Information

About Carter, Kohler and Walbro Carburetors used on Kohler K-series and Magnum

Engines, and Various Fuel Systems

Information

About Carter, Kohler and Walbro Carburetors used on Kohler K-series and Magnum

Engines, and Various Fuel Systems

Information

About Carter, Kohler and Walbro Carburetors used on Kohler K-series and Magnum

Engines, and Various Fuel Systems

Information

About Carter, Kohler and Walbro Carburetors used on Kohler K-series and Magnum

Engines, and Various Fuel Systems

Educating and Inspiring Small Engine, Lawn & Garden, and Garden

Pulling Tractor Enthusiasts Since 1996. Where Science and Common Sense Come

Together for Safety and Improved Engine/Tractor Performance |

A-1

Miller's Performance Enterprises - Parts & Services

Webstore |  Available Soon - Detailed Illustrated Plans

on How to Construct a Professional Pull-Back and Self-Propelled Garden

Tractor/Small Wheel Mini Rod Pulling Sleds

Available Soon - Detailed Illustrated Plans

on How to Construct a Professional Pull-Back and Self-Propelled Garden

Tractor/Small Wheel Mini Rod Pulling Sleds

Nowadays, prices are subject to change without notice. Click

Refresh to see any

changes or updates. Optimized for 1152 x 864 computer screen resolution.

To search for a word or phrase in any of my websites, press the CTRL

and F

and F  keys on

your keyboard simultaneously to open the Find or Search dialog box in your

web browser. And being I have no

apprentice to update and pay for my websites so they'll

continue to be on the Internet, they will be removed forever when I'm no

longer around. Scroll down this website or click/tap the links below to

jump down to...

keys on

your keyboard simultaneously to open the Find or Search dialog box in your

web browser. And being I have no

apprentice to update and pay for my websites so they'll

continue to be on the Internet, they will be removed forever when I'm no

longer around. Scroll down this website or click/tap the links below to

jump down to...

There's a cheater in every sport, and competition garden

tractor pulling is no different. Honest pullers who ignore the cheater(s)

are fools. And when there's prize money involved, a fool and their money

are soon parted. Anyway, to make competition pulling a fun, fair and enjoyable

sport and experience for the entire family, be protective of your equipment!

While at the pulls, keep an eye on your carburetor and

fuel shut-off valve! When a competitive or winning

pulling tractor is left alone, it's been known that certain disgruntled pullers

(sore losers

There's a cheater in every sport, and competition garden

tractor pulling is no different. Honest pullers who ignore the cheater(s)

are fools. And when there's prize money involved, a fool and their money

are soon parted. Anyway, to make competition pulling a fun, fair and enjoyable

sport and experience for the entire family, be protective of your equipment!

While at the pulls, keep an eye on your carburetor and

fuel shut-off valve! When a competitive or winning

pulling tractor is left alone, it's been known that certain disgruntled pullers

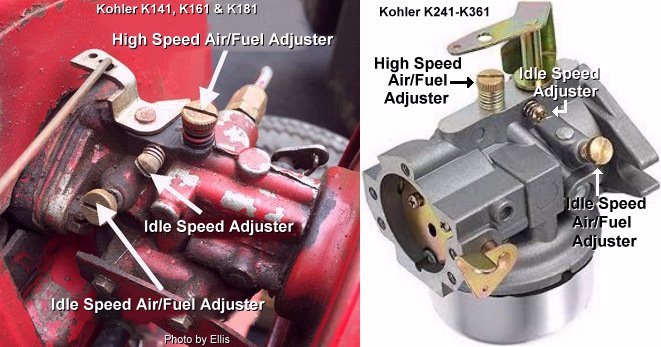

(sore losers  ) belonging

to various associations/clubs, virtually anywhere and everywhere, will turn

the high speed air/fuel adjuster one way or the other, or close the

fuel shut-off valve to keep the engine from

running at it's full potential, or from running at all. This is one of the

easiest, dishonest and sneaky ways to retard or disable and sabotage a

competitor's tractor. All a cheater needs is an opportunity in an attempt

to gain an advantage on the track. This is also the fastest way for a pulling

association or club to gain a bad reputation and lose honest pullers. (Bad

news travels fast.) This type of dishonest behavior doesn't happen often,

but you need to be prepared if or when it does happen. To be prepared for

this unforeseeable event, it'll be a good idea to cover the entire carburetor

with a

drawstring bag, or better yet, cover the entire tractor

with a canvas or heavy blanket and keep an eye on it.

Keep an eye on your

kill switch plug, too! Always try to stay one step ahead of a cheater.

Go here for more information:

Do some garden tractor pullers act like spoiled brats?

) belonging

to various associations/clubs, virtually anywhere and everywhere, will turn

the high speed air/fuel adjuster one way or the other, or close the

fuel shut-off valve to keep the engine from

running at it's full potential, or from running at all. This is one of the

easiest, dishonest and sneaky ways to retard or disable and sabotage a

competitor's tractor. All a cheater needs is an opportunity in an attempt

to gain an advantage on the track. This is also the fastest way for a pulling

association or club to gain a bad reputation and lose honest pullers. (Bad

news travels fast.) This type of dishonest behavior doesn't happen often,

but you need to be prepared if or when it does happen. To be prepared for

this unforeseeable event, it'll be a good idea to cover the entire carburetor

with a

drawstring bag, or better yet, cover the entire tractor

with a canvas or heavy blanket and keep an eye on it.

Keep an eye on your

kill switch plug, too! Always try to stay one step ahead of a cheater.

Go here for more information:

Do some garden tractor pullers act like spoiled brats?

YouTube video: Pulling Sled Exposed For Cheating? You Decide.. https://www.youtube.com/watch?v=7Jd5rEuaZZA

Advertisement: (Prices are subject to change without notice.)

| Click here to contact A-1 Miller's Performance

Enterprises to place an order, send your parts for repairing, and/or for

FREE professional and honest technical customer service assistance and support

and payment options. Please contact A-1 Miller's if you need a part or

parts, or service(s) performed that's not listed or mentioned in this

website.

How the Remote Fuel Primer System Works: The fuel primer bulb on a snowblower engine connects directly to the float bowl and takes place of the atmospheric vent hole in the float bowl. The bulb itself has a small atmospheric vent hole. When the bulb is compressed (small atmospheric vent hole sealed), this creates air pressure within the bulb, tubing and float bowl, which force fuel up through the main jet/nozzle (emulsion tube), creating a slight flooding condition in the throttle bore. Thus, helping a cold engine without a choke plate start much easier. With this system, the engine cannot be "over-choked," which could foul the spark plug. The fuel primer system can also be used as a manual accelerator pump when an engine hesitates to rev up on its own. With the original atmospheric vent opening (air passageway from inside the float bowl area to outside of carburetor) in the carburetor plugged, a short brass tube is inserted into a drilled hole in the float bowl area on the side of the carburetor body, and with a small fuel hose connecting the carburetor to the primer bulb assembly, which is mounted on the steering column support pedestal. How to Install and Use My Remote Fuel Primer System:

FYI - Most [cold] engines will not start when fuel is introduced directly into the combustion chamber through the spark plug hole. Doing this only results in a flooding condition and the engine may not start. Gas (or starting fluid) needs to be mixed with incoming air through the carburetor intake so the air can atomize the fuel (break down into a fine mist) to burn more thoroughly so the engine will be able to start quicker.

|

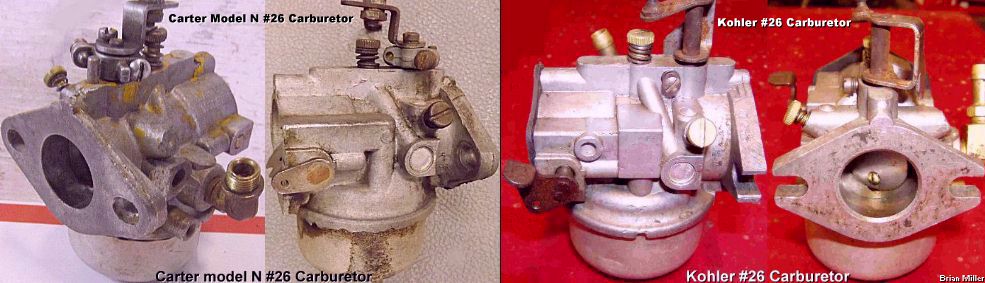

Identification of Carter and Kohler Carburetors -

(Corrected and updated 3/11/21) The types of carburetors that's used on Kohler engine models K90/K91, K141, K160/K161, KV161, L160/L161, L181, K181 and M8 are as follows:

The Carter

Model N #13 and #16 carburetors are designed specifically for Kohler

engine model K90 and K91 (which are the same engine), and certain low RPM

K141 engines. The throttle bore measures .810" diameter and the venturi is

.542" diameter. When used on a Kohler engine model K141, K160/K161, certain

KV161,

L160/L161, L181, K181 or M8, due to the smaller throttle

bore and restrictive venturi, and velocity or volume of air that's required,

the bigger engine may not produce full power at 3,600 RPM. (It'll be the

same as using a

restrictor plate, or a small 2-barrel carburetor versus

a big 4-barrel carburetor on an automotive engine.) This carburetor came

on various other makes and models of engines, too. It was a popular carburetor

for its time. Measure the throttle bore with a

dial or digital caliper, and measure the venturi with a

plug gauge, such as a deep-well socket or round tubing of the right outside

diameter. The original Kohler (originally Carter) part numbers for this

carburetor are: A-220100, A-220574, A-220745, A-220777, C-220777, E-220517,

F-220762, F-230501, D-220451, G-220517, 46 053 03-S. Being this carburetor

is no longer made in the USA; Kohler part # 46 853 01-S), its replacement

is the Walbro WHL #36 or the aftermarket Carter-replicated carburetor.

The Carter

Model N #13 and #16 carburetors are designed specifically for Kohler

engine model K90 and K91 (which are the same engine), and certain low RPM

K141 engines. The throttle bore measures .810" diameter and the venturi is

.542" diameter. When used on a Kohler engine model K141, K160/K161, certain

KV161,

L160/L161, L181, K181 or M8, due to the smaller throttle

bore and restrictive venturi, and velocity or volume of air that's required,

the bigger engine may not produce full power at 3,600 RPM. (It'll be the

same as using a

restrictor plate, or a small 2-barrel carburetor versus

a big 4-barrel carburetor on an automotive engine.) This carburetor came

on various other makes and models of engines, too. It was a popular carburetor

for its time. Measure the throttle bore with a

dial or digital caliper, and measure the venturi with a

plug gauge, such as a deep-well socket or round tubing of the right outside

diameter. The original Kohler (originally Carter) part numbers for this

carburetor are: A-220100, A-220574, A-220745, A-220777, C-220777, E-220517,

F-220762, F-230501, D-220451, G-220517, 46 053 03-S. Being this carburetor

is no longer made in the USA; Kohler part # 46 853 01-S), its replacement

is the Walbro WHL #36 or the aftermarket Carter-replicated carburetor.

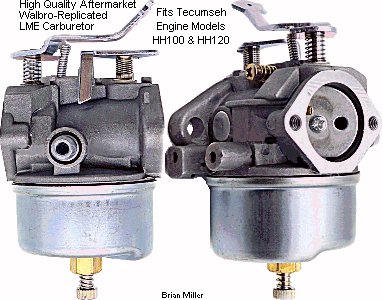

High Quality Aftermarket

Carter Model N-Replicated Carburetor. The throttle bore in this particular

carburetor measures .811" diameter and the venturi is .588" diameter. This

is an alternative universal low cost carburetor that can be used on Kohler

engine models

K181,

L181 or M8. Due

to the larger size of the venturi, this carburetor may not work correctly

on the Kohler models K90/K91, K141 or K160/K161 engines. Irrelevant Carter

or Kohler part number(s).

High Quality Aftermarket

Carter Model N-Replicated Carburetor. The throttle bore in this particular

carburetor measures .811" diameter and the venturi is .588" diameter. This

is an alternative universal low cost carburetor that can be used on Kohler

engine models

K181,

L181 or M8. Due

to the larger size of the venturi, this carburetor may not work correctly

on the Kohler models K90/K91, K141 or K160/K161 engines. Irrelevant Carter

or Kohler part number(s).

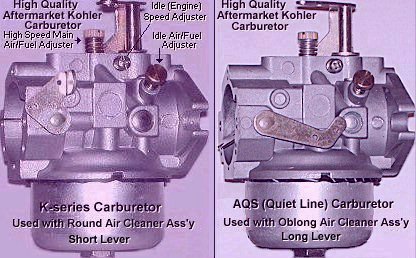

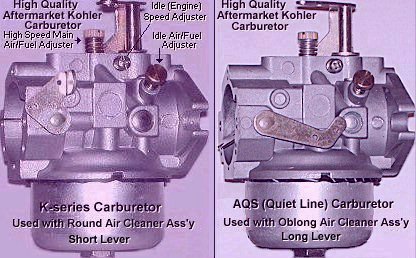

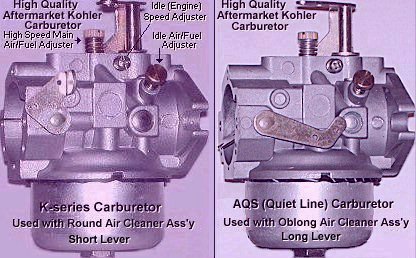

FYI - When Edelbrock bought out the automotive division of Carter Carburetor Corporation sometime before 1984, Carter sold their line of small engine carburetors to Kohler Engines in 1985. And for some reason, Kohler retained the Carter Model N wording on the #13, #16, #18, #20 and #22 carburetors. But on the bigger Carter #26 and #30 single cylinder engine carburetors, Kohler redesigned (and actually improved) the throttle shaft with an integrated lever; incorporated the idle speed adjustment screw w/spring in the carburetor body; redesigned the size of holes in the choke plates according to engine size; and made slots in the carburetor body for easier installation and removal on and off the engine. And Kohler included two additional air cleaner mounting screw holes for the Kohler AQS "Quiet Line" engine models K241-K361. Everything else remained the same on the Carter and Kohler carburetors, with the exception of various redesigned choke levers. Kohler didn't retain the Carter #28 carburetor because it's too similar to the #30 carburetor. But the #28 carburetor is available only in aftermarket. Although the #26 and #28 carburetors are available in aftermarket, for some reason, the #30 carburetor is not available in aftermarket. Six different variations of the Carter or Kohler carburetors was made for the Kohler K-series K241 through K361 engines, KT-series, and the K482, K532 and K582 engines. (NOTE: If it's rebuildable or repairable, please do not discard your Carter or Kohler carburetor or other OEM Kohler parts. Most discontinued Kohler parts are hard to find nowadays, and nothing works better than the original part(s) that came on the engine.)

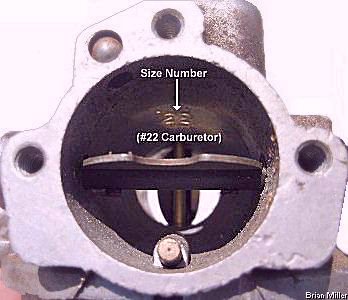

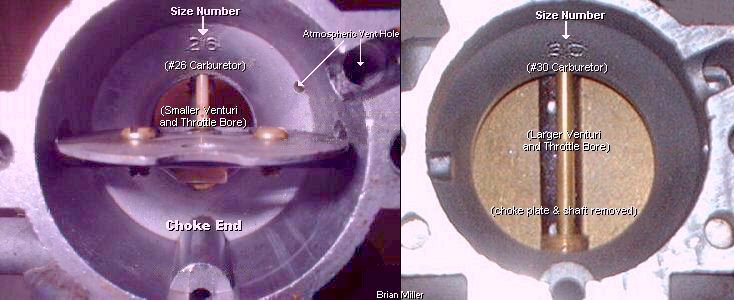

The size number (diameter of

throttle bore) for the Carter or Kohler carburetors is embossed inside the

upper part of the choke end, just above the venturi. But not all Kohler

carburetors have a number embossed. In this case, the throttle bore (throttle

plate area) will need to be measured to determine the exact size of the

carburetor. The size number refers to the amount of air that can flow through

the carburetor.

The size number (diameter of

throttle bore) for the Carter or Kohler carburetors is embossed inside the

upper part of the choke end, just above the venturi. But not all Kohler

carburetors have a number embossed. In this case, the throttle bore (throttle

plate area) will need to be measured to determine the exact size of the

carburetor. The size number refers to the amount of air that can flow through

the carburetor.

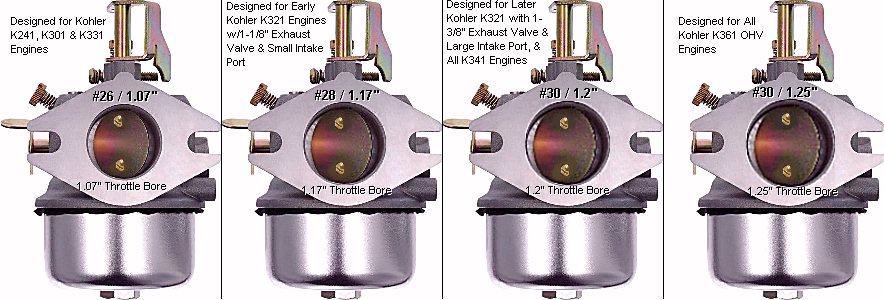

The carburetor with 26 embossed in the choke end has a 26mm or 1.07" diameter throttle bore. (26mm converts close to 1.070"). The carburetor with 28 embossed in the choke end has a 28mm diameter or 1.17" throttle bore. (28mm converts close to 1.170".) And the carburetor with 30 embossed in the choke end has a 30mm or 1.200" diameter throttle bore (30mm converts close to 1.200".) For precision, when measuring the throttle bore to determine the size, it's best to use a dial or digital caliper.

FYI: Some people advertise online that the carburetor for Kohler engine models K241, M10, K301 or M12 can also be used on Kohler engine models K321, M14, K341, M16 and K361. But I know for a fact that if the K241, M10, K301 or M12 carburetor is used on a K321, M14, K341, M16 or K361, which produces 14hp, 16hp and 18hp, respectively, with the correct carburetors, would produce about 12hp, 14hp and 15hp, and make less torque, because the engine would be drawing less air through the smaller carburetor to produce not as much compression. I guess the seller don't know the difference between these carburetors, because they look virtually identical on the outside. Or maybe the seller figures what most people don't know, makes them more money.

The carburetors used on Kohler

engine models K241, M10, K301, M12, K321, M14, K341, M16 and K361 are different.

They may appear the same on the outside, but be very different on the inside.

The K241, M10, K301 and M12 engines require a carburetor with a 1.07" throttle

bore and venturi that measures .812" diameter. The K321, M14 engines requires

a carburetor with a 1.2" throttle bore and venturi that measures .937" diameter.

The K341, M16 engines requires a carburetor with a 1.2" throttle bore and

venturi that measures 1.000" diameter. And the K361 engine requires a carburetor

with a 1.250" throttle bore and venturi that measures 1.062" diameter. If

the wrong carburetor is used on any particular engine, the engine may not

run right and not produce full power. The carburetors that's used on various

models of Kohler engines are as follows:

The carburetors used on Kohler

engine models K241, M10, K301, M12, K321, M14, K341, M16 and K361 are different.

They may appear the same on the outside, but be very different on the inside.

The K241, M10, K301 and M12 engines require a carburetor with a 1.07" throttle

bore and venturi that measures .812" diameter. The K321, M14 engines requires

a carburetor with a 1.2" throttle bore and venturi that measures .937" diameter.

The K341, M16 engines requires a carburetor with a 1.2" throttle bore and

venturi that measures 1.000" diameter. And the K361 engine requires a carburetor

with a 1.250" throttle bore and venturi that measures 1.062" diameter. If

the wrong carburetor is used on any particular engine, the engine may not

run right and not produce full power. The carburetors that's used on various

models of Kohler engines are as follows:

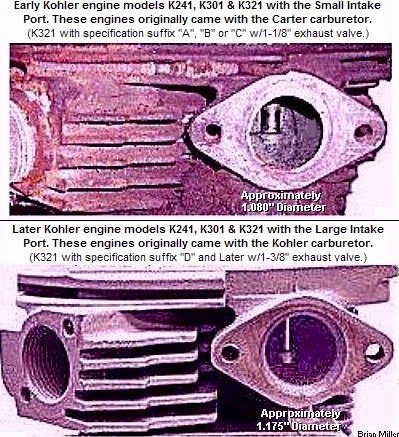

Also, after 1985, Kohler

gave the K321 engine a larger 1-3/8" exhaust valve and made the intake port

larger in diameter. These are engines with specification suffix "D" and later.

The larger exhaust valve , bigger intake port and bigger #30 carburetor allows

for more air to enter and exit out of the combustion chamber so the engine

will produce full 14hp at 3,600 RPM. By the way - The early K321 engine with

the small intake port and small exhaust valve make a good stock 4,000 RPM

stock competition pulling engine, but the later K321 engine with the big

intake port and big exhaust valve make an excellent open RPM competition

pulling engine.

Also, after 1985, Kohler

gave the K321 engine a larger 1-3/8" exhaust valve and made the intake port

larger in diameter. These are engines with specification suffix "D" and later.

The larger exhaust valve , bigger intake port and bigger #30 carburetor allows

for more air to enter and exit out of the combustion chamber so the engine

will produce full 14hp at 3,600 RPM. By the way - The early K321 engine with

the small intake port and small exhaust valve make a good stock 4,000 RPM

stock competition pulling engine, but the later K321 engine with the big

intake port and big exhaust valve make an excellent open RPM competition

pulling engine.

There's another #30 carburetor

designed specifically for the Kohler engine model K582. The throttle shaft

is positioned horizontally and the idle fuel mixture screw is directly on

top of the carburetor body instead of at an angle on the side. This OEM Kohler

carburetor is discontinued from Kohler L, but

is available in aftermarket as the Kohler-replicated fully adjustable #28

carburetor with a 1.17" throttle bore J. FYI:

Lots of people advertise online that the carburetor for the K482 and K532

can also be used on the K582. But I know for a fact that if the K482 and

K532 carburetor is used on the K582, which produces 24hp with the correct

carburetor, would produce about 21hp and make less torque, because the engine

would be drawing less air through the smaller carburetor to produce not as

much compression. I guess the seller don't know the difference between these

carburetors, because they look virtually identical on the outside. Or maybe

the seller figures what most people don't know, makes them more money.

There's another #30 carburetor

designed specifically for the Kohler engine model K582. The throttle shaft

is positioned horizontally and the idle fuel mixture screw is directly on

top of the carburetor body instead of at an angle on the side. This OEM Kohler

carburetor is discontinued from Kohler L, but

is available in aftermarket as the Kohler-replicated fully adjustable #28

carburetor with a 1.17" throttle bore J. FYI:

Lots of people advertise online that the carburetor for the K482 and K532

can also be used on the K582. But I know for a fact that if the K482 and

K532 carburetor is used on the K582, which produces 24hp with the correct

carburetor, would produce about 21hp and make less torque, because the engine

would be drawing less air through the smaller carburetor to produce not as

much compression. I guess the seller don't know the difference between these

carburetors, because they look virtually identical on the outside. Or maybe

the seller figures what most people don't know, makes them more money.

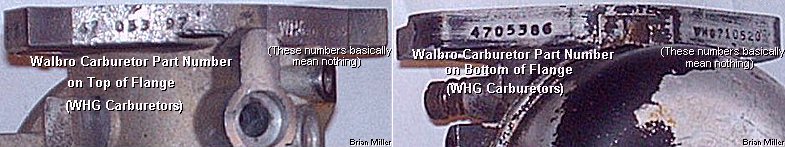

By the way - the part number of all Kohler-made and Walbro carburetors are stamped on the right side of the mounting flange. Don't refer to the numbers just below the fuel inlet port. They represent nothing that I know of. Click here to identify a Kohler or Walbro carburetor and matching parts: Kohler Carburetor Reference Manual TP-2377-E.pdf. If there's no numbers anywhere on the carburetor body, then it's definitely an aftermarket carburetor. Because Carter, Kohler and Walbro ALWAYS stamp a part number on the flange of all their carburetors.

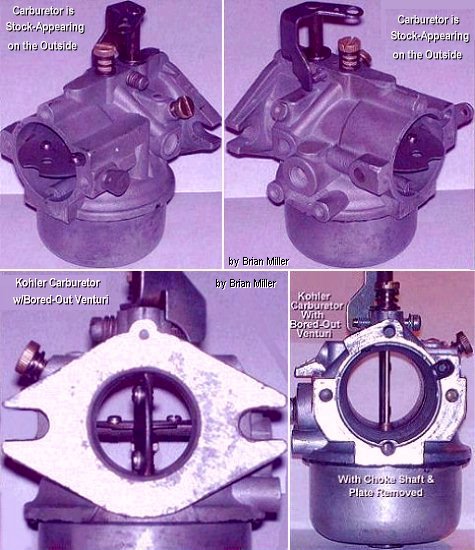

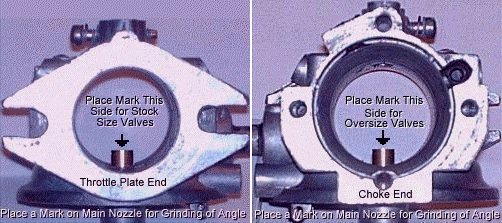

Airflow / CFM (Cubic Feet per Minute) | NOTE: A bored-out venturi and reworked carburetor is when it's modified for maximum performance for competition pulling only.

FYI - The throttle bore itself in a Carter or Kohler #26/1.07" carburetor can be bored to 1.17" (#28 size) or 1.2" (#30 size), and the main jet/nozzle (emulsion tube) will still bottom out against the throttle bore, and of course, a 1.17" or 1.2" throttle shaft and plate would need to be used. But the boring process will break through the idle fuel mixing well (the idle progression holes and the welch plug hole) that's next to the throttle plate. Modifications to this area would need to be made by threading in an 1/8" Allen pipe plug where the welch plug is (or was), and drilling and installing a small brass or copper tube from the idle fuel mixture adjuster screw down into the float bowl, next to the float, with enough clearance so it won't interfere with the movement of the float. A 1/4-28 UNF x 3/4" thread length bolt will also need to be installed where the high speed air/fuel needle adjuster is (was) to block off a vacuum leak to will occur with the modifications of the idle air/fuel mixing well. Actually, it would be MUCH easier and less cost effective to just convert either a Carter or Kohler #28 or #30 carburetor for high performance use and not having to do anything to modify the idle fuel passageway.

Boring-out of the venturi in the carburetor alone will not help to increase engine performance. To increase the overall airflow in and out of the combustion chamber for improved engine performance, and if sanctioning club's rules allow this, the intake (and exhaust) port runners must be enlarged, too. This is called "porting an engine." The [stock size] valves will also need to be reworked and undercut to increase airflow. Or larger reworked and undercut valves and a cam with more lift and duration will need to be used.

For competition pulling, carburetor design and size depends on port sizes, valve sizes, if the intake valve and seat have 30º/31º angles and undercut heads, and the cam profile (lift and duration) is important. If an engine has stock ports, valves and cam, a plain stock carburetor can be used. But if the ports and valves have been reworked for more airflow, and a bigger cam is going to be used, then a bored-out carburetor with a .995" or 1" venturi can be used for best performance. A bored-out venturi and reworked carburetor is when the carburetor is modified for maximum performance for general yard and garden use, and/or for competition pulling.

The 26mm carburetor obviously has a smaller throttle bore. Therefore, is restricted as to how much air can flow through it, even with the venturi removed. It'll work excellent on a hot K241 or mild K301 engine, but the larger 28mm and 30mm carburetors flows more air, 7.7% more for the 28mm, and 15.5% more for the 30mm. Which are ideal for a hot K301 and larger engines with porting, polishing, bigger valves and a big cam. If you feel that a single 30mm carburetor won't flow enough air for your particular engine, then either a "Super Carb," Dellorto, Mikuni, S&S Super D or twin Kohler carburetor setup (on a "Y" intake) should be used. If you have a K321 Kohler engine, and you can't find a #28 or #30 carburetor, then a Carter or Kohler #26 carburetor will work just fine for general lawn and garden use. Personally, I ran a stock Kohler #26 on the K321 Kohler engine that's on my 6,000 lb. self-propelled pulling sled for 10 years and the engine didn't lack any power whatsoever.

Using a carburetor with a small

venturi and/or small throttle bore versus one with a bigger venturi and/or

bigger throttle bore on a Kohler engine is similar to using an

automotive 2 barrel carburetor versus

a 4 barrel carburetor. The one with bigger venturis and/or bigger throttle

bores will allow the engine to draw more air at higher RPM so it can develop

more compression, which will allow it to produce more power. The exception

to this rule is the Carter/Kohler #26 or Walbro #52 carburetor that's designed

for the Kohler K241, K301, M10 and M12 engines, versus the Carter/Kohler

#28 and #30 or Walbro #60 or #64 carburetors that's designed for the K321,

K341, K361, M14 and M16 engines. In stock condition and due to its small

displacement, the K241 and M10 engines isn't capable of drawing enough air

or creating enough velocity through the #30, #60 or #64 carburetor, and possibly

the #28 carburetor, to suck the fuel from the nozzle so the engine can rev

up on its own.

Using a carburetor with a small

venturi and/or small throttle bore versus one with a bigger venturi and/or

bigger throttle bore on a Kohler engine is similar to using an

automotive 2 barrel carburetor versus

a 4 barrel carburetor. The one with bigger venturis and/or bigger throttle

bores will allow the engine to draw more air at higher RPM so it can develop

more compression, which will allow it to produce more power. The exception

to this rule is the Carter/Kohler #26 or Walbro #52 carburetor that's designed

for the Kohler K241, K301, M10 and M12 engines, versus the Carter/Kohler

#28 and #30 or Walbro #60 or #64 carburetors that's designed for the K321,

K341, K361, M14 and M16 engines. In stock condition and due to its small

displacement, the K241 and M10 engines isn't capable of drawing enough air

or creating enough velocity through the #30, #60 or #64 carburetor, and possibly

the #28 carburetor, to suck the fuel from the nozzle so the engine can rev

up on its own.

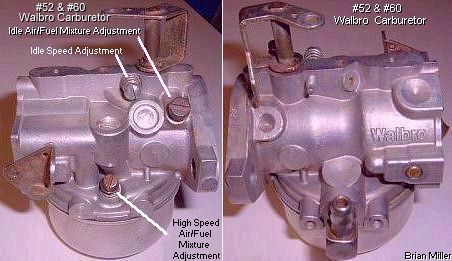

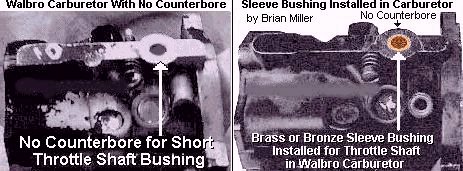

Identification and Information About Walbro WHG #52, #60 and #64 Carburetors -

The Walbro WHG #52, #60 and #64

carburetors originally come on all Magnum engines. These carburetors are

direct replacements for the Kohler carburetors. The Walbro #52 carburetor

has a throttle bore diameter of 1.07" and is designed for use on models K241,

M10, K301, M12, KT17 (first design), KT17 Series II, KT19 (first design),

KT19 Series II, KT21, MV16, M18, MV18, M20 and MV20 engines. And the Walbro

#60 or #64 carburetor have a throttle bore diameter of 1.2" and is designed

for the K321, M14, K341, M16 engines, and being the 1.25" Kohler carburetor

that was originally designed for the K361 engine is longer available, the

only option is to use the Walbro #60 or #64 carburetor.

The Walbro WHG #52, #60 and #64

carburetors originally come on all Magnum engines. These carburetors are

direct replacements for the Kohler carburetors. The Walbro #52 carburetor

has a throttle bore diameter of 1.07" and is designed for use on models K241,

M10, K301, M12, KT17 (first design), KT17 Series II, KT19 (first design),

KT19 Series II, KT21, MV16, M18, MV18, M20 and MV20 engines. And the Walbro

#60 or #64 carburetor have a throttle bore diameter of 1.2" and is designed

for the K321, M14, K341, M16 engines, and being the 1.25" Kohler carburetor

that was originally designed for the K361 engine is longer available, the

only option is to use the Walbro #60 or #64 carburetor.

The older Walbro WHG #52, #60 and #64 carburetors are reliable and they seem to last a long time before requiring service. Most older Walbros are worth rebuilding, because the float valve seats are made of hardened solid bronze, which is actually harder than cast iron. They were manufactured back in the day when most business owners took pride in their products and offered their customers a quality product.

But the newer Walbro carburetors, especially the ones that come on recently-built aluminum block small air-cooled engines, are notorious for leaking gas after several years of use. Although overhaul/rebuild carburetor kits are available, it really does no good to rebuild them and install a new fuel inlet valve because the float valve seat is made of soft brass, which erodes with use due to microscopic particles of dirt/debris that pass through the filtering material in the fuel filter, and in most Walbro carburetors, the seat is not replaceable. The fuel inlet seat in older Walbro carburetors are made of hardened compressed bronze, which is actually harder than cast iron. There is no indication or records of when Walbro made the change from the hard seat to the soft seat.

The fine mesh filter screen

and filtering material in fuel filters can only block certain size of dirt

and debris from entering the carburetor. Any extremely tiny particles that

can pass through the fuel filter will build up in the bottom of the float

bowl and can eventually clog the main fuel jet. Lightweight and suspended

particles in the fuel of the float bowl gets sucked up through the main jet

and is burned in the combustion chamber. The best way to remove built-up

stuck and stubborn debris from inside the float bowl is to use a 2" brass

wire cup brush (shown to the right ->) with a hand-held power drill, and

then use 150± P.S.I. compressed air with an

air blow gun nozzle to clear out the debris from the main

jet hole and clear out the entire float bowl area of the carburetor. On very

rare occasions, a hair can pass through a fine mesh fuel filter screen and

become lodged (trapped) between the float valve and inlet seat, causing the

carburetor to slightly flood with gas. When this happens, the hair can be

successfully removed with 150± P.S.I. compressed air and an air blow

gun nozzle and the same float valve and seat can be reused because chances

are, they will not be damaged.

The fine mesh filter screen

and filtering material in fuel filters can only block certain size of dirt

and debris from entering the carburetor. Any extremely tiny particles that

can pass through the fuel filter will build up in the bottom of the float

bowl and can eventually clog the main fuel jet. Lightweight and suspended

particles in the fuel of the float bowl gets sucked up through the main jet

and is burned in the combustion chamber. The best way to remove built-up

stuck and stubborn debris from inside the float bowl is to use a 2" brass

wire cup brush (shown to the right ->) with a hand-held power drill, and

then use 150± P.S.I. compressed air with an

air blow gun nozzle to clear out the debris from the main

jet hole and clear out the entire float bowl area of the carburetor. On very

rare occasions, a hair can pass through a fine mesh fuel filter screen and

become lodged (trapped) between the float valve and inlet seat, causing the

carburetor to slightly flood with gas. When this happens, the hair can be

successfully removed with 150± P.S.I. compressed air and an air blow

gun nozzle and the same float valve and seat can be reused because chances

are, they will not be damaged.

To put it in plain English: If your Walbro carburetor doesn't leak gas out the choke end, but need an overhaul/rebuild, then it may be worthwhile to install a new kit. But if it does leak gas, then I doubt that a new float valve will fix the problem. Your only options are: install a fuel shut-off valve and turn off the fuel every time the engine is not in use, or install a rebuilt Carter or Kohler K-series carburetor.

About 90% of small engine carburetors are manufactured by Walbro nowadays, and I don't think that one is better than the other. The trick to getting the soft brass seat (and needle/float valve) to last longer is to use a fuel filter with a very fine mesh or pleated paper element. The finer, the better. Because it's the microscopic dirt/debris/grit that passes through the filter that causes the seat (and needle/float valve) to erode and wear. And every pressed-in brass seat that I've replaced ALWAYS leaked gas. There's just no way to get them to seal with the carburetor body, not even with high strength liquid thread locker.

The only problem using a Walbro on a pulling tractor or for high performance application is they can't be bored-out or modified in any way because the throttle bore wall (where the venturi is located) is too thin. Therefore, they're limited to how much air can flow through them. The US government EPA laws required that Kohler and all other small engine manufacturers redesign their carburetors so the engine will produce less air pollution. So they started using a redesigned emissions-controlled, EPA-approved Walbro carburetor with a fixed/non-adjustable main jet. This is to prevent people from setting the air/fuel ratio too rich and create more air pollution. The older-designed Walbros that have an adjustable main jet, which is located on the lower right side of the carburetor, are still available new. main jets of various sizes are available for most carburetors with a fixed/non-adjustable main jet so the engine will run correctly depending on the altitude level, atmospheric/barometric pressure and air temperature where the engine will be used.

A small engine with a fixed, non-adjustable high speed main jet carburetor is supposed to run at a maximum of 3,200 RPM. If the RPM is set higher, the air/fuel mixture will lean out (too much air and not enough fuel), resulting in the engine overheating, which will eventually cause the cylinder head to burn-out, or premature wear to the piston and rings, resulting in the engine burning crankcase oil. The way around this is to drill out the high speed main jet a few thousandths of an inch to give the engine more fuel. But only do this if it's absolutely necessary! If an engine lacks sufficient power at 3,200 RPM, then it obviously needs a professional valve job performed and/or major tune-up.

(Added 7/18/20) If a small engine cylinder head is burned out (usually close to the exhaust valve), if it's burned out where the gasket seals, as long as there's no cracks in the head, it can be successfully welded up, machined flat, the bolt hole redrilled and be put back into service. The following items are what causes cylinder head burn-out...

Walbro WHG #52, #60 and #64 carburetors work great for ordinary lawn and garden equipment, general lawn work and they're perfect for basic stock low RPM/low performance pulling tractors with an engine that's governed to a maximum of 3,200 RPM with a fixed/non-adjustable main jet, or 3,600 RPM with a fully adjustable main jet. A carburetor with a fixed/non-adjustable main jet is limited to just 3,200 RPM and should never be operated faster for an extended length of time. Although the venturi cannot be bored-out on a Walbro, they work equally as well as the older Carter or Kohler carburetors when used on a stock engine. The main jet in the newer Walbro WHG #52, #60 and #64 carburetors are calibrated at the factory to provide the engine with just the right amount of fuel at 3,200 RPM. Therefore, the fixed/non-adjustable main jet inside the carburetor cannot be replaced with an adjustable one.

Advertisement: (Prices are subject to change without notice.)

| Click here to contact A-1 Miller's Performance Enterprises to place an order, send your parts for repairing, and/or for FREE professional and honest technical customer service assistance and support and payment options. Please contact A-1 Miller's if you need a part or parts, or service(s) performed that's not listed or mentioned in this website. | |

If a small engine cylinder head is burned out (usually close to the exhaust valve), as long as there's no cracks in the head, it can be successfully welded up, machined flat, the bolt hole redrilled and be put back into service.

NOTE - If it's repairable, please do not discard your cylinder head or other OEM Kohler parts. Most discontinued Kohler parts in good, usable/rebuildable condition are hard to find nowadays, and nothing works better than the original part(s) the engine was designed for. |

Carter or Kohler or Walbro Fully Adjustable main jet Carburetors VS. Walbro Fixed/Non-Adjustable Main Jet Carburetor RPM to Horsepower specifications - By the way - running a small engine at 3,600 RPM will NOT shorten the life of the engine.

Walbro WHG #52, #60 and #64 carburetors with a fixed/non-adjustable main

jet are designed with emission controls in mind to run leaner to create less

air pollution. However, the main problem with most Walbros having a

fixed/non-adjustable main jet is during cooler weather operation. During

cool weather, and running at 3,200 RPM, the engine will sometimes run too

lean on fuel and operate erratically. To fix this, first of all, make sure

the hole (orifice) in the main jet is not partially clogged. If it is, use

a

carburetor jet cleaner wire set or an

oxy-acetylene welding torch tip cleaner to clear any debris

that may be lodged in the hole. IMPORTANT:

When cleaning the hole (orifice) in the main jet, use a wire cleaner of the

correct size, and be careful not to enlarge the hole, or the engine may run

too rich on fuel! This cannot be undone! Then use 150±

P.S.I. compressed air with an

air blow gun nozzle to clear out any dirt/debris. If the

engine still runs too lean on fuel, simply enlarge the hole (orifice) in

the main jet a few thousandths of an inch. Then use 150± P.S.I. compressed

air with an air blow gun nozzle to clear out any metal particles. Be careful

not to enlarge the hole (orifice) in the main jet too much, or the engine

will run rich on fuel! The hole (orifice) diameter in the OEM factory

main jet for 100% gasoline is 3/64" (.047"). If necessary, enlarge the main

jet and fuel inlet holes with a #55 (.052") drill bit. That's a .0052"

difference. After doing this, for cool weather, the engine should run better,

last longer and produce more power. But don't enlarge the hole (orifice)

in the main jet too much! A too big of a hole (orifice) will cause an engine

to run too rich on fuel, making it blow black smoke out the exhaust and possibly

fouling the spark plug. If the hole (orifice) is made too large, the carburetor

will be useless for gasoline, and E85 fuel must be used.

But if an engine is going to be used only during warm weather and if it runs

okay [during warm weather], don't enlarge the hole (orifice) in the main

jet.

carburetor jet cleaner wire set or an

oxy-acetylene welding torch tip cleaner to clear any debris

that may be lodged in the hole. IMPORTANT:

When cleaning the hole (orifice) in the main jet, use a wire cleaner of the

correct size, and be careful not to enlarge the hole, or the engine may run

too rich on fuel! This cannot be undone! Then use 150±

P.S.I. compressed air with an

air blow gun nozzle to clear out any dirt/debris. If the

engine still runs too lean on fuel, simply enlarge the hole (orifice) in

the main jet a few thousandths of an inch. Then use 150± P.S.I. compressed

air with an air blow gun nozzle to clear out any metal particles. Be careful

not to enlarge the hole (orifice) in the main jet too much, or the engine

will run rich on fuel! The hole (orifice) diameter in the OEM factory

main jet for 100% gasoline is 3/64" (.047"). If necessary, enlarge the main

jet and fuel inlet holes with a #55 (.052") drill bit. That's a .0052"

difference. After doing this, for cool weather, the engine should run better,

last longer and produce more power. But don't enlarge the hole (orifice)

in the main jet too much! A too big of a hole (orifice) will cause an engine

to run too rich on fuel, making it blow black smoke out the exhaust and possibly

fouling the spark plug. If the hole (orifice) is made too large, the carburetor

will be useless for gasoline, and E85 fuel must be used.

But if an engine is going to be used only during warm weather and if it runs

okay [during warm weather], don't enlarge the hole (orifice) in the main

jet.

On the newer carburetors with a fixed/non-adjustable main jet, the hole (orifice) in the main jet may need to be enlarged .002"-.003" to give the engine a little more fuel so it'll run better at higher RPM. Otherwise, the engine could "burn up" or wear out prematurely due to the lean air/fuel mixture. I have an assortment of tiny drill bits that I use on our customer's lawn & garden equipment carburetors.

A new

style Walbro carburetor with a fixed/non-adjustable main jet should never

be used on a non-governed (wide-open throttle) engine or on an engine that's

going to turn at 3,200 RPM! The reason for this is because if an engine operates

faster with a carburetor having a fixed/non-adjustable main jet, it'll run

too lean on fuel at high RPM (it'll draw much more air than fuel), which

will cause the combustion chamber to overheat and the excessive heat will

likely damage the piston and rings and possibly warp the cylinder head and/or

exhaust valve or even crack the cast iron engine block.

A lean fuel mixture can also melt away part of the

aluminum in the combustion chamber of an aluminum block engine.

A new

style Walbro carburetor with a fixed/non-adjustable main jet should never

be used on a non-governed (wide-open throttle) engine or on an engine that's

going to turn at 3,200 RPM! The reason for this is because if an engine operates

faster with a carburetor having a fixed/non-adjustable main jet, it'll run

too lean on fuel at high RPM (it'll draw much more air than fuel), which

will cause the combustion chamber to overheat and the excessive heat will

likely damage the piston and rings and possibly warp the cylinder head and/or

exhaust valve or even crack the cast iron engine block.

A lean fuel mixture can also melt away part of the

aluminum in the combustion chamber of an aluminum block engine.

The size number on the Walbro WHG #52, #60 and #64 carburetors is embossed inside the carburetor and can be seen by looking inside the upper part of the choke end, just above the venturi. A "52" carburetor has a 26mm diameter throttle bore, which converts closely to 1.024 inches (26 ÷ 25.4 = 1.024"), but actually measures 1.07".

And being the venturi in the

old-style Carter Model N #13, #16, #18, #20, #22 carburetors used on Kohler

engine models K90/K91, K141, K160/K161, KV161,

L160/L161,

L181, K181 can't be bored-out either, the only option for pulling

competitively with these is to fabricate an adapter to fasten to the intake

port on the engine block and use a #52 Walbro or #26 Carter or Kohler carburetor.

And being the venturi in the

old-style Carter Model N #13, #16, #18, #20, #22 carburetors used on Kohler

engine models K90/K91, K141, K160/K161, KV161,

L160/L161,

L181, K181 can't be bored-out either, the only option for pulling

competitively with these is to fabricate an adapter to fasten to the intake

port on the engine block and use a #52 Walbro or #26 Carter or Kohler carburetor.

The best way to determine which engine any particular carburetor is made for is to measure the diameter of the throttle bore. Because a set of numbers that's stamped on the carburetor body mean nothing, not even to Kohler Engine dealers. If a carburetor measures .822" (13/16"), then it's designed for the K141, K160/K161, L160/L161, L181, K181 engines. If it measures 1.07", then it's for the 10hp or 12hp engines. And if it measures 1.17" or 1.2", it's for a K321, K341 or K361 engine.

The Wrong Type of Choke Lever!

Whenever I get a carburetor with the choke lever in the wrong position, if

it has a steel choke shaft, I just grind the lever off at the flare and weld

it back on the shaft in the right position. But if it has a brass shaft,

I use a steel choke shaft out of a junk carburetor. Or if I don't have a

used one in stock, I machine a steel choke shaft from a 1/4" mild steel rod.

Like the old saying goes: "There's more than one way to skin a cat."

The Unknown and Tricky Choke Shaft Detent Ball and Spring -

The choke shaft detent ball is a tiny 1/8" (Carter or Kohler

carburetors) or 5/32" (Walbro carburetors) steel ball, and the detent spring

is a small, stout 1/8" or 5/32" diameter compression spring located inside

the air cleaner mounting hole at the 9:00 position when facing the choke

end with the float area down. Certain Walbro carburetors have the ball and

spring located at the 3:00 position. The detent ball and spring is under

pressure by the choke shaft, and is held in the open position by an indention

(small shallow hole) in the shaft. The detent ball and spring are required

only for hand-operation of the choke plate to keep it in the open position

on stand-alone engines without a remote control cable, such as a competition

garden pulling tractor, garden tiller, generator/welder, air compressor,

water pump, etc. If the choke is operated by a cable, such as on a lawn &

garden tractor, then these parts aren't needed and will serve no purpose

whatsoever. Before removing the choke shaft from the carburetor body, and

to prevent the detent ball (and possibly spring) from popping out and getting

lost, using your left hand, hold your thumb over the screw hole and index

or middle finger over the end of the choke shaft hole, then slowly and gently

pull the choke shaft out of the hole, watching that the ball don't pop out

and get lost. Replace these if lost so the choke will stay open while the

engine is running.

The choke shaft detent ball is a tiny 1/8" (Carter or Kohler

carburetors) or 5/32" (Walbro carburetors) steel ball, and the detent spring

is a small, stout 1/8" or 5/32" diameter compression spring located inside

the air cleaner mounting hole at the 9:00 position when facing the choke

end with the float area down. Certain Walbro carburetors have the ball and

spring located at the 3:00 position. The detent ball and spring is under

pressure by the choke shaft, and is held in the open position by an indention

(small shallow hole) in the shaft. The detent ball and spring are required

only for hand-operation of the choke plate to keep it in the open position

on stand-alone engines without a remote control cable, such as a competition

garden pulling tractor, garden tiller, generator/welder, air compressor,

water pump, etc. If the choke is operated by a cable, such as on a lawn &

garden tractor, then these parts aren't needed and will serve no purpose

whatsoever. Before removing the choke shaft from the carburetor body, and

to prevent the detent ball (and possibly spring) from popping out and getting

lost, using your left hand, hold your thumb over the screw hole and index

or middle finger over the end of the choke shaft hole, then slowly and gently

pull the choke shaft out of the hole, watching that the ball don't pop out

and get lost. Replace these if lost so the choke will stay open while the

engine is running.

Installing the choke shaft over the friction (detent) ball and spring can be tricky. This is how it's performed -

Place the carburetor on a sturdy work bench or table, or gently

clamped level it in a bench vise with the choke end facing upward and the

float bowl facing toward you.

Place the carburetor on a sturdy work bench or table, or gently

clamped level it in a bench vise with the choke end facing upward and the

float bowl facing toward you.

How to Adjust the Air/Fuel Mixture Screws on a Kohler (or virtually any small engine) Fully Adjustable Carburetor - [Return To Previous Paragraph, Section or Website][Top of Page]

Operation of the Slow- and Mid-Range Carburetor Functions -

At idle speed, the engine operates

only through the idle fuel passageway. As a metered amount of air is drawn

through slow air bleed jets, fuel is drawn through main jet and further metered

through slow jet. Air and fuel are mixed in body of slow jet and exit to

idle progression (transfer port) chamber. From idle progression chamber,

air fuel mixture is metered through idle port passage. At low idle air/fuel

mixture is controlled by setting of idle fuel adjusting screws. This mixture

is then mixed with main body of air and delivered to engine. As throttle

plate opening increases, greater amounts of air/fuel mixture are drawn in

through fixed and metered idle progression holes. As throttle plate opens

further, vacuum signal become great enough at venturi so main circuit begins

to work.

At idle speed, the engine operates

only through the idle fuel passageway. As a metered amount of air is drawn

through slow air bleed jets, fuel is drawn through main jet and further metered

through slow jet. Air and fuel are mixed in body of slow jet and exit to

idle progression (transfer port) chamber. From idle progression chamber,

air fuel mixture is metered through idle port passage. At low idle air/fuel

mixture is controlled by setting of idle fuel adjusting screws. This mixture

is then mixed with main body of air and delivered to engine. As throttle

plate opening increases, greater amounts of air/fuel mixture are drawn in

through fixed and metered idle progression holes. As throttle plate opens

further, vacuum signal become great enough at venturi so main circuit begins

to work.

Operation of the High Speed Main Jet -

At high speeds/loads engine operates on main circuit. As a metered amount of air is drawn through air jet, fuel is drawn through main jet. Air and fuel are mixed in main nozzles then enters main body of air flow where further mixing of fuel and air occurs. This mixture is then delivered to combustion chamber. Carburetor has a fixed main circuit; no adjustment is possible.

If the engine runs well at idle and at higher RPM, don't worry about how the idle and high speed air/fuel mixture adjustment screws are set. Carburetor adjustments depend on the altitude level, atmospheric/barometric pressure and air temperature where the engine will be operated. In higher elevations, air is thin or less dense. Therefore, the engine requires more air than fuel to run well. But in lower elevations, air is heavy or dense, and because of this, the engine requires less air than fuel. So there is obviously no "one set adjustment" for all carburetors in all areas. And no new or rebuilt carburetor with adjustable jet(s) for small engines, automotive or whatever, come from the manufacturer or rebuilder with the idle speed, idle air/fuel mixture or the high speed air/fuel mixture adjustments set correctly. This is true for ordinary lawn and garden, and all small engines, and competition pulling engines alike, with the exception of [Walbro] carburetors with the fixed/non-adjustable high speed jet.

How the Idle Fuel Passageway Works in the Carter and Kohler Carburetors -

On the Carter or Kohler (and Walbro) carburetors, the hole towards the bottom of the long main needle adjuster is supposed to be open and not clogged, so the engine can draw fuel through it for idling from the float bowl. The idle fuel passageway for a Carter or Kohler carburetors goes as follows: Fuel is first drawn through the lower end via the tiny hole(s) (orifice) on the high speed needle adjuster, then through engine vacuum, fuel is drawn up through the tube, and over and down toward the idle air/fuel mixture screw (which sets at an angle), and then fuel is drawn into the throttle bore, next to the throttle plate. The information mentioned below Ê is mainly for Carter or Kohler carburetors. The fuel mixture screws are used as follows:

Use a

1/32" high speed steel spiral drill bit or

1/32" end mill to enlarge the [single] lower hole (orifice)

in high speed needle air/fuel adjuster screw in Carter Model N #13, #16,

#18, #20, #22 carburetors, and Carter or Kohler #26, #28 and #30 carburetors

to create more suction for fuel through the tube to help the engine start

quicker (with throttle in idle position), idle smoothly, and idle down upon

deceleration without stalling. No need to use this on adjuster with two lower

holes. NOTE: Carefully enlarge the hole by hand with drill bit

clamped in a

mini micro pin vise hand drill chuck. And be careful when

using any tiny drill bit because they can break easily. After enlarging hole,

clear out any metal cuttings from inside the adjuster tube with 150±

P.S.I. compressed air and an air blow gun nozzle.

Use a

1/32" high speed steel spiral drill bit or

1/32" end mill to enlarge the [single] lower hole (orifice)

in high speed needle air/fuel adjuster screw in Carter Model N #13, #16,

#18, #20, #22 carburetors, and Carter or Kohler #26, #28 and #30 carburetors

to create more suction for fuel through the tube to help the engine start

quicker (with throttle in idle position), idle smoothly, and idle down upon

deceleration without stalling. No need to use this on adjuster with two lower

holes. NOTE: Carefully enlarge the hole by hand with drill bit

clamped in a

mini micro pin vise hand drill chuck. And be careful when

using any tiny drill bit because they can break easily. After enlarging hole,

clear out any metal cuttings from inside the adjuster tube with 150±

P.S.I. compressed air and an air blow gun nozzle.

Many times when cleaning a Carter or Kohler carburetor, the

welch plug that's on the side of the carburetor doesn't need to be removed.

The only time it needs to be removed is when the tiny fuel feed hole that's

next to the throttle plate become clogged with dried gas or debris. To clear

this hole, with the idle air/fuel mixture screw and the high speed needle

adjuster removed, thread a 1/4-28 UNF screw/bolt in place of the high speed

needle adjuster (this will place more air pressure against the idle fuel

feed hole), apply 150± P.S.I. compressed air with an

air blow gun nozzle in the idle mixture screw hole, and

place your finger inside the throttle bore over the fuel feed hole, and if

you feel air come out of the hole, the hole is cleared out. If air does come

out of the idle fuel feed hole, then the welch plug will need to be removed

and manually cleared out with a

carburetor jet cleaner wire set or an

oxy-acetylene welding torch tip cleaner. A new welch plug

will need to be installed.

Many times when cleaning a Carter or Kohler carburetor, the

welch plug that's on the side of the carburetor doesn't need to be removed.

The only time it needs to be removed is when the tiny fuel feed hole that's

next to the throttle plate become clogged with dried gas or debris. To clear

this hole, with the idle air/fuel mixture screw and the high speed needle

adjuster removed, thread a 1/4-28 UNF screw/bolt in place of the high speed

needle adjuster (this will place more air pressure against the idle fuel

feed hole), apply 150± P.S.I. compressed air with an

air blow gun nozzle in the idle mixture screw hole, and

place your finger inside the throttle bore over the fuel feed hole, and if

you feel air come out of the hole, the hole is cleared out. If air does come

out of the idle fuel feed hole, then the welch plug will need to be removed

and manually cleared out with a

carburetor jet cleaner wire set or an

oxy-acetylene welding torch tip cleaner. A new welch plug

will need to be installed.

If an engine blows black smoke out the exhaust while running, then here are the main causes:

Black exhaust smoke is when an engine is getting too much gas and/or not enough air in the combustion chamber. The causes for this are either... (listed from most common to rare causes)

Also, sometimes flooding of the carburetor will deposit gas in the crankcase oil, but only in a vertical shaft engine. Because gas can't seep into the crankcase on horizontal shaft engines. The cause of the problem is the carburetor is flooding. The gas seeps past the piston ring gaps and into the crankcase. To fix this, clean the float valve (needle and seat) in the carburetor, or install a new carburetor overhaul/rebuild kit with a new float valve needle and seat. Also, clean out the fuel hoses with 150± P.S.I. compressed air and an air blow gun nozzle and install a new fuel filter. And then the crankcase oil will need to be drained and clean/uncontaminated motor oil installed.

The OEM Kohler Carburetor Intake Air/Fuel Mixture Baffle Plate -

The purpose of the OEM Kohler

carburetor/intake air/fuel mixture baffle plate is to atomize (reduced into

smaller particles) or "swirl" the incoming air/fuel mixture more efficiently

at higher RPM so the engine will produce more horsepower and torque. This

part was made by Kohler of stamped .018" thickness aluminum with inside

45º/angled tabs/baffles, and installed on certain opposed (flathead)

twin cylinder engines carburetor and intake manifold sandwiched between two

(ordinary/.030" thickness) mounting gaskets. The discontinued OEM Kohler

part number for this is 52 063 40-S. And according to the official Kohler

engine parts list, this particular part originally came on Kohler Magnum

model M18 engines with specification numbers: 24620, 24644, 24665, 24666

(all AYP); 24646 (Cub Cadet); model MV18 engines with specification numbers:

58553, 58556, 58560, 58561 (all AYP); M20 engines with specification numbers:

49603, 49634 (both AYP); and model MV20 engines with specification numbers:

57525 (Exmark); 57526 (Yardman); 57527, 57528, 57529 (all AYP). If you're

lucky enough to find one of these, it can be used on the Kohler single cylinder

engine models K241, M10, K301, M12, K321, K330/K331, M14, K341, M16 and K361

to improve the performance at higher RPM. This part is guaranteed to work!

It showed a slight increase in horsepower and torque when tested on my personal

engine dyno. It's the next best thing to having a

fuel injected engine.

[Return

To Previous Paragraph or Section]

The purpose of the OEM Kohler

carburetor/intake air/fuel mixture baffle plate is to atomize (reduced into

smaller particles) or "swirl" the incoming air/fuel mixture more efficiently

at higher RPM so the engine will produce more horsepower and torque. This

part was made by Kohler of stamped .018" thickness aluminum with inside

45º/angled tabs/baffles, and installed on certain opposed (flathead)

twin cylinder engines carburetor and intake manifold sandwiched between two

(ordinary/.030" thickness) mounting gaskets. The discontinued OEM Kohler

part number for this is 52 063 40-S. And according to the official Kohler

engine parts list, this particular part originally came on Kohler Magnum

model M18 engines with specification numbers: 24620, 24644, 24665, 24666

(all AYP); 24646 (Cub Cadet); model MV18 engines with specification numbers:

58553, 58556, 58560, 58561 (all AYP); M20 engines with specification numbers:

49603, 49634 (both AYP); and model MV20 engines with specification numbers:

57525 (Exmark); 57526 (Yardman); 57527, 57528, 57529 (all AYP). If you're

lucky enough to find one of these, it can be used on the Kohler single cylinder

engine models K241, M10, K301, M12, K321, K330/K331, M14, K341, M16 and K361

to improve the performance at higher RPM. This part is guaranteed to work!

It showed a slight increase in horsepower and torque when tested on my personal

engine dyno. It's the next best thing to having a

fuel injected engine.

[Return

To Previous Paragraph or Section]

Information About Using a Carburetor Intake Tube/Spacer (Fuel Atomization Chamber) -

Using

a fuel atomization chamber intake tube or spacer to distance the carburetor

away from the engine block allows the fuel to atomize better (break down

into smaller particles or a fine mist) so the engine will produce more power

and torque at higher RPM. The further the carburetor is spaced from the engine

block (flathead engines) or cylinder head(s) on OHV engines, the better the

fuel will atomize and the more power the engine will produce at higher RPMs.

It works, and it works great. This is why most makes and models of carbureted

small engines [other than the cast iron block single cylinder Kohler] have

a long intake tube, and why most naturally-aspirated carbureted high-performance

automotive V6 and V8 engines use a high-rise intake manifold. Again, it's

the next best thing to having a

fuel injected engine.

Using

a fuel atomization chamber intake tube or spacer to distance the carburetor

away from the engine block allows the fuel to atomize better (break down

into smaller particles or a fine mist) so the engine will produce more power

and torque at higher RPM. The further the carburetor is spaced from the engine

block (flathead engines) or cylinder head(s) on OHV engines, the better the

fuel will atomize and the more power the engine will produce at higher RPMs.

It works, and it works great. This is why most makes and models of carbureted

small engines [other than the cast iron block single cylinder Kohler] have

a long intake tube, and why most naturally-aspirated carbureted high-performance

automotive V6 and V8 engines use a high-rise intake manifold. Again, it's

the next best thing to having a

fuel injected engine.

A 1" carburetor spacer will definitely help atomize the fuel into smaller particles so the engine will produce more noticeable power, and it'll help the engine last longer and burn less fuel. On average, dyno tests had proven that engines with a 1" spacer produced about 12% more horsepower and torque. This is why virtually all [aluminum block] Briggs & Stratton, Tecumseh, and other makes and models of small engines use a factory-installed intake tube. But for some reason, cast iron block single cylinder Kohler engines are the only ones that didn't come with an intake tube.

When choosing the length of the intake tube, it seems that a 3" length works best for gas, and 5" length works best for E85 or methanol fuels. Because gas runs more lean than E85 or methanol, it requires less space or distance to fully atomize (be reduced into smaller particles), and being E85 and methanol fuels run richer, they need more space or distance to fully atomize before these enter the combustion chamber.

For competition pulling, if an association's/club's rules state that no intake tube can be used with the carburetor, the OEM Kohler carburetor intake air/fuel mixture baffle plate (as described above) and/or a heat isolator gasket will work great instead. The heat isolator gasket isolates the carburetor body from the engine heat so when the cool fuel from the carburetor makes contact with the warm/hot engine (intake runner), it will instantly atomize better (be reduced into smaller particles) before it enters the combustion chamber, which will help the engine produce more horsepower and torque. Yet again, it's the next best thing to having a fuel injected engine.

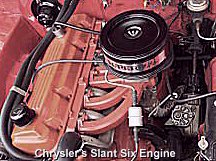

FYI - The automotive V8 high rise intake manifold and Chrysler's

Slant Six engine (with the longer intake manifold runners) were designed

to atomize the fuel better so the engine will produce more power at higher

RPM and get better fuel mileage at any RPM. If anyone tells you differently

about the Chrysler slant six engine, then they are wrong! These are the ONLY

reasons Chrysler made the slant six engine, designed it the way they did

and it works!

FYI - The automotive V8 high rise intake manifold and Chrysler's

Slant Six engine (with the longer intake manifold runners) were designed

to atomize the fuel better so the engine will produce more power at higher

RPM and get better fuel mileage at any RPM. If anyone tells you differently

about the Chrysler slant six engine, then they are wrong! These are the ONLY

reasons Chrysler made the slant six engine, designed it the way they did

and it works!

In addition, "roughing up" the inside of the intake tube will help create turbulence to "break up" and atomize the fuel better and should help a Kohler engine produce a few more ponies. This works for automotive engines, and it should work for Kohler engines as well.

On single cylinder

Kohler competition pulling engines that run at open RPM, when using a mounting

gasket between the intake tube and intake port, due to normal high RPM engine

vibration, the [somewhat soft] gasket will allow the tube (and carburetor)

to vibrate and possibly cause one half of the intake port (with a huge enlarged

port opening, which weakens the port) to break off. This is based on fact

and has been known to happen. So to prevent this from happening, instead

of using a gasket, a shallow, narrow groove can be machined in one end of

the flange of the tube for a reusable small cross-sectional diameter neoprene

rubber O-ring. The O-ring will take place of the gasket to prevent a vacuum

leak. The O-ring will compress, guaranteeing metal to metal contact to secure

the tube directly to the engine block. The same can be done to a carburetor

mounting flange.

On single cylinder

Kohler competition pulling engines that run at open RPM, when using a mounting

gasket between the intake tube and intake port, due to normal high RPM engine

vibration, the [somewhat soft] gasket will allow the tube (and carburetor)

to vibrate and possibly cause one half of the intake port (with a huge enlarged

port opening, which weakens the port) to break off. This is based on fact

and has been known to happen. So to prevent this from happening, instead

of using a gasket, a shallow, narrow groove can be machined in one end of

the flange of the tube for a reusable small cross-sectional diameter neoprene

rubber O-ring. The O-ring will take place of the gasket to prevent a vacuum

leak. The O-ring will compress, guaranteeing metal to metal contact to secure

the tube directly to the engine block. The same can be done to a carburetor

mounting flange.

Another way to gain more horsepower and torque at virtually any RPM besides roughing up the inside of the intake tube is to fabricate a spiral fuel atomizer from ordinary sheet metal steel. This particular part is made the same length but a few thousandths bigger in width than the intake tube, twisted one time (180º), and is fitted snugly inside the intake tube. This is a dyno-proven add-on and performance modification that increases engine horsepower and torque by about 5-10%.

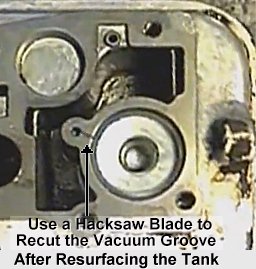

Also for competition pulling, with an intake tube in use, mounting gaskets are not necessary. Just resurface the carburetor mounting flange and ends of the intake tube (if needed) on a wide, flat belt sander, large flat sanding disc or on the side of an abrasive metal cutting wheel on a electric chop saw (the kind that automotive muffler shops use) (use eye protection!), and then apply a thin bead of clear RTV silicone adhesive sealant with no gasket. When a gasket is used, the bolts or nuts (with studs) are tightened, the softness of the gasket could cause the carburetor flange to warp and possibly break. With no gasket involved, there will be metal to metal contact with the silicone filling in the open gaps between the two metals, and there is NO WAY the flange can warp or possibly break! By the way - I've always preferred to use clear RTV silicone adhesive sealant for three reasons: Gaskets don't always seal the irregularities between mating metals, especially thin metal covers; being it's an adhesive, it bonds parts together, forming a leak-proof seal; and being it's clear, it makes for a clean and professional-looking repair job. When applied sparingly, it can't be easily seen or noticed between the parts.

The Cause of Slight Carburetor Flooding or "Loading Up on Fuel" at Slow Idle with a High-Performance/Long Duration Camshaft -

Sometimes when using a high-performance/long duration camshaft, regardless if the engine has a stock or modified carburetor, if the engine idles for a long period of time, it may run rich on fuel at a slow idle speed. What causes this is with a long duration cam, intake vacuum is low and with a single cylinder engine, being the valves stay open longer, excess fuel builds up in the carburetor and/or intake tube. All engines with a long duration camshaft have lower than normal vacuum at slow idle. The longer the duration a cam has, the lower the vacuum. What causes excess fuel to build up in the intake is the long duration of the cam lobes holds the [intake] valve open longer, and at slow idle, pressure of the piston moving upward in the cylinder blows some of the air/fuel back into the carburetor and/or intake tube. And as the engine is revved up, raw unburned fuel black smoke (gas) will blow out the exhaust pipe until the fuel is cleared out of the carburetor and/or intake tube. With the engine running well above idle, air become trapped within the combustion chamber and the piston don't have time to push any air/fuel back into the carburetor and/or intake tube. This happens with all types of fuels and there's nothing that can be done about it. It's the nature of the long duration camshaft. Some might think when this happens that there's something wrong with the carburetor, and nothing can be done to the idle fuel passageway to prevent this. Just make a simple adjustment with the idle air/fuel mixture screw, set the engine at a fast idle and don't allow the engine to idle for a long period of time. [Return To Previous Paragraph or Section]

The Major Causes of Carburetor Flooding -

FYI - I don't put any additives in my gas. I think it's a waste of money and effort, and gives false hope. I filter out the dirt and remove any water from the [somewhat fresh] left-over gas that's in my customer's small engine equipment, and dump it in my personal car or truck so it will mix with the fresh gas that's already in the tank. Then I always use fresh/purchased gas with no additives in my customer's small engine equipment.

What prevents most carburetor and fuel system from having problems when using gasoline is to run the engine out of fuel or draining the entire fuel system if it's not going to be used for more than 30 days at a time. If there's no fuel left in the system, then there should be no problems. The following causes are listed from most common to rare.

If fuel drips out of or from the carburetor...

Fuel leak at the carburetor float

bowl rubber O-ring seal. Only happens when engine is in operation. Circumference

of float bowl not sealing tight against the

neoprene

rubber O-ring seal and fuel baffle/splash shield in carburetor body.

Fuel leak at the carburetor float

bowl rubber O-ring seal. Only happens when engine is in operation. Circumference

of float bowl not sealing tight against the

neoprene

rubber O-ring seal and fuel baffle/splash shield in carburetor body.

If gas constantly pours out of the carburetor...

The best way to remove built-up

stuck and stubborn debris from inside the float bowl is to use a 2" brass

wire cup brush (shown to the right ->) with a hand-held power drill, and

then use 150± P.S.I. compressed air with an

air blow gun nozzle to clear out the debris from the main

jet hole and clear out the entire float bowl area of the carburetor.

The best way to remove built-up

stuck and stubborn debris from inside the float bowl is to use a 2" brass

wire cup brush (shown to the right ->) with a hand-held power drill, and

then use 150± P.S.I. compressed air with an

air blow gun nozzle to clear out the debris from the main

jet hole and clear out the entire float bowl area of the carburetor.

If the carburetor on an engine

has been setting for some time without an air cleaner/filter assembly, and

if gas pours out of the carburetor only when cranking the engine, especially

with a mechanical fuel pump, then the gas stops pouring out when the engine

isn't cranked, check for a clogged atmospheric vent opening (air passageway

from inside the float bowl area to outside of carburetor) in the carburetor.

Sometimes a

mud dauber (wasp-like insect) will build their nest in

a place like this. (I've seen this happen a few times with my customer

carburetor rebuilds.)

If the carburetor on an engine

has been setting for some time without an air cleaner/filter assembly, and

if gas pours out of the carburetor only when cranking the engine, especially

with a mechanical fuel pump, then the gas stops pouring out when the engine

isn't cranked, check for a clogged atmospheric vent opening (air passageway

from inside the float bowl area to outside of carburetor) in the carburetor.

Sometimes a

mud dauber (wasp-like insect) will build their nest in

a place like this. (I've seen this happen a few times with my customer

carburetor rebuilds.)

What makes crankcase oil black is blow-by due to either worn piston rings, carburetor flooding or the engine running rich on fuel (gas). And if there's gas in the oil (you can smell the presence of gas), this means there's a hole in the diaphragm in the mechanical fuel pump. Being there are no fuel pump repair kits available nowadays, an either good used or new replacement fuel pump is required.

How to Separate Gasoline from Water -

No need to dispose of fresh gas just because it's contaminated with water (and/or dirt and debris). And with the price of gas nowadays, this would be a wise thing to do.

Gasoline and alcohol fuels

are both extremely flammable! Use caution and don't smoke, avoid making sparks

or don't have an open flame exposed when working near or with either of them.

Work in a well-ventilated area, too.

Gasoline and alcohol fuels

are both extremely flammable! Use caution and don't smoke, avoid making sparks

or don't have an open flame exposed when working near or with either of them.

Work in a well-ventilated area, too.

By the way - As business is booming, we've been to many competition garden tractor pulls through the years and noticed that some pulling tractors leak fuel in places where a fuel leak shouldn't be. Therefore, I think the safety inspections should include checking the fuel hoses for dry-rotting, cracks, fuel leaks, loose fittings, etc. (The tractors should have sturdy wheelie bars, too.) The inspectors should grab hold of the fuel hose(s) with their hand, bend it and slightly jerk on it to check for durability. This is very important. Especially in a kid's class. Don't wait until a small issue become a major problem, then turn in to a catastrophe. If a pulling club's sanctioning safety rules are enforced, and pullers would build their tractors right and maintain them regularly, there wouldn't be any injuries, fires, or fear of a fire. Click or tap here to read more about a competition garden pulling tractor catching on fire.

If an engine won't idle or idles poorly, if it's a Carter or

Kohler carburetor, chances are, there's old, dried gas debris inside the

high speed air/fuel needle adjuster tube. To fix this, first, on an adjuster

with only one lower hole, carefully enlarge the hole with a

1/32" high speed steel spiral drill bit or

1/32" end mill. Then use a small, bendable mild steel wire,

such as a

bread wrapper wire twist tie with the coating stripped

off, to clean out inside the tube. And use the 150± P.S.I. compressed

air with an

air blow gun nozzle to thoroughly clear out the tube. Suck

through the tube with your mouth to make sure it's clear and unclogged. (Proven

method that works.) If performing this won't clear out the tube, then a new

or used unclogged high speed air/fuel needle adjuster screw will need to

be acquired. But make sure it's the correct adjuster for your particular

carburetor!

If an engine won't idle or idles poorly, if it's a Carter or

Kohler carburetor, chances are, there's old, dried gas debris inside the

high speed air/fuel needle adjuster tube. To fix this, first, on an adjuster

with only one lower hole, carefully enlarge the hole with a