Information About Small Engine Porting, Valves, Springs, Lifters

and Camshafts

Information About Small Engine Porting, Valves, Springs, Lifters

and Camshafts

Information About Small Engine Porting, Valves, Springs, Lifters

and Camshafts

Information About Small Engine Porting, Valves, Springs, Lifters

and Camshafts

Educating and Inspiring Small Engine, Lawn & Garden, and Garden

Pulling Tractor Enthusiasts Since 1996. Where Science and Common Sense Come

Together for Safety and Improved Engine/Tractor Performance |

A-1

Miller's Performance Enterprises - Parts & Services

Webstore |  Available Soon - Detailed Illustrated Plans

on How to Construct a Professional Pull-Back and Self-Propelled Garden

Tractor/Small Wheel Mini Rod Pulling Sleds

Available Soon - Detailed Illustrated Plans

on How to Construct a Professional Pull-Back and Self-Propelled Garden

Tractor/Small Wheel Mini Rod Pulling Sleds

Nowadays, prices are subject to change without notice. Click

Refresh to see any

changes or updates. Optimized for 1152 x 864 computer screen resolution.

To search for a word or phrase in any of my websites, press the CTRL

and F

and F  keys on

your keyboard simultaneously to open the Find or Search dialog box in your

web browser. And being I have no

apprentice to update and pay for my websites so they'll

continue to be on the Internet, they will be removed forever when I'm no

longer around. Scroll down the website or click the links

below.

keys on

your keyboard simultaneously to open the Find or Search dialog box in your

web browser. And being I have no

apprentice to update and pay for my websites so they'll

continue to be on the Internet, they will be removed forever when I'm no

longer around. Scroll down the website or click the links

below.

Information About the Valves in Four Stroke Engines -

FYI - I receive many phone calls and emails from people who tell A-1 Miller's that when they have a problem with how poorly their engine runs. They say they cleaned and rebuilt the carburetor, but the engine would not run well, or still run the same. So they remove the carburetor, cleaned it again, and the engine still acts the same. So they check the carburetor again! They say they checked it over and cleaned it multiple times. Then they move on to the ignition system, but it checks out okay, too. Anyway, I tell them if you checked and cleaned the carburetor that many times and everything looked okay with it, then the problem obviously ISN'T in the carburetor or with the ignition! There are other things that help make an engine run, such as the valves. I tell them to check the valve clearances, severely leaking valves, or a professional valve job (this is when the valve faces and seats are recut or reground to specs or new valve(s) are installed and the valve clearances are set to factory specs so the engine will restore full compression) may need to be performed. Performing a valve job will restore full compression, which will allow the engine to start quicker, idle smoothly, rev up with no hesitation, produce lots of power, and run for a long time without stalling or dying (when the ignition timing and carburetor adjustments are set correctly, too). Also, check for a loose valve seat (Kohler 18hp OHV). The valves are the hardest working parts in any 4-cycle engine. They need attention, too. So many people are ignorant or know nothing about the valves, how they work or their purpose. So before disassembling, inspecting, cleaning and perhaps rebuilding the carburetor, you might want to check the valve clearances to see if they don't need to be reset to factory specs. Because I found that sometimes carburetor problems are valve-related.

If a 4-cycle engine cranks over too easy and is hard to start, and when it (or if) does start, it loses power and/or dies for no apparent reason after running for a while, then chances are the problem is in the valves. Valve faces and/or seats become worn (grooved) after many hours of use, and this lessons the clearance between the valve stems and lifters or rocker arms. Metal contracts (shrinks) when cold and expands (swells) when hot. Knowing this, when an engine reaches operating temperature, the valves get hot and swell, especially the exhaust valve, and this lessons the clearance between the stems and lifters or rocker arms. The hotter a valve gets, the less clearance it will have. When there's inadequate clearance, the valves will not be able to fully close or stay closed long enough to seal in sufficient amount of compression within the combustion chamber, the engine will lose compression, making the engine suddenly die, and hard to start and when it does start, it won't produce much power. Due to fuel vapors escaping the combustion chamber, sometimes gas will blow out the carburetor when the engine is accelerated, too. And when the engine dies for no apparent reason, it'll be almost impossible to restart when hot. To fix this, a professional valve job will need to be performed. What causes valve faces and/or seats to wear is lack of an air filter element (which will wear parts within the entire combustion chamber under dusty conditions), a dirty air filter, a defective air filter, or an air filter that has not been changed in a long time. Air filtration is very important with any engine. Especially under extreme dusty conditions. And just like fuel filters, air filters can only filter out dust particles so small. The smallest pieces of dust penetrates the microscopic holes in the filter material, and wears parts within the combustion chamber.

In most cases, the valve face will more than the seat because

the moving part always wears more than the stationary part. And main thing

that cause valve face wear on the exhaust valve is a worn

valve guide, which cause the face to scrape against

the seat upon closing, and/or carbon deposits being lodged between the valve

face and seat. The intake valve face wears from guide wear also and/or either

lack of an air filter or not frequently using a new air filter. Clogged filters

can cause microscopic dust particles to penetrate the filter and enter the

combustion chamber. Due to microscopic dust particles that pass through the

air filter (which is unpreventable), this cause the valve face and seat to

wear against each other, and as they wear, the gap closes up between the

valve stem and lifter (tappet). This is why it's necessary to check and/or

adjust the valves every 500 hours of

engine run time. This is also why

it's important to use a quality-made air filter, and change it regularly,

especially under dusty conditions. Only the valves in engines with solid

lifters (tappets) need periodic adjusting. The valves in engines with hydraulic

lifters don't need adjusting because the oil in the lifters compensate for

the valve face and seat wear. An intake valve with a worn (grooved) 45º

face angle can be reground to a 30º angle, and of course the seat will

also need to be reground to a 31º to match the valve face.

In most cases, the valve face will more than the seat because

the moving part always wears more than the stationary part. And main thing

that cause valve face wear on the exhaust valve is a worn

valve guide, which cause the face to scrape against

the seat upon closing, and/or carbon deposits being lodged between the valve

face and seat. The intake valve face wears from guide wear also and/or either

lack of an air filter or not frequently using a new air filter. Clogged filters

can cause microscopic dust particles to penetrate the filter and enter the

combustion chamber. Due to microscopic dust particles that pass through the

air filter (which is unpreventable), this cause the valve face and seat to

wear against each other, and as they wear, the gap closes up between the

valve stem and lifter (tappet). This is why it's necessary to check and/or

adjust the valves every 500 hours of

engine run time. This is also why

it's important to use a quality-made air filter, and change it regularly,

especially under dusty conditions. Only the valves in engines with solid

lifters (tappets) need periodic adjusting. The valves in engines with hydraulic

lifters don't need adjusting because the oil in the lifters compensate for

the valve face and seat wear. An intake valve with a worn (grooved) 45º

face angle can be reground to a 30º angle, and of course the seat will

also need to be reground to a 31º to match the valve face.

The valves, especially the exhaust valve, is/are the hardest working part(s) of the engine. The valve face(s) can wear more than the piston rings. This is one thing so many mechanics overlook, yet so simple to fix.

How to Test for Leaking or Burnt Valves - [Top of Page]

The appearance of used

valves in an engine are like women,

you can't always go by looks. In other words, the appearance of valves in

an engine won't tell you if they're sealing in compression 100% or not. To

test for leaking valves on virtually any 4-cycle flathead engine, first of

all, both valve clearances should be checked and adjusted to specs, if needed,

before performing this test. Now with the carburetor, muffler or exhaust

pipe and [flathead] cylinder head removed, and with the piston positioned

exactly at TDC on the compression stroke (this is when both valves are fully

closed), apply

Liquid Wrench (spray) or

WD-40 around each valve and with a rag/shop towel wrapped

around an

air blow gun nozzle with the rag/shop towel snug against

the port to seal in the air pressure so maximum pressure will be applied

to the valves, apply 150± PSI compressed air through the exhaust and

intake ports. To perform this same test on an over head valve (OHV) engine,

the cylinder head will need to be removed and [lightly] clamped in a bench

vise. Anyway, if multiple bubbles form (slight leakage) and/or if the liquid

gets "blown out" around the valves (severe leakage) when applying the air

pressure, this means the valves are leaking or burnt and a professional valve

job is required. Performing a valve job will restore full compression, which

will allow the engine to start quicker, idle smoothly, rev up with no hesitation,

produce lots of power, and run for a long time without stalling or dying

(when the ignition timing and carburetor adjustments are set correctly, too).

Do not use soapy water to perform this test because the water content will

cause the cast iron to rust if not immediately cleaned off and thoroughly

dried. The "bubbles" part of this test won't be accurate with freshly reground

valves and seats (fresh valve job) because the valves haven't worn into the

seats yet to form a perfect seal. This is known as valve wear-in or more

commonly as engine break-in. Click the photo to the right ->

è to watch how this test is performed

on

YouTube.

By the way - The video shows both valves fully closed with the piston positioned

at TDC on the compression stroke. And if you're wondering, the Automatic

Compression Release (ACR) only works with the exhaust valve. It doesn't hold

the exhaust valve open when the piston is at top dead center (TDC) on the

compression stroke. It only works when the piston is traveling about halfway

up in the cylinder just before it reaches top dead center (BTDC) on the

compression stroke.

The appearance of used

valves in an engine are like women,

you can't always go by looks. In other words, the appearance of valves in

an engine won't tell you if they're sealing in compression 100% or not. To

test for leaking valves on virtually any 4-cycle flathead engine, first of

all, both valve clearances should be checked and adjusted to specs, if needed,

before performing this test. Now with the carburetor, muffler or exhaust

pipe and [flathead] cylinder head removed, and with the piston positioned

exactly at TDC on the compression stroke (this is when both valves are fully

closed), apply

Liquid Wrench (spray) or

WD-40 around each valve and with a rag/shop towel wrapped

around an

air blow gun nozzle with the rag/shop towel snug against

the port to seal in the air pressure so maximum pressure will be applied

to the valves, apply 150± PSI compressed air through the exhaust and

intake ports. To perform this same test on an over head valve (OHV) engine,

the cylinder head will need to be removed and [lightly] clamped in a bench

vise. Anyway, if multiple bubbles form (slight leakage) and/or if the liquid

gets "blown out" around the valves (severe leakage) when applying the air

pressure, this means the valves are leaking or burnt and a professional valve

job is required. Performing a valve job will restore full compression, which

will allow the engine to start quicker, idle smoothly, rev up with no hesitation,

produce lots of power, and run for a long time without stalling or dying

(when the ignition timing and carburetor adjustments are set correctly, too).

Do not use soapy water to perform this test because the water content will

cause the cast iron to rust if not immediately cleaned off and thoroughly

dried. The "bubbles" part of this test won't be accurate with freshly reground

valves and seats (fresh valve job) because the valves haven't worn into the

seats yet to form a perfect seal. This is known as valve wear-in or more

commonly as engine break-in. Click the photo to the right ->

è to watch how this test is performed

on

YouTube.

By the way - The video shows both valves fully closed with the piston positioned

at TDC on the compression stroke. And if you're wondering, the Automatic

Compression Release (ACR) only works with the exhaust valve. It doesn't hold

the exhaust valve open when the piston is at top dead center (TDC) on the

compression stroke. It only works when the piston is traveling about halfway

up in the cylinder just before it reaches top dead center (BTDC) on the

compression stroke.

Performing a Compression Leak Down Test with a Leak Down Tester -

With the piston is positioned

exactly at Top Dead Center (TDC) on the compression stroke, the automatic

compression release (ACR) mechanism allows the exhaust valve to fully close,

then a leak down test can be performed. The ACR effects a compression test

when performed with a

compression tester, but not a leak down test (as long as

the piston is at TDC on the compression stroke). 0º TDC is when the

piston is at its very top in the cylinder with both valves fully closed.

It is also when the T mark on the flywheel is aligned with

the raised boss on the bearing plate, and The alignment can be seen with

a flashlight through the sight hole in the bearing plate. But the best way

to determine if an engine needs to

be rebuilt is to remove the cylinder head & look at the edge of the piston.

If the carbon is washed away, this means the rings & piston are worn

and the engine needs rebuilding.

With the piston is positioned

exactly at Top Dead Center (TDC) on the compression stroke, the automatic

compression release (ACR) mechanism allows the exhaust valve to fully close,

then a leak down test can be performed. The ACR effects a compression test

when performed with a

compression tester, but not a leak down test (as long as

the piston is at TDC on the compression stroke). 0º TDC is when the

piston is at its very top in the cylinder with both valves fully closed.

It is also when the T mark on the flywheel is aligned with

the raised boss on the bearing plate, and The alignment can be seen with

a flashlight through the sight hole in the bearing plate. But the best way

to determine if an engine needs to

be rebuilt is to remove the cylinder head & look at the edge of the piston.

If the carbon is washed away, this means the rings & piston are worn

and the engine needs rebuilding.

FYI - If you have a Kohler 7-16hp ACR camshaft that was broke in two by a thrown connecting rod, save the spring off of it. It can be used on another good cam that may not have one. Or if your ACR spring places little or weak pressure against the flyweights/levers, it can be re-bent or reshape to its original condition to place sufficient tension against the flyweights/levers.

Along with a dirty air filter, or no air filter, a worn throttle shaft

will also cause excessive wear to the valve faces and seats, especially the

intake valve and seat. These are the #1 cause of most engines wearing out

prematurely. The air filter situation is obvious, but if a carburetor has

a worn throttle shaft, this will create a vacuum leak and the engine will

idle poorly, if at all at times. Not to mention the engine will also draw

in dirty air, causing wear on the valve faces/seats and piston rings, and

engine will burn oil. More than .010" of play is considered too much for

throttle shaft wear. Plus, at operating running speeds (3,600 RPM), the extra

air will cause the engine to run lean on fuel, which will overheat the combustion

chamber and cause the cylinder head to warp (blow a head gasket) and the

piston and rings to wear prematurely, eventually resulting in severe engine

wear and excessive oil burning. Along with regular maintenance, repair of

a worn throttle shaft is required to help an engine last a long time. The

most accurate way to check for amount of wear is with a

dial indicator.

Along with a dirty air filter, or no air filter, a worn throttle shaft

will also cause excessive wear to the valve faces and seats, especially the

intake valve and seat. These are the #1 cause of most engines wearing out

prematurely. The air filter situation is obvious, but if a carburetor has

a worn throttle shaft, this will create a vacuum leak and the engine will

idle poorly, if at all at times. Not to mention the engine will also draw

in dirty air, causing wear on the valve faces/seats and piston rings, and

engine will burn oil. More than .010" of play is considered too much for

throttle shaft wear. Plus, at operating running speeds (3,600 RPM), the extra

air will cause the engine to run lean on fuel, which will overheat the combustion

chamber and cause the cylinder head to warp (blow a head gasket) and the

piston and rings to wear prematurely, eventually resulting in severe engine

wear and excessive oil burning. Along with regular maintenance, repair of

a worn throttle shaft is required to help an engine last a long time. The

most accurate way to check for amount of wear is with a

dial indicator.

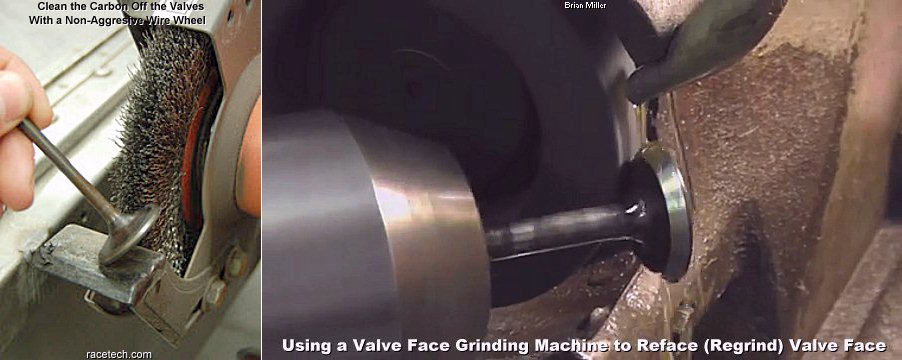

The Difference Between an Amature Valve Job and Performing a Professional Valve Job -

First of all, performing a

professional valve job is when the valve faces and seats are recut or reground

to specs or new valve(s) are installed and the valve clearances are set to

factory specs so the engine will restore full compression, which will allow

the engine to start quicker, idle smoothly, rev up with no hesitation, produce

lots of power, and run for a long time without stalling or dying (when the

ignition timing and carburetor adjustments are set correctly, too). Therefore,

when some people rebuild an engine,

they will not perform a professional valve job! Sometimes they pay no attention

whatsoever to the valves. But when they do, they just clean the valves and

lap them in with

valve grinding compound (which can be purchased online

and at virtually any auto parts store). They think this is a how valves and

seats are reground and how a valve job is performed. And many people won't

even set the valve clearances afterwards! Valves and seats become warped

(slightly bent or moved out of alignment) due to heating of cast iron (or

aluminum) the first time the engine was ran. This is how all flathead engines

and OHV cylinder heads "take shape" or bend and twist a few thousandths of

an inch. The valve faces need to be reground in a valve grinding/refacer

machine so they can be "trued-up" again, and the seats need to be recut or

reground with specialized valve seat tooling so the seat will be in perfect

alignment with the centerline of the valve guide again.

First of all, performing a

professional valve job is when the valve faces and seats are recut or reground

to specs or new valve(s) are installed and the valve clearances are set to

factory specs so the engine will restore full compression, which will allow

the engine to start quicker, idle smoothly, rev up with no hesitation, produce

lots of power, and run for a long time without stalling or dying (when the

ignition timing and carburetor adjustments are set correctly, too). Therefore,

when some people rebuild an engine,

they will not perform a professional valve job! Sometimes they pay no attention

whatsoever to the valves. But when they do, they just clean the valves and

lap them in with

valve grinding compound (which can be purchased online

and at virtually any auto parts store). They think this is a how valves and

seats are reground and how a valve job is performed. And many people won't

even set the valve clearances afterwards! Valves and seats become warped

(slightly bent or moved out of alignment) due to heating of cast iron (or

aluminum) the first time the engine was ran. This is how all flathead engines

and OHV cylinder heads "take shape" or bend and twist a few thousandths of

an inch. The valve faces need to be reground in a valve grinding/refacer

machine so they can be "trued-up" again, and the seats need to be recut or

reground with specialized valve seat tooling so the seat will be in perfect

alignment with the centerline of the valve guide again.

Just cleaning the valves, setting the clearances to specs and "lapping them in" is not performing a professional valve job. If the engine lacks power or dies frequently, then chances are, the valves (and seats) aren't burnt, they're just warped from normal engine heat. This happens on seasoned flathead engine blocks and OHV (Over Head Valve) cylinder heads for the first time. And chances are, the valve faces are worn too, due to normal wear against the seats. This is what causes insufficient or lesser valve clearance. BUT, just lapping the valves in with the seats without first regrinding either will show if the valve face is making contact with the seat 360º or not. If the valve head is warped, slightly bent or burnt, part of the valve lapping compound will NOT make 360º contact with the face, but will likely with the seat. Because seats rarely get severely "get out of alignment" with the valve.

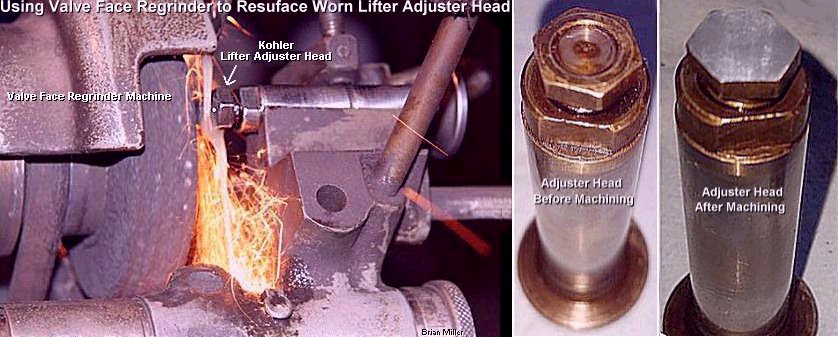

How to Perform a Professional Valve Job -

Dotted lines or skip marks

on valve faces after lapping-in means the stone in the valve grinding/refacer

machine needs to be trued-up. The stone must be periodically trued-up, because

due to a lot of use, it will wear unevenly, resulting in skip marks, an erratic

or "lumpy" valve face.

Dotted lines or skip marks

on valve faces after lapping-in means the stone in the valve grinding/refacer

machine needs to be trued-up. The stone must be periodically trued-up, because

due to a lot of use, it will wear unevenly, resulting in skip marks, an erratic

or "lumpy" valve face.

FYI - Valve seat inserts in Kohler flathead engines, with the exception of the K361 OHV engine, are made of extremely hardened steel and rarely wear, get damaged, crack or loosen. In fact, I have never replaced a valve seat in any of the 100's of Kohler flathead engines that I've professionally rebuilt over the years. All I do to valve seats is recut or regrind the 46º [intake or exhaust factory angle] or 31º angle [intake only; to increase airflow] to put them back in perfect alignment with the centerline of the valve guide to ensure proper 360º valve sealing. And regardless to what some amateur or inexperienced engine rebuilders believe, valve seats are always recut or reground while in the block (or OHV engine). They are never removed to be recut or reground.

Before regrinding the valve faces and seats, the valve guides should be measured for excessive wear and replaced or repaired with a thin-wall bronze sleeve/liner if necessary, then the valve seats can be recut or reground with valve cutting or grinding/refacer equipment to be perpendicular with the centerline of the valve guides. This is important because the cast iron or aluminum engine block (flathead) or OHV (Over Head Valve) cylinder head can "move" or "bend and twist" just a few thousandths of an inch when it got hot for the very first time under normal operating conditions. This is called metal taking shape. Anyway, this "bending and twisting" of the metal can unseat the valve(s), and cause the engine to loose power, not idle well, and make carburetor adjustments difficult, especially at idle. I've seen this happen many times when individuals would rebuild their own engines. Valve lapping only places a rough surface on the valve face(s) and seat(s) so they'll wear-in with each other to produce a perfect seal, but the seats and faces may not be perfectly in-line with the valve stem, which can cause leaking of compression, resulting in lose of engine power. If one don't have their own valve grinder, most automotive machine shops will regrind valve faces for a few bucks. They can also regrind or recut the seats in a flathead engine block or an OHV cylinder head.

FYI - The alternative to installing new replacement OEM-type valve guide(s) is to have the old [worn] guide(s) reamed for installation of thin-wall bronze sleeves/liners (bushings), which can be installed by an experienced and reputable automotive machine shop. Thin-wall bronze valve guides are a low-cost and actually works better than replacing the OEM guide in most engines. Bronze lasts longer than cast iron guides because it is harder material and it retains more oil for better lubrication of the valve stem. Installing CLASSIC Bronze-Liners

The valve faces need to be lapped in enough to create a gray colored line that's the same width of the valve seat (1/16"-3/32" wide) midway in the valve face. Then thoroughly clean off the valve lapping compound from the valve and seat, and look to see if the valve lapping compound made contact 360º around the valve face and seat. Most valves will lap midway on the valve face. The outer and inner areas of the valve face should remain shiny from the regrinding process or from being new, and the whole area of the seat should look gray. If this is the case, then the valve should seal 100% when it wears into the seat.

Valve Head Margin -

Most used valves can be reground and reused in an engine and

give good service for a long time if the face is not severely burnt, head

has a wide margin, and the stem is not bent. The minimum margin width for

Kohler valves is .030". If the margin is too thin, the head of the valve,

especially the exhaust valve due to extreme heat, could become concaved or

collapse in the seat. When this happens, the clearance between the lifter

and valve stem is lessened and the valve will not fully close, and the angles

of the seat valve face will not match, causing the valve to possibly leak

and/or burn. FYI - Regardless of what you've heard, running an engine

without a muffler or some kind of exhaust system will NOT cause the exhaust

valve to burn. This is an old mechanic's myth that got started many years

ago when poor quality metal was used in the manufacturing of exhaust valves.

Technology in

metallurgy and quality of exhaust valves have advanced

a lot in recent years.

Most used valves can be reground and reused in an engine and

give good service for a long time if the face is not severely burnt, head

has a wide margin, and the stem is not bent. The minimum margin width for

Kohler valves is .030". If the margin is too thin, the head of the valve,

especially the exhaust valve due to extreme heat, could become concaved or

collapse in the seat. When this happens, the clearance between the lifter

and valve stem is lessened and the valve will not fully close, and the angles

of the seat valve face will not match, causing the valve to possibly leak

and/or burn. FYI - Regardless of what you've heard, running an engine

without a muffler or some kind of exhaust system will NOT cause the exhaust

valve to burn. This is an old mechanic's myth that got started many years

ago when poor quality metal was used in the manufacturing of exhaust valves.

Technology in

metallurgy and quality of exhaust valves have advanced

a lot in recent years.

Regrinding the valve faces at a 30º or 45º angle places the valve head in perfect alignment (perpendicular) with the stem or "straightens them out" again so they'll be good as new. And regrinding or re-cutting the seats at a 31º or 46º angle ensures that the valve stems will be centered in the valve guides and the faces will seal 360º around. The reason for the 30º/31º or 45º/46º angles are so the valves and seats can wear into each other, producing a 30-½º or 45-½º angle for each, creating a perfect 100% seal. If each were reground at the same angle, carbon deposits would become lodged between them and eventually the valve face would burn. Anyway, after the valves and seats are reground, the valve clearances can be set at specs with the piston positioned exactly at top dead center on the compression stroke. Then lap them in so the faces will produce a wear pattern on the seats (the lapping process helps produce the perfect 30-½º or 45-½º angle for each). After the valves are matched perfectly with the seats after about 2 hours of normal engine operation, the engine should start quicker, produce more power and the valves should last the life of the engine.

If you want a factory stock lawn & garden or stock competition pulling engine with an intake valve that has a factory-ground 45º/46º intake valve and seat, for it to produce a few more ponies, regrind the intake valve face and seat at 30º and 31º, respectively. Doing this will allow slightly more air (and fuel) to enter the combustion chamber to create higher compression pressures. It will do absolutely no harm to the engine either. Briggs & Stratton have been doing this (plus other performance enhancements) to their flathead aluminum block engines since 1969, and it works great! Briggs even gave the cylinder head on their 3.5hp flathead lawn mower engines a specially designed combustion chamber that increases the air charge when the incoming air (and fuel) enters the combustion chamber, and scavenges the burnt gases more thoroughly when exiting the combustion chamber!

As a matter

of fact, since 1969, ALL Briggs & Stratton flathead aluminum block engines

are built-to-the-max at 3,600 RPM at the factory to produce as power as possible,

but still last a long time. This does not lessen the longevity of the engine.

All B&S aluminum block single cylinder engines and the B&S flathead

opposed twin cylinder engines have a factory-installed performance-ground

camshaft with increased duration/overlap. This is why the opposed twin cylinder

engines produce a "lope, lope, lope" sound out the exhaust at slow idle.

This can't be heard with the single cylinder engines. There are very few-to-no

improvements or modifications that can be made to B&S engines so they

will produce more horsepower and torque at 3,600 RPM, with the exception

of the 5hp B&S flathead racing go-kart engines, which run at open RPM.

Why Kohler didn't follow B&S's method of building to the max engines,

I have no idea.

As a matter

of fact, since 1969, ALL Briggs & Stratton flathead aluminum block engines

are built-to-the-max at 3,600 RPM at the factory to produce as power as possible,

but still last a long time. This does not lessen the longevity of the engine.

All B&S aluminum block single cylinder engines and the B&S flathead

opposed twin cylinder engines have a factory-installed performance-ground

camshaft with increased duration/overlap. This is why the opposed twin cylinder

engines produce a "lope, lope, lope" sound out the exhaust at slow idle.

This can't be heard with the single cylinder engines. There are very few-to-no

improvements or modifications that can be made to B&S engines so they

will produce more horsepower and torque at 3,600 RPM, with the exception

of the 5hp B&S flathead racing go-kart engines, which run at open RPM.

Why Kohler didn't follow B&S's method of building to the max engines,

I have no idea.

On twin cylinder engines, it's important that after the valve clearances are set on the cylinder with the piston positioned at TDC on the compression stroke, the crankshaft will need to be rotated 180º so the valves on the opposing cylinder can be set with the piston positioned at TDC on the compression stroke. Failure to rotate the crankshaft 180º will give the cylinder with the piston positioned at TDC on the exhaust stroke excessive clearance and the valves will make a very loud tapping sound when the engine is running.

Seat Width -

When regrinding or recutting valve

sears, first cut or regrind the seat with a 46º

[Neway] cutter or [Sioux] grinding/refacer stone until it

makes contact 360º around the seat, then use a 31º cutter or

grinding/refacer stone to narrow the seat width to factory specs if it's

too wide.

When regrinding or recutting valve

sears, first cut or regrind the seat with a 46º

[Neway] cutter or [Sioux] grinding/refacer stone until it

makes contact 360º around the seat, then use a 31º cutter or

grinding/refacer stone to narrow the seat width to factory specs if it's

too wide.

Ever noticed that when looking up valve clearances for an engine, the manufacturer will always show two figures? Example: Intake valve clearance: .008" - .010"; Exhaust valve clearance: .014" - .016". The greater clearance is for a fresh valve job. Because as an engine runs, due to the 30º or 45º angle on the valve face(s) and the 31º or 46º angle on the seat(s), the valves and the seats wears together (break-in period), forming a 30-½º or 45-½º angle on each, which causes the clearances to become slightly lessened. (As the valves wears into the seats, forming a perfect seal, you may notice the engine produces slightly more power.) And for an engine (valves) that's been in use for some time, the valves should be set at the lesser clearance because the valve faces and seats are already worn into each other (broke-in).

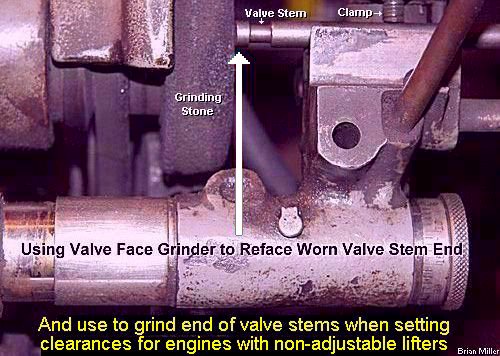

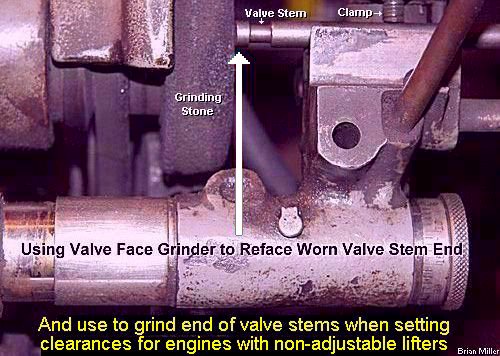

It's also important that the

end of the valve stem is perfectly flat. This will allow for correct valve

adjustment and valve action, especially in an OHV (Over Head Valve) engine

with rocker arms.

It's also important that the

end of the valve stem is perfectly flat. This will allow for correct valve

adjustment and valve action, especially in an OHV (Over Head Valve) engine

with rocker arms.

By the way - I get a lot of engines in my shop that need a valve job performed. Many other small engine repair shops will ignore the valves (or they're not trained to perform professional valve jobs) and assume the hard-starting problem is elsewhere with the engine.

If they're not burnt, then chances are, the valves and seats become warped from the block being heated under normal use after it was new and the metal "takes shape." Aluminum blocks (and heads) are worse than cast iron blocks (and heads). This happens with small engines as well as automotive engines. The block will actually deform a few thousands of an inch, moving the valves off the seats slightly, causing them to leak. Sometimes the cylinder wall(s) will deform a few thousands of an inch, too. Once the "seasoned" block or head takes shape, they won't warp any more. If the valves are leaking, then the valves and seats will need to be recut or reground so they're be in perfect alignment with each other and perpendicular with the valve guides.

Performing a Compression Test on a Stock or High-Performance Small Engine with a Compression Tester -

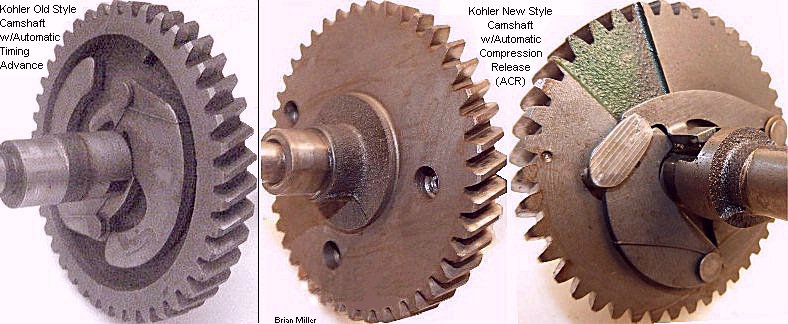

An accurate compression reading

can't be performed on an engine with an unaltered OEM camshaft due to the

compression release mechanism on one of the cam lobes. Depending on the make

and model of engine, the compression release is either a small hump (early

B&S, certain Tecumseh's, etc.) or mechanical lever/pin (newer B&S,

Kohler, some Tecumseh, etc.) on one of the camshaft lobes that holds either

the intake or exhaust valve open about .050" while the piston is traveling

halfway up in the cylinder on the compression stroke. On OEM camshafts with

a working compression release mechanism and if the valve clearances are adjusted

to specs, the compression release relieves about half the compression air

from the combustion chamber at cranking speed. This is so the engines with

fixed advanced ignition timing will start easier. When attempting to start

an engine with fixed advanced ignition timing, if the compression release

isn't working or if the valve (with the compression release) have too much

stem-to-lifter clearance (out of adjustment), the engine will "kick back"

every time. "Kick back" occurs when the crankshaft suddenly and violently

rebounds or rotates in the opposite direction, which is could bend or break

the starter armature shaft or the aluminum starter housing.

An accurate compression reading

can't be performed on an engine with an unaltered OEM camshaft due to the

compression release mechanism on one of the cam lobes. Depending on the make

and model of engine, the compression release is either a small hump (early

B&S, certain Tecumseh's, etc.) or mechanical lever/pin (newer B&S,

Kohler, some Tecumseh, etc.) on one of the camshaft lobes that holds either

the intake or exhaust valve open about .050" while the piston is traveling

halfway up in the cylinder on the compression stroke. On OEM camshafts with

a working compression release mechanism and if the valve clearances are adjusted

to specs, the compression release relieves about half the compression air

from the combustion chamber at cranking speed. This is so the engines with

fixed advanced ignition timing will start easier. When attempting to start

an engine with fixed advanced ignition timing, if the compression release

isn't working or if the valve (with the compression release) have too much

stem-to-lifter clearance (out of adjustment), the engine will "kick back"

every time. "Kick back" occurs when the crankshaft suddenly and violently

rebounds or rotates in the opposite direction, which is could bend or break

the starter armature shaft or the aluminum starter housing.

On certain B&S, Kohler models K90/K91, K141, K160/K161, K181, L161, L181, M8, some Tecumseh, etc. engines without adjustable lifters, but with an automatic (mechanical) compression release (ACR) on the camshaft, there is no way to perform an accurate compression test with a compression tester. All that can be done to test the compression is rotate the flywheel quickly by hand in the opposite direction of normal engine rotation. If it rebounds sharply, the engine has adequate compression. FYI - If you have a Kohler 7-16hp ACR camshaft that was broke in two by a thrown connecting rod, save the spring off of it. It can be used on another good cam that may not have one. Or if your ACR spring places little or weak pressure against the flyweights/levers, it can be re-bent or reshape to its original condition to place sufficient tension against the flyweights/levers.

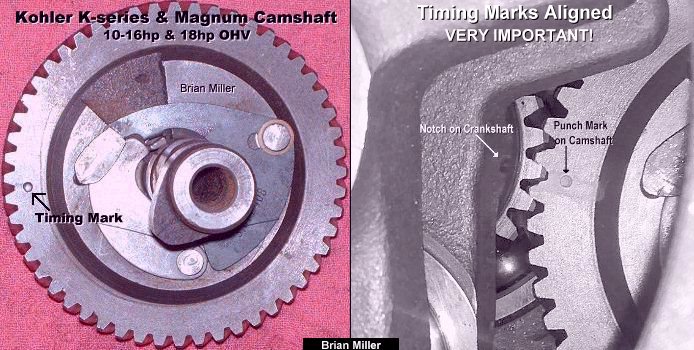

There are two ways to perform an accurate compression test with a compression tester on the Kohler K-series and Magnum engine models K241, M10, K301, M12, K321, M14, K341, M16 and K361:

To obtain an accurate compression pressure reading, perform the test with a fully charged battery, a starter that's in good condition and the throttle in the wide open position. Or with pull rope engines, place the throttle in the wide open position. When performing a compression test with a gauge on an air-cooled engine, keep in mind that, depending on how the engine is built, the compression ratio or the compression pressure can vary from one engine to another. It depends on the size of the bore and stroke, the volume of the combustion chamber in the cylinder head, if the camshaft has a compression release or not and how much duration the cam lobes have. If a cam has a compression release mechanism, being approximately half the compression is released from the combustion chamber at cranking speed, the compression reading will be cut approximately in half.

When performing a compression test on an engine under compression, the K241 and M10 Kohler can be from 98 to 150 psi. On a K301 and M12, it can be from 112 to 170 psi. On a K321 and M14, it can range from 120 to 190 psi. And on a K341 and M16, it can be from 127 up to 192 psi.

And cranking speeds, a long duration cam will relieve some of the combustion chamber pressure, resulting in a lower than normal reading. The more the duration, the lower the reading. Calculate the reading with the duration of the cam in the engine against the duration of a stock OEM cam. Example: If the compression pressure is 100 psi, multiple 100 by 285 (duration of cam that's in the engine) and then divide the answer by 223 degrees (duration of a stock OEM cam), which gives 128 psi.

And Remember...

Rather if it's for general lawn and garden use, competition racing or competition pulling, the parts inside any fresh-built engine needs to fully wear into each other. This is otherwise known as engine break-in. Rings don't "seat." They wear-into the cylinder wall, and wear-in rather quickly. But the valve faces on the other hand, takes longer to wear into the seats. The valve faces are ground at either 30º or 45º angle, and the seats are ground or cut at either 31º or 46º angle (to match the valve face). As they wear into each other, they form a 30½º or 45½º angle. The harder material valves are made of, the longer it takes for them to "seat." With rotators, it takes less time for the valves to "seat" or wear-in. Some pullers (customers) tell A-1 Miller's that engines I built for them run stronger every time they pull them without making any major adjustments or changes. This is because the valves are wearing into the seats to better seal in the compression. I remember a few years ago when I performed a valve job on my 1985 Chevy 350 truck engine. The engine ran good and strong afterwards, but I noticed after about 1,000 miles or so, it produced a little more power. This is because the valve faces wore into the seats, forming a perfect seal. So just to let you know, a rebuilt engine with a fresh valve job will not produce full power the first few times it's ran, even in a dyno test.

Just cleaning

the valves and lapping them in (with a valve

lapping tool and compound), then assume the engine will run fine for

many years without problems is definitely not how a professional valve job

is performed.

Valve grinding compound, which can be purchased online

and at virtually any auto parts store, is not meant for "grinding valves".

I realize it reads on the label: "Valve Grinding Compound," but this

is wrong because it doesn't regrind valves (or seats) whatsoever. A valve

seat cutter/grinder and valve refacer/grinding machine is meant to do this.

The

valve grinding compound (which can be purchased online

and at virtually any auto parts store) is actually used to create a rough

surface on the valve face and seat so they'll wear into each other as they

break in, forming a perfect seal to keep the valves from leaking out compression.

Just cleaning

the valves and lapping them in (with a valve

lapping tool and compound), then assume the engine will run fine for

many years without problems is definitely not how a professional valve job

is performed.

Valve grinding compound, which can be purchased online

and at virtually any auto parts store, is not meant for "grinding valves".

I realize it reads on the label: "Valve Grinding Compound," but this

is wrong because it doesn't regrind valves (or seats) whatsoever. A valve

seat cutter/grinder and valve refacer/grinding machine is meant to do this.

The

valve grinding compound (which can be purchased online

and at virtually any auto parts store) is actually used to create a rough

surface on the valve face and seat so they'll wear into each other as they

break in, forming a perfect seal to keep the valves from leaking out compression.

Remember, when/if you have a

repair shop perform a valve job, be sure to ask them how it's done. In other

words, test their knowledge. If they say that the valves be removed, cleaned

up, lapped in, then set the clearance, this is not the correct way to do

it. Due to normal engine heat and "twisting" of the engine block (which is

normal and happens to all flathead engines and OHV (Over Head Valve) cylinder

heads), valve heads become warped. New engine blocks (or cylinder head on

OHV engines) rather it be cast iron or aluminum, will sometimes become

"distorted" (bend and twist) a few thousands of an inch when it gets hot

from normal use. The valves will become warped to match the warped block

(or head). Therefore, to prevent loss of valuable compression and engine

power, the valve faces will need to be reground in a valve grinding/refacer

machine and the seats recut or reground with a valve seat cutter or grinder

to put everything back in correct alignment. The head will literally move

a few thousands of an inch offcenter of the valve stem. Therefore, the valve

faces must be reground in a valve grinding/refacer machine, or if a valve

is severely burnt, it should be replaced. And again, due to normal engine

heat, the valve seats will literally move a few thousands of an inch offcenter

of the valve guide. Therefore, the seats must

be reground with a seat grinder or cutter so the valve faces will seal 360º

around the seats. (And always wear

eye protection whenever working with metal!)

Remember, when/if you have a

repair shop perform a valve job, be sure to ask them how it's done. In other

words, test their knowledge. If they say that the valves be removed, cleaned

up, lapped in, then set the clearance, this is not the correct way to do

it. Due to normal engine heat and "twisting" of the engine block (which is

normal and happens to all flathead engines and OHV (Over Head Valve) cylinder

heads), valve heads become warped. New engine blocks (or cylinder head on

OHV engines) rather it be cast iron or aluminum, will sometimes become

"distorted" (bend and twist) a few thousands of an inch when it gets hot

from normal use. The valves will become warped to match the warped block

(or head). Therefore, to prevent loss of valuable compression and engine

power, the valve faces will need to be reground in a valve grinding/refacer

machine and the seats recut or reground with a valve seat cutter or grinder

to put everything back in correct alignment. The head will literally move

a few thousands of an inch offcenter of the valve stem. Therefore, the valve

faces must be reground in a valve grinding/refacer machine, or if a valve

is severely burnt, it should be replaced. And again, due to normal engine

heat, the valve seats will literally move a few thousands of an inch offcenter

of the valve guide. Therefore, the seats must

be reground with a seat grinder or cutter so the valve faces will seal 360º

around the seats. (And always wear

eye protection whenever working with metal!)

Valves can leak! For example, if fuel sprays out of the carburetor on a opposed twin cylinder engine when it's running at fast speed, then the following causes are.

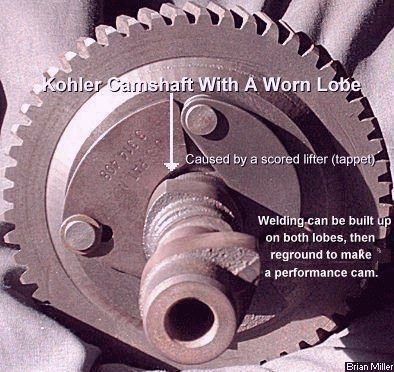

But if a valve isn't opening

or opening very little when the engine is cranked over, then chances are,

the nose or toe on a lobe on the camshaft is wore down. This happens when

water gets in the crankcase and over time, condensation attaches itself to

the base of the lifter, rusting and pitting it. While the engine is running,

the rusted and pitted lifter wears (or grinds) the lobe until it's wore down

or "rounded." This sort of thing will also prevent a single cylinder engine

from revving up.

But if a valve isn't opening

or opening very little when the engine is cranked over, then chances are,

the nose or toe on a lobe on the camshaft is wore down. This happens when

water gets in the crankcase and over time, condensation attaches itself to

the base of the lifter, rusting and pitting it. While the engine is running,

the rusted and pitted lifter wears (or grinds) the lobe until it's wore down

or "rounded." This sort of thing will also prevent a single cylinder engine

from revving up.

About Lead Content in Gasoline -

Lead in gas was actually meant for older (pre-1970) automotive engines because they had soft cast iron valve seats. The cylinder heads were made of cast iron and the seats were cut or ground directly into the head with no hardened inserts. These seats was not heat-treated and would wear when no lead is present in gas. However, the later model automobile engine valve seats (1971-present) are heat-treated and last a lot longer. The seats were still cut or ground in the [cast iron] heads, but are heat-treated. The aluminum automotive heads have heat-treated steel inserts for valve seats. And virtually ALL small engine valve seats come from the factory heat-treated. They are steel inserts, and rarely wear when no lead is present in gas.

How to Perform a Professional Valve Job - [Top of Page]

First of all, performing a

professional valve job will restore full compression, which will allow the

engine to start quicker, idle smoothly, rev up with no hesitation, produce

lots of power, and run for a long time without stalling or dying (when the

ignition timing and carburetor adjustments are set correctly, too). So to

gain more power and torque from virtually any flathead single or opposed

twin cylinder engine, perform a professional valve job and the valve clearances

will need to be increased. Resurface the cylinder heads on a flat sanding

disc to ensure 100% head gasket sealing. Nothing else may be needed to be

done to the engine, except for perhaps a professional tune up. Many opposed

twin cylinder engines have inadequate valve clearances and this robs the

engine of proper operation and valuable power. Perform a professional valve

job, and set the clearances (between the valve stems and lifters) at .010"

for the intake and .014" for the exhaust. After increasing the valve clearances,

the engine will start quicker, idle better and produce more power at low

and high RPM.

First of all, performing a

professional valve job will restore full compression, which will allow the

engine to start quicker, idle smoothly, rev up with no hesitation, produce

lots of power, and run for a long time without stalling or dying (when the

ignition timing and carburetor adjustments are set correctly, too). So to

gain more power and torque from virtually any flathead single or opposed

twin cylinder engine, perform a professional valve job and the valve clearances

will need to be increased. Resurface the cylinder heads on a flat sanding

disc to ensure 100% head gasket sealing. Nothing else may be needed to be

done to the engine, except for perhaps a professional tune up. Many opposed

twin cylinder engines have inadequate valve clearances and this robs the

engine of proper operation and valuable power. Perform a professional valve

job, and set the clearances (between the valve stems and lifters) at .010"

for the intake and .014" for the exhaust. After increasing the valve clearances,

the engine will start quicker, idle better and produce more power at low

and high RPM.

To do a poor quality valve job, some people will remove the valves, clean them thoroughly, then use valve grinding compound (which can be purchased online and at virtually any auto parts store) to reseal them to the seats, then if they think of it, reset the valve clearances. Doing this might help an engine run better, but it's not how to perform a professional and/or performance valve job so the engine will start quicker, idle smoothly, accelerate without hesitation, and produce full power at higher RPM.

Valve clearances in the Kohler Engine Specifications and Tolerances charts are given with a lesser and greater clearance. Example: .008"-.010" intake, and .017"-.019" exhaust. The lesser clearance is for worn-in valve faces and seats, and the greater clearance is for freshly-ground valve faces and seats, or new valves with fresh-reground seats. Because as a freshly-ground valve face or new valve wear into the seat, the clearance between the valve stem and lifter is lessened.

To perform a professional valve job on a opposed twin cylinder flathead B&S or Kohler engine, the parts that will be needed are: two head gaskets, two crankcase breather gaskets, intake manifold mounting gaskets and valve stem seals (for intake valves only). New valve guides, especially for the exhaust valves, may also be needed. But that's to be determined once the valves are removed. The valve faces and valve seats angles are to be reground or recut at 45° (intake valve face for Kohler), 30° (intake valve face for B&S) and 46° (intake and exhaust seats for Kohler and exhaust seat only for B&S), 31° (intake seat for B&S), respectively. If you can't do this yourself, a local automotive machine shop can do it for you. You'll need to take the engine or tractor to the shop to have the valve seats reground or recut. Make sure they're reground or recut at the proper angle, too! And it'll be a good idea to have both cylinder heads resurfaced on a on a wide, flat belt- or disc-sander/grinder to remove any warpage and restore flatness, and to ensure 100% head gasket sealing. The head bolts can be reused. They rarely go bad.

The tools that's required to perform a professional valve job are as follows:

To perform a professional valve job correctly the first time so the engine will start quicker, idle smoothly and rev to full RPMs:

First

rotate the crankshaft until the piston is at top dead center (TDC) on the

compression stroke. Or if the crank is out of the block (during an engine

rebuild), rotate the camshaft until both valves are fully closed. If it's

a twin- or multi-cylinder engine, do this for each cylinder.

First

rotate the crankshaft until the piston is at top dead center (TDC) on the

compression stroke. Or if the crank is out of the block (during an engine

rebuild), rotate the camshaft until both valves are fully closed. If it's

a twin- or multi-cylinder engine, do this for each cylinder.

If a valve stem is bent,

chances are, it can be straightened and the valve can be reused. I repair

bent valves in my big metal lathe with success. Here's how to do

it:

If a valve stem is bent,

chances are, it can be straightened and the valve can be reused. I repair

bent valves in my big metal lathe with success. Here's how to do

it:

First of all, if there's a crack

in the valve stem, it must be replaced, especially when used in an

OHV (Over Head Valve) engine. It's best to inspect the stem for a hairline

crack with a strong magnifying glass or better yet, a powerful

microscope. Do not attempt to

weld up a cracked valve stem, especially an exhaust valve and after straightening

it! It will break later!

First of all, if there's a crack

in the valve stem, it must be replaced, especially when used in an

OHV (Over Head Valve) engine. It's best to inspect the stem for a hairline

crack with a strong magnifying glass or better yet, a powerful

microscope. Do not attempt to

weld up a cracked valve stem, especially an exhaust valve and after straightening

it! It will break later!

Use steel feeler gauges to set

the valve clearances. For the K241-K341 engines, for general lawn and garden

use, the valve clearances are: .008"-.010" for the intake and .017"-.019"

for the exhaust with the piston at TDC on the compression stroke. This is

when both valves are fully closed. For competition pulling, set the valve

clearances at .010" for the intake and .014" for the exhaust.

Use steel feeler gauges to set

the valve clearances. For the K241-K341 engines, for general lawn and garden

use, the valve clearances are: .008"-.010" for the intake and .017"-.019"

for the exhaust with the piston at TDC on the compression stroke. This is

when both valves are fully closed. For competition pulling, set the valve

clearances at .010" for the intake and .014" for the exhaust.

When checking the valve lash

on any engine, the piston in the cylinder for the valves that you're checking

(on multiple cylinder engines) must be at top dead center (TDC) on the

compression stroke. This places the lifters on the base circle of the cam

lobes. The reason there's a valve lash is so the valves can fully close,

sealing in the compressed air/fuel mixture in the combustion chamber. Too

little lash, and some of the compression will escape through one or both

valves, and in over time, a valve may burn. Too much lash, and the valves

won't open fully, preventing the engine from producing full power.

When checking the valve lash

on any engine, the piston in the cylinder for the valves that you're checking

(on multiple cylinder engines) must be at top dead center (TDC) on the

compression stroke. This places the lifters on the base circle of the cam

lobes. The reason there's a valve lash is so the valves can fully close,

sealing in the compressed air/fuel mixture in the combustion chamber. Too

little lash, and some of the compression will escape through one or both

valves, and in over time, a valve may burn. Too much lash, and the valves

won't open fully, preventing the engine from producing full power.

use a

valve lapping tool to lap the valves in

the seats (use this tool to rotate each valve back and forth with both hands)

until the "grinding sound" goes away. This process is important. It seals

the valves to the seats.

use a

valve lapping tool to lap the valves in

the seats (use this tool to rotate each valve back and forth with both hands)

until the "grinding sound" goes away. This process is important. It seals

the valves to the seats.

After lapping in the valves, remove

the valves and thoroughly clean the compound material from the valves and

seats, then inspect the valve faces to see if the compound made full contact

of 360º around each valve face and seat. If it didn't, then the valve

is warped, or the face or seat wasn't ground correctly and will need to be

re-done.

After lapping in the valves, remove

the valves and thoroughly clean the compound material from the valves and

seats, then inspect the valve faces to see if the compound made full contact

of 360º around each valve face and seat. If it didn't, then the valve

is warped, or the face or seat wasn't ground correctly and will need to be

re-done.

chainsaw bar tip grease gun to make this much easier and

less messy), stick one half of a keeper to it, apply another dab of grease

inside the keeper, then carefully place the keeper on the valve stem (in

the right direction). Do it this way with each keeper half. The grease securely

holds the keepers/locks/collets to the valve stem

until the retainer can be released over them.

chainsaw bar tip grease gun to make this much easier and

less messy), stick one half of a keeper to it, apply another dab of grease

inside the keeper, then carefully place the keeper on the valve stem (in

the right direction). Do it this way with each keeper half. The grease securely

holds the keepers/locks/collets to the valve stem

until the retainer can be released over them.

What Are Valve Rotators and Why Are They Used?

For a non-pulling engine, valve rotators help prevent valves

from burning by rotating the valve slightly as it opens to scrape away any

carbon deposits from the valve face and seat. If an engine didn't come with

valve rotators (most early Kohler engines didn't), they can be installed

instead of the stamped steel non-rotator retainers. Many automotive engines

use valve rotators, too. A rotator should be used with the exhaust valve

because that's the one where the carbon exits the combustion chamber, and

is optional for use with the intake valve. Rotators can be used in any K141-K341

Kohler engine. It's important that a rotator be used with the 1-9/16"

uncompressed height OEM valve spring to prevent coil bind at full valve lift,

which may result in cam breakage. Stamped or machined steel retainers require

a 1-3/4" uncompressed height OEM spring. If the shorter 1-9/16" spring is

used with a non-rotator retainer, the valve(s) may float, and/or the

keepers/locks/collets may become dislodged from the

valve stem at higher RPM. Although valve rotators are extremely strong,

competition pulling engines don't require them because they don't run long

enough for carbon to build up in the combustion chamber. By the way - valve

keepers usually don't wear or get damaged because they don't rotate on the

valve stem. To check yours, with a valve out of the engine, install a valve

retainer or rotator on the valve, then the keepers, and then pull back hard

on the retainer or rotator. If the retainer or rotator holds or squeezes

the keepers tight in the groove, then they can be reused.

For a non-pulling engine, valve rotators help prevent valves

from burning by rotating the valve slightly as it opens to scrape away any

carbon deposits from the valve face and seat. If an engine didn't come with

valve rotators (most early Kohler engines didn't), they can be installed

instead of the stamped steel non-rotator retainers. Many automotive engines

use valve rotators, too. A rotator should be used with the exhaust valve

because that's the one where the carbon exits the combustion chamber, and

is optional for use with the intake valve. Rotators can be used in any K141-K341

Kohler engine. It's important that a rotator be used with the 1-9/16"

uncompressed height OEM valve spring to prevent coil bind at full valve lift,

which may result in cam breakage. Stamped or machined steel retainers require

a 1-3/4" uncompressed height OEM spring. If the shorter 1-9/16" spring is

used with a non-rotator retainer, the valve(s) may float, and/or the

keepers/locks/collets may become dislodged from the

valve stem at higher RPM. Although valve rotators are extremely strong,

competition pulling engines don't require them because they don't run long

enough for carbon to build up in the combustion chamber. By the way - valve

keepers usually don't wear or get damaged because they don't rotate on the

valve stem. To check yours, with a valve out of the engine, install a valve

retainer or rotator on the valve, then the keepers, and then pull back hard

on the retainer or rotator. If the retainer or rotator holds or squeezes

the keepers tight in the groove, then they can be reused.

Most Kohler engines have the short valve spring (1-9/16") with the rotator on the exhaust valve, and the long spring (1-3/4") with the stamped retainer on the intake valve.

How to Perform a Professional Valve Job on a B&S or Kohler Opposed Twin Cylinder Engine -

| To gain more power and torque from virtually any flathead two or opposed

twin cylinder engine, perform a professional valve job and the valve clearances

will need to be increased. Resurface the cylinder heads on a flat sanding

disc to ensure proper head gasket sealing. Nothing else may be needed to

be done to the engine, except for perhaps a professional tune up. Many opposed

twin cylinder engines have inadequate valve clearances and this robs the

engine of proper operation and valuable power. Perform a professional valve

job, and set the clearances (between the valve stems and lifters) at .010"

for the intake and .014" for the exhaust. After increasing the valve clearances,

the engine will start quicker, idle better and produce more power at low

and high RPM.

To perform a professional valve job on a opposed twin cylinder flathead B&S or Kohler engine, the parts that will be needed are: two head gaskets, two crankcase breather gaskets, intake manifold mounting gaskets and valve stem seals (for intake valves only). New valve guides, especially for the exhaust valves, may also be needed. But that's to be determined once the valves are removed. A quality-made valve spring compressor tool is required to remove and reinstall the valves. The valve faces and valve seat angles are to be recut or reground at 45º (intake valve face for Kohler), 30º (intake valve face for B&S) and 46º (intake and exhaust seats for Kohler and exhaust seat only for B&S), 31º (intake seat for B&S), respectively. If you can't do this yourself, a local automotive machine shop can do it for you. You'll need to take the engine or tractor to the shop to have the valve seats recut or reground. Make sure they're recut or reground at the proper angle, too! And it'll be a good idea to have both cylinder heads resurfaced on a flat sanding disc to ensure 100% head gasket sealing. The head bolts can be reused. They rarely go bad. |

Advertisement: (Prices are subject to change without notice.) FYI - Due to new EPA rules and regulations, Kohler (and many other small engine manufacturers) are phasing out many parts for their flathead and cast iron block engines. But the parts in question may be available in aftermarket.

| Click here to contact A-1 Miller's Performance Enterprises to place an order, send your parts for repairing, and/or for FREE professional and honest technical customer service assistance and support and payment options. Please contact A-1 Miller's if you need a part or parts, or service(s) performed that's not listed or mentioned in this website. | ||

Intake Valve. Fits

Kohler engine models KT90/KT91. Head diameter: 15/16". New Old Stock.

Discontinued Kohler part # 220008-S. $32.00 each, plus shipping &

handling. (When available.) Intake Valve. Fits

Kohler engine models KT90/KT91. Head diameter: 15/16". New Old Stock.

Discontinued Kohler part # 220008-S. $32.00 each, plus shipping &

handling. (When available.)

Exhaust Valve. Fits Kohler engine models KT90/KT91. OEM Kohler part # 220009-S. $60.55 each, plus shipping & handling. NOTE: Before lapping in valves, it's best to have the valve seats recut or reground so they'll be in correct alignment with the centerline of the valve guides. Otherwise, the valves may not make a full 360º contact with the seats, resulting in leakage and the engine will lose compression, be hard to start, lose power and possibly make a popping sound through the carburetor or out the exhaust at idle speed. And be sure to set the clearances correctly, too. And if the end of the valve stem is accidentally ground too short, it can be made long again by building up welding with a MIG or TIG welder, then ground to the correct valve clearance.

Intake Valves. Fits Kohler engine models K141, K160/K161 K181, L161, L181, M8. Dimensions: head diameter: 1-3/8"; overall length: 4.065"; stem diameter: .309"; 45º face angle.

NOTE: Before lapping in valves, it's best to have the valve seats recut or reground so they'll be in correct alignment with the centerline of the valve guides. Otherwise, the valves may not make a full 360º contact with the seats, resulting in leakage and the engine will lose compression, be hard to start, lose power and possibly make a popping sound through the carburetor or out the exhaust at idle speed. And be sure to set the clearances correctly, too. And if the end of the valve stem is accidentally ground too short, it can be made long again by building up welding with a MIG or TIG welder, then ground to the correct valve clearance.

1-3/8" Diameter Intake Valves. Fits Kohler engine models K241, M10, K301, M12, K321, M14, K341, M16, K482, K532 and K582. Dimensions - Head diameter: 1-3/8"; Length: 4.640"; Stem diameter: .3095"; Face angle: 45º.

1-3/8" Diameter Exhaust Valves for later model K321's, M14 (suffix "D" and later), K341, M16, K532 and K582 (for K582 after serial # 9165450). Dimensions - Head diameter: 1.373; Length: 4.639; Stem diameter: .3075; Face Angle: 45º.

NOTE: Before lapping in valves, it's best to have the valve seats recut or reground so they'll be in correct alignment with the centerline of the valve guides. Otherwise, the valves may not make a full 360º contact with the seats, resulting in leakage and the engine will lose compression, be hard to start, lose power and possibly make a popping sound through the carburetor or out the exhaust at idle speed. And be sure to set the clearances correctly, too. And if the end of the valve stem is accidentally ground too short, it can be made long again by building up welding with a MIG or TIG welder, then ground to the correct valve clearance.

8mm (.315") Chucking Reamer. Use to enlarge valve guides for installation of oversize or aftermarket valves with an 8mm valve stem in Kohler engine models K361, KT19, KT19 Series II, M20 and MV20, or 1.720" oversize valve in 10-16hp Kohler engines. $20.00 each, plus shipping & handling.

NOTE: Before lapping in valves, it's best to have the valve seats recut or reground so they'll be in correct alignment with the centerline of the valve guides. Otherwise, the valves may not make a full 360º contact with the seats, resulting in leakage and the engine will lose compression, be hard to start, lose power and possibly make a popping sound through the carburetor or out the exhaust at idle speed. And be sure to set the clearances correctly, too. And if the end of the valve stem is accidentally ground too short, it can be made long again by building up welding with a MIG or TIG welder, then ground to the correct valve clearance.

Intake Valves. Each valve listed below fits Kohler engine models KT17 (first design), KT17 Series II, MV16, M18 and MV18. Replaces discontinued Kohler part #'s 52 016 05-S (listed for M18, MV18); 52 017 01-S, 52 017 02-S, 52 017 03-S ), 52 017 05-S (all four listed for KT17); 52 017 07-S, 52 017-08-S (both listed for MV16, M18). Dimensions: head diameter: 1.373"; overall length: 3.641".

Exhaust Valves. Each valve listed below fits Kohler engine models KT17 (first design), KT17 Series II, MV16, M18 and MV18. Dimensions: head diameter: 1.373"; overall length: 3.641".

Intake Valves. Fits Kohler engine models KT19 first design, KT19 Series II, KT21, M20 and MV20. Replaces discontinued Kohler part #'s 52 016 02-S, 52 017 03 (listed for KT19), 52 017 07-S, 52 017 08-S. Dimensions: head diameter: 1.373"; overall length: 3.926".

Exhaust Valves. Fits Kohler engine models KT19 first design, KT19 Series II, KT21, M20 and MV20. Replaces discontinued Kohler part #'s 52 016 02-S, 52 017 03, 52 017 07-S, 52 017 08-S. Dimensions: head diameter: 1.373"; overall length: 3.926".

NOTE: Before lapping in valves, it's best to have the valve seats recut or reground so they'll be in correct alignment with the centerline of the valve guides. Otherwise, the valves may not make a full 360º contact with the seats, resulting in leakage and the engine will lose compression, be hard to start, lose power and possibly make a popping sound through the carburetor or out the exhaust at idle speed. And be sure to set the clearances correctly, too. And if the end of the valve stem is accidentally ground too short, it can be made long again by building up welding with a MIG or TIG welder, then ground to the correct valve clearance.

è New valves for other makes and models of small engines are also available. |

||

| Valve Guides -

FYI - Valve guides are made of

either cast iron or bronze, and not steel. Cast iron and bronze are very

hard and porous metals. They absorb oil and lubricate the valve stems for

longer wear. NOTE: The alternative to installing

new replacement OEM-type valve guide(s) is to have the old [worn] guide(s)

reamed for installation of thin-wall bronze sleeves/liners (bushings), which

can be installed by an experienced and reputable automotive machine shop.

Thin-wall bronze valve guides are a low-cost and actually works better than

replacing the OEM guide in most engines. Bronze lasts longer than cast iron

guides because it is harder material and it retains more oil for better

lubrication of the valve stem.

Installing CLASSIC Bronze-Liners

[Return To Previous Paragraph, Section

or Website]

|

||

A-1

Miller's Valve Guide Removal and Installation Tool for use with all Kohler

K-series and Magnum engines. IMPORTANT: The engine block could crack if

guides are removed or installed with a hydraulic press! Therefore, it's

best to use a big, heavy hammer (with this tool) to drive out the old guide

into the valve spring compartment and use the same hammer (with this tool)

to install the new guide externally from inside the valve pocket. When installing

the new guide, be sure to hammer straight down in alignment with the guide

bore hole and not at an angle. Hitting the guide at an angle could cause

it to break. Install new guides until flush with the valve pocket. This tool

can be used with either OEM Kohler and aftermarket offset valve guides. Machined

at a 90º angle where the pilot meets the shank. Dimensions: .300" pilot

x 1/2" diameter shank x 5" overall length. A-1 Miller part. $20.00

each, plus shipping & handling. [Return

To Previous Paragraph, Section or Website] A-1

Miller's Valve Guide Removal and Installation Tool for use with all Kohler

K-series and Magnum engines. IMPORTANT: The engine block could crack if

guides are removed or installed with a hydraulic press! Therefore, it's

best to use a big, heavy hammer (with this tool) to drive out the old guide

into the valve spring compartment and use the same hammer (with this tool)

to install the new guide externally from inside the valve pocket. When installing

the new guide, be sure to hammer straight down in alignment with the guide

bore hole and not at an angle. Hitting the guide at an angle could cause

it to break. Install new guides until flush with the valve pocket. This tool

can be used with either OEM Kohler and aftermarket offset valve guides. Machined

at a 90º angle where the pilot meets the shank. Dimensions: .300" pilot

x 1/2" diameter shank x 5" overall length. A-1 Miller part. $20.00

each, plus shipping & handling. [Return

To Previous Paragraph, Section or Website] |

||

High

Quality, High Speed Steel Chucking Reamers. Precision ground to provide

correct stem-to-guide clearance. Will not allow valve stem to be too loose

or too tight in guide. When reaming guide, use an electric hand drill with

plenty of oil in guide. Before installing valve, apply motor oil on stem

for lubrication to reduce wear to guide and prevent valve from sticking.

[Return To Previous Paragraph, Section

or Website] High

Quality, High Speed Steel Chucking Reamers. Precision ground to provide

correct stem-to-guide clearance. Will not allow valve stem to be too loose

or too tight in guide. When reaming guide, use an electric hand drill with

plenty of oil in guide. Before installing valve, apply motor oil on stem

for lubrication to reduce wear to guide and prevent valve from sticking.

[Return To Previous Paragraph, Section

or Website]

|

||

Valve

Stem Seals. Required to prevent crankcase oil from draining down into

(OHV) or being suctioned into (flatheads) the combustion chamber through

the guide. Silicone rubber w/metal clamp. NOTE: Apply clean motor oil,

gear oil or lubricating grease on valve stem before inserting valve through

seal to provide lubrication of the stem, guide and seal. Dimensions:

5/16" I.D. (stem) x .500" I.D. (guide) x .600" O.D. NOTE: Some early production

KT17 models do not use valve stem seals. Valve

Stem Seals. Required to prevent crankcase oil from draining down into

(OHV) or being suctioned into (flatheads) the combustion chamber through

the guide. Silicone rubber w/metal clamp. NOTE: Apply clean motor oil,