automotive Services

- (Posted 6/28/24.) [Top of Page]

A-1 Miller's Performance Enterprises now offers complete old school automotive

rebuilding and modifications, and car and truck repairs, modifications and

building of custom-made hot rods, street rods, motorcycle repairs. Chevrolet,

GMC, Chrysler, Ford, Harley-Davidson, etc. Prices vary depending on make,

model and year of engine, and which modifications are needed. Prices are

subject to change without notice. And remember - Perfection takes time. If

it's worth having, it's worth waiting for. It'll be money well spent.

If interested, please contact below.

Competitively Built and Nice-Appearing Small Wheel

(26-12.00x12 tires) Mini Rod Pulling Tractors (Posted 3/7/25.)

[Top of Page]

A-1 Miller's Performance

Enterprises now offers construction of competitive small wheel (26-12.00x12

tires) mini rod pulling tractors.

A-1 Miller's Performance

Enterprises now offers construction of competitive small wheel (26-12.00x12

tires) mini rod pulling tractors.

Small wheel mini rod with 229 or 4.3 Chevy V6 engine (built to the max),

manual transmission and 8" or 9" Ford rear end. (As shown.) $15.000.

But price and details may vary depending on clubs' rules and customer's

preferences.

Prices are subject to change without notice. And remember - Perfection takes

time. If it's worth having, it's worth waiting for. It'll be money well spent.

If interested, please contact below.

Available Soon - Detailed Illustrated Plans on How

to Construct a Professional Pull-Back Garden Tractor Pulling Sled and a

Self-Propelled Garden Tractor/Small Wheel Mini Rod Pulling Sled (Weight Transfer

Machines) - (Updated 7/16/24) [Top of Page]

FYI - I'm getting closer to

completing my sled plans. But being I have lots of work to do in my shop,

I work on designing my sled plans in my spare time. As soon as my plans with

an inventory list of parts to use and with illustrations are perfected, I'll

post the announcement in my websites. And as for prices of the pull-back

sled and self-propelled sled plans, I'm not sure yet. Make me an offer and

I'll consider it. And remember - Perfection takes time. If it's worth having,

it's worth waiting for. It'll be money well spent. Contact

information below.

FYI - I'm getting closer to

completing my sled plans. But being I have lots of work to do in my shop,

I work on designing my sled plans in my spare time. As soon as my plans with

an inventory list of parts to use and with illustrations are perfected, I'll

post the announcement in my websites. And as for prices of the pull-back

sled and self-propelled sled plans, I'm not sure yet. Make me an offer and

I'll consider it. And remember - Perfection takes time. If it's worth having,

it's worth waiting for. It'll be money well spent. Contact

information below.

Quality-Built and Nice-Appearing Garden Tractor &

Mini Rod Self-Propelled Tractor Pulling Sleds (Weight Transfer Machines)

For Sale - (Updated 8/17/24) [Top of Page]

Sleds will be built as orders are placed. A minimum 50% deposit

is required for all sled purchases. Buyer/purchaser can test sled with their

pulling tractors or vehicles on our 200 ft. dirt track, and then can tow

it on the road (like a trailer) or haul it on a large, sturdy trailer. Sleds

are designed with style and made beautiful to admire, and painted metallic

or color of your choice. Also, sleds are designed to start easy, pull smoothly

and sure to stop with grouser bar. They will also have a safety release lever

up front so when the weight box tops out and trips it, it will automatically

disengage the clutch to prevent major damage to the drive mechanism for the

weight box. And it will have another safety release lever at the rear in

case the clutch (for the weight box) is engaged when backing up the sled.

The self-propelled sleds will have a variable speed mechanical drive system

with hydraulics to lower the two front steering wheels/tires, and the bigger

sled will use hydraulics to bring the weight box back to its starting position.

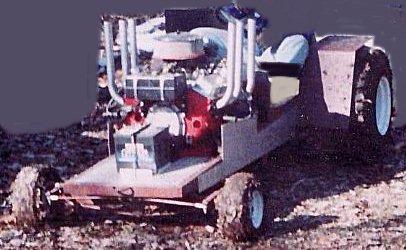

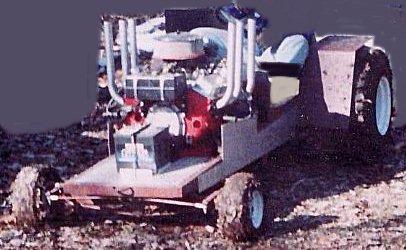

By the way - the self-propelled garden tractor pulling sled that I built

in 1995 (and sold in 2021) is such an excellent design, I realized later

that I made something very special when other people copied it. It's still

in use today; click or tap photo of it to the right for a larger view.

Sleds will be built as orders are placed. A minimum 50% deposit

is required for all sled purchases. Buyer/purchaser can test sled with their

pulling tractors or vehicles on our 200 ft. dirt track, and then can tow

it on the road (like a trailer) or haul it on a large, sturdy trailer. Sleds

are designed with style and made beautiful to admire, and painted metallic

or color of your choice. Also, sleds are designed to start easy, pull smoothly

and sure to stop with grouser bar. They will also have a safety release lever

up front so when the weight box tops out and trips it, it will automatically

disengage the clutch to prevent major damage to the drive mechanism for the

weight box. And it will have another safety release lever at the rear in

case the clutch (for the weight box) is engaged when backing up the sled.

The self-propelled sleds will have a variable speed mechanical drive system

with hydraulics to lower the two front steering wheels/tires, and the bigger

sled will use hydraulics to bring the weight box back to its starting position.

By the way - the self-propelled garden tractor pulling sled that I built

in 1995 (and sold in 2021) is such an excellent design, I realized later

that I made something very special when other people copied it. It's still

in use today; click or tap photo of it to the right for a larger view.

-

Small size, pull-back

(non-motorized) sled with open cabin and cooling fan, comfortable swivel

seat and controls within easy reach for operator. For use with 1,050 lb.

garden pulling tractors and up to 1,500 lb. small wheel (26-12.00x12 tires)

mini rod pulling tractors. Length of sled: 12 ft. Total weight of sled fully

loaded with weights: approximately 4,000 lb. $6,000.00 each.

Small size, pull-back

(non-motorized) sled with open cabin and cooling fan, comfortable swivel

seat and controls within easy reach for operator. For use with 1,050 lb.

garden pulling tractors and up to 1,500 lb. small wheel (26-12.00x12 tires)

mini rod pulling tractors. Length of sled: 12 ft. Total weight of sled fully

loaded with weights: approximately 4,000 lb. $6,000.00 each.

-

Small size, self-propelled (motorized) sled with open cabin and cooling fan,

windshield, comfortable swivel seat for operator comfort and controls within

easy reach for operator. Twin cylinder air-cooled small engine and transmission

will be positioned forward in sled with weight box drive transmission and

clutch system positioned rearward of sled. For use with 1,050 lb. garden

pulling tractors and up to 1,500 lb. small wheel (26-12.00x12 tires) mini

rod pulling tractors. Length of sled: 16 ft. Total weight of sled fully loaded

with weights: approximately 7,000 lb. $25,000.00 each.

-

Medium size, self-propelled (motorized) sled with enclosed air-conditioned

operator's cabin, comfortable swivel seat for operator comfort and controls

within easy reach for operator. Automotive engine (Chevy V8 with glasspack

mufflers) and transmissions will be positioned forward in sled with weight

box drive transmission and clutch system positioned rearward of sled. For

use with mini trucks, big wheel mini rods and antique/classic tractors. Length

of sled: 25 ft. Total weight of sled fully loaded with weights: approximately

18,000 lb. $250,000.00 each.

-

Prices are subject to change without notice. And remember - Perfection takes

time. If it's worth having, it's worth waiting for. It'll be money well spent.

If interested, please contact below.

Complete Narrowed Automotive Rear End/Differential

for Use in Garden Tractor Pulling Sled - [Top of

Page]

Details Include -

Details Include -

-

When connected to an automotive 3- or 4-speed manual transmission, this narrowed

rear end controls the movement of the weight box in a garden tractor pulling

sled (weight transfer machine).

-

Non-Posi-Trac automotive rear end with a low geared ring and pinion gear

ratio.

-

Professionally narrow axle housings and axle shafts as short as possible.

-

Install a minimal tooth count sprocket for a #50 or #60 roller chain on right

axle (when facing center yoke) and reinstall brake drum assembly on left

axle (to act as the engagement/disengagement clutch for weight box) with

a long emergency/parking brake cable.

-

All rear ends will be narrowed as orders are placed. A minimum of 50% deposit

is required on all narrowed rear end purchases.

-

Complete Narrowed Automotive Rear End Assembly: $1,000.00 each, plus

shipping and handling.

-

Prices are subject to change without notice. And remember - Perfection takes

time. If it's worth having, it's worth waiting for. It'll be money well spent.

If interested, please contact below.

To place an order, send your item(s) for repairing, and/or

for customer service assistance, and FREE honest and accurate technical

support, please contact: A-1 Miller's Performance Enterprises, 12091

N Route B, Hallsville, MO (Missouri) 65255-9604 USA. Please call in your

order or send an email with a list parts you need and your contact information.

To place an order, send your item(s) for repairing, and/or

for customer service assistance, and FREE honest and accurate technical

support, please contact: A-1 Miller's Performance Enterprises, 12091

N Route B, Hallsville, MO (Missouri) 65255-9604 USA. Please call in your

order or send an email with a list parts you need and your contact information.

Phone: 1-573-881-7229 (cell;

call, text or leave voicemail) or use

Whatsapp. Please call

Monday-Friday, 9am to 5pm, Central time zone, except holidays. If no answer,

please try again later.

Phone: 1-573-881-7229 (cell;

call, text or leave voicemail) or use

Whatsapp. Please call

Monday-Friday, 9am to 5pm, Central time zone, except holidays. If no answer,

please try again later.  E-mail:

pullingtractor@aol.com.

Payment Options. A-1 Miller's shop is open

to the public Monday-Friday, 9am to 5pm, Central time zone, with an appointment

on weekends, except holidays. If you're the kind of person who don't trust

delivery/shipping companies (mis)handling your high-dollar and fragile

merchandise, you can make the long drive to A-1 Miller's new shop (click

image to the right) to personally purchase parts, or drop off and/or pick

up your carburetor, clutch assembly, engine and/or parts, etc., for repairing

and/or rebuilding. Or visit the address of our (old) shop mentioned above

to drop off your engine, transmission, transaxle, garden tractor, small motorized

vehicle, etc. We also custom build pulling tractors and other small vehicles.

Please contact me before coming so I'll be at my shop waiting for your arrival.

When you visit our shop, you will be dealing directly with the owner for

the best customer service. "The road to a [trusted] friend's house (or

shop) is never long." Don't sacrifice quality workmanship for distance.

Photos

of our new building/shop are posted here!

12091 N Route B, Hallsville, MO - Google Maps.

[Return To Previous Paragraph, Section

or Website]

E-mail:

pullingtractor@aol.com.

Payment Options. A-1 Miller's shop is open

to the public Monday-Friday, 9am to 5pm, Central time zone, with an appointment

on weekends, except holidays. If you're the kind of person who don't trust

delivery/shipping companies (mis)handling your high-dollar and fragile

merchandise, you can make the long drive to A-1 Miller's new shop (click

image to the right) to personally purchase parts, or drop off and/or pick

up your carburetor, clutch assembly, engine and/or parts, etc., for repairing

and/or rebuilding. Or visit the address of our (old) shop mentioned above

to drop off your engine, transmission, transaxle, garden tractor, small motorized

vehicle, etc. We also custom build pulling tractors and other small vehicles.

Please contact me before coming so I'll be at my shop waiting for your arrival.

When you visit our shop, you will be dealing directly with the owner for

the best customer service. "The road to a [trusted] friend's house (or

shop) is never long." Don't sacrifice quality workmanship for distance.

Photos

of our new building/shop are posted here!

12091 N Route B, Hallsville, MO - Google Maps.

[Return To Previous Paragraph, Section

or Website]

Return To Previous Website | Top

of Page

Copyright © 1996-Present. This website created, designed and

maintained by A-1 Miller's Performance Enterprises

Vacuum and recharge automotive

a/c system: $50.00 - $100.00 labor only, depending on year, make,

model and size of vehicle. Extra charge for compressor lubricating oil and

refrigerant (Freon).

Vacuum and recharge automotive

a/c system: $50.00 - $100.00 labor only, depending on year, make,

model and size of vehicle. Extra charge for compressor lubricating oil and

refrigerant (Freon).

A-1 Miller's Performance

Enterprises now offers construction of competitive small wheel (26-12.00x12

tires) mini rod pulling tractors.

A-1 Miller's Performance

Enterprises now offers construction of competitive small wheel (26-12.00x12

tires) mini rod pulling tractors.

FYI - I'm getting closer to

completing my sled plans. But being I have lots of work to do in my shop,

I work on designing my sled plans in my spare time. As soon as my plans with

an inventory list of parts to use and with illustrations are perfected, I'll

post the announcement in my websites. And as for prices of the pull-back

sled and self-propelled sled plans, I'm not sure yet. Make me an offer and

I'll consider it. And remember - Perfection takes time. If it's worth having,

it's worth waiting for. It'll be money well spent.

FYI - I'm getting closer to

completing my sled plans. But being I have lots of work to do in my shop,

I work on designing my sled plans in my spare time. As soon as my plans with

an inventory list of parts to use and with illustrations are perfected, I'll

post the announcement in my websites. And as for prices of the pull-back

sled and self-propelled sled plans, I'm not sure yet. Make me an offer and

I'll consider it. And remember - Perfection takes time. If it's worth having,

it's worth waiting for. It'll be money well spent.

Sleds will be built as orders are placed. A minimum 50% deposit

is required for all sled purchases. Buyer/purchaser can test sled with their

pulling tractors or vehicles on our 200 ft. dirt track, and then can tow

it on the road (like a trailer) or haul it on a large, sturdy trailer. Sleds

are designed with style and made beautiful to admire, and painted metallic

or color of your choice. Also, sleds are designed to start easy, pull smoothly

and sure to stop with grouser bar. They will also have a safety release lever

up front so when the weight box tops out and trips it, it will automatically

disengage the clutch to prevent major damage to the drive mechanism for the

weight box. And it will have another safety release lever at the rear in

case the clutch (for the weight box) is engaged when backing up the sled.

The self-propelled sleds will have a variable speed mechanical drive system

with hydraulics to lower the two front steering wheels/tires, and the bigger

sled will use hydraulics to bring the weight box back to its starting position.

By the way - the self-propelled garden tractor pulling sled that I built

in 1995 (and sold in 2021) is such an excellent design, I realized later

that I made something very special when other people copied it. It's still

in use today; click or tap photo of it to the right for a larger view.

Sleds will be built as orders are placed. A minimum 50% deposit

is required for all sled purchases. Buyer/purchaser can test sled with their

pulling tractors or vehicles on our 200 ft. dirt track, and then can tow

it on the road (like a trailer) or haul it on a large, sturdy trailer. Sleds

are designed with style and made beautiful to admire, and painted metallic

or color of your choice. Also, sleds are designed to start easy, pull smoothly

and sure to stop with grouser bar. They will also have a safety release lever

up front so when the weight box tops out and trips it, it will automatically

disengage the clutch to prevent major damage to the drive mechanism for the

weight box. And it will have another safety release lever at the rear in

case the clutch (for the weight box) is engaged when backing up the sled.

The self-propelled sleds will have a variable speed mechanical drive system

with hydraulics to lower the two front steering wheels/tires, and the bigger

sled will use hydraulics to bring the weight box back to its starting position.

By the way - the self-propelled garden tractor pulling sled that I built

in 1995 (and sold in 2021) is such an excellent design, I realized later

that I made something very special when other people copied it. It's still

in use today; click or tap photo of it to the right for a larger view.

Small size, pull-back

(non-motorized) sled with open cabin and cooling fan, comfortable swivel

seat and controls within easy reach for operator. For use with 1,050 lb.

garden pulling tractors and up to 1,500 lb. small wheel (26-12.00x12 tires)

mini rod pulling tractors. Length of sled: 12 ft. Total weight of sled fully

loaded with weights: approximately 4,000 lb. $6,000.00 each.

Small size, pull-back

(non-motorized) sled with open cabin and cooling fan, comfortable swivel

seat and controls within easy reach for operator. For use with 1,050 lb.

garden pulling tractors and up to 1,500 lb. small wheel (26-12.00x12 tires)

mini rod pulling tractors. Length of sled: 12 ft. Total weight of sled fully

loaded with weights: approximately 4,000 lb. $6,000.00 each.

Details Include -

Details Include -

Phone: 1-573-881-7229 (cell;

call, text or leave voicemail) or use

Phone: 1-573-881-7229 (cell;

call, text or leave voicemail) or use

E-mail:

E-mail: