How to Rebuild and Modify the Cub Cadet

Garden Tractor Drive Clutch Assembly for Durable Service

How to Rebuild and Modify the Cub Cadet

Garden Tractor Drive Clutch Assembly for Durable Service

|

|

|

Educating and Inspiring Small Engine, Lawn & Garden, and Garden

Pulling Tractor Enthusiasts Since 1996. Where Science and Common Sense Come

Together for Safety and Improved Engine/Tractor Performance |

A-1

Miller's Performance Enterprises - Parts & Services

Webstore |  Available Soon - Detailed Illustrated Plans

on How to Construct a Professional Pull-Back and Self-Propelled Garden

Tractor/Small Wheel Mini Rod Pulling Sleds

Available Soon - Detailed Illustrated Plans

on How to Construct a Professional Pull-Back and Self-Propelled Garden

Tractor/Small Wheel Mini Rod Pulling Sleds

Nowadays, prices are subject to change without notice. Click

Refresh to see any

changes or updates. Optimized for 1152 x 864 computer screen resolution.

To search for a word or phrase in any of my websites, press the CTRL

and F

and F  keys on

your keyboard simultaneously to open the Find or Search dialog box in your

web browser. And being I have no

apprentice to update and pay for my websites so they'll

continue to be on the Internet, they will be removed forever when I'm no

longer around.

keys on

your keyboard simultaneously to open the Find or Search dialog box in your

web browser. And being I have no

apprentice to update and pay for my websites so they'll

continue to be on the Internet, they will be removed forever when I'm no

longer around.

On the direct-drive Cub Cadet

garden tractor, power from the engine is through the

clutch and

driveshaft

assembly to the

transaxle

and to the rear tires. If the clutch is severely worn or if stock (OEM) parts

may slip and little power or torque will be transferred, especially when

using the tractor for competition pulling (especially with a big engine in

a fast gear), gardening or to haul heavy loads. An engine in a competition

pulling tractor that's built to the max or runs at high RPM or at

wide

open throttle produce a lot more torque than what the engineers at Cub

Cadet originally anticipated for the driveline to handle. Therefore, the

clutch assembly is the weak point (and the

one-piece carrier and coarse spline

axles), and will need to be reinforced and built up for strength for

durability and to prevent slippage. Remember: towards the end of the track,

if the tires don't spin or the engine bogs down, then the clutch will slip

or something elsewhere in the driveline will possibly twist or break.

On the direct-drive Cub Cadet

garden tractor, power from the engine is through the

clutch and

driveshaft

assembly to the

transaxle

and to the rear tires. If the clutch is severely worn or if stock (OEM) parts

may slip and little power or torque will be transferred, especially when

using the tractor for competition pulling (especially with a big engine in

a fast gear), gardening or to haul heavy loads. An engine in a competition

pulling tractor that's built to the max or runs at high RPM or at

wide

open throttle produce a lot more torque than what the engineers at Cub

Cadet originally anticipated for the driveline to handle. Therefore, the

clutch assembly is the weak point (and the

one-piece carrier and coarse spline

axles), and will need to be reinforced and built up for strength for

durability and to prevent slippage. Remember: towards the end of the track,

if the tires don't spin or the engine bogs down, then the clutch will slip

or something elsewhere in the driveline will possibly twist or break.

Types of Cub Cadet Garden Tractor Clutch Assemblies -

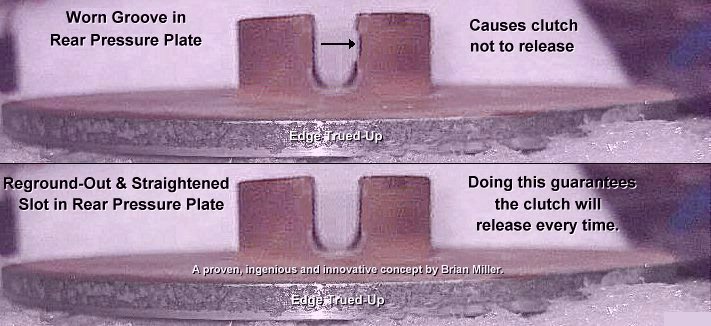

An ordinary clutch assembly for general lawn and garden use consist of a OEM quality steel driveshaft, composite clutch disc and an OEM pressure spring. But a clutch assembly for heavy lawn and garden use consist of a heavy duty 3- or 6-pin drive plate, either high strength steel or stainless steel driveshaft, either a single aftermarket composite clutch disc or a single aluminum clutch disc, and definitely a much stiffer pressure spring for placing a heavier load against the clutch disc. Also, the OEM Cub Cadet garden tractor pressure plates will definitely need to be trued-up in a metal lathe (with a self-centering 3-jaw chuck) so they'll be perfectly round and faced (resurfaced) until perfectly flat for better clutch adhesion. Because new OEM pressure plates are made of stamped steel and are not machined whatsoever. This means they are not perfectly flat and they wobble from the factory when new. If used OEM pressure plates have not been resurfaced before, then chances are, they'll still be thick enough after being resurfaced. Always remove the minimal amount of metal to retain maximum thickness so they will not warp when hot. (IMPORTANT: If you don't feel comfortable using a metal lathe, please consult a professional and experienced machinist with a lathe.) The same happens to automotive flywheels and pressure plates as the clutch disc wears. They need to be resurfaced too, when installing a new clutch disc. And the heavier or stronger the clutch assembly is, the more it will cost. By the way - if the rotating clutch parts are precision balanced, installed and adjusted correctly, the OEM Cub Cadet or aftermarket garden tractor composite clutch disc setup should last a long time, a lot longer than the popular aftermarket 3 puck metallic clutch disc.

Cub Cadet made four different 3-pin clutch drive plates. The bolt circle pattern for the three clutch disc drive pins/partially threaded studs and four mounting holes are the same for all drive plates listed below.

The first clutch drive plate

is designed for the IH-built narrow- and wide-frame Cub Cadet garden tractor

models 70, 71, 72, 73, 100, 102, 104, 106, 122, 124, 126, 86, 108 and 128

all with a solid-mounted engine. It's made of flat, solid/non-flexible, 1/8"

thickness steel, with a bronze bushing (pilot bearing) pressed in the center

to support the driveshaft, and have coiled/spiral

pins to drive the clutch disc. This type of drive plate can also be used

on the Cub Cadet "Quiet Line" rubber ISO-mounted engine garden tractors (listed

below Ê) as long as

solid motor mounts are installed. It's Cub

Cadet part # IH-384652-R12.

The first clutch drive plate

is designed for the IH-built narrow- and wide-frame Cub Cadet garden tractor

models 70, 71, 72, 73, 100, 102, 104, 106, 122, 124, 126, 86, 108 and 128

all with a solid-mounted engine. It's made of flat, solid/non-flexible, 1/8"

thickness steel, with a bronze bushing (pilot bearing) pressed in the center

to support the driveshaft, and have coiled/spiral

pins to drive the clutch disc. This type of drive plate can also be used

on the Cub Cadet "Quiet Line" rubber ISO-mounted engine garden tractors (listed

below Ê) as long as

solid motor mounts are installed. It's Cub

Cadet part # IH-384652-R12.

Depending on the class your tractor is going to pull in and engine size/modifications, there are many variations in which clutch/driveshaft design and carrier/axles to use. Listed are the weakest to the strongest:

Using Quality Driveshaft Material Is Important!

Most driveshafts are likely to

break at the second coiled/spiral pin hole, just in front of the

clutch release/throw-out bearing. Because

that's where the most vibration usually occurs. They also break just behind

the pressure spring, in front of the

pillow block bearing, due to temporary

frame twisting (narrow frames) when pulling. If this happens, it's best to

install a split clamping/locking collar.

Most driveshafts are likely to

break at the second coiled/spiral pin hole, just in front of the

clutch release/throw-out bearing. Because

that's where the most vibration usually occurs. They also break just behind

the pressure spring, in front of the

pillow block bearing, due to temporary

frame twisting (narrow frames) when pulling. If this happens, it's best to

install a split clamping/locking collar.

What mainly makes the driveshaft break at 4,000+ RPM is either...

If quality driveshaft material is used, and if the rotating parts are precision balanced and if a carrier bearing is also installed (above 4,000 RPM. The factory setting of maximum RPM for virtually all small gas engines, including all of Kohler engines is 3,600), the driveshaft could possibly last the life of the tractor. Even when used in high-performance conditions.

Remember, in the direct-drive Cub Cadet garden tractor, the entire clutch/driveshaft assembly rotates the same speed as the engine. For reliability in a highly modified tractor that turns well above 4,000 RPM, the driveshaft must be made of quality, solid hardened steel that can resist torsional twist. Such as high strength 1144 stress proof steel, heat-treated 4140 chrome-moly steel or ultra tough 304 alloy stainless steel.

Advertisement: (Prices are subject to change without notice.) Click here to contact A-1 Miller's Performance Enterprises to place an order, send your parts for repairing, and/or for FREE professional and honest technical customer service assistance and support and payment options. Please contact A-1 Miller's if you need a part or parts, or service(s) performed that's not listed or mentioned in this website. | [Top of Page]

| Click here to contact A-1 Miller's Performance Enterprises to place an order, send your parts for repairing, and/or for FREE professional and honest technical customer service assistance and support and payment options. Please contact A-1 Miller's if you need a part or parts, or service(s) performed that's not listed or mentioned in this website. | [Top of Page] |

Professionally Rebuild YOUR IH Cub Cadet Original Garden Tractor Clutch Assembly. NOTE: I'll try to keep the total rebuild price reasonable, but being replacement parts for the Original clutch are hard to find nowadays, the price may be higher. $350.00± each for parts and labor, plus return shipping & handling.

Professionally Rebuild YOUR IH- or MTD-built Cub Cadet Garden Tractor Clutch Assembly. $250.00± each for parts and labor, plus return shipping & handling. Professionally Rebuilt IH- or MTD-built Cub Cadet Garden Tractor Clutch Assemblies for General Lawn and Garden Use. Includes all narrow, wide and spread frame models. When ordering, please specify model of tractor and if it has a creeper drive or not. $350.00± each, depending on model, plus return shipping & handling. Professionally Rebuilt IH- or MTD-built Cub Cadet Garden Tractor Clutch Assemblies for Heavy Duty Use or Competition Pulling. Includes all narrow, wide and spread frame models. $500.00± each, depending on model and usage, plus return shipping & handling.

|

| Cub Cadet Garden Tractor Driveshafts

- Click here to contact A-1 Miller's Performance

Enterprises to place an order, send your parts for repairing, and/or for

FREE professional and honest technical customer service assistance and support

and payment options. Please contact A-1 Miller's if you need a part or

parts, or service(s) performed that's not listed or mentioned in this website.

| [Top of Page]

Click here to contact A-1 Miller's Performance Enterprises to place an order, send your parts for repairing, and/or for FREE professional and honest technical customer service assistance and support and payment options. If you need a part or parts that's not listed in this website, please contact A-1 Miller's and we'll see if we can get it at a reasonable price. | [Top of Page]

Replacement Heavy Duty Coiled/Spiral Pins for Cub Cadet Creeper Drives, Garden Tractor Driveshafts and 3-Pin Clutch Drive Plate. Each made of high strength, heat treated, hardened carbon steel. Minimum Rockwell hardness is C42. [Return To Previous Section, Paragraph or Website]

1/4" Diameter Heavy Duty Coiled/Spiral Pins for all other models of Cub Cadet garden tractor driveshafts. 6,500 P.S.I. breaking strength. NOTE: The driveshafts with or without a creeper drive use the same number of coiled/spiral pins. There's two to drive the pressure plates (1-1/2" length), one behind the main pressure spring (1" length), and two in the tubular coupler (1" length for the small diameter coupler, or 1-1/2" length for the large diameter coupler). NOTE - On the narrow frame Cub Cadet garden tractors, a grade 8 bolt w/locknut can be used to connect the coupler to the input shaft in the transaxle for much easier installation and removal.

|

OEM

Cub Cadet Garden Tractor 3-Pin Solid Clutch Drive Plate.

Designed for IH-built Cub Cadet garden tractor models 70, 71, 72, 73, 86,

100, 102, 104, 108, 122, 124, 126 and 128 with the solid-mounted engine.

These models have the engine fastened directly to the frame with no rubber

motor mounts. If you want to use this type of drive plate in a "Quiet Line"

model 800, 1000 or 1200 with the ISO-mounted engine, then a set of A-1 Miller's

solid motor mounts must also be installed,

making the clutch/driveshaft assembly rigid throughout so less wear will

occur to the clutch assembly. IMPORTANT: To prevent the pilot bushing

(and holes in the clutch disc) from wearing excessively, it's highly recommended

that your OEM pressure plates be trued-up (and faced (resurfaced) until perfectly

flat for better clutch adhesion) in a

metal lathe. And before reinstalling the driveshaft/clutch

assembly in the tractor, apply automotive grease inside the pilot bushing

and/or on the front of the driveshaft. Because if either is dry, chances

are, the driveshaft will wear the bushing excessively or bind up in the bushing,

and the clutch may not release. OEM

Cub Cadet Garden Tractor 3-Pin Solid Clutch Drive Plate.

Designed for IH-built Cub Cadet garden tractor models 70, 71, 72, 73, 86,

100, 102, 104, 108, 122, 124, 126 and 128 with the solid-mounted engine.

These models have the engine fastened directly to the frame with no rubber

motor mounts. If you want to use this type of drive plate in a "Quiet Line"

model 800, 1000 or 1200 with the ISO-mounted engine, then a set of A-1 Miller's

solid motor mounts must also be installed,

making the clutch/driveshaft assembly rigid throughout so less wear will

occur to the clutch assembly. IMPORTANT: To prevent the pilot bushing

(and holes in the clutch disc) from wearing excessively, it's highly recommended

that your OEM pressure plates be trued-up (and faced (resurfaced) until perfectly

flat for better clutch adhesion) in a

metal lathe. And before reinstalling the driveshaft/clutch

assembly in the tractor, apply automotive grease inside the pilot bushing

and/or on the front of the driveshaft. Because if either is dry, chances

are, the driveshaft will wear the bushing excessively or bind up in the bushing,

and the clutch may not release.

|

Cub Cadet Garden Tractor

3-Pin Flexible Center Clutch Drive Plate. Designed for IH-built

Cub Cadet garden tractor "Quiet Line" models 800, 1000 and 1200, including

models 1250, 1450 and 1650 with a hydrostatic disconnect attachment. All

these models have a rubber ISO-mounted engine to

reduce vibration throughout the tractor for operator comfort. IMPORTANT

- To maintain balance of this particular drive plate, one spiral pin is longer

than the other two - do not grind it down! And both pressure plates should

be trued-up (and faced (resurfaced) until perfectly flat for better clutch

adhesion) in a metal lathe to prevent the possibility of breakage. FYI -

The OEM Cub Cadet clutch pressure plates are made of stamped steel, which

makes them somewhat oblong or "egg-shaped" and not machined perfectly round,

which cause the clutch disc and drive plate to wear and eventually break.

This is what cause the pilot bushing to prematurely wear. And before reinstalling

the driveshaft/clutch assembly in the tractor, apply automotive grease inside

the pilot bushing and/or on the front of the driveshaft. Because if either

is dry, chances are, the driveshaft can bind up in the bushing, the clutch

may not release, and cause severe wear to both the bushing and driveshaft.

Replaces discontinued Cub Cadet flexible drive plate part # IH-106545-C93. Cub Cadet Garden Tractor

3-Pin Flexible Center Clutch Drive Plate. Designed for IH-built

Cub Cadet garden tractor "Quiet Line" models 800, 1000 and 1200, including

models 1250, 1450 and 1650 with a hydrostatic disconnect attachment. All

these models have a rubber ISO-mounted engine to

reduce vibration throughout the tractor for operator comfort. IMPORTANT

- To maintain balance of this particular drive plate, one spiral pin is longer

than the other two - do not grind it down! And both pressure plates should

be trued-up (and faced (resurfaced) until perfectly flat for better clutch

adhesion) in a metal lathe to prevent the possibility of breakage. FYI -

The OEM Cub Cadet clutch pressure plates are made of stamped steel, which

makes them somewhat oblong or "egg-shaped" and not machined perfectly round,

which cause the clutch disc and drive plate to wear and eventually break.

This is what cause the pilot bushing to prematurely wear. And before reinstalling

the driveshaft/clutch assembly in the tractor, apply automotive grease inside

the pilot bushing and/or on the front of the driveshaft. Because if either

is dry, chances are, the driveshaft can bind up in the bushing, the clutch

may not release, and cause severe wear to both the bushing and driveshaft.

Replaces discontinued Cub Cadet flexible drive plate part # IH-106545-C93.

|

A-1 Miller's Professional Repair Service - Weld Spiral

Pin Collars on YOUR OEM IH Cub Cadet Garden Tractor Drive Plate. This adds

approximately 85% more strength to prevent from bending or flexing of drive

plate while under severe strain from heavy duty use or competition pulling.

Labor include true-up drive plate in

metal lathe to remove wobble or run-out to reduce vibration.

We always perform this repair to a customer's drive plate, as part of the

complete clutch rebuild. IMPORTANT: To prevent the pilot bushing (and

holes in the clutch disc) from wearing excessively, it's highly recommended

that your OEM pressure plates be trued-up (and faced (resurfaced) until perfectly

flat for better clutch adhesion) in a

metal lathe. And before reinstalling the driveshaft/clutch

assembly in the tractor, apply automotive grease inside the pilot bushing

and/or on the front of the driveshaft. Because if either is dry, chances

are, the driveshaft will wear the bushing excessively or bind up in the bushing,

and the clutch may not release. A-1 Miller's Professional Repair Service - Weld Spiral

Pin Collars on YOUR OEM IH Cub Cadet Garden Tractor Drive Plate. This adds

approximately 85% more strength to prevent from bending or flexing of drive

plate while under severe strain from heavy duty use or competition pulling.

Labor include true-up drive plate in

metal lathe to remove wobble or run-out to reduce vibration.

We always perform this repair to a customer's drive plate, as part of the

complete clutch rebuild. IMPORTANT: To prevent the pilot bushing (and

holes in the clutch disc) from wearing excessively, it's highly recommended

that your OEM pressure plates be trued-up (and faced (resurfaced) until perfectly

flat for better clutch adhesion) in a

metal lathe. And before reinstalling the driveshaft/clutch

assembly in the tractor, apply automotive grease inside the pilot bushing

and/or on the front of the driveshaft. Because if either is dry, chances

are, the driveshaft will wear the bushing excessively or bind up in the bushing,

and the clutch may not release.

|

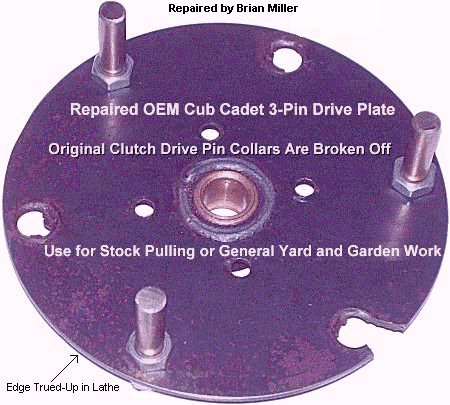

A-1 Miller's Professional

Repair Service - Repair your OEM IH Cub Cadet garden tractor 3-pin clutch

drive plate when the three OEM drive pin collar(s) are broken off with three

hardened steel drive studs. No need to purchase another drive plate. Work

include true-up drive plate in

metal lathe to remove wobble or run-out to reduce vibration

and for precision alignment installation of drive studs. I can also do this

to repair a customer's drive plate, as part of the clutch rebuild. Three

new holes drilled precisely at 2.5625" from dead center on a milling machine

with a super indexing spacer. IMPORTANT: To prevent the pilot bushing

(and holes in the clutch disc) from wearing excessively, it's highly recommended

that your OEM pressure plates be trued-up (and faced (resurfaced) until perfectly

flat for better clutch adhesion) in a

metal lathe. And before reinstalling the driveshaft/clutch

assembly in the tractor, apply automotive grease inside the pilot bushing

and/or on the front of the driveshaft. Because if either is dry, chances

are, the driveshaft will wear the bushing excessively or bind up in the bushing,

and the clutch may not release. A-1 Miller's Professional

Repair Service - Repair your OEM IH Cub Cadet garden tractor 3-pin clutch

drive plate when the three OEM drive pin collar(s) are broken off with three

hardened steel drive studs. No need to purchase another drive plate. Work

include true-up drive plate in

metal lathe to remove wobble or run-out to reduce vibration

and for precision alignment installation of drive studs. I can also do this

to repair a customer's drive plate, as part of the clutch rebuild. Three

new holes drilled precisely at 2.5625" from dead center on a milling machine

with a super indexing spacer. IMPORTANT: To prevent the pilot bushing

(and holes in the clutch disc) from wearing excessively, it's highly recommended

that your OEM pressure plates be trued-up (and faced (resurfaced) until perfectly

flat for better clutch adhesion) in a

metal lathe. And before reinstalling the driveshaft/clutch

assembly in the tractor, apply automotive grease inside the pilot bushing

and/or on the front of the driveshaft. Because if either is dry, chances

are, the driveshaft will wear the bushing excessively or bind up in the bushing,

and the clutch may not release.

|

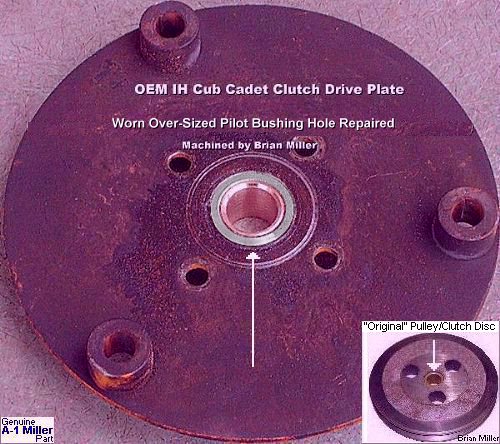

A-1 Miller's Professional Repair Service - Repair Worn

Over-Size Pilot Bushing Hole in YOUR IH Cub Cadet Garden Tractor Drive Plate,

or Repair Bushing in YOUR Cub Cadet "Original" Garden Tractor Pulley/Clutch

Disc for Installation of OEM-size Pilot Bushing. No need to purchase another

drive plate. Work include true-up drive plate in

metal lathe to remove wobble or run-out to reduce vibration.

I can also do this to repair a customer's drive plate, as part of the clutch

rebuild. Work is performed in a large metal lathe. IMPORTANT: To prevent

the pilot bushing (and holes in the clutch disc) from wearing excessively,

it's highly recommended that your OEM pressure plates be trued-up (and faced

(resurfaced) until perfectly flat for better clutch adhesion) in a

metal lathe. And before reinstalling the driveshaft/clutch

assembly in the tractor, apply automotive grease inside the pilot bushing

and/or on the front of the driveshaft. Because if either is dry, chances

are, the driveshaft will wear the bushing excessively or bind up in the bushing,

and the clutch may not release. A-1 Miller's Professional Repair Service - Repair Worn

Over-Size Pilot Bushing Hole in YOUR IH Cub Cadet Garden Tractor Drive Plate,

or Repair Bushing in YOUR Cub Cadet "Original" Garden Tractor Pulley/Clutch

Disc for Installation of OEM-size Pilot Bushing. No need to purchase another

drive plate. Work include true-up drive plate in

metal lathe to remove wobble or run-out to reduce vibration.

I can also do this to repair a customer's drive plate, as part of the clutch

rebuild. Work is performed in a large metal lathe. IMPORTANT: To prevent

the pilot bushing (and holes in the clutch disc) from wearing excessively,

it's highly recommended that your OEM pressure plates be trued-up (and faced

(resurfaced) until perfectly flat for better clutch adhesion) in a

metal lathe. And before reinstalling the driveshaft/clutch

assembly in the tractor, apply automotive grease inside the pilot bushing

and/or on the front of the driveshaft. Because if either is dry, chances

are, the driveshaft will wear the bushing excessively or bind up in the bushing,

and the clutch may not release.

|

A-1 Miller's Professional

Repair Service - Convert your OEM IH or MTD Cub Cadet garden tractor

clutch drive plate from 3-pin (IH) or 3-stud (MTD) to 3-pin/3-stud or 6-stud.

Work includes true-up plate in

metal lathe to remove wobble or run-out to reduce vibration,

drill three new holes precisely at 2.5625" from dead center on a milling

machine with a super indexing spacer to match OEM pins or studs, and then

install 3 additional hardened steel studs, lock washers and nuts. I can also

do this to repair a customer's drive plate, as part of the clutch rebuild.

NOTE: Clutch disc must be precision-drilled with 3 additional holes to

accept the 3 additional drive studs. IMPORTANT: To prevent the pilot bushing

(and holes in the clutch disc) from wearing excessively, it's highly recommended

that your OEM pressure plates be trued-up (and faced (resurfaced) until perfectly

flat for better clutch adhesion) in a

metal lathe. And before reinstalling the driveshaft/clutch

assembly in the tractor, apply automotive grease inside the pilot bushing

and/or on the front of the driveshaft. Because if either is dry, chances

are, the driveshaft will wear the bushing excessively or bind up in the bushing,

and the clutch may not release. $60.00 each drive plate, includes

parts and labor, plus return shipping & handling. A-1 Miller's Professional

Repair Service - Convert your OEM IH or MTD Cub Cadet garden tractor

clutch drive plate from 3-pin (IH) or 3-stud (MTD) to 3-pin/3-stud or 6-stud.

Work includes true-up plate in

metal lathe to remove wobble or run-out to reduce vibration,

drill three new holes precisely at 2.5625" from dead center on a milling

machine with a super indexing spacer to match OEM pins or studs, and then

install 3 additional hardened steel studs, lock washers and nuts. I can also

do this to repair a customer's drive plate, as part of the clutch rebuild.

NOTE: Clutch disc must be precision-drilled with 3 additional holes to

accept the 3 additional drive studs. IMPORTANT: To prevent the pilot bushing

(and holes in the clutch disc) from wearing excessively, it's highly recommended

that your OEM pressure plates be trued-up (and faced (resurfaced) until perfectly

flat for better clutch adhesion) in a

metal lathe. And before reinstalling the driveshaft/clutch

assembly in the tractor, apply automotive grease inside the pilot bushing

and/or on the front of the driveshaft. Because if either is dry, chances

are, the driveshaft will wear the bushing excessively or bind up in the bushing,

and the clutch may not release. $60.00 each drive plate, includes

parts and labor, plus return shipping & handling.

|

Heavy Duty 6-Pin x 1/8"

Thickness Clutch Drive Plate. Made with hardened steel studs. Can be

used with 6 hole composite or metallic clutch disc, or three pins can be

removed for use with a 3 hole clutch disc. Fits IH- and MTD-built Cub Cadet

garden tractors with OEM Cub Cadet clutch disc, aftermarket composite clutch

disc or aftermarket metallic clutch disc. Designed for heavy yard and garden

use, snow blowing or open RPM competition pulling

(pillow block bearing and brace also

recommended). Holes for all six drive studs drilled precisely at 2.5625"

from dead center on a milling machine with a super indexing spacer to match

drive holes in OEM Cub Cadet clutch disc or billet aluminum clutch disc.

NOTE: To prevent damage to the clutch assembly, when used in a Cub Cadet

"Quiet Line" model 800, 1000 or 1200, solid motor

mounts must also be installed. And the 3 hole clutch disc must be

precision-drilled with 3 additional holes precision aligned drilled to accept

the 3 additional drive studs in this 6-pin plate. IMPORTANT: To prevent the

pilot bushing (and holes in the clutch disc) from wearing excessively, it's

highly recommended that your OEM pressure plates be trued-up (and faced

(resurfaced) until perfectly flat for better clutch adhesion) in a

metal lathe with a 3 jaw chuck. Also, before reinstalling

the driveshaft/clutch assembly in the tractor, apply automotive grease inside

the pilot bushing and/or on the front of the driveshaft. Because if either

is dry, chances are, the driveshaft will wear the bushing excessively or

bind up in the bushing, and the clutch may not release. $105.00

each, plus shipping & handling. Heavy Duty 6-Pin x 1/8"

Thickness Clutch Drive Plate. Made with hardened steel studs. Can be

used with 6 hole composite or metallic clutch disc, or three pins can be

removed for use with a 3 hole clutch disc. Fits IH- and MTD-built Cub Cadet

garden tractors with OEM Cub Cadet clutch disc, aftermarket composite clutch

disc or aftermarket metallic clutch disc. Designed for heavy yard and garden

use, snow blowing or open RPM competition pulling

(pillow block bearing and brace also

recommended). Holes for all six drive studs drilled precisely at 2.5625"

from dead center on a milling machine with a super indexing spacer to match

drive holes in OEM Cub Cadet clutch disc or billet aluminum clutch disc.

NOTE: To prevent damage to the clutch assembly, when used in a Cub Cadet

"Quiet Line" model 800, 1000 or 1200, solid motor

mounts must also be installed. And the 3 hole clutch disc must be

precision-drilled with 3 additional holes precision aligned drilled to accept

the 3 additional drive studs in this 6-pin plate. IMPORTANT: To prevent the

pilot bushing (and holes in the clutch disc) from wearing excessively, it's

highly recommended that your OEM pressure plates be trued-up (and faced

(resurfaced) until perfectly flat for better clutch adhesion) in a

metal lathe with a 3 jaw chuck. Also, before reinstalling

the driveshaft/clutch assembly in the tractor, apply automotive grease inside

the pilot bushing and/or on the front of the driveshaft. Because if either

is dry, chances are, the driveshaft will wear the bushing excessively or

bind up in the bushing, and the clutch may not release. $105.00

each, plus shipping & handling. |

Clutch Drive Studs w/nuts and split lock washers for Cub

Cadet garden tractors. IMPORTANT: Installing three additional

clutch drive stud in a drive plate is something that must be performed with

precision accuracy. And it's highly recommended that your OEM pressure

plates be trued-up in a

metal lathe (with a self-centering 3-jaw chuck) so they'll

be perfectly round (to reduce premature pilot bushing wear, and faced

(resurfaced) until perfectly flat for better clutch adhesion) to prevent

premature wearing of the new pilot bushing and drive pins in the drive plate,

and holes in the clutch disc. Clutch Drive Studs w/nuts and split lock washers for Cub

Cadet garden tractors. IMPORTANT: Installing three additional

clutch drive stud in a drive plate is something that must be performed with

precision accuracy. And it's highly recommended that your OEM pressure

plates be trued-up in a

metal lathe (with a self-centering 3-jaw chuck) so they'll

be perfectly round (to reduce premature pilot bushing wear, and faced

(resurfaced) until perfectly flat for better clutch adhesion) to prevent

premature wearing of the new pilot bushing and drive pins in the drive plate,

and holes in the clutch disc.

|

Do this only if the front

axle have been moved forward -

Do this only if the front

axle have been moved forward -

On the narrow frame Cub Cadet garden tractors, if the front

axle have been moved forward, reinforce the frame rails where the engine

mounting holes are to reduce normal high-RPM engine vibration travel that

could lead to both frame and driveshaft breakage. To do so, stiffen the frame

rails where the engine mounting bolt holes are by welding two 1/4" thick

steel plates under the frame. Longer engine mounting bolts must be used,

too. The reason for this is because when the front axle center support is

moved, the remaining frame material isn't thick enough to hold up to the

engine vibration.

On the narrow frame Cub Cadet garden tractors, if the front

axle have been moved forward, reinforce the frame rails where the engine

mounting holes are to reduce normal high-RPM engine vibration travel that

could lead to both frame and driveshaft breakage. To do so, stiffen the frame

rails where the engine mounting bolt holes are by welding two 1/4" thick

steel plates under the frame. Longer engine mounting bolts must be used,

too. The reason for this is because when the front axle center support is

moved, the remaining frame material isn't thick enough to hold up to the

engine vibration.

For the spread frame models with the ISO (rubber) motor mounts, replace the rubber mounts with a set of our solid steel motor mounts or remove the brackets and fabricate a minimum 1/4" thick plate steel, set it at the right height and weld it to the frame. But the engine mounting holes and oil drain plug hole must be properly located (centered) and drilled in the plate first. This is much easier to do on a platform work table than on the floor or ground. [Return to Previous Section, Paragraph or Website]

|

|

|

|

|

|

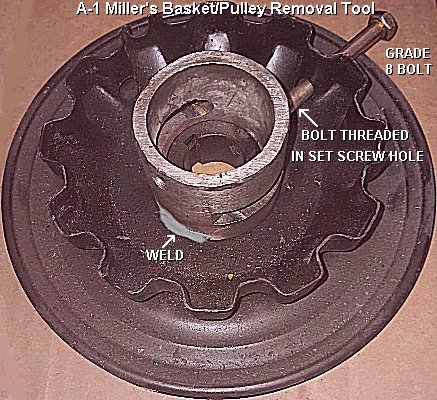

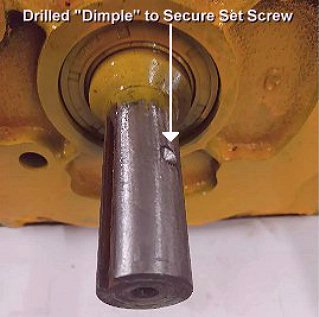

How to Remove the Driveshaft/Clutch Assembly from a Cub Cadet Garden Tractor: (This is much easier performed on a platform work table than on the floor or ground.) (Updated 9/13/22)

The coiled/spiral pin in

the input shaft on the transaxle of a narrow frame Cub Cadet garden tractor

can be very difficult to remove and somewhat difficult to access from underneath.

Therefore, it's recommended that a 1" hole should be drilled through the

top of a short tunnel cover (center section of the tractor frame), or through

the side of a tall tunnel cover in direct alignment with the coiled/spiral

pin, then use a long 1/4" roll pin punch and medium size hammer to drive

the pin from the coupler. Don't attempt to drill-out the coiled/spiral pin.

They're just as hard as a high quality drill bit. After the pin is removed

and the clutch assembly is rebuilt, upon reinstallation in the tractor, use

a socket in the drilled hole to fasten a hardened steel 1/4" diameter

[grade 8 or Allen head] bolt in the coupler.

The coiled/spiral pin in

the input shaft on the transaxle of a narrow frame Cub Cadet garden tractor

can be very difficult to remove and somewhat difficult to access from underneath.

Therefore, it's recommended that a 1" hole should be drilled through the

top of a short tunnel cover (center section of the tractor frame), or through

the side of a tall tunnel cover in direct alignment with the coiled/spiral

pin, then use a long 1/4" roll pin punch and medium size hammer to drive

the pin from the coupler. Don't attempt to drill-out the coiled/spiral pin.

They're just as hard as a high quality drill bit. After the pin is removed

and the clutch assembly is rebuilt, upon reinstallation in the tractor, use

a socket in the drilled hole to fasten a hardened steel 1/4" diameter

[grade 8 or Allen head] bolt in the coupler.

For cosmetic purpose, hide the drilled hole with a 1" plastic

or metal hole plug. Just push the plug in the hole for a nice distinctive

look. And sometimes when driving out the coiled/spiral pin, the pounding

will bend the input shaft in the transaxle. If this happens, the input shaft

will need to be straightened (and hope it doesn't break later because the

metal have been weakened) or a good used input shaft will need to be installed.

This is why it's highly recommended that a hardened steel (grade 8) 1/4"

bolt/lock nut be used in the coupler in place of the coiled/spiral pin because

if the driveshaft ever needs to be removed again, removing a bolt/lock nut

would be a lot easier than driving out a stubborn coiled/spiral pin. Plus,

it'll be easier on your nerves and on the input shaft.

For cosmetic purpose, hide the drilled hole with a 1" plastic

or metal hole plug. Just push the plug in the hole for a nice distinctive

look. And sometimes when driving out the coiled/spiral pin, the pounding

will bend the input shaft in the transaxle. If this happens, the input shaft

will need to be straightened (and hope it doesn't break later because the

metal have been weakened) or a good used input shaft will need to be installed.

This is why it's highly recommended that a hardened steel (grade 8) 1/4"

bolt/lock nut be used in the coupler in place of the coiled/spiral pin because

if the driveshaft ever needs to be removed again, removing a bolt/lock nut

would be a lot easier than driving out a stubborn coiled/spiral pin. Plus,

it'll be easier on your nerves and on the input shaft.

On the IH-built models 800, 1000

and 1200, there's a 5/8" steel ball at the end of the driveshaft located

inside the rear flex arm coupler (with the bronze swivel bushing). Do not

lose this ball! It will need to be reused when reinstalling the clutch

assembly/driveshaft in the tractor. This ball is located at the end of

the driveshaft and inside the rear flex arm coupler (with the bronze swivel

bushing) and sometimes gets lost when removing the clutch assembly/driveshaft

from the tractor. It allows the driveshaft to "move side to side" with the

engine (that's mounted on rubber mounts). If it's left out, the clutch

assembly/driveshaft will move further back 5/8" when the clutch pedal is

depressed, and the clutch disc will not release and operate correctly. The

MTD-built models have no steel ball. The end of the [5/8" longer] driveshaft

is pointed, which fits in the pilot hole of the input shaft in the

transaxle.

On the IH-built models 800, 1000

and 1200, there's a 5/8" steel ball at the end of the driveshaft located

inside the rear flex arm coupler (with the bronze swivel bushing). Do not

lose this ball! It will need to be reused when reinstalling the clutch

assembly/driveshaft in the tractor. This ball is located at the end of

the driveshaft and inside the rear flex arm coupler (with the bronze swivel

bushing) and sometimes gets lost when removing the clutch assembly/driveshaft

from the tractor. It allows the driveshaft to "move side to side" with the

engine (that's mounted on rubber mounts). If it's left out, the clutch

assembly/driveshaft will move further back 5/8" when the clutch pedal is

depressed, and the clutch disc will not release and operate correctly. The

MTD-built models have no steel ball. The end of the [5/8" longer] driveshaft

is pointed, which fits in the pilot hole of the input shaft in the

transaxle.

How to Disassemble the Clutch Components from the Driveshaft -

To disassemble the clutch components from the driveshaft, first place the front pressure plate hub on slightly open jaws of a bench vise, and use a quality-made 1/4" coiled/spiral pin punch and a medium size hammer to drive out the coiled/spiral pin. Then the pressure plates, clutch disc clutch release/throw-out bearing and pressure spring should all slide off the driveshaft.

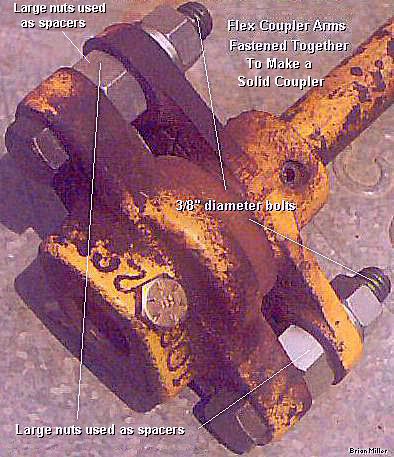

Fasten the Coupler Arms Together To Make One Rigid Driveshaft Coupler -

With solid

motor mounts installed in a Cub Cadet "Quiet Line" garden tractor that

originally came with a rubber ISO-mounted engine, the driveshaft will not

be able to "move" with the engine and there'll be less chance of clutch parts

prematurely wearing or breaking. The flexible rubber disc(s) at the end of

the driveshaft will be useless too, and could deteriorate over time. So instead

of replacing the OEM coupler arms with a machined rigid tubular coupler,

make the coupler arms rigid by removing the flexible rubber disc(s) and install

a couple of 3/8" thickness spacers for a single disc, and a couple of 3/4"

thickness spacers for double composite clutch discs, and fasten the arms

together with a couple of 3/8" diameter hardened steel bolts. (Large nuts

are used as spacers in the photo to the right.) By the way - one rubber flex

disc is 3/8" thick. This setup is just as strong as using a rigid tubular

coupler, and it cost a lot less.

With solid

motor mounts installed in a Cub Cadet "Quiet Line" garden tractor that

originally came with a rubber ISO-mounted engine, the driveshaft will not

be able to "move" with the engine and there'll be less chance of clutch parts

prematurely wearing or breaking. The flexible rubber disc(s) at the end of

the driveshaft will be useless too, and could deteriorate over time. So instead

of replacing the OEM coupler arms with a machined rigid tubular coupler,

make the coupler arms rigid by removing the flexible rubber disc(s) and install

a couple of 3/8" thickness spacers for a single disc, and a couple of 3/4"

thickness spacers for double composite clutch discs, and fasten the arms

together with a couple of 3/8" diameter hardened steel bolts. (Large nuts

are used as spacers in the photo to the right.) By the way - one rubber flex

disc is 3/8" thick. This setup is just as strong as using a rigid tubular

coupler, and it cost a lot less.

If the outer parts of the

two arms don't come together or meet when the bolts are tightened (be careful

not to tighten the bolts too tight if the arms don't meet, they could break),

a couple of thin flat washers may need to be added as shims next to the spacers.

And before fastening the arms together with the spacers, first slide the

arms on the driveshaft so they'll be in perfect alignment with each other,

and tighten the bolts. See the photo to the right ->. Also, if you want,

leave out the 5/8" diameter [swivel/spacer] steel ball. It'll serve no purpose

when using solid motor mounts and when making

the coupler arms rigid.

If the outer parts of the

two arms don't come together or meet when the bolts are tightened (be careful

not to tighten the bolts too tight if the arms don't meet, they could break),

a couple of thin flat washers may need to be added as shims next to the spacers.

And before fastening the arms together with the spacers, first slide the

arms on the driveshaft so they'll be in perfect alignment with each other,

and tighten the bolts. See the photo to the right ->. Also, if you want,

leave out the 5/8" diameter [swivel/spacer] steel ball. It'll serve no purpose

when using solid motor mounts and when making

the coupler arms rigid.

FYI - Many pullers convert the hydrostatic drive Cub Cadet garden tractor models 109, 129, 149 and 169 (wide frames with a solid mounted engine) and models 1250, 1450 and 1650 (wide frames with a rubber ISO-mounted engine) into a clutch drive tractor. All that's needed are the clutch assembly with the hanger support bracket for the release lever and a complete transaxle out of a gear drive Cub Cadet garden tractor model 86, 108, 128 (wide frames with a solid mounted engine) or models 800, 1000 or 1200 (wide frames with a rubber ISO-mounted engine). A set of A-1 Miller's solid motor mounts will be also be needed if the tractor originally have the ISO rubber motor mounts. The braking mechanism, preferably the internal "wet" brake, out of a wide frame Cub Cadet garden tractor will also be needed.

Do not fasten the two coupler

arms directly together on the IH Cub Cadet "Original" garden tractor because

the driveshaft needs to move up or down to tighten the drive belt with the

engine. Leave the flexible rubber disc in place, even for pulling competition.

Or a 5/8" I.D. universal joint can be installed instead.

Do not fasten the two coupler

arms directly together on the IH Cub Cadet "Original" garden tractor because

the driveshaft needs to move up or down to tighten the drive belt with the

engine. Leave the flexible rubber disc in place, even for pulling competition.

Or a 5/8" I.D. universal joint can be installed instead.

A rigid tubular rear driveshaft coupler with a worn center

can be repaired by boring out the center and installing a press-fit steel

sleeve. Then ream the sleeve to .626" (16mm) for a slip-fit on the driveshaft.

Then the holes for the coiled/spiral pins

can be drilled. The boring and reaming process should be performed on

a

milling machine with a

super indexing spacer or in a

metal lathe with a self-centering 3-jaw chuck.

(IMPORTANT: If you don't feel comfortable using

a metal lathe, please consult a professional and experienced machinist with

a lathe.)

A rigid tubular rear driveshaft coupler with a worn center

can be repaired by boring out the center and installing a press-fit steel

sleeve. Then ream the sleeve to .626" (16mm) for a slip-fit on the driveshaft.

Then the holes for the coiled/spiral pins

can be drilled. The boring and reaming process should be performed on

a

milling machine with a

super indexing spacer or in a

metal lathe with a self-centering 3-jaw chuck.

(IMPORTANT: If you don't feel comfortable using

a metal lathe, please consult a professional and experienced machinist with

a lathe.)

Installing a coiled/spiral pin in the rear of the driveshaft

to connect the coupler to the input shaft on the transaxle of a Cub Cadet

garden tractor can be very difficult. To make it much easier, simply use

a 1/4" grade 8 bolt instead. For strength, the shank (unthreaded part) of

the bolt needs to have full contact with the coupler and driveshaft. And

as long as the driveshaft is in correct alignment with the centerline of

the crankshaft and transaxle input shaft, with the coiled/spiral pin holes

in-line with each other, and not offset 90°, at around 4,000 RPM, this

should not cause the driveshaft to "shake around" or vibrate whatsoever.

At high RPM or at

wide

open throttle, a center support pillow

block bearing and brace should be used midway on the driveshaft.

Installing a coiled/spiral pin in the rear of the driveshaft

to connect the coupler to the input shaft on the transaxle of a Cub Cadet

garden tractor can be very difficult. To make it much easier, simply use

a 1/4" grade 8 bolt instead. For strength, the shank (unthreaded part) of

the bolt needs to have full contact with the coupler and driveshaft. And

as long as the driveshaft is in correct alignment with the centerline of

the crankshaft and transaxle input shaft, with the coiled/spiral pin holes

in-line with each other, and not offset 90°, at around 4,000 RPM, this

should not cause the driveshaft to "shake around" or vibrate whatsoever.

At high RPM or at

wide

open throttle, a center support pillow

block bearing and brace should be used midway on the driveshaft.

For pulling applications, rubber motor mounts (and the flexible coupler at the rear of the driveshaft) absorbs valuable horsepower, which must be transferred to the rear tires for full power to the track. The rubber motor mounts will also cause the engine to vibrate excessively at high RPM or at wide open throttle. Plus, with normal use of the tractor, rubber motor mounts could cause the flexible 3-pin drive plate and/or the driveshaft to eventually break. If a tractor that have rubber motor mounts and a flexible coupler is going to be used for competition pulling, definitely install some metal motor mounts.

First of all, when using a milling machine, use a spotting drill bit, or use a center punch or transfer punch to locate exactly where the hole needs to be drilled to prevent the drill bit from "skating" on the surface. This will position and guide the drill bit to bore EXACTLY where the hole needs to be drilled. And due to the natural expansion of a roll, coiled or coiled/spiral pin, ALWAYS drill the hole with a drill bit that's one size smaller than the actual size for the roll, coiled or coiled/spiral pin's size, to allow for sufficient compression of the pin when installed in the hole. For example: for a 1/4" roll, coiled or coiled/spiral pin, initially drill the hole with a 15/64" drill bit (one size smaller than the 1/4" drill bit), then finish enlarging the same hole with a 1/4" drill bit. Doing this will guarantee the hole will be EXACTLY 1/4" in diameter. If the hole is initially drilled with just the 1/4" bit, chances are, this will cause the hole to be wallowed out, making it too big for the 1/4" roll, coiled or coiled/spiral pin. [Return to Previous Section, Paragraph or Website]

Advertisement: (Prices are subject to change without notice.) Click here to contact A-1 Miller's Performance Enterprises to place an order, send your parts for repairing, and/or for FREE professional and honest technical customer service assistance and support and payment options. Please contact A-1 Miller's if you need a part or parts, or service(s) performed that's not listed or mentioned in this website. | [Top of Page]

| Solid Motor Mount Kit for Cub

Cadet "Quiet Line" Garden Tractors. Replace OEM Rubber ISO-Mounts with a

Set of Solid Motor Mounts to Prevent Repeated and Costly Damage to the Clutch

Components! [Top of Page]

Details include:

|

|||

OEM-Thickness

Bronze Pilot Bushing. Fits all pre-1981 gear drive IH-built Cub Cadet garden

tractor models 70, 71, 72, 73, 86, 100, 102, 104, 106, 108, 122, 124, 126

and 128, except "Quiet Line" models. This is also the replacement bushing

for the IH Cub Cadet "Original" garden tractor pulley/clutch disc. Dimensions:

5/8" I.D. x 7/8" O.D. x 3/4" length. IMPORTANT: To prevent the replacement

pilot bushing from premature wear, both OEM pressure plates should be trued-up

in a

metal lathe (with a self-centering 3-jaw chuck) so they'll

be perfectly round (to reduce premature pilot bushing wear, and faced

(resurfaced) until perfectly flat for better clutch adhesion), and before

reinstalling the driveshaft/clutch assembly in the tractor, apply automotive

grease inside the pilot bushing and/or on the front of the driveshaft. Because

if the bushing is dry, chances are, the driveshaft can bind up in the bushing,

the clutch may not release, and cause severe wear to both the bushing and

driveshaft. OEM-Thickness

Bronze Pilot Bushing. Fits all pre-1981 gear drive IH-built Cub Cadet garden

tractor models 70, 71, 72, 73, 86, 100, 102, 104, 106, 108, 122, 124, 126

and 128, except "Quiet Line" models. This is also the replacement bushing

for the IH Cub Cadet "Original" garden tractor pulley/clutch disc. Dimensions:

5/8" I.D. x 7/8" O.D. x 3/4" length. IMPORTANT: To prevent the replacement

pilot bushing from premature wear, both OEM pressure plates should be trued-up

in a

metal lathe (with a self-centering 3-jaw chuck) so they'll

be perfectly round (to reduce premature pilot bushing wear, and faced

(resurfaced) until perfectly flat for better clutch adhesion), and before

reinstalling the driveshaft/clutch assembly in the tractor, apply automotive

grease inside the pilot bushing and/or on the front of the driveshaft. Because

if the bushing is dry, chances are, the driveshaft can bind up in the bushing,

the clutch may not release, and cause severe wear to both the bushing and

driveshaft.

|

|||

Thin-Wall Bronze

Pilot Bushing Insert for installing inside a worn OEM bronze pilot bushing

in all pre-1981 gear drive IH Cub Cadet garden tractor models 70, 71, 72,

73, 86, 100, 102, 104, 106, 108, 122, 124, 126 and 128, except "Quiet Line"

models. Can also be used inside the OEM bushing in the IH Cub Cadet "Original"

garden tractor pulley/clutch disc. Dimensions: 5/8" I.D. x 3/4" O.D. x 3/4"

length. NOTE: Worn OEM bushing must be precision center-bored to .750"

in a

metal lathe (with a self-centering 3-jaw chuck) so this

bushing will have a press fit. IMPORTANT: To prevent the replacement pilot

bushing from premature wear, both OEM pressure plates should be faced

(resurfaced) and trued-up in a metal lathe (with a self-centering 3-jaw chuck)

so they'll be perfectly round (to reduce premature pilot bushing wear, and

faced (resurfaced) until perfectly flat for better clutch adhesion), and

before reinstalling the driveshaft/clutch assembly in the tractor, apply

automotive grease inside the pilot bushing and/or on the front of the driveshaft.

Because if the bushing is dry, chances are, the driveshaft can bind up in

the bushing, the clutch may not release, and cause severe wear to both the

bushing and driveshaft. $3.00 each, plus shipping & handling. Thin-Wall Bronze

Pilot Bushing Insert for installing inside a worn OEM bronze pilot bushing

in all pre-1981 gear drive IH Cub Cadet garden tractor models 70, 71, 72,

73, 86, 100, 102, 104, 106, 108, 122, 124, 126 and 128, except "Quiet Line"

models. Can also be used inside the OEM bushing in the IH Cub Cadet "Original"

garden tractor pulley/clutch disc. Dimensions: 5/8" I.D. x 3/4" O.D. x 3/4"

length. NOTE: Worn OEM bushing must be precision center-bored to .750"

in a

metal lathe (with a self-centering 3-jaw chuck) so this

bushing will have a press fit. IMPORTANT: To prevent the replacement pilot

bushing from premature wear, both OEM pressure plates should be faced

(resurfaced) and trued-up in a metal lathe (with a self-centering 3-jaw chuck)

so they'll be perfectly round (to reduce premature pilot bushing wear, and

faced (resurfaced) until perfectly flat for better clutch adhesion), and

before reinstalling the driveshaft/clutch assembly in the tractor, apply

automotive grease inside the pilot bushing and/or on the front of the driveshaft.

Because if the bushing is dry, chances are, the driveshaft can bind up in

the bushing, the clutch may not release, and cause severe wear to both the

bushing and driveshaft. $3.00 each, plus shipping & handling. |

|||

Tubular Driveshaft Couplers. Available in OEM stock

length, 1" longer than stock length (to lessen driveshaft wobble) or 3" rigid

tubular carbon steel driveshaft one-piece rigid tubular coupler. For a

custom-length coupler, exact locations where the coiled/spiral pin holes

need to be drilled are required. Custom-length rigid tubular driveshaft couplers,

up to 6" length are available. To find the location of the coiled/spiral

pin holes, install the driveshaft in the tractor with the engine fastened

to the frame with a couple of bolts, make sure the clutch disc is midway

on the drive pins, then measure precisely from the rear coiled/spiral pin

hole on the driveshaft to the coiled/spiral pin hole in the input shaft in

the transaxle, then add 3/4" for the overall length of the coupler. And one-piece

couplers to replace rubber flex coupler disc and coupler arms on AQS (Quiet

Line) Cub Cadet garden tractor models 800, 1000, 1050 and 1200 when using

solid motor mounts. The 800, 1000 and 1200

coupler will come with two roll pin holes for single or double rubber flex

coupler(s). NOTE: The 3" aftermarket coupler is

used only for competition pulling tractors with a shortened driveshaft so

the input shaft/pinion drive gear can be changed to vary the ground speed

of the tractor. And when ordering, please specify model of Cub Cadet garden

tractor, overall length and coiled/spiral pin hole locations. Tubular Driveshaft Couplers. Available in OEM stock

length, 1" longer than stock length (to lessen driveshaft wobble) or 3" rigid

tubular carbon steel driveshaft one-piece rigid tubular coupler. For a

custom-length coupler, exact locations where the coiled/spiral pin holes

need to be drilled are required. Custom-length rigid tubular driveshaft couplers,

up to 6" length are available. To find the location of the coiled/spiral

pin holes, install the driveshaft in the tractor with the engine fastened

to the frame with a couple of bolts, make sure the clutch disc is midway

on the drive pins, then measure precisely from the rear coiled/spiral pin

hole on the driveshaft to the coiled/spiral pin hole in the input shaft in

the transaxle, then add 3/4" for the overall length of the coupler. And one-piece

couplers to replace rubber flex coupler disc and coupler arms on AQS (Quiet

Line) Cub Cadet garden tractor models 800, 1000, 1050 and 1200 when using

solid motor mounts. The 800, 1000 and 1200

coupler will come with two roll pin holes for single or double rubber flex

coupler(s). NOTE: The 3" aftermarket coupler is

used only for competition pulling tractors with a shortened driveshaft so

the input shaft/pinion drive gear can be changed to vary the ground speed

of the tractor. And when ordering, please specify model of Cub Cadet garden

tractor, overall length and coiled/spiral pin hole locations.

|

|||

| IMPORTANT: To prevent either replacement pilot bushing listed below from wearing prematurely, for clutch drive tractors, both pressure plates should be trued-up and faced (resurfaced) in a metal lathe (with a self-centering 3-jaw chuck) so they'll be perfectly round and flat (for better clutch adhesion). And before reinstalling the driveshaft/clutch assembly in the tractor, apply automotive chassis or wheel bearing grease inside the pilot bushing and/or on the front of the driveshaft. Because if the bushing or driveshaft is dry, chances are, the driveshaft can bind up in the bushing, the clutch may not release, and cause severe wear to both the bushing and driveshaft. | |||

Replacement

Self-Aligning Spherical Bronze Bushing w/Outer Steel Race/Retainer. Fits

pilot bushing retainers listed below and input shaft coupler arm further

below in Cub Cadet "Quiet Line" rubber

ISO-mounted engine garden tractor models 482, 580, 582, 582 Special,

680, 682, 782, 782D, 784, 800, 882, 982, 984, 1000, 1050, 1200, 1204, 1210,

1211, 1250, 1282, 1450, 1512, 1541, 1572, 1604, 1606, 1650, 1710, 1711, 1712,

1772, 1806, 1810, 1811, 1860, 1872, 1912, 1914 and 2072. Install with hammer

and socket. OEM Cub Cadet part # 941-3004. $52.00 each, plus shipping

& handling. Replacement

Self-Aligning Spherical Bronze Bushing w/Outer Steel Race/Retainer. Fits

pilot bushing retainers listed below and input shaft coupler arm further

below in Cub Cadet "Quiet Line" rubber

ISO-mounted engine garden tractor models 482, 580, 582, 582 Special,

680, 682, 782, 782D, 784, 800, 882, 982, 984, 1000, 1050, 1200, 1204, 1210,

1211, 1250, 1282, 1450, 1512, 1541, 1572, 1604, 1606, 1650, 1710, 1711, 1712,

1772, 1806, 1810, 1811, 1860, 1872, 1912, 1914 and 2072. Install with hammer

and socket. OEM Cub Cadet part # 941-3004. $52.00 each, plus shipping

& handling. |

Round Retainer

with Pressed-In Self-Aligning Spherical Pilot Bushing. Fits Cub Cadet "Quiet

Line" rubber ISO-mounted engine garden tractor

models 800, 1000, 1200, 1250, 1450 and 1650. OEM Cub Cadet IH-126205-C2.

$141.00 each, plus shipping & handling. Round Retainer

with Pressed-In Self-Aligning Spherical Pilot Bushing. Fits Cub Cadet "Quiet

Line" rubber ISO-mounted engine garden tractor

models 800, 1000, 1200, 1250, 1450 and 1650. OEM Cub Cadet IH-126205-C2.

$141.00 each, plus shipping & handling. |

||

Rectangular Flange with

Pressed-In Self-Aligning Spherical Bronze Pilot Bushing. Fits Cub Cadet "Quiet

Line" rubber ISO-mounted engine garden tractor

models 680, 682, 782, 784, 1204, 1210, 1211, 1250, 1282, 1450, 1541, 1650,

1710, 1711, 1712, 1810, 1811, 1812, 1860, 1872 and 2072. OEM Cub Cadet part

# 903-0204. $33.65 each, plus shipping & handling. Rectangular Flange with

Pressed-In Self-Aligning Spherical Bronze Pilot Bushing. Fits Cub Cadet "Quiet

Line" rubber ISO-mounted engine garden tractor

models 680, 682, 782, 784, 1204, 1210, 1211, 1250, 1282, 1450, 1541, 1650,

1710, 1711, 1712, 1810, 1811, 1812, 1860, 1872 and 2072. OEM Cub Cadet part

# 903-0204. $33.65 each, plus shipping & handling. |

Rectangular

Flange with Pressed-In Self-Aligning Spherical Bronze Pilot Bushing. Fits

Cub Cadet "Quiet Line" rubber ISO-mounted

engine garden tractor models 982, 984, 986, 1912 and 1914. Discontinued Cub

Cadet part # 703-0231. $45.00 each with new bushing, plus shipping

& handling. (When available or in stock.) Rectangular

Flange with Pressed-In Self-Aligning Spherical Bronze Pilot Bushing. Fits

Cub Cadet "Quiet Line" rubber ISO-mounted

engine garden tractor models 982, 984, 986, 1912 and 1914. Discontinued Cub

Cadet part # 703-0231. $45.00 each with new bushing, plus shipping

& handling. (When available or in stock.) |

Rectangular Flange with

Pressed-In Self-Aligning Spherical Bronze Pilot Bushing. Fits Cub Cadet "Quiet

Line" rubber ISO-mounted engine garden tractor

models Fits models 1050, 1535 and 1806. OEM Cub Cadet part # 903-1492.

$50.20 each, plus shipping & handling. Rectangular Flange with

Pressed-In Self-Aligning Spherical Bronze Pilot Bushing. Fits Cub Cadet "Quiet

Line" rubber ISO-mounted engine garden tractor

models Fits models 1050, 1535 and 1806. OEM Cub Cadet part # 903-1492.

$50.20 each, plus shipping & handling. |

|

Transaxle

Input Shaft Coupler Arm with 5/8" Hole and 25/64" Alignment Hole. Fits

Cub Cadet "Original" garden tractor and Cub Cadet garden tractor models 105,

107, 109, 123, 125, 127, 129, 147, 149 and 169. NOTE: This particular

part goes on the input shaft of the transaxle and not on the driveshaft.

The 5/8" hole goes on the input shaft, and the 3/8" stub shaft on driveshaft

fits in the 3/8" alignment hole. Can also be used on a custom-built steering

shaft setup of a mini-rod pulling tractor as a type of U-joint with a maximum

35º rotational angle with either flex coupler disc listed below. Dimensions:

25/64" bolt holes spaced 3" apart x 25/64" center pilot hole (for support

end of driveshaft) x 5/8" center hole.

[Return To Previous Section, Paragraph

or Website] Transaxle

Input Shaft Coupler Arm with 5/8" Hole and 25/64" Alignment Hole. Fits

Cub Cadet "Original" garden tractor and Cub Cadet garden tractor models 105,

107, 109, 123, 125, 127, 129, 147, 149 and 169. NOTE: This particular

part goes on the input shaft of the transaxle and not on the driveshaft.

The 5/8" hole goes on the input shaft, and the 3/8" stub shaft on driveshaft

fits in the 3/8" alignment hole. Can also be used on a custom-built steering

shaft setup of a mini-rod pulling tractor as a type of U-joint with a maximum

35º rotational angle with either flex coupler disc listed below. Dimensions:

25/64" bolt holes spaced 3" apart x 25/64" center pilot hole (for support

end of driveshaft) x 5/8" center hole.

[Return To Previous Section, Paragraph

or Website]

|

|||

Driveshaft (or Input Shaft) Coupler Arm

with 5/8" Straight-Through Hole. Fits Cub Cadet garden tractor models

482, 580, 582, 680, 682, 782, 782D, 784, 782D, 800, 882, 1000, 1050, 1100,

1200, 1204, 1210, 1211, 1250, 1282, 1450, 1512, 1541, 1604, 1650, 1710, 1711,

1712, 1806, 1810, 1811, 1812 and 1860. NOTE: This particular part goes

on the driveshaft and not on the input shaft of the transaxle. Additional

Note: This part can be substituted for the coupler arm listed above for Cub

Cadet "Original" garden tractor and Cub Cadet garden tractor models 105,

107, 109, 123, 125, 127, 129, 147, 149 and 169 with a new unmachined driveshaft

(with a 5/8" stub shaft instead of OEM 3/8" stub shaft) when used on the

transaxle input shaft with end of driveshaft at 5/8" for better stability

and less wear to stub shaft and coupler arm. (A-1 Miller's improved design.)

Can also be used on a custom-built steering shaft setup of a mini-rod

pulling tractor as a type of U-joint with a maximum 35º rotational angle

with either rubber flex coupler disc listed below. Dimensions: 25/64" bolt

holes spaced 3" apart x 5/8" center through-hole.

[Return To Previous Section, Paragraph

or Website] Driveshaft (or Input Shaft) Coupler Arm

with 5/8" Straight-Through Hole. Fits Cub Cadet garden tractor models

482, 580, 582, 680, 682, 782, 782D, 784, 782D, 800, 882, 1000, 1050, 1100,

1200, 1204, 1210, 1211, 1250, 1282, 1450, 1512, 1541, 1604, 1650, 1710, 1711,

1712, 1806, 1810, 1811, 1812 and 1860. NOTE: This particular part goes

on the driveshaft and not on the input shaft of the transaxle. Additional

Note: This part can be substituted for the coupler arm listed above for Cub

Cadet "Original" garden tractor and Cub Cadet garden tractor models 105,

107, 109, 123, 125, 127, 129, 147, 149 and 169 with a new unmachined driveshaft

(with a 5/8" stub shaft instead of OEM 3/8" stub shaft) when used on the

transaxle input shaft with end of driveshaft at 5/8" for better stability

and less wear to stub shaft and coupler arm. (A-1 Miller's improved design.)

Can also be used on a custom-built steering shaft setup of a mini-rod

pulling tractor as a type of U-joint with a maximum 35º rotational angle

with either rubber flex coupler disc listed below. Dimensions: 25/64" bolt

holes spaced 3" apart x 5/8" center through-hole.

[Return To Previous Section, Paragraph

or Website]

|

|||

Transaxle Input Shaft Coupler Arm with Self-Aligning

Spherical Bronze Swivel Bushing and Outer Steel Race/Retainer. Each fits

Cub Cadet garden tractor models 482, 580, 582, 682, 782, 782D, 800, 882,

1000, 1050, 1100, 1200, 1204, 1210, 1211, 1250, 1282, 1450, 1512, 1541, 1604,

1650, 1710, 1711, 1712, 1806, 1810, 1811, 1812 and 1860. Dimensions: bolt

holes spaced 3" apart x 5/8" center through-hole. NOTE: This particular

part goes on the input shaft of the transaxle and not on the driveshaft. Transaxle Input Shaft Coupler Arm with Self-Aligning

Spherical Bronze Swivel Bushing and Outer Steel Race/Retainer. Each fits

Cub Cadet garden tractor models 482, 580, 582, 682, 782, 782D, 800, 882,

1000, 1050, 1100, 1200, 1204, 1210, 1211, 1250, 1282, 1450, 1512, 1541, 1604,

1650, 1710, 1711, 1712, 1806, 1810, 1811, 1812 and 1860. Dimensions: bolt

holes spaced 3" apart x 5/8" center through-hole. NOTE: This particular

part goes on the input shaft of the transaxle and not on the driveshaft.

|

|||

5/8" Steel Ball. Fits IH-built Cub Cadet garden tractor models

800, 1000 and 1200. This ball is located at the end of the driveshaft

and inside the rear flex arm coupler (with the bronze swivel bushing; listed

above) and sometimes gets lost when removing the clutch assembly/driveshaft

from the tractor. It allows the driveshaft to "move side to side" with the

engine (that's mounted on rubber mounts). If it's left out, the clutch

assembly/driveshaft will move further back 5/8" when the clutch pedal is

depressed, and the clutch disc will not release and operate correctly. The

MTD-built models have no steel ball. The end of the [5/8" longer] driveshaft

is pointed, which fits in the pilot hole of the input shaft in the

transaxle. 5/8" Steel Ball. Fits IH-built Cub Cadet garden tractor models

800, 1000 and 1200. This ball is located at the end of the driveshaft

and inside the rear flex arm coupler (with the bronze swivel bushing; listed

above) and sometimes gets lost when removing the clutch assembly/driveshaft

from the tractor. It allows the driveshaft to "move side to side" with the

engine (that's mounted on rubber mounts). If it's left out, the clutch

assembly/driveshaft will move further back 5/8" when the clutch pedal is

depressed, and the clutch disc will not release and operate correctly. The

MTD-built models have no steel ball. The end of the [5/8" longer] driveshaft

is pointed, which fits in the pilot hole of the input shaft in the

transaxle.

|

|||

Reinforced

Rubber Driveshaft Flex Coupler Disc. Designed specifically for Cub Cadet

"Quiet Line" garden tractor models 482, 580, 582, 582 Special, 682, 782,

782D, 800, 882, 982, 984, 986, 1000, 1050, 1100, 1200, 1204, 1210, 1211,

1250, 1282, 1450, 1512, 1541, 1604, 1606, 1650, 1710, 1711, 1712, 1806, 1810,

1811, 1812, 1860, 1872, 1912, 1914 and 2072. Can also be used on the IH Cub

Cadet "Original" garden tractor. All IH-built Cub Cadet models require one

flex coupler disc at each end of driveshaft, and all MTD-built Cub Cadet

models use two flex coupler discs at each end of driveshaft. Very tough,

reinforced rubber/weaved composite material. Allows for out-of-alignment

rotation of driveshaft in rubber ISO-mounted

engine tractors to prevent damage to the clutch parts or hydrostatic pump.

Has larger center hole than coupler listed above to clear housing in coupler

arm with self-aligning spherical bushing. Can be substituted for flex coupler

listed above. Can also be used in a steering shaft setup of a custom-built

mini-rod pulling tractor as a type of U-joint with a maximum 35º rotational

angle with coupler arm(s) listed above. 13/32" bolt holes spaced 3" apart.

OEM Cub Cadet part # 722-3000. $29.00 each, plus shipping & handling. Reinforced

Rubber Driveshaft Flex Coupler Disc. Designed specifically for Cub Cadet

"Quiet Line" garden tractor models 482, 580, 582, 582 Special, 682, 782,

782D, 800, 882, 982, 984, 986, 1000, 1050, 1100, 1200, 1204, 1210, 1211,

1250, 1282, 1450, 1512, 1541, 1604, 1606, 1650, 1710, 1711, 1712, 1806, 1810,

1811, 1812, 1860, 1872, 1912, 1914 and 2072. Can also be used on the IH Cub

Cadet "Original" garden tractor. All IH-built Cub Cadet models require one

flex coupler disc at each end of driveshaft, and all MTD-built Cub Cadet

models use two flex coupler discs at each end of driveshaft. Very tough,

reinforced rubber/weaved composite material. Allows for out-of-alignment

rotation of driveshaft in rubber ISO-mounted

engine tractors to prevent damage to the clutch parts or hydrostatic pump.

Has larger center hole than coupler listed above to clear housing in coupler

arm with self-aligning spherical bushing. Can be substituted for flex coupler

listed above. Can also be used in a steering shaft setup of a custom-built

mini-rod pulling tractor as a type of U-joint with a maximum 35º rotational

angle with coupler arm(s) listed above. 13/32" bolt holes spaced 3" apart.

OEM Cub Cadet part # 722-3000. $29.00 each, plus shipping & handling.

|

|||

The OEM Cub Cadet

Hydrostatic Drive Garden Tractor Hub (shown to the left in the photo below;

Cub Cadet part # IH-394034-R32) in IH Cub Cadet garden tractor models 105,

107, 109, 123, 125, 127, 129, 147, 149 and 169 is notorious for the slots

becoming severely worn due to a slight misalignment of the engine with the

driveshaft. To fix this, replace this hub with the parts shown to the right

-> in the photo below. Because these parts will last a lot longer, and

they'll produce no noise. Modification to the front of the driveshaft will

need to be made. Click here to contact

A-1 Miller's Performance Enterprises to place an order, send your parts for

repairing, and/or for FREE professional and honest technical customer service

assistance and support and payment options. If you need a

part or parts that's not listed in this website, please contact A-1 Miller's

and we'll see if we can get it at a reasonable price. The OEM Cub Cadet

Hydrostatic Drive Garden Tractor Hub (shown to the left in the photo below;

Cub Cadet part # IH-394034-R32) in IH Cub Cadet garden tractor models 105,

107, 109, 123, 125, 127, 129, 147, 149 and 169 is notorious for the slots

becoming severely worn due to a slight misalignment of the engine with the

driveshaft. To fix this, replace this hub with the parts shown to the right

-> in the photo below. Because these parts will last a lot longer, and

they'll produce no noise. Modification to the front of the driveshaft will

need to be made. Click here to contact

A-1 Miller's Performance Enterprises to place an order, send your parts for

repairing, and/or for FREE professional and honest technical customer service

assistance and support and payment options. If you need a

part or parts that's not listed in this website, please contact A-1 Miller's

and we'll see if we can get it at a reasonable price.

|

|||

The main cause of breakage of the OEM Cub Cadet garden tractor

aluminum hub adapter on competition pulling engines that run at wide open

throttle is using out-of-balance OEM pressure plates and OEM 3-pin clutch

drive plate, and/or not installing the large flat washer under the nut or

bolt (as described below Ê). So as long

as the drive plate and pressure plates are trued-up in a

metal lathe (with a self-centering 3-jaw chuck) so they'll

be perfectly round (to reduce premature pilot bushing wear, and faced

(resurfaced) until perfectly flat for better clutch adhesion) to remove the

run-out or wobble so they'll be precision balanced, this hub have been known

to hold up very well even in a highly modified competition pulling tractor

as long as the original 1/4" thick x no less than 1-1/4" O.D. flat washer

is installed under the flywheel nut or bolt with hardened 1/4" bolts w/split

lock washers to securely fasten the drive plate to the hub. Otherwise,

it's pretty tough.

The main cause of breakage of the OEM Cub Cadet garden tractor

aluminum hub adapter on competition pulling engines that run at wide open

throttle is using out-of-balance OEM pressure plates and OEM 3-pin clutch

drive plate, and/or not installing the large flat washer under the nut or

bolt (as described below Ê). So as long

as the drive plate and pressure plates are trued-up in a

metal lathe (with a self-centering 3-jaw chuck) so they'll

be perfectly round (to reduce premature pilot bushing wear, and faced

(resurfaced) until perfectly flat for better clutch adhesion) to remove the

run-out or wobble so they'll be precision balanced, this hub have been known

to hold up very well even in a highly modified competition pulling tractor

as long as the original 1/4" thick x no less than 1-1/4" O.D. flat washer

is installed under the flywheel nut or bolt with hardened 1/4" bolts w/split

lock washers to securely fasten the drive plate to the hub. Otherwise,

it's pretty tough.

Separate the Brake and Clutch Operations - (This have been done by many professional pullers in the past.)