How

to Repair, Improve and Modify the Steering on a Cub Cadet and Other Makes

and Models of Garden Tractors

How

to Repair, Improve and Modify the Steering on a Cub Cadet and Other Makes

and Models of Garden Tractors

How

to Repair, Improve and Modify the Steering on a Cub Cadet and Other Makes

and Models of Garden Tractors

How

to Repair, Improve and Modify the Steering on a Cub Cadet and Other Makes

and Models of Garden Tractors

Educating and Inspiring Small Engine, Lawn & Garden, and Garden

Pulling Tractor Enthusiasts Since 1996. Where Science and Common Sense Come

Together for Safety and Improved Engine/Tractor Performance |

A-1

Miller's Performance Enterprises - Parts & Services

Webstore |  Available Soon - Detailed Illustrated Plans

on How to Construct a Professional Pull-Back and Self-Propelled Garden

Tractor/Small Wheel Mini Rod Pulling Sleds | Pull-Back and Self-Propelled

Pulling Sleds For Sale (Weight Transfer Machines)

Available Soon - Detailed Illustrated Plans

on How to Construct a Professional Pull-Back and Self-Propelled Garden

Tractor/Small Wheel Mini Rod Pulling Sleds | Pull-Back and Self-Propelled

Pulling Sleds For Sale (Weight Transfer Machines)

Nowadays, prices are subject to change without notice. Click

Refresh to see any

changes or updates. Optimized for 1152 x 864 computer screen resolution.

To search for a word or phrase in any of my websites, press the CTRL

and F

and F  keys on

your keyboard simultaneously to open the Find or Search dialog box in your

web browser. And being I have no

apprentice to update and pay for my websites so they'll

continue to be on the Internet, they will be removed forever when I'm no

longer around.

keys on

your keyboard simultaneously to open the Find or Search dialog box in your

web browser. And being I have no

apprentice to update and pay for my websites so they'll

continue to be on the Internet, they will be removed forever when I'm no

longer around.

When building a garden tractor for pulling, it's best to remove and disassemble everything. (This is much easier to do on a platform work table.) Clean and inspect all the parts for wear, especially the steering parts. This is one important thing many people overlook. Steering is very important, especially in pulling, and should never be overlooked or neglected. Loose or worn steering parts can be dangerous. A puller may just tighten the steering box adjustments, inspect the tie rods and that's it. But there's more to it than just making proper adjustments...

How to Remove the Steering Wheel from a Cub Cadet or Virtually Any Garden Tractor with a ROSS Steering Assembly - There are several ways to remove the steering wheel -

DO NOT STRIKE THE SPLINED END OF THE STEERING

SHAFT WITH A BIG HAMMER IN AN ATTEMPT TO REMOVE THE STEERING

WHEEL! Doing this could cause the internal threads in

the lower part of the cast aluminum steering box housing to split and crack

the case or break off entirely. Or if the housing is cracked, the bottom

of the steering box could break off entirely later, which would be dangerous

because the tractor could go out of control, especially when pulling on the

track.

DO NOT STRIKE THE SPLINED END OF THE STEERING

SHAFT WITH A BIG HAMMER IN AN ATTEMPT TO REMOVE THE STEERING

WHEEL! Doing this could cause the internal threads in

the lower part of the cast aluminum steering box housing to split and crack

the case or break off entirely. Or if the housing is cracked, the bottom

of the steering box could break off entirely later, which would be dangerous

because the tractor could go out of control, especially when pulling on the

track.

To prevent damage to the threads on the steering shaft, install an ordinary length 5/8-18 UNF nut on the shaft threaded down until flush with the end of the threads, and while pulling upward on the steering wheel with your hands (assistance/help may be needed), give the nut a short blast with an air chisel. Do not use the short OEM steering wheel retaining jam nut because threads on the shaft may become damaged. AND DO NOT USE A BIG HAMMER! If the end of the steering shaft was hammered on without the nut installed in an effort to remove the steering wheel, which caused the threads to become flared-out or "mushroomed", well, there two ways to fix this... (A-1 Miller's provides this repair service, too.)

The easy way to fix this is...

Use a

hacksaw or

reciprocating saw (also known as a

saw-saw) to cut the damaged threads off the steering shaft

next to the splines.

Use a

hacksaw or

reciprocating saw (also known as a

saw-saw) to cut the damaged threads off the steering shaft

next to the splines.

The more complicated way to fix this and retain the OEM look of the stud with the retaining nut is...

Remove the steering shaft from

the steering box assembly.

Remove the steering shaft from

the steering box assembly.

Use either a

steering wheel puller (with bolts) or an

automotive harmonic balancer/vibration damper puller (with

bolts) and a

bearing separator, or use only a

3-jaw gear puller to "pull" the steering wheel off the

shaft. To prevent damage to the steering wheel, make sure the jaws of a gear

puller won't break or crack the plastic around the hub.

Use either a

steering wheel puller (with bolts) or an

automotive harmonic balancer/vibration damper puller (with

bolts) and a

bearing separator, or use only a

3-jaw gear puller to "pull" the steering wheel off the

shaft. To prevent damage to the steering wheel, make sure the jaws of a gear

puller won't break or crack the plastic around the hub.

As the last resort, if the steering

shaft itself must be literary cut-off with a

hacksaw or

reciprocating saw (also known as a

saw-saw), just under the steering wheel, the splined part

of the shaft can be replaced with the steering shaft (that's in good condition)

out of a 1949 to 1994 GM (General Motors) car or truck. Only a short section

of the splined end of the shaft will need to be used. The GM automotive shaft

next to the splines will need to be machined down fit inside the ROSS [hollow]

steering shaft, then the GM shaft can be pressed inside the ROSS shaft with

an 1/8" gap. Fill in the gap with welding around where the two shafts meet.

The lump of weld will need to be either machined down (in a metal lathe;

for use of a solid metal bushing) or ground down (with a hand grinder for

use of a ball bearing) so the upper bushing or bearing will slide on the

shaft. Installation of the steering wheel and hub adapter are explained below

Ê.

As the last resort, if the steering

shaft itself must be literary cut-off with a

hacksaw or

reciprocating saw (also known as a

saw-saw), just under the steering wheel, the splined part

of the shaft can be replaced with the steering shaft (that's in good condition)

out of a 1949 to 1994 GM (General Motors) car or truck. Only a short section

of the splined end of the shaft will need to be used. The GM automotive shaft

next to the splines will need to be machined down fit inside the ROSS [hollow]

steering shaft, then the GM shaft can be pressed inside the ROSS shaft with

an 1/8" gap. Fill in the gap with welding around where the two shafts meet.

The lump of weld will need to be either machined down (in a metal lathe;

for use of a solid metal bushing) or ground down (with a hand grinder for

use of a ball bearing) so the upper bushing or bearing will slide on the

shaft. Installation of the steering wheel and hub adapter are explained below

Ê.

Replace

that worn, cracked (and not to mention unsightly and boring/plain looking)

OEM (Original Equipment Manufacturer) steering wheel with an attractive,

small diameter (10" or 12") automotive-style/hot rod

custom steering wheel or a

chrome spoke steering wheel! A custom or chrome spoke steering

wheel will, without a doubt, improve the overall appearance of the entire

tractor.

Replace

that worn, cracked (and not to mention unsightly and boring/plain looking)

OEM (Original Equipment Manufacturer) steering wheel with an attractive,

small diameter (10" or 12") automotive-style/hot rod

custom steering wheel or a

chrome spoke steering wheel! A custom or chrome spoke steering

wheel will, without a doubt, improve the overall appearance of the entire

tractor.

To adapt a custom steering wheel

to the ROSS [splined end] steering shaft, and if the splines and threads

on the shaft are in good condition, the only custom automotive steering wheel

installation adapter kit I found that fits close on the ROSS splined steering

shaft is an aftermarket early GM automotive steering wheel hub adapter kit,

Grant part # 3196, that's made for most General Motors

cars and trucks from 1949 to 1994 without telescopic steering. Leave out

the horn switch plate and install multiple flat washers on the supplied steering

wheel mounting bolts so the steering wheel will install tight against the

hub.

To adapt a custom steering wheel

to the ROSS [splined end] steering shaft, and if the splines and threads

on the shaft are in good condition, the only custom automotive steering wheel

installation adapter kit I found that fits close on the ROSS splined steering

shaft is an aftermarket early GM automotive steering wheel hub adapter kit,

Grant part # 3196, that's made for most General Motors

cars and trucks from 1949 to 1994 without telescopic steering. Leave out

the horn switch plate and install multiple flat washers on the supplied steering

wheel mounting bolts so the steering wheel will install tight against the

hub.

The GM automotive adapter center spline has the correct diameter, but the number of splines are not a perfect fit, so it will need to be gently tapped onto the steering shaft. Or the center splined hub from a 1949 to 1994 OEM GM steering wheel can be used instead. But the three small holes in the hub will need to be enlarged and tapped for three 1/4" bolts for installation of the custom steering wheel. But if you don't want to use the GM adapter, the splined hub from an early model Cub Cadet steering wheel with the spokes cut off, and a large flat washer (with three tapped 1/4" bolt holes for installation of the custom steering wheel) welded to the adapter can be used. Once the steering wheel is removed, position the front tires forward, fasten the splined adapter on the steering shaft (with the choice of hardware listed below Ê), then fasten the steering wheel with the adapter facing in the straight ahead position.

Use the OEM ROSS (Cub Cadet, John Deere, etc.) steering wheel retaining nut or an aftermarket 5/8-18 UNF nylon insert jam nut with a thin flat washer to secure the steering wheel and hub to the steering shaft. For easier installation of the steering wheel retaining nut, use a 5/8-18 UNF threading die and die holder wrench to straighten damaged threads on the shaft, and for much easier removal of the steering wheel (for whatever reason), apply anti-seize compound/lubricant in the splines of the steering wheel hub and on the splines of the steering shaft, then torque the nut to 65 ft. lb.

Install the three 1/4" bolts

from the bottom up, install the steering wheel, then install

stainless steel acorn nuts with a split lock washer to

the bolts (studs) to fasten the steering wheel for a nice looking and

(rust-proof) professional look. Then to hide the (unsightly) large center

retaining nut, install a 15/16"

stainless steel lug nut cover. These are made for semi

tractor-trailers, which are available at most truck stops and on eBay. Or,

to hide the three bolts and retaining nut, install a

Install the three 1/4" bolts

from the bottom up, install the steering wheel, then install

stainless steel acorn nuts with a split lock washer to

the bolts (studs) to fasten the steering wheel for a nice looking and

(rust-proof) professional look. Then to hide the (unsightly) large center

retaining nut, install a 15/16"

stainless steel lug nut cover. These are made for semi

tractor-trailers, which are available at most truck stops and on eBay. Or,

to hide the three bolts and retaining nut, install a

chrome-plated universal custom

automotive horn button (center cap). To do this, machine a large flat washer

in a metal lathe so the washer will be slightly larger than the inside diameter

of the horn button. Fasten the washer in the steering wheel to the three

1/4" bolts with a couple of stacked smaller flat washers under the large

washer. Snap the horn button onto the washer and that's it! Snap the horn

button onto the washer and that's it!

chrome-plated universal custom

automotive horn button (center cap). To do this, machine a large flat washer

in a metal lathe so the washer will be slightly larger than the inside diameter

of the horn button. Fasten the washer in the steering wheel to the three

1/4" bolts with a couple of stacked smaller flat washers under the large

washer. Snap the horn button onto the washer and that's it! Snap the horn

button onto the washer and that's it!

|

|

|

|

|

|

How To Fix Loose or "Sloppy" Steering Parts -

To improve the steering on a Cub Cadet garden tractor, is to remove, disassemble, clean, inspect, repair as necessary, reassemble, adjust, then lubricate the steering box unit with automotive grease through the Zerk grease fitting. By the way - adjustments are made much easier with the steering box assembly out of the tractor. Remember - grease fittings provide preventive maintenance when used regularly. Because grease cost less than any major repair of equipment.

Don't Be A Slob When Rebuilding A Steering Unit!

Always be professional whenever building or rebuilding anything! Before reassembling a steering unit, always take the time to provide a neat and absolutely clean work environment. Make sure that your tools, shop/business towels, steering parts and hands are clean, too. Don't allow any dust or dirt to enter the work bench or table, including the steering box and it's parts. If necessary, place the parts on a large, clean cloth or cardboard to keep them clean and organized until they're ready to be installed. The reason everything should be kept as clean as possible is because even the smallest bit of dirt inside a steering box will "grind away" at the internal parts, causing unnecessary wear.

How to remove the steering box/column unit from the tractor - (This is much easier to do on a platform work table.)

How to disassemble the steering unit -

How to reassemble the steering unit -

NOTE: If new internal steering box parts are needed in a rebuild, you can get them at virtually any Cub Cadet garden tractor dealer. Most John Deere lawn & garden service centers and parts stores offers the same parts for the steering box in their models 110, 112, 120, 140, 200, 210, 212, 214, 216, 300, 312, 316 and 317. The steering box in these tractors, which is made by ROSS, are very similar to the ones used in the Cub Cadet garden tractors, except for the mounting holes. The internal parts are basically the same, but new John Deere parts are more expensive than new Cub Cadet garden tractor parts.

Ever had the steering column tube get pulled out of the steering box on a Cub Cadet garden tractor? Well, doing the below Ê will guarantee that it will never get pulled out again -

automotive exhaust pipe expander/spreader tool. (Available

at virtually any auto parts store and on eBay.)

automotive exhaust pipe expander/spreader tool. (Available

at virtually any auto parts store and on eBay.)

NOTE: If the upper part of the steering tube becomes damaged from removing the steering wheel, it can be straightened back to its original shape with the automotive exhaust pipe expander/spreader tool and a 2-3 lb. hammer. The internal steering shaft must be removed, so the tool will work.

Tie rods are an integral part of a vehicle's steering.

Just as its name suggests, a tie rod connects the vehicle's steering linkage

to the steering arm, and the steering arm is attached to the front spindle.

Tie rods are an integral part of a vehicle's steering.

Just as its name suggests, a tie rod connects the vehicle's steering linkage

to the steering arm, and the steering arm is attached to the front spindle.

If a tie rod is badly worn loose and performing

the below doesn't "tighten" it, and you have doubts that it may fail in the

future, then by all means, replace it with a known good used one or a new

one. Actually, for heavy lawn and garden use or for a competition pulling

tractor, it's best to use aircraft-quality ball-joint ends, which are called

Heim joints, with a flat washer and rubber dust/dirt shields installed.

If a tie rod is badly worn loose and performing

the below doesn't "tighten" it, and you have doubts that it may fail in the

future, then by all means, replace it with a known good used one or a new

one. Actually, for heavy lawn and garden use or for a competition pulling

tractor, it's best to use aircraft-quality ball-joint ends, which are called

Heim joints, with a flat washer and rubber dust/dirt shields installed.

How to "Tighten" a Worn Tie Rod -

Front Axle Pivot Pin, Tie Rod, Heim Joints, Drag Link Steering Joints and Custom-Made Steering Links - NOTE: Before ordering any of the parts listed below, it'll be best to completely disassemble your steering assembly and thoroughly clean all the parts to determine exactly which replacement part(s) it will need. Because certain parts wear more than others, while other parts don't wear at all.

Zinc-Plated Steel Nylon

Insert Steering Wheel Retaining Jam Locknut. Will not loosen under normal

circumstances. Fits all Cub Cadet garden tractors and other makes and models

of garden tractors with 5/8-18 UNF threads on steering shaft. IMPORTANT

- For easier installation of this nut, use a 5/8-18 UNF

threading die and

die holder wrench to straighten damaged threads on shaft,

and for much easier removal of steering wheel, apply

anti-seize compound/lubricant on splines of steering wheel

hub and steering shaft, then torque nut to 65 ft. lb. High quality

aftermarket. Replaces discontinued Cub Cadet part # 912-3021. $3.00

each, plus shipping & handling. Zinc-Plated Steel Nylon

Insert Steering Wheel Retaining Jam Locknut. Will not loosen under normal

circumstances. Fits all Cub Cadet garden tractors and other makes and models

of garden tractors with 5/8-18 UNF threads on steering shaft. IMPORTANT

- For easier installation of this nut, use a 5/8-18 UNF

threading die and

die holder wrench to straighten damaged threads on shaft,

and for much easier removal of steering wheel, apply

anti-seize compound/lubricant on splines of steering wheel

hub and steering shaft, then torque nut to 65 ft. lb. High quality

aftermarket. Replaces discontinued Cub Cadet part # 912-3021. $3.00

each, plus shipping & handling.

|

Felt Sealing Washer for

Upper Steering Column Shaft. Blocks contamination of dust and dirt that can

wear the upper bushing. Apply oil to trap more dust and dirt. Not required

with sealed bearing listed further below. Fits all models of IH- and MTD-built

Cub Cadet garden tractors and other makes and models of garden tractors with

a 3/4" steering shaft. Made of interwoven wool. Dimensions: 3/4" I.D. x 1-1/4"

O.D. x 1/4" thick. Felt Sealing Washer for

Upper Steering Column Shaft. Blocks contamination of dust and dirt that can

wear the upper bushing. Apply oil to trap more dust and dirt. Not required

with sealed bearing listed further below. Fits all models of IH- and MTD-built

Cub Cadet garden tractors and other makes and models of garden tractors with

a 3/4" steering shaft. Made of interwoven wool. Dimensions: 3/4" I.D. x 1-1/4"

O.D. x 1/4" thick.

|

Bearing/Race Sets for ROSS and CCC Steering

Boxes. Fits Cub Cadet "Original" garden tractor, and Cub Cadet garden

tractor models 70, 71, 72, 73, 86, 100, 102, 104, 105, 106, 107, 108, 109,

122, 123, 124, 125, 126, 127, 128, 129, 147, 149, 169, 482, 580, 582, 680,

682, 782, 782D, 784, 800, 882, 982, 984, 986, 1912, 1914, 1000, 1100, 1200,

1210, 1211, 1250, 1282, 1450, 1512, 1572, 1604, 1606, 1650, 1710, 1711, 1712,

1772, 1806, 1810, 1811, 1812, 1872, 2072, including Cub Lo Boy models 154,

184 and 185; Ford LGT; Jacobsen; John Deere models 60, 70, 100, 110, 112,

120, 140, 200, 208, 210, 212, 214, 216, 300, 312, 314, 316, 317 and 400;

Massey Ferguson / Harris MF models 14, 16, 1200, 1450, 1650, 1655 and 1855;

MTD Farm King; Snapper; Wheel Horse; and various other makes and models of

garden tractors with the ROSS or CCC aluminum housing steering box.

NOTE: The rounded or curved cup/race is OEM Cub Cadet (discontinued),

and the bearing sets that is offered here come with the flat cup/race, which

are aftermarket. These aftermarket cups/races are interchangeable with the

OEM Cub Cadet cups/races, so either will fit and function equally. IMPORTANT:

For

preventive maintenance and smoother steering, lubricate

steering box and all steering parts through Zerk

grease fittings with an

automotive grease gun once a year. Dimensions of each

part: 5/16" balls; nylon cages/spacers: 1.500" O.D.; cups/races: 1.550" O.D.

[Top of Page]

Bearing/Race Sets for ROSS and CCC Steering

Boxes. Fits Cub Cadet "Original" garden tractor, and Cub Cadet garden

tractor models 70, 71, 72, 73, 86, 100, 102, 104, 105, 106, 107, 108, 109,

122, 123, 124, 125, 126, 127, 128, 129, 147, 149, 169, 482, 580, 582, 680,

682, 782, 782D, 784, 800, 882, 982, 984, 986, 1912, 1914, 1000, 1100, 1200,

1210, 1211, 1250, 1282, 1450, 1512, 1572, 1604, 1606, 1650, 1710, 1711, 1712,

1772, 1806, 1810, 1811, 1812, 1872, 2072, including Cub Lo Boy models 154,

184 and 185; Ford LGT; Jacobsen; John Deere models 60, 70, 100, 110, 112,

120, 140, 200, 208, 210, 212, 214, 216, 300, 312, 314, 316, 317 and 400;

Massey Ferguson / Harris MF models 14, 16, 1200, 1450, 1650, 1655 and 1855;

MTD Farm King; Snapper; Wheel Horse; and various other makes and models of

garden tractors with the ROSS or CCC aluminum housing steering box.

NOTE: The rounded or curved cup/race is OEM Cub Cadet (discontinued),

and the bearing sets that is offered here come with the flat cup/race, which

are aftermarket. These aftermarket cups/races are interchangeable with the

OEM Cub Cadet cups/races, so either will fit and function equally. IMPORTANT:

For

preventive maintenance and smoother steering, lubricate

steering box and all steering parts through Zerk

grease fittings with an

automotive grease gun once a year. Dimensions of each

part: 5/16" balls; nylon cages/spacers: 1.500" O.D.; cups/races: 1.550" O.D.

[Top of Page]

|

Foam Rubber Dust/Grease Seal.

Fits Cub Cadet "Original" garden tractor steering box. Replace or install

this part when old one is deteriorated, torn or missing to prevent dust and

dirt from entering inside steering box. May also fit various other early

makes and models of garden tractors. Will not fit later models of Cub Cadet

garden tractors, Ford LGT, Jacobsen, John Deere, Massey Ferguson, MTD Farm

King, Snapper, Wheel Horse or Cub Lo-Boy. If the opening in your steering

box match this part, then it will fit. Part of discontinued OEM Cub Cadet

part # IH-376478-R91. $20.00± each, depending on source and

availability, plus shipping & handling. (When available.) Foam Rubber Dust/Grease Seal.

Fits Cub Cadet "Original" garden tractor steering box. Replace or install

this part when old one is deteriorated, torn or missing to prevent dust and

dirt from entering inside steering box. May also fit various other early

makes and models of garden tractors. Will not fit later models of Cub Cadet

garden tractors, Ford LGT, Jacobsen, John Deere, Massey Ferguson, MTD Farm

King, Snapper, Wheel Horse or Cub Lo-Boy. If the opening in your steering

box match this part, then it will fit. Part of discontinued OEM Cub Cadet

part # IH-376478-R91. $20.00± each, depending on source and

availability, plus shipping & handling. (When available.)

|

1/2" Diameter Cam Follower / Stud (Adjustable Steering Pin).

Replace worn cam follower for "tighter" and less "sloppy" or "loose" steering,

and for safer operation of tractor. Fits Cub Cadet "Original" garden tractor

and Cub Cadet garden tractor models 70, 71, 72, 73, 86, 100, 102, 104, 105,

106, 107, 108, 109, 122, 123, 124, 125, 126, 127, 128, 129, 147, 149, 169,

482, 580, 582, 582 Special, 680, 682, 782, 782D, 784, 800, 882, 1000, 1100,

1200, 1250, 1282, 1450, 1512, 1604, 1606, 1650, 1710, 1711, 1712, 1961, 1962,

1963, including many other makes and models of garden tractors with the ROSS

steering box. 1/2-20 UNF threads.

Jam nut sold extra (listed below). IMPORTANT: For

preventive maintenance and smoother steering, lubricate

steering box and all steering parts through Zerk

grease fittings with an

automotive grease gun once a year. 1/2" Diameter Cam Follower / Stud (Adjustable Steering Pin).

Replace worn cam follower for "tighter" and less "sloppy" or "loose" steering,

and for safer operation of tractor. Fits Cub Cadet "Original" garden tractor

and Cub Cadet garden tractor models 70, 71, 72, 73, 86, 100, 102, 104, 105,

106, 107, 108, 109, 122, 123, 124, 125, 126, 127, 128, 129, 147, 149, 169,

482, 580, 582, 582 Special, 680, 682, 782, 782D, 784, 800, 882, 1000, 1100,

1200, 1250, 1282, 1450, 1512, 1604, 1606, 1650, 1710, 1711, 1712, 1961, 1962,

1963, including many other makes and models of garden tractors with the ROSS

steering box. 1/2-20 UNF threads.

Jam nut sold extra (listed below). IMPORTANT: For

preventive maintenance and smoother steering, lubricate

steering box and all steering parts through Zerk

grease fittings with an

automotive grease gun once a year.

|

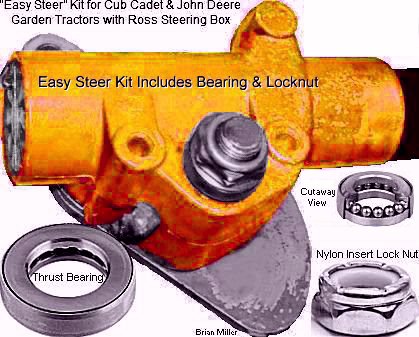

"Easy

Steer" Upgrade Kits. Provides easier steering with slightly less

effort, especially with a front end loader bucket. Fits all IH- and certain

MTD-built Cub Cadet, John Deere, Massey Ferguson, Ford LGT, Jacobsen, MTD

Farm King, Wheel Horse and various other makes and models of garden tractors

with the ROSS or CCC aluminum housing steering box, except Cub Lo-Boy.

Each kit listed below includes new high quality pre-lubricated sealed thrust

ball bearing and nylon-insert lock nut. Replaces double OEM

jam nuts

and

thrust

washer on 5/8" or 3/4" diameter pitman arm stud. Install bearing with

shielding (wording on bearing) against steering box, and tighten nut to remove

looseness, then back off nut until pitman arm rotates freely without binding.

NOTE: The Easy Steer Upgrade Kit will NOT work on the steering box with

the pivot shaft bolt NOT welded to the steering arm in MTD-built Cub Cadet

garden tractor models 782, 784, 786, 1340, 1440, 1535, 1541, 1810, 1811,

1861, 1863, 1912 and 1914 because the protruding threads are too short.

[Top of Page] "Easy

Steer" Upgrade Kits. Provides easier steering with slightly less

effort, especially with a front end loader bucket. Fits all IH- and certain

MTD-built Cub Cadet, John Deere, Massey Ferguson, Ford LGT, Jacobsen, MTD

Farm King, Wheel Horse and various other makes and models of garden tractors

with the ROSS or CCC aluminum housing steering box, except Cub Lo-Boy.

Each kit listed below includes new high quality pre-lubricated sealed thrust

ball bearing and nylon-insert lock nut. Replaces double OEM

jam nuts

and

thrust

washer on 5/8" or 3/4" diameter pitman arm stud. Install bearing with

shielding (wording on bearing) against steering box, and tighten nut to remove

looseness, then back off nut until pitman arm rotates freely without binding.

NOTE: The Easy Steer Upgrade Kit will NOT work on the steering box with

the pivot shaft bolt NOT welded to the steering arm in MTD-built Cub Cadet

garden tractor models 782, 784, 786, 1340, 1440, 1535, 1541, 1810, 1811,

1861, 1863, 1912 and 1914 because the protruding threads are too short.

[Top of Page]

|

Adjustment Plug for ROSS

Steering Box. Fits all models of IH built (ROSS) and MTD-built (CCC) Cub

Cadet garden tractors; Cub Lo-Boy models 154, 184 and 185; Ford LGT; Jacobsen;

John Deere models 60, 70, 100, 110, 112, 120, 140, 200, 208, 210, 212, 214,

216, 300, 312, 314, 316, 317 and 400; Massey Ferguson / Harris MF models

14, 16, 1200, 1450, 1650, 1655 and 1855; MTD Farm King; Snapper; Wheel Horse;

and various other makes and models of garden tractors with the ROSS or

CCC aluminum housing steering box. Dimensions: 1.734" outside of threads

diameter. Used and in good condition. Discontinued Cub Cadet part # IH-394288-R1.

$30.00 each, plus shipping & handling. (When available.) Adjustment Plug for ROSS

Steering Box. Fits all models of IH built (ROSS) and MTD-built (CCC) Cub

Cadet garden tractors; Cub Lo-Boy models 154, 184 and 185; Ford LGT; Jacobsen;

John Deere models 60, 70, 100, 110, 112, 120, 140, 200, 208, 210, 212, 214,

216, 300, 312, 314, 316, 317 and 400; Massey Ferguson / Harris MF models

14, 16, 1200, 1450, 1650, 1655 and 1855; MTD Farm King; Snapper; Wheel Horse;

and various other makes and models of garden tractors with the ROSS or

CCC aluminum housing steering box. Dimensions: 1.734" outside of threads

diameter. Used and in good condition. Discontinued Cub Cadet part # IH-394288-R1.

$30.00 each, plus shipping & handling. (When available.) |

Front Axle Center Pivot

Pin. Fits all IH Cub Cadet narrow and wide frame garden tractor models 70,

71, 72, 73, 86, 100, 102, 104, 105, 106, 107, 108, 109, 122, 123, 124, 125,

126, 127, 128 129, 147, 149, 169, 800, 1000, 1100, 1200, 1250, 1450 and 1650.

Made of hardened steel. Dimensions: 3/4" x 4-3/8" length. IMPORTANT: For

preventive maintenance, lubricate

Zerk grease fittings with an

automotive grease gun once a year. Front Axle Center Pivot

Pin. Fits all IH Cub Cadet narrow and wide frame garden tractor models 70,

71, 72, 73, 86, 100, 102, 104, 105, 106, 107, 108, 109, 122, 123, 124, 125,

126, 127, 128 129, 147, 149, 169, 800, 1000, 1100, 1200, 1250, 1450 and 1650.

Made of hardened steel. Dimensions: 3/4" x 4-3/8" length. IMPORTANT: For

preventive maintenance, lubricate

Zerk grease fittings with an

automotive grease gun once a year.

|

Heavy Duty Tie Rod Steering

Joints with incorporated protective rubber dust seal. Each can be used on

riding mowers, lawn and garden tractors, ordinary garden tractors, go-karts,

King Midget micro cars, small motorized vehicles,

competition garden pulling tractors, small wheel mini-rod pulling tractors,

compact tractors, automotive throttle linkages, automotive transmission shifter

linkages, etc. Allows for up to 20º angle of misalignment without binding.

Before initial installation, apply clean motor oil under rubber dust seal

to help extend life of ball joint. Heavy Duty Tie Rod Steering

Joints with incorporated protective rubber dust seal. Each can be used on

riding mowers, lawn and garden tractors, ordinary garden tractors, go-karts,

King Midget micro cars, small motorized vehicles,

competition garden pulling tractors, small wheel mini-rod pulling tractors,

compact tractors, automotive throttle linkages, automotive transmission shifter

linkages, etc. Allows for up to 20º angle of misalignment without binding.

Before initial installation, apply clean motor oil under rubber dust seal

to help extend life of ball joint.

|

A-1 Miller's

Heavy Duty

Custom-Made Linkage Assemblies. Tie rod linkage, drag

link, shifter linkage or clutch linkage for your ordinary garden tractor,

go-kart, small motorized vehicle, compact tractor, mini-rod, hot rod, etc.

NOTE: When ordering, please specify model of garden tractor, or exact

length of linkage from center of mounting studs (tie rods) or center of mounting

bolts (Heim joints), and size of tie rods or ball joints. Or better yet,

and if you wish, ship me your original linkage so I can duplicate it into

a heavy duty linkage. Available in 1/4", 5/16", 3/8", 1/2", 5/8" and

3/4" sizes. [Top of Page]

|

Click here to contact A-1 Miller's for FREE honest and accurate technical support and/or for ordering information and payment options. Please contact A-1 Miller's if you need a part or parts, or service performed that's not listed or mentioned in this website. [Top of Page]

Teflon Thrust Washers for Steering Knuckles and Front

Axle. Installs where steering knuckles makes contact with underneath

of axle (load-bearing and friction area), and is centered by the steel

bushings/spacers (listed below). Provides easier steering with less effort,

especially with a snow plow or front end loader bucket. Each Teflon thrust

washer listed below fits various makes and models of garden tractors with

3/4", 7/8" or 1" diameter front vertical spindle shafts. These washers are

made of very tough, long wearing and slippery

polytetrafluoroethylene

(PTFE), and not ordinary nylon or plastic. Reduces steering effort about

85% and eliminates metal to metal friction, which can result in hard steering

and wear to axle and steering knuckles (even when knuckles are lubricated

once a year). Apply automotive grease when installing. Go here for more

information:

Polytetrafluoroethylene (PTFE): Complete Guide. Teflon Thrust Washers for Steering Knuckles and Front

Axle. Installs where steering knuckles makes contact with underneath

of axle (load-bearing and friction area), and is centered by the steel

bushings/spacers (listed below). Provides easier steering with less effort,

especially with a snow plow or front end loader bucket. Each Teflon thrust

washer listed below fits various makes and models of garden tractors with

3/4", 7/8" or 1" diameter front vertical spindle shafts. These washers are

made of very tough, long wearing and slippery

polytetrafluoroethylene

(PTFE), and not ordinary nylon or plastic. Reduces steering effort about

85% and eliminates metal to metal friction, which can result in hard steering

and wear to axle and steering knuckles (even when knuckles are lubricated

once a year). Apply automotive grease when installing. Go here for more

information:

Polytetrafluoroethylene (PTFE): Complete Guide.

|

Steering Knuckle/Front Axle Spacers (Steel Sleeve Bushings).

Does not include bolts or castle nuts. Replace worn spacers for dilapidated

front tires and for easier steering. Each spacer listed below fits various

front axles in Cub Cadet garden tractor models 86, 108, 109, 128, 129, 149,

169, 482, 580, 582, 680, 682, 782, 782D, 784, 800, 882, 1000, 1050, 1100,

1200, 1204, 1210, 1211, 1250, 1450, 1512, 1604, 1606, 1650, 1710, 1711, 1712,

1806, 1810, 1811 and 1812. NOTE: The steering knuckles are supposed to

"clamp" against these spacers with the OEM bolts/nuts, and the bushings/spacers

are supposed to rotate/swivel in the axle housing with movement of the steering

knuckles. IMPORTANT: For

preventive maintenance and smoother steering, lubricate

these parts through Zerk grease fitting with

an

automotive grease gun once a year. Steering Knuckle/Front Axle Spacers (Steel Sleeve Bushings).

Does not include bolts or castle nuts. Replace worn spacers for dilapidated

front tires and for easier steering. Each spacer listed below fits various

front axles in Cub Cadet garden tractor models 86, 108, 109, 128, 129, 149,

169, 482, 580, 582, 680, 682, 782, 782D, 784, 800, 882, 1000, 1050, 1100,

1200, 1204, 1210, 1211, 1250, 1450, 1512, 1604, 1606, 1650, 1710, 1711, 1712,

1806, 1810, 1811 and 1812. NOTE: The steering knuckles are supposed to

"clamp" against these spacers with the OEM bolts/nuts, and the bushings/spacers

are supposed to rotate/swivel in the axle housing with movement of the steering

knuckles. IMPORTANT: For

preventive maintenance and smoother steering, lubricate

these parts through Zerk grease fitting with

an

automotive grease gun once a year.

|

Steering

Knuckle/Front Axle Bronze Bushings. Replace worn bushings for dilapidated

front tires and for easier steering. Fits Cub Cadet garden tractor models

982, 984, 986, 1572, 1772, 1782, 1872, 1882, 1912, 1914, 2072, 2082, 2084,

2086, 2182 and 2284. Dimensions: 1" I.D. x 1.125" O.D. x 1" Length. Use these

to replace existing OEM worn bushings or repair worn (oblong) axle spindle

holes when no bushings are originally installed (when the spindles make metal

to metal contact with the cast iron axle). If no bushings were originally

installed in the axle, then spindle holes must be professionally

precision-aligned bored (machined) to accept bushings. Other sizes of bushings

are available. IMPORTANT: If no Zerk grease

fittings are installed in the axle to lubricate the spindle shafts for

easier steering and longevity of the bushings, it's recommended to install

these, too. For

preventive maintenance and smoother steering, lubricate

these parts through these parts through Zerk grease

fitting with an

automotive grease gun once a year. High quality

aftermarket. Replaces discontinued Cub Cadet part #'s 741-3005, 941-3005.

$18.00/set of 4 bushings, plus shipping & handling. Steering

Knuckle/Front Axle Bronze Bushings. Replace worn bushings for dilapidated

front tires and for easier steering. Fits Cub Cadet garden tractor models

982, 984, 986, 1572, 1772, 1782, 1872, 1882, 1912, 1914, 2072, 2082, 2084,

2086, 2182 and 2284. Dimensions: 1" I.D. x 1.125" O.D. x 1" Length. Use these

to replace existing OEM worn bushings or repair worn (oblong) axle spindle

holes when no bushings are originally installed (when the spindles make metal

to metal contact with the cast iron axle). If no bushings were originally

installed in the axle, then spindle holes must be professionally

precision-aligned bored (machined) to accept bushings. Other sizes of bushings

are available. IMPORTANT: If no Zerk grease

fittings are installed in the axle to lubricate the spindle shafts for

easier steering and longevity of the bushings, it's recommended to install

these, too. For

preventive maintenance and smoother steering, lubricate

these parts through these parts through Zerk grease

fitting with an

automotive grease gun once a year. High quality

aftermarket. Replaces discontinued Cub Cadet part #'s 741-3005, 941-3005.

$18.00/set of 4 bushings, plus shipping & handling. |

How to Fix a Loose-Fitting Drag Link Arm -

To fix a

loose-fitting drag link arm on the narrow frame Cub Cadet garden tractor

models 70, 71, 72, 73, 100, 102, 104, 105, 106, 107, 122, 123, 124, 125,

126 or 147, the hub must be "clamped" to the horizontal spindle. To do this...

To fix a

loose-fitting drag link arm on the narrow frame Cub Cadet garden tractor

models 70, 71, 72, 73, 100, 102, 104, 105, 106, 107, 122, 123, 124, 125,

126 or 147, the hub must be "clamped" to the horizontal spindle. To do this...

How to Lengthen the Drag Link (link that goes between pitman arm to steering arm on spindle) When the Front Axle is Repositioned Forward:

Measure

the distance the front axle was moved forward. Make a note of the measurement.

Measure

the distance the front axle was moved forward. Make a note of the measurement.

Front Axle Assembly for Cub Cadet Garden Tractor Models 70, 71, 72, 73,

100, 102, 104, 105, 106, 107, 122, 123, 124, 125, 126, 127 and 147

Front Axle Assembly for Cub Cadet Garden Tractor Models 86, 108, 109,

128, 129, 149, 169, 482, 582, 582 Special, 682, 782, 800, 1000, 1100, 1200,

1250, 1450 and 1650

Front Axle Assembly for Cub Cadet Garden Tractor Models 482, 580, 582,

582 Special, 680, 682, 782, 782D, 882, 1050, 1204, 1210, 1211, 1282 and

1512.

Front Axle Assembly for Cub Cadet Garden Tractor Models 982, 984, 986,

1572, 1772, 1782, 1872, 1882, 1912, 1914, 2072, 2082, 2084, 2086, 2165, 2182

and 2284

Front Axle Assembly for Cub Cadet Garden Tractor Models 1340, 1535, 1541,

1860 and 1862

Front Axle Assembly for Cub Cadet Garden Tractor Models 1440, 1861, 1863

and 1864

If the front tires on the narrow frame Cub Cadet garden tractor models listed above look "dilapidated" (tires tilt inward), this means the spindle shafts are bent from doing too many ground-pounding wheelies and weren't reinforced. If the spindle shafts are bent, they could possibly break off. Therefore, to prevent them from getting bent again or breaking off...

Raise and support the front of the tractor, and remove the

front tires. This is much easier and safer to do on a

platform work table with

a sturdy, overhead beam or gantry crane and a chain hoist.

Raise and support the front of the tractor, and remove the

front tires. This is much easier and safer to do on a

platform work table with

a sturdy, overhead beam or gantry crane and a chain hoist.

On a narrow frame Cub Cadet garden tractor, to fix worn spindle shaft holes in the axle itself, the holes would need to be bored or reamed out and a couple of thin-wall bronze bushings will need to be pressed-in for the top and bottom ends of the hole. And remember - grease fittings provide preventive maintenance when used regularly. Because grease cost less than any major repair of equipment.

How to Lower the Front End 2-3/8"± on Cub Cadet Garden Tractor Models 86, 108, 109, 128, 129, 149, 169, 582, 582 Special, 680, 682, 782, 800, 882, 1000, 1050, 1100, 1200, 1204, 1210, 1211, 1250, 1282, 1450, 1512, 1535 and 1650 -

Pivoting Axle VS Solid-Mounted Axle for Competition Pulling -

I've seen competition garden pulling tractors with the OEM swivel front axle and I've seen some with a custom-made solid-mounted front axle, which is welded to the frame. And I noticed that one doesn't help the tractor to pull or steer down the track any better than the other. So it seems it's just the pullers' or tractor builder's preference if he or she wants an axle that swivels or not.

How to Repair Worn Pivot Pin Holes for the Front Axle -

Sometimes,

due to many years of lack of lubrication (yearly general maintenance), the

pivoting pin will rust in the front axle and this will cause the 3/16" spiral

support pin in the pivoting pin and front hole of the mounting bracket to

break, and then the pivoting pin will pivot and wear the holes oblong in

the mounting bracket. Which causes the axle to become wobbly, unstable, and

have "sloppy" steering. The only way to fix the "looseness" of the pivoting

hole is to have the holes bored for installation of two welded-in steel reducer

spacer rings.

Sometimes,

due to many years of lack of lubrication (yearly general maintenance), the

pivoting pin will rust in the front axle and this will cause the 3/16" spiral

support pin in the pivoting pin and front hole of the mounting bracket to

break, and then the pivoting pin will pivot and wear the holes oblong in

the mounting bracket. Which causes the axle to become wobbly, unstable, and

have "sloppy" steering. The only way to fix the "looseness" of the pivoting

hole is to have the holes bored for installation of two welded-in steel reducer

spacer rings.

The front axle mounting bracket on all Cub Cadet garden tractors is welded to the frame, so either the welding would need to be ground away, or perhaps the bracket can be machined with it installed on the frame. Well, to repair a tractor with worn pivot holes like the ones in the photo to the right...

To place an order, send your item(s) for repairing, and/or

for customer service assistance, and FREE honest and accurate technical support,

please contact: A-1 Miller's Performance Enterprises, 12091 N Route B,

Hallsville, MO (Missouri) 65255-9604 USA. Please call in your order or send

an email with a list parts you need and your contact information.

To place an order, send your item(s) for repairing, and/or

for customer service assistance, and FREE honest and accurate technical support,

please contact: A-1 Miller's Performance Enterprises, 12091 N Route B,

Hallsville, MO (Missouri) 65255-9604 USA. Please call in your order or send

an email with a list parts you need and your contact information.

Phone: 1-573-881-7229 (cell;

call, text or leave voicemail). Please call Monday-Friday, 9am to 5pm, Central

time zone, except holidays. If no answer, please try again later.

Phone: 1-573-881-7229 (cell;

call, text or leave voicemail). Please call Monday-Friday, 9am to 5pm, Central

time zone, except holidays. If no answer, please try again later.

E-mail:

pullingtractor@aol.com. A-1 Miller's

shop is open to the public Monday-Friday, 9am to 5pm, Central time zone,

with an appointment on weekends, except holidays. If you're the kind of person

who don't trust delivery/shipping companies (mis)handling your high-dollar

and fragile merchandise, you can make the long drive to A-1 Miller's new

shop (click image to the right) to personally purchase parts, or drop off

and/or pick up your carburetor, clutch assembly, and/or other parts for repairing

and/or rebuilding. Or visit our new shop to drop off your parts. Please contact

us before coming so we'll be at our shop waiting for your arrival. When you

visit our shop, you will be dealing directly with the owner for the best

customer service. "The road to a [trusted] friend's house (or shop) is

never long." Don't sacrifice quality workmanship for distance.

Payment Options below.

Photos

of our new building/shop are posted here!

12091 N Route B, Hallsville, MO - Google Maps.

[Return To Previous Paragraph, Section

or Website]

E-mail:

pullingtractor@aol.com. A-1 Miller's

shop is open to the public Monday-Friday, 9am to 5pm, Central time zone,

with an appointment on weekends, except holidays. If you're the kind of person

who don't trust delivery/shipping companies (mis)handling your high-dollar

and fragile merchandise, you can make the long drive to A-1 Miller's new

shop (click image to the right) to personally purchase parts, or drop off

and/or pick up your carburetor, clutch assembly, and/or other parts for repairing

and/or rebuilding. Or visit our new shop to drop off your parts. Please contact

us before coming so we'll be at our shop waiting for your arrival. When you

visit our shop, you will be dealing directly with the owner for the best

customer service. "The road to a [trusted] friend's house (or shop) is

never long." Don't sacrifice quality workmanship for distance.

Payment Options below.

Photos

of our new building/shop are posted here!

12091 N Route B, Hallsville, MO - Google Maps.

[Return To Previous Paragraph, Section

or Website]

Payment Options, and We Ship to Canada and

Worldwide

Item(s) in a package or cushioned envelope weighing less than 1 lb. is sent

by US Postal Service Airmail Letter Post for a 4-7 days delivery. Packaged

item(s) weighing over 1 lb. and up to 66 lb. is sent by US Postal Service

Airmail Parcel Post for a 4-10 days delivery. I cannot use the US Postal

Services' Flat Rate Priority Mail envelopes and boxes to ship outside U.S.

territories. Item(s) weighing over 67 lbs. or more is sent by FedEx Ground

or equivalent services. We try to keep our shipping cost to customers within

reason. Therefore, we don't ship our products in a fancy-looking package

with our company name and/or logo on it because most customers will just

toss it in the trash after they remove the contents. And being there is no

USPS tracking number outside the US, all I can do is make sure I write your

address correctly on the customs form and on your package.

My websites are not set up to process orders and accept payments. Therefore, to place an order with me, please call either number above or send an email with a list of parts you need, with your name, complete and correct postal mailing address and phone number. For payment options, I accept cash (in person), USPS Postal Money Orders, cashier's checks, business checks, MasterCard, VISA, Discover, American Express (please add 2.5% to the total amount for the credit/debit card processor's surcharge). If paying with a credit/debit card, please call me at either number above. Or to make a payment to me through PayPal, please click this link: https://www.paypal.com. Or use Cash App (username: pullingtractor) or Venmo (username: Pullingtractor) to make a payment to me. And be sure to mention a description of what the payment is for with your full name, postal address, phone number and email address. If sending a money order or cashier's check, please include a note in the envelope with your name, complete mailing address, phone number, email address and a description of what the payment is for. I'll make a note of your order when I have all your information, and I may have to order some of the parts on your list, which should take a few days to come in, but I will send everything to you as soon as I have the parts in stock after I receive your payment.

Return To Previous Website | Top of Page | Copyright © 1996-Present. This website created, designed and maintained by A-1 Miller's Performance Enterprises