A-1 Miller's Performance Enterprises Webstore

of Electrical Parts

A-1 Miller's Performance Enterprises Webstore

of Electrical Parts

A-1 Miller's Performance Enterprises Webstore

of Electrical Parts

A-1 Miller's Performance Enterprises Webstore

of Electrical Parts

Nowadays, prices are subject to change without notice. Click

Refresh to see any

changes or updates. Optimized for 1152 x 864 computer screen resolution.

To search for a word or phrase in any of my websites, press the CTRL

and F

and F  keys on

your keyboard simultaneously to open the Find or Search dialog box in your

web browser. Scroll down this website or click/tap the links below to

jump down to...

keys on

your keyboard simultaneously to open the Find or Search dialog box in your

web browser. Scroll down this website or click/tap the links below to

jump down to...

| FYI - All aftermarket parts offered in this website are of very high quality and come with an unconditional guarantee. As a matter of fact, the aftermarket parts are just as good or better quality than most OEM Kohler parts. However, certain OEM Kohler and aftermarket parts are no longer available, but might still be available from a source in new old stock. | |||||||

Vibration-Proof Surface-Mount Small Engine Tachometers/Hour Meters |

Durable/Reinforced Electric Competition Pulling Engine Cooling Fan |

Killswitch, Ignition/Lights/Auxiliary Switches, Starter Switches and Electrical Accessory Switches |

|||||

Click here to contact A-1 Miller's Performance Enterprises to place an order, send your parts for repairing, and/or for FREE professional and honest technical customer service assistance and support and payment options. Please contact A-1 Miller's if you need a part or parts, or service(s) performed that's not listed or mentioned in this website. Prices are subject to change without notice.

Universal Electric Fuel Level Gauge Kit. 2" gauge can

be mounted in dash of tractor, vehicle or in control panel of equipment.

Use a 2"

hole saw and power drill or

annular cutter to cut hole in dash or panel. Fuel level

reading on gauge can be adjusted or corrected for shallow to deep tanks to

13-1/2" by shortening float rod. Includes wiring harness and instructions.

Operates with 9-36 volts DC. Wire Connections - 1-> Ignition Switch (Battery

Positive (+) Post); 2-> Negative Ground (Battery Negative (—) Post);

3-> Signal Input (Fuel Gauge); 5-> Illuminated Backlight (Connect to

Instrument Cluster or Dash Lights). Complete Kit. $45.00

each, plus shipping & handling. Universal Electric Fuel Level Gauge Kit. 2" gauge can

be mounted in dash of tractor, vehicle or in control panel of equipment.

Use a 2"

hole saw and power drill or

annular cutter to cut hole in dash or panel. Fuel level

reading on gauge can be adjusted or corrected for shallow to deep tanks to

13-1/2" by shortening float rod. Includes wiring harness and instructions.

Operates with 9-36 volts DC. Wire Connections - 1-> Ignition Switch (Battery

Positive (+) Post); 2-> Negative Ground (Battery Negative (—) Post);

3-> Signal Input (Fuel Gauge); 5-> Illuminated Backlight (Connect to

Instrument Cluster or Dash Lights). Complete Kit. $45.00

each, plus shipping & handling. |

|

High

Quality Small Engine Inductive Tachometer/Hour Meter with Replaceable

Battery. A tachometer is required for monitoring and/or setting the

maximum speed of a small engine, which is normally 3,200 or 3,600 RPM (depending

on type of carburetor), to prevent from over-revving and possible damage

to the engine or dangerous flywheel explosion. Very accurate, vibration-proof

and weatherproof construction. Can be surface-mounted and secured with two

screws to monitor engine RPM, or hand-held to set engine RPM. Large 3/8 inch

LCD display. Works with magneto or battery-powered ignition systems by selecting

engine type by programming S1 and S2 buttons. If tachometer does not turn

on automatically as soon as engine starts, press and hold the two buttons

at the same time. Instructions included. Reads up to 99,999 RPM. Hour

meter reads up to 9999:59 hours/minutes. Programmable maintenance hour setting

with service icon, a service reminder when to change oil or other maintenance.

Can be manually reset to Zero hours. Easy installation: Single wire wraps

around spark plug wire and secured with two supplied nylon zip-ties. No wire

terminal connections required. Includes replaceable CR2450 battery. Dimensions:

2" wide x 1-3/4" depth x 3/4" height. $25.00 each, plus shipping &

handling. Click here to print

out instructions. Please let me know if you're

interested in purchasing this item and I'll give you the total amount with

shipping and payment options. High

Quality Small Engine Inductive Tachometer/Hour Meter with Replaceable

Battery. A tachometer is required for monitoring and/or setting the

maximum speed of a small engine, which is normally 3,200 or 3,600 RPM (depending

on type of carburetor), to prevent from over-revving and possible damage

to the engine or dangerous flywheel explosion. Very accurate, vibration-proof

and weatherproof construction. Can be surface-mounted and secured with two

screws to monitor engine RPM, or hand-held to set engine RPM. Large 3/8 inch

LCD display. Works with magneto or battery-powered ignition systems by selecting

engine type by programming S1 and S2 buttons. If tachometer does not turn

on automatically as soon as engine starts, press and hold the two buttons

at the same time. Instructions included. Reads up to 99,999 RPM. Hour

meter reads up to 9999:59 hours/minutes. Programmable maintenance hour setting

with service icon, a service reminder when to change oil or other maintenance.

Can be manually reset to Zero hours. Easy installation: Single wire wraps

around spark plug wire and secured with two supplied nylon zip-ties. No wire

terminal connections required. Includes replaceable CR2450 battery. Dimensions:

2" wide x 1-3/4" depth x 3/4" height. $25.00 each, plus shipping &

handling. Click here to print

out instructions. Please let me know if you're

interested in purchasing this item and I'll give you the total amount with

shipping and payment options.

Wiring Instructions:

Wiring is the same for the hall effect and inductive proximity sensors. Certain proximity sensors have an LED (Light Emitting Diode), which flashes when in close proximity of target. If the proximity sensor is wired incorrectly, the LED will illuminate at all times.

|

Durable/Reinforced Electric Competition Pulling Engine Cooling Fan - Click here to contact A-1 Miller's Performance Enterprises to place an order, send your parts for repairing, and/or for FREE professional and honest technical customer service assistance and support and payment options. Please contact A-1 Miller's if you need a part or parts, or service(s) performed that's not listed or mentioned in this website. [Top of Page]

Superior Quality, High Velocity 12 Volt Auxiliary Engine Cooling Fan. Use an electric fan to cool a competition garden tractor pulling engine with a steel flywheel and no cooling fins. Unlike fan blades that's fastened to the flywheel, an electric fan will not produce drag and rob power from the engine. Install fan with motor forward of blades (for maximum velocity) aimed toward exhaust area of engine. Fasten fan housing on a sturdy angle steel support brace with 1/4" bolts, flat washers, lock washers and nuts, in front of engine or behind grille in a garden tractor. See photos to the right and below. No need to mount fan housing on rubber grommets; these will serve no purpose whatsoever. Fan motor is 100% secured and reinforced to plastic housing to withstand severe engine vibration to prevent fan motor from loosening and become inoperable when pulling. Distinctive feature by A-1 Miller's. NOTE: These fans are designed to be run for a short while only. If they are ran continuously, they may burn up. Draws 2.6 amps, produces 145 CFM. Measures 3" diameter and 5" length. IMPORTANT: It's recommended that the fan not be run while pulling because due to normal engine vibration, the brush holders inside motor could break. Turn fan on ONLY between pull-offs or when tuning engine. $40.00 each, plus shipping & handling.

|

Killswitch, Ignition/Lights/Auxiliary, Starter Switches and Electrical Accessory Switches - Click here to contact A-1 Miller's Performance Enterprises to place an order, send your parts for repairing, and/or for FREE professional and honest technical customer service assistance and support and payment options. Please contact A-1 Miller's if you need a part or parts, or service(s) performed that's not listed or mentioned in this website. [Top of Page]

Break-Away / Grounding-Type Safety Kill Switch with

Pull-Pin. Use for competition pulling only; mount on rear of tractor.

When the pin pulled, it grounds the ignition coil from producing spark. If

using with a self-energizing magneto or electronic/solid state ignition systems:

Connect one wire to the chassis ground, and connect the other wire to the

points/condenser wire or to the kill terminal on the solid state ignition

coil/module. If using with a battery-powered ignition system: Connect one

wire to the chassis ground, and connect the other wire to the coil negative

(–) terminal. NOTE: With battery-powered ignition, as soon as pin

is pulled (engine will die), manually shut off ignition switch right away

to prevent possible damage to the ignition coil and electronic ignition module

if equipped with crank trigger ignition. This type of switch does not

disable power to the

electric fuel pump on a pulling tractor. It must be

shut-off manually by the ignition switch or an OFF-ON toggle switch. Break-Away / Grounding-Type Safety Kill Switch with

Pull-Pin. Use for competition pulling only; mount on rear of tractor.

When the pin pulled, it grounds the ignition coil from producing spark. If

using with a self-energizing magneto or electronic/solid state ignition systems:

Connect one wire to the chassis ground, and connect the other wire to the

points/condenser wire or to the kill terminal on the solid state ignition

coil/module. If using with a battery-powered ignition system: Connect one

wire to the chassis ground, and connect the other wire to the coil negative

(–) terminal. NOTE: With battery-powered ignition, as soon as pin

is pulled (engine will die), manually shut off ignition switch right away

to prevent possible damage to the ignition coil and electronic ignition module

if equipped with crank trigger ignition. This type of switch does not

disable power to the

electric fuel pump on a pulling tractor. It must be

shut-off manually by the ignition switch or an OFF-ON toggle switch.

|

||

High Quality Universal Switches. Designed for use with

Self-Energizing Magneto Ignition, Solid State Ignition, OEM Solid State

Ignition (SSI) for Tecumseh's Cast Iron Block Engines, or with OEM Kohler

Breakerless Ignition. These can be used on virtually any small engine

installed on lawn and garden equipment, garden tillers, go-karts, chainsaws,

log splitters, portable air compressors, portable generators/welders, portable

water pumps, etc. with a magneto or solid state ignition, and a recoil/rope

starter or a push-button starter switch, if engine is equipped with an

electric starter.

Very durable, tough switches. High Quality Universal Switches. Designed for use with

Self-Energizing Magneto Ignition, Solid State Ignition, OEM Solid State

Ignition (SSI) for Tecumseh's Cast Iron Block Engines, or with OEM Kohler

Breakerless Ignition. These can be used on virtually any small engine

installed on lawn and garden equipment, garden tillers, go-karts, chainsaws,

log splitters, portable air compressors, portable generators/welders, portable

water pumps, etc. with a magneto or solid state ignition, and a recoil/rope

starter or a push-button starter switch, if engine is equipped with an

electric starter.

Very durable, tough switches.

|

||

High Quality Universal

Switches for Battery-Powered Ignition and Electrical Accessories. Very durable,

tough switches. Either can be used for ignition, lights,

electric fuel

pump, electric PTO clutch, etc. When used for ignition, use with

push-button starter switch (listed below). Terminals or wires on switches

listed below makes contact when in the ON position. Can be used on virtually

anything that have a battery-powered ignition or electrical system, such

as: garden tractors, go-karts, competition pulling tractors, small motorized

vehicles, mini-rods, hot-rods, farm tractors, automobiles, etc. Each can

be mounted in dashboard, instrument panel, engine control panel, etc. High Quality Universal

Switches for Battery-Powered Ignition and Electrical Accessories. Very durable,

tough switches. Either can be used for ignition, lights,

electric fuel

pump, electric PTO clutch, etc. When used for ignition, use with

push-button starter switch (listed below). Terminals or wires on switches

listed below makes contact when in the ON position. Can be used on virtually

anything that have a battery-powered ignition or electrical system, such

as: garden tractors, go-karts, competition pulling tractors, small motorized

vehicles, mini-rods, hot-rods, farm tractors, automobiles, etc. Each can

be mounted in dashboard, instrument panel, engine control panel, etc.

|

||

High Quality Universal

Push-Button Switches. Each can be mounted in pedestal, dashboard, instrument

panel, engine control panel, flywheel shroud, etc. High Quality Universal

Push-Button Switches. Each can be mounted in pedestal, dashboard, instrument

panel, engine control panel, flywheel shroud, etc.

|

||

High Quality Universal 3-Position OFF-ON-START MAGNETO

Ignition Key Switch. Designed specifically for Self-Energizing Magneto

Ignition, Solid State Ignition, OEM Solid State Ignition (SSI) for Tecumseh's

Cast Iron Block Engines, or with OEM Kohler Breakerless Ignition. Can

be used for various makes and models of riding mowers, lawn & garden

tractors, garden tractors and various small engine equipment with magneto

or solid state ignition. Identification of 5 blade terminals: B =

Battery (+); G = Ground (terminal is grounded to body of switch);

L = Lights (use a separate OFF-ON switch connected to this terminal

to power an electric PTO clutch); M = Magneto (Ignition); S

= Solenoid (small terminal). Key positions: OFF position makes contact with

M+G; IGNITION position makes contact with B+L; START position makes contact

with B+S. Each terminal identified for correct wiring connections. IMPORTANT:

Use with a starter solenoid/relay to crank the engine to prevent burning

out internal contacts in switch. NOTE: If engine is equipped with an

alternator/stator charging system, the center terminal on the voltage

rectifier/regulator connects to the positive (+) battery post. If using an

ammeter/amp gauge, connect the gauge/meter to the positive (+) battery post,

then to the B terminal on the switch. Trace the wires on your tractor/equipment

to see if they match the terminals on this switch. If they don't match, the

plug-in spade connectors/wires can be rearranged in the plastic connector

housing to match the corresponding terminals on the switch. To do this, use

a small flat blade screwdriver to depress the locking tab/tang so the plug-in

connector can be pulled out from the plastic connector housing. Bend the

locking tab/tang up slightly before reinserting it in the plastic connector

so it will be secured in place. Or for a universal application, use #250

slip-on female spade crimp-type wire connectors. Requires 5/8" diameter mounting

hole. High Quality Universal 3-Position OFF-ON-START MAGNETO

Ignition Key Switch. Designed specifically for Self-Energizing Magneto

Ignition, Solid State Ignition, OEM Solid State Ignition (SSI) for Tecumseh's

Cast Iron Block Engines, or with OEM Kohler Breakerless Ignition. Can

be used for various makes and models of riding mowers, lawn & garden

tractors, garden tractors and various small engine equipment with magneto

or solid state ignition. Identification of 5 blade terminals: B =

Battery (+); G = Ground (terminal is grounded to body of switch);

L = Lights (use a separate OFF-ON switch connected to this terminal

to power an electric PTO clutch); M = Magneto (Ignition); S

= Solenoid (small terminal). Key positions: OFF position makes contact with

M+G; IGNITION position makes contact with B+L; START position makes contact

with B+S. Each terminal identified for correct wiring connections. IMPORTANT:

Use with a starter solenoid/relay to crank the engine to prevent burning

out internal contacts in switch. NOTE: If engine is equipped with an

alternator/stator charging system, the center terminal on the voltage

rectifier/regulator connects to the positive (+) battery post. If using an

ammeter/amp gauge, connect the gauge/meter to the positive (+) battery post,

then to the B terminal on the switch. Trace the wires on your tractor/equipment

to see if they match the terminals on this switch. If they don't match, the

plug-in spade connectors/wires can be rearranged in the plastic connector

housing to match the corresponding terminals on the switch. To do this, use

a small flat blade screwdriver to depress the locking tab/tang so the plug-in

connector can be pulled out from the plastic connector housing. Bend the

locking tab/tang up slightly before reinserting it in the plastic connector

so it will be secured in place. Or for a universal application, use #250

slip-on female spade crimp-type wire connectors. Requires 5/8" diameter mounting

hole.

|

||

Universal Wiring Harness with Plastic Connector Housing

and Slide-On Connectors. Replace damaged entire connector, terminals

and wiring, use as new wiring harness on a custom-made project, or use this

part when converting from Breakerless Ignition to battery-powered

points/condenser ignition. Fits universal OFF-ON-START key switches listed

above and other key switches with same terminal configuration. Three terminals

in this part will also fit the OEM Cub Cadet garden tractor OFF-ON-START

key switch listed above. 18" length color-coded wires for easy identification.

$13.00 each, plus shipping & handling. Universal Wiring Harness with Plastic Connector Housing

and Slide-On Connectors. Replace damaged entire connector, terminals

and wiring, use as new wiring harness on a custom-made project, or use this

part when converting from Breakerless Ignition to battery-powered

points/condenser ignition. Fits universal OFF-ON-START key switches listed

above and other key switches with same terminal configuration. Three terminals

in this part will also fit the OEM Cub Cadet garden tractor OFF-ON-START

key switch listed above. 18" length color-coded wires for easy identification.

$13.00 each, plus shipping & handling.

Electrical Plastic Connector Housing Only. Replace damaged connector housing when the brass slide-on spade crimp wire connectors (listed below) are in good condition. Fits universal OFF-ON-START key switches listed above and other key switches with same terminal configuration. Three slots in this part will also fit the OEM Cub Cadet garden tractor OFF-ON-START key switch listed above. Requires 1/4" width slide-on brass spade crimp wire connectors with locking tab/tang below. $8.00 each, plus shipping & handling.

|

||

OFF-ON

Main/Master Disconnect/Cutoff Switch with Removable Key. Use this 100

amp capacity switch to disable all power throughout the equipment to prevent

sabotage an/or an accidental electrical short that could burn up the wiring

system or entire equipment. Useful when equipment is not used for a period

of time to prevent a slow drain on the battery, prevent short circuits when

performing electrical service on equipment, or for a pulling tractor to prevent

accidental starts or to prevent sabotage at the pull sites by disgruntled

pullers. Connect between negative (–) battery post and equipment ground.

Copper terminals with brass hex nuts for improved continuity. Comes with

protective weather cap and two removable nylon key locks. Mounting hardware

not included. $19.00 each, plus shipping & handling.

[Return to previous paragraph, section

or website] OFF-ON

Main/Master Disconnect/Cutoff Switch with Removable Key. Use this 100

amp capacity switch to disable all power throughout the equipment to prevent

sabotage an/or an accidental electrical short that could burn up the wiring

system or entire equipment. Useful when equipment is not used for a period

of time to prevent a slow drain on the battery, prevent short circuits when

performing electrical service on equipment, or for a pulling tractor to prevent

accidental starts or to prevent sabotage at the pull sites by disgruntled

pullers. Connect between negative (–) battery post and equipment ground.

Copper terminals with brass hex nuts for improved continuity. Comes with

protective weather cap and two removable nylon key locks. Mounting hardware

not included. $19.00 each, plus shipping & handling.

[Return to previous paragraph, section

or website] |

Universal Starter Solenoids/Relays | FYI - Solenoids and relays are used in a starting circuit or any electrical component that draws a lot of amps, as well as horn and blower motor circuits, to prevent excessive current from flowing through a low amperage switch, which can cause it to burn out. Click here to contact A-1 Miller's Performance Enterprises to place an order, send your parts for repairing, and/or for FREE professional and honest technical customer service assistance and support and payment options. Please contact A-1 Miller's if you need a part or parts, or service(s) performed that's not listed or mentioned in this website. [Top of Page]

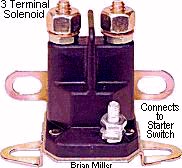

Light Duty, 3 Terminal,

12 Volt Plastic Casing Starter Solenoid/Relay. Universal Usage. Suitable

for lawn and garden equipment, and stock competition pulling engines. Prevents

burning out a manual light-duty push button switch and eliminates need for

a heavy duty switch in a custom wiring circuit. Intermittent duty. Use to

temporarily activate any maximum 80 amp capacity electrical accessory. If

continually energized for long period of time, plastic body may melt. Internally

grounded through mounting base. Studs: 10-32 UNF, 1/4-20 UNC.. High quality

aftermarket. Grounded mounting base. Wiring connections: Small terminal connects

to key switch or momentary push button switch to energize solenoid. One large

terminal connects to positive (+) battery post, and the other large terminal

connects to starter motor, horn, kill switch pull motor on sled, etc. Light Duty, 3 Terminal,

12 Volt Plastic Casing Starter Solenoid/Relay. Universal Usage. Suitable

for lawn and garden equipment, and stock competition pulling engines. Prevents

burning out a manual light-duty push button switch and eliminates need for

a heavy duty switch in a custom wiring circuit. Intermittent duty. Use to

temporarily activate any maximum 80 amp capacity electrical accessory. If

continually energized for long period of time, plastic body may melt. Internally

grounded through mounting base. Studs: 10-32 UNF, 1/4-20 UNC.. High quality

aftermarket. Grounded mounting base. Wiring connections: Small terminal connects

to key switch or momentary push button switch to energize solenoid. One large

terminal connects to positive (+) battery post, and the other large terminal

connects to starter motor, horn, kill switch pull motor on sled, etc.

|

Loop-Type Cable/Wire/Hose Clamps. Use to secure throttle or

choke cables, or for safe routing of electrical wire(s), battery cable, small

remote fuel primer hose or bundle of wires along frame. Each requires 3/16"

mounting screw. Loop-Type Cable/Wire/Hose Clamps. Use to secure throttle or

choke cables, or for safe routing of electrical wire(s), battery cable, small

remote fuel primer hose or bundle of wires along frame. Each requires 3/16"

mounting screw.

|

Conversion Kit for Kohler engine models K241, K301, K321 or K341 to Convert from the Tediousness Recoil/Rope Start to the Convenience of an Electric Gear Starter. Click here to contact A-1 Miller's Performance Enterprises to place an order, send your parts for repairing, and/or for FREE professional and honest technical customer service assistance and support and payment options. Please contact A-1 Miller's if you need a part or parts, or service(s) performed that's not listed or mentioned in this website. [Top of Page]

Magneto Armature Ignition

Stator/Coil with Small Charging Coil. Fits various Kohler engines with

stator/coil mounted on bearing plate underneath flywheel with two magnets

inside flywheel. Common with various generator engines. Coil has 1.0 ohm

internal primary resistor. NOTE: This coil should produce a stronger spark

when used with the Universal Solid State Electronic

Ignition Module. Or the engine could be

converted to battery-powered

ignition.

How

magneto coils generate a spark. IMPORTANT: Use a new copper

core/non-resistor AC Delco, Autolite or Champion spark plug of the correct

type gapped at .025" for longer coil life. Use of a

resistor type spark plug

will void warranty. Magneto Armature Ignition

Stator/Coil with Small Charging Coil. Fits various Kohler engines with

stator/coil mounted on bearing plate underneath flywheel with two magnets

inside flywheel. Common with various generator engines. Coil has 1.0 ohm

internal primary resistor. NOTE: This coil should produce a stronger spark

when used with the Universal Solid State Electronic

Ignition Module. Or the engine could be

converted to battery-powered

ignition.

How

magneto coils generate a spark. IMPORTANT: Use a new copper

core/non-resistor AC Delco, Autolite or Champion spark plug of the correct

type gapped at .025" for longer coil life. Use of a

resistor type spark plug

will void warranty.

|

| Conversion Kit for Kohler engine models K241, K301, K321 or K341 to

Convert from the Tediousness Recoil/Rope Start to the Convenience of an Electric

Gear Starter. Very useful in cold weather when most Kohler engines are

harder to start. Can be used for virtually any lawn and garden equipment,

including log splitters, air compressors, generators/welders, water pumps,

etc. NOTE: The early K241 and K301 engines must have a curved indentation

above the two bolt holes on the right side of the block (when facing the

flywheel) to install the upper mount starter motor. Also needed, but

not included with kit listed below: minimum #16 gauge (AWG) stranded copper

wire w/crimp terminals (length?) to connect the small terminal on the solenoid

to the supplied push button starter switch; minimum #8 gauge (AWG) red insulated

stranded copper wire w/crimp terminals (length?) to connect the gear starter

to one of the large terminals on the solenoid; minimum #8 gauge (AWG) red

insulated stranded copper wire w/crimp terminals (length?) to connect the

positive (+) battery post directly to the other large terminal on the solenoid;

minimum #8 gauge (AWG) black insulated stranded copper wire w/crimp terminals

(length?) to connect the negative (–) battery post directly to

engine/chassis ground; and a (preferably new) fully charged

12 volt minimum 350 CCA battery, or a

12 volt portable jump start/battery booster.

Kit Includes:

Additional Required Wiring for Conversion Kit listed above... Please specify if any of the listed below are needed and the length of each wire.

|

High Torque Starter Motor and Rebuilds - Click here to contact A-1 Miller's Performance Enterprises to place an order, send your parts for repairing, and/or for FREE professional and honest technical customer service assistance and support and payment options. Please contact A-1 Miller's if you need a part or parts, or service(s) performed that's not listed or mentioned in this website. [Top of Page]

| A-1 Miller's Professional Repair Service - Replace worn drive end OEM bushing with a new bronze bushing in YOUR small engine gear starter. Starter motor must be in good condition with no burnt windings, damage or broken magnets. $35.00 for parts and labor, plus return shipping & handling. | ||

High Torque

Gear Starter Motors. Fits Kohler engine models K141, K161 and K181. 12 volt

negative ground. All starter motors are high torque nowadays. They have 20%

more wire windings than the early OEM Kohler starter, giving it 20% more

cranking power. Draws less amps; a smaller size battery can be used. Cranks

engine about twice as fast and draws less amps than an ordinary starter.

But with a

broken compression release, a direct-drive high torque starter may not be

able to crank the engine. It'll be best to adjust the valve clearances, repair

the compression release mechanism or replace the cam with a working compression

release. FYI - The aftermarket starter motors I

sell are the same as OEM Kohler starters. Kohler just place a big markup

on theirs because it comes in a Kohler brand box and the starter has the

Kohler name stamped on it. Kohler part # 41 098 08-S. High Torque

Gear Starter Motors. Fits Kohler engine models K141, K161 and K181. 12 volt

negative ground. All starter motors are high torque nowadays. They have 20%

more wire windings than the early OEM Kohler starter, giving it 20% more

cranking power. Draws less amps; a smaller size battery can be used. Cranks

engine about twice as fast and draws less amps than an ordinary starter.

But with a

broken compression release, a direct-drive high torque starter may not be

able to crank the engine. It'll be best to adjust the valve clearances, repair

the compression release mechanism or replace the cam with a working compression

release. FYI - The aftermarket starter motors I

sell are the same as OEM Kohler starters. Kohler just place a big markup

on theirs because it comes in a Kohler brand box and the starter has the

Kohler name stamped on it. Kohler part # 41 098 08-S.

|

||

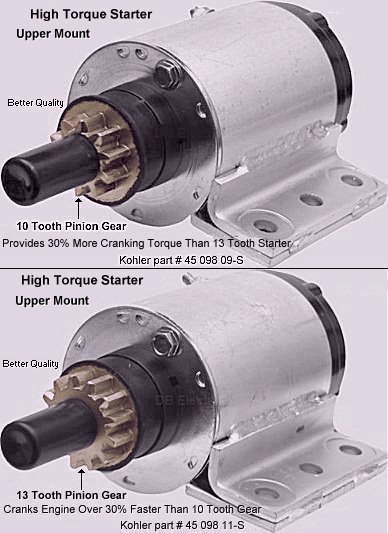

10 and 13 Tooth Upper Mount High Torque Gear Starter Motors.

(Mounting bolts are below starter motor.) Each fits Kohler K-series engine

models K241, K301, K321, K341 and K361. The only difference between the 10

tooth and 13 tooth starters are, on the 10 tooth, the welded mounting bracket

is straight, and on the 13 tooth, the bracket is slightly bent outward so

the starter gear can properly engage with the flywheel gear. 12 volt negative

ground. All new starter motors are high torque nowadays. These have 20% more

wire windings than the early OEM Kohler starter, giving them 20% more cranking

power. Cranks engine about twice as fast and draws less amps than an ordinary

old-style starter. It'll crank the engine with less effort. Therefore, a

smaller battery can be used. The 10 tooth starter provides 13% more cranking

torque than the 13 tooth starter, and the 13 tooth starter cranks the engine

30% faster than the 10 tooth starter. The 13 tooth starter is best to be

used with a working compression release. But with

a broken compression release, a direct-drive high torque starter may not

be able to crank over the engine past the compression stroke. Therefore,

it'll be best to adjust the valve clearances, repair the compression release

mechanism, replace the cam with a working compression release or use the

gear reduction (Toyota) starter. FYI - The aftermarket starters

offered here are the same quality as the OEM Kohler starters. Kohler just

place a big markup on theirs because it comes in a box with the Kohler name

on it and the starter has the Kohler name stamped on it. NOTE: To

install the upper mount starter on an early K241 and K301 engine, the block

must have the curved (inward) indentation above the two bolt holes on the

right side (when facing the flywheel). Otherwise, a starter/generator will

need to be installed. 10 and 13 Tooth Upper Mount High Torque Gear Starter Motors.

(Mounting bolts are below starter motor.) Each fits Kohler K-series engine

models K241, K301, K321, K341 and K361. The only difference between the 10

tooth and 13 tooth starters are, on the 10 tooth, the welded mounting bracket

is straight, and on the 13 tooth, the bracket is slightly bent outward so

the starter gear can properly engage with the flywheel gear. 12 volt negative

ground. All new starter motors are high torque nowadays. These have 20% more

wire windings than the early OEM Kohler starter, giving them 20% more cranking

power. Cranks engine about twice as fast and draws less amps than an ordinary

old-style starter. It'll crank the engine with less effort. Therefore, a

smaller battery can be used. The 10 tooth starter provides 13% more cranking

torque than the 13 tooth starter, and the 13 tooth starter cranks the engine

30% faster than the 10 tooth starter. The 13 tooth starter is best to be

used with a working compression release. But with

a broken compression release, a direct-drive high torque starter may not

be able to crank over the engine past the compression stroke. Therefore,

it'll be best to adjust the valve clearances, repair the compression release

mechanism, replace the cam with a working compression release or use the

gear reduction (Toyota) starter. FYI - The aftermarket starters

offered here are the same quality as the OEM Kohler starters. Kohler just

place a big markup on theirs because it comes in a box with the Kohler name

on it and the starter has the Kohler name stamped on it. NOTE: To

install the upper mount starter on an early K241 and K301 engine, the block

must have the curved (inward) indentation above the two bolt holes on the

right side (when facing the flywheel). Otherwise, a starter/generator will

need to be installed.

|

||

High Torque

Lower Mount Gear Starter Motors. (Mounting bolts are above starter motor.)

Fits certain Kohler engine models K241, K301, K321 and K341 engines. 12 volt

negative ground. All new starter motors are high torque nowadays. They have

20% more wire windings than the early OEM Kohler starter, giving it 20% more

cranking power. Cranks engine about twice as fast and draws less amps than

an ordinary starter; a smaller battery can be used.

But with a

broken compression release, a direct-drive high torque starter may not be

able to crank the engine. It'll be best to adjust the valve clearances, repair

the compression release mechanism or replace the cam with a working compression

release. FYI - The aftermarket starter motors I

sell are the same as OEM Kohler starters. Kohler just place a big markup

on theirs because it comes in a box with the Kohler name on it and the starter

has the Kohler name stamped on it. High Torque

Lower Mount Gear Starter Motors. (Mounting bolts are above starter motor.)

Fits certain Kohler engine models K241, K301, K321 and K341 engines. 12 volt

negative ground. All new starter motors are high torque nowadays. They have

20% more wire windings than the early OEM Kohler starter, giving it 20% more

cranking power. Cranks engine about twice as fast and draws less amps than

an ordinary starter; a smaller battery can be used.

But with a

broken compression release, a direct-drive high torque starter may not be

able to crank the engine. It'll be best to adjust the valve clearances, repair

the compression release mechanism or replace the cam with a working compression

release. FYI - The aftermarket starter motors I

sell are the same as OEM Kohler starters. Kohler just place a big markup

on theirs because it comes in a box with the Kohler name on it and the starter

has the Kohler name stamped on it.

|

||

High Torque

Gear Starter Motors for Kohler Magnum engine models M8, M10, M12, M14 and

M16 engines. 12 volt. All new starter motors are high torque nowadays. They

have 20% more wire windings than the early OEM Kohler starter, giving it

20% more cranking power. Cranks engine about twice as fast and draws less

amps than an ordinary starter; a smaller battery can be used. Length: 7-1/4";

mounting studs: two 1/4"-20; O.D. housing: 3-1/16"; center to center mount:

2-1/2"'.

But with a

broken compression release, a direct-drive high torque starter may not be

able to crank the engine. It'll be best to adjust the valve clearances, repair

the compression release mechanism or replace the cam with a working compression

release. FYI - The aftermarket starter motors I

sell are the same as OEM Kohler starters. Kohler just place a big markup

on theirs because it comes in a box with the Kohler name on it and the starter

has the Kohler name stamped on it. High Torque

Gear Starter Motors for Kohler Magnum engine models M8, M10, M12, M14 and

M16 engines. 12 volt. All new starter motors are high torque nowadays. They

have 20% more wire windings than the early OEM Kohler starter, giving it

20% more cranking power. Cranks engine about twice as fast and draws less

amps than an ordinary starter; a smaller battery can be used. Length: 7-1/4";

mounting studs: two 1/4"-20; O.D. housing: 3-1/16"; center to center mount:

2-1/2"'.

But with a

broken compression release, a direct-drive high torque starter may not be

able to crank the engine. It'll be best to adjust the valve clearances, repair

the compression release mechanism or replace the cam with a working compression

release. FYI - The aftermarket starter motors I

sell are the same as OEM Kohler starters. Kohler just place a big markup

on theirs because it comes in a box with the Kohler name on it and the starter

has the Kohler name stamped on it.

|

||

High Torque

Gear Starter Motors. Fits Kohler opposed twin engine models MV16, KT17, KT17

Series II, KT19, KT19 Series II, KT21, M18, MV18, M20 and MV20. 12 volt negative

ground. All new starter motors are high torque nowadays. They have 20% more

wire windings than the early OEM Kohler starter, giving it 20% more cranking

power. Cranks engine about twice as fast and draws less amps than an ordinary

starter; a smaller battery can be used. Due to their low compression, the

Kohler opposed twin cylinder engines do not have a compression release, nor

do they need one. FYI - The aftermarket starter motors I sell are the

same as OEM Kohler starters. Kohler just place a big markup on theirs because

it comes in a box with the Kohler name on it and the starter has the Kohler

name stamped on it. High Torque

Gear Starter Motors. Fits Kohler opposed twin engine models MV16, KT17, KT17

Series II, KT19, KT19 Series II, KT21, M18, MV18, M20 and MV20. 12 volt negative

ground. All new starter motors are high torque nowadays. They have 20% more

wire windings than the early OEM Kohler starter, giving it 20% more cranking

power. Cranks engine about twice as fast and draws less amps than an ordinary

starter; a smaller battery can be used. Due to their low compression, the

Kohler opposed twin cylinder engines do not have a compression release, nor

do they need one. FYI - The aftermarket starter motors I sell are the

same as OEM Kohler starters. Kohler just place a big markup on theirs because

it comes in a box with the Kohler name on it and the starter has the Kohler

name stamped on it.

|

||

High Torque

Gear Starter Motors for Kohler engine models K482, K532 and K582. NOTES:

(1) Additional 6.6mm unthreaded hole in additional DE mounting position,

(1) 5.9mm unthreaded hole in CE frame, 1/4-20 threaded battery terminal,

128.2mm magnetic field case length, rubber skirt drive. 12 volt. All new

starter motors are high torque nowadays. They have 20% more wire windings

than the early OEM Kohler starter, giving it 20% more cranking power. Draws

less amps; a smaller battery can be used. Cranks engine about twice as fast

and draws less amps than an ordinary starter.

But with a

broken compression release, a direct-drive high torque starter may not be

able to crank the engine. It'll be best to adjust the valve clearances, repair

the compression release mechanism or replace the cam with a working compression

release. FYI - The aftermarket starter motors I

sell are the same as OEM Kohler starters. Kohler just place a big markup

on theirs because it comes in a box with the Kohler name on it and the starter

has the Kohler name stamped on it. High Torque

Gear Starter Motors for Kohler engine models K482, K532 and K582. NOTES:

(1) Additional 6.6mm unthreaded hole in additional DE mounting position,

(1) 5.9mm unthreaded hole in CE frame, 1/4-20 threaded battery terminal,

128.2mm magnetic field case length, rubber skirt drive. 12 volt. All new

starter motors are high torque nowadays. They have 20% more wire windings

than the early OEM Kohler starter, giving it 20% more cranking power. Draws

less amps; a smaller battery can be used. Cranks engine about twice as fast

and draws less amps than an ordinary starter.

But with a

broken compression release, a direct-drive high torque starter may not be

able to crank the engine. It'll be best to adjust the valve clearances, repair

the compression release mechanism or replace the cam with a working compression

release. FYI - The aftermarket starter motors I

sell are the same as OEM Kohler starters. Kohler just place a big markup

on theirs because it comes in a box with the Kohler name on it and the starter

has the Kohler name stamped on it.

|

||

High Torque 12

Volt Gear Starter Motors with Solenoid Shift. Fits Kohler V-twin engine models

CH25, CH620, CH621, CH640, CH641, CH670, CH680, CH682, CH730, CH732, CH735,

CH740, CH742, CH745, CH750, CH752, CH940, CH960, CH980, CH1000, CV620, CV640,

CV670, CV680, CV682, CV730, CV730, CV732, CV740, CV742, CV745, CV750, CV752,

CV940, CV960, CV980, CV1000, ECH630, ECH650, ECH680, ECH730, ECH740, ECH749,

ECH940, ECH980, ECV630, ECV650, ECV680, ECV730, ECV740, ECV749, ECV850, ECV860,

ECV870, ECV880, ECV940, ECV980, ELH775, EZT715, EZT725, EZT740, EZT750, FCV740,

KT715, LH630, LH640, LH685, LH690, LH750, LH755, LH775, LV680, PCH680, PCH740,

PCV680, PCV740, PCV850, PCV860, ZT710, ZT720, ZT730 and ZT740. NOTES: 10-tooth

drive starter. All new starter motors are high torque nowadays. They have

20% more wire windings than the early OEM Kohler starter, giving it 20% more

cranking power. Draws less amps; a smaller battery can be used. Cranks engine

about twice as fast and draws less amps than an ordinary starter.

But with a broken

compression release, a direct-drive high torque starter may not be able to

crank the engine. It'll be best to adjust the valve clearances, repair the

compression release mechanism or replace the cam with a working compression

release. FYI - The aftermarket starter motors I

sell are the same as OEM Kohler starters. Kohler just place a big markup

on theirs because it comes in a box with the Kohler name on it and the starter

has the Kohler name stamped on it. High Torque 12

Volt Gear Starter Motors with Solenoid Shift. Fits Kohler V-twin engine models

CH25, CH620, CH621, CH640, CH641, CH670, CH680, CH682, CH730, CH732, CH735,

CH740, CH742, CH745, CH750, CH752, CH940, CH960, CH980, CH1000, CV620, CV640,

CV670, CV680, CV682, CV730, CV730, CV732, CV740, CV742, CV745, CV750, CV752,

CV940, CV960, CV980, CV1000, ECH630, ECH650, ECH680, ECH730, ECH740, ECH749,

ECH940, ECH980, ECV630, ECV650, ECV680, ECV730, ECV740, ECV749, ECV850, ECV860,

ECV870, ECV880, ECV940, ECV980, ELH775, EZT715, EZT725, EZT740, EZT750, FCV740,

KT715, LH630, LH640, LH685, LH690, LH750, LH755, LH775, LV680, PCH680, PCH740,

PCV680, PCV740, PCV850, PCV860, ZT710, ZT720, ZT730 and ZT740. NOTES: 10-tooth

drive starter. All new starter motors are high torque nowadays. They have

20% more wire windings than the early OEM Kohler starter, giving it 20% more

cranking power. Draws less amps; a smaller battery can be used. Cranks engine

about twice as fast and draws less amps than an ordinary starter.

But with a broken

compression release, a direct-drive high torque starter may not be able to

crank the engine. It'll be best to adjust the valve clearances, repair the

compression release mechanism or replace the cam with a working compression

release. FYI - The aftermarket starter motors I

sell are the same as OEM Kohler starters. Kohler just place a big markup

on theirs because it comes in a box with the Kohler name on it and the starter

has the Kohler name stamped on it.

|

||

High Torque Gear

Starter Motor for Briggs & Stratton 14, 16, 18 and 20hp Opposed Twin

Cylinder Engines. 12 volt. All new starter motors are high torque nowadays.

They have 15% more wire windings than the short version starter, giving it

15% more cranking power. Draws less amps; a smaller battery can be used.

Cranks engine about twice as fast and draws less amps than an ordinary starter.

FYI - The aftermarket starter motors I sell are the same as OEM Briggs

& Stratton starters. Briggs just place a big markup on theirs because

it comes in a box with their name on it and the starter has the Briggs &

Stratton logo stamped on it. High Torque Gear

Starter Motor for Briggs & Stratton 14, 16, 18 and 20hp Opposed Twin

Cylinder Engines. 12 volt. All new starter motors are high torque nowadays.

They have 15% more wire windings than the short version starter, giving it

15% more cranking power. Draws less amps; a smaller battery can be used.

Cranks engine about twice as fast and draws less amps than an ordinary starter.

FYI - The aftermarket starter motors I sell are the same as OEM Briggs

& Stratton starters. Briggs just place a big markup on theirs because

it comes in a box with their name on it and the starter has the Briggs &

Stratton logo stamped on it.

|

Voltage Regulator, Diodes, Voltage Rectifiers/Regulators, Charging Stators, and Internal Flywheel Charging Magnets - Click here to contact A-1 Miller's Performance Enterprises to place an order, send your parts for repairing, and/or for FREE professional and honest technical customer service assistance and support and payment options. Please contact A-1 Miller's if you need a part or parts, or service(s) performed that's not listed or mentioned in this website. [Top of Page]

Analog 15 Amp

Voltage Regulator for 12 Volt Starter/Generators. If the charging system

continues to charge with no gradual moving back of the needle to zero on

an analog ammeter/amp gauge (if installed) while the

engine is running, this will put too much voltage throughout the entire

electrical system, which could eventually burn up the ignition coil, battery,

burn out light bulbs, burn up the electric PTO clutch, burn up the electronic

ignition control module (crank trigger ignition)

and burn up the any other electrical components. With the terminals facing

you, they read: L = Lights | Bat = Battery | F = Field, A = Armature (on

the bottom). L connects to the Lights (if equipped); Bat connects to the

ignition switch, which connects to the battery positive (+) post; F connects

to the Field terminal on the starter/generator; and A connects to the Armature

terminal on the starter/generator. The frame of the regulator must be securely

grounded to the engine, tractor or equipment through the mounting bolts,

which connects to the battery negative (–) post. NOTE: Cannot be

substituted for use with the alternator/stator charging system. Analog 15 Amp

Voltage Regulator for 12 Volt Starter/Generators. If the charging system

continues to charge with no gradual moving back of the needle to zero on

an analog ammeter/amp gauge (if installed) while the

engine is running, this will put too much voltage throughout the entire

electrical system, which could eventually burn up the ignition coil, battery,

burn out light bulbs, burn up the electric PTO clutch, burn up the electronic

ignition control module (crank trigger ignition)

and burn up the any other electrical components. With the terminals facing

you, they read: L = Lights | Bat = Battery | F = Field, A = Armature (on

the bottom). L connects to the Lights (if equipped); Bat connects to the

ignition switch, which connects to the battery positive (+) post; F connects

to the Field terminal on the starter/generator; and A connects to the Armature

terminal on the starter/generator. The frame of the regulator must be securely

grounded to the engine, tractor or equipment through the mounting bolts,

which connects to the battery negative (–) post. NOTE: Cannot be

substituted for use with the alternator/stator charging system.

|

|

Two Wire Rectifier

Diodes. The 3- and 4-amp diodes can be used in a 12 volt non-regulated small

engine alternator/stator charging system to convert alternating current (AC)

to direct current (DC) to recharge the battery and/or power low-amperage

DC electrical accessories, such as LED lights, small electric motors, etc.

A diode is not required for

filament light bulbs, fluorescent and/or an electric PTO

clutch. The 1 amp diode can be used on an engine with a small charging coil

next to the magneto ignition coil on the stator to energize the field windings

in a direct-drive 120/240 volt AC portable generator powered by a small engine

or for a belt-driven

automotive alternator that's powered by a small engine so the

alternator/generator will produce electricity as soon as the engine starts.

IMPORTANT - Install the diode with the silver stripe toward the generator's

field windings. And do not overload the amperage of the diode or it may burn

up. Two Wire Rectifier

Diodes. The 3- and 4-amp diodes can be used in a 12 volt non-regulated small

engine alternator/stator charging system to convert alternating current (AC)

to direct current (DC) to recharge the battery and/or power low-amperage

DC electrical accessories, such as LED lights, small electric motors, etc.

A diode is not required for

filament light bulbs, fluorescent and/or an electric PTO

clutch. The 1 amp diode can be used on an engine with a small charging coil

next to the magneto ignition coil on the stator to energize the field windings

in a direct-drive 120/240 volt AC portable generator powered by a small engine

or for a belt-driven

automotive alternator that's powered by a small engine so the

alternator/generator will produce electricity as soon as the engine starts.

IMPORTANT - Install the diode with the silver stripe toward the generator's

field windings. And do not overload the amperage of the diode or it may burn

up.

FYI - Briggs & Stratton engines have either one or two OEM alternator stators and they are joined together in two half circles under the flywheel. Some engines only come with one half stator. Each half produce 3 amps of power & 14 volts @ 3,600 RPM. If an engine comes with two stators joined together, one half produces AC, which is used to power the lights and electric PTO clutch. And the other half also produce AC, but is connected to a minimum 3 amp/14 volt diode, which is used to only recharge the battery. Under normal yard use, 3 amps is not enough to overcharge and burn up the battery. If both stator halves are wired together from the factory (as they are on certain engines), they will produce 6 amps of AC power and a 6 amp electronic/solid state voltage rectifier/regulator is used to power the lights, electric PTO clutch and recharge the battery. |

|

Electronic/Solid

State Voltage Rectifier/Regulator for Old Style 10 Amp Output 12 Volt Alternator

Charging Stators (listed below). If the charging system continues to generate

full charge with no gradual moving back of the needle to zero on an analog

ammeter/amp gauge (if installed) while the engine

is running, the excessive overcharging may eventually burn out the primary

windings in the ignition coil, burn up the electronic ignition control module

(crank trigger), burn up the battery, burn

out light bulbs, electric PTO clutch, and any other electrical accessories.

These will also work with virtually any 15 or 20 amp small engine

alternator/stator charging system. Orientation of terminals are "three in

a row" (AC | BAT+ | AC). NOTE: Cannot be substituted for use with the

starter/generator charging system. FYI: After many years of use and

for reasons unknown (even to me), the old-style 10 amp charging system is

notorious for generating very few amps, about 3 amps more or less maximum

at full governed engine speed, and I have no idea why. I believe this is

why the 10 amp stator was a short-lived item that was discontinued from Kohler

and replaced with the more reliable 15 or 20 amp stator charging system,

which works much better and is still in use on many makes and models of small

engines today. So if your engine has the 10 amp charging system and it only

generates a few amps, it may need to be upgraded with the new-style 15 or

20 charging system. Electronic/Solid

State Voltage Rectifier/Regulator for Old Style 10 Amp Output 12 Volt Alternator

Charging Stators (listed below). If the charging system continues to generate

full charge with no gradual moving back of the needle to zero on an analog

ammeter/amp gauge (if installed) while the engine

is running, the excessive overcharging may eventually burn out the primary

windings in the ignition coil, burn up the electronic ignition control module

(crank trigger), burn up the battery, burn

out light bulbs, electric PTO clutch, and any other electrical accessories.

These will also work with virtually any 15 or 20 amp small engine

alternator/stator charging system. Orientation of terminals are "three in

a row" (AC | BAT+ | AC). NOTE: Cannot be substituted for use with the

starter/generator charging system. FYI: After many years of use and

for reasons unknown (even to me), the old-style 10 amp charging system is

notorious for generating very few amps, about 3 amps more or less maximum

at full governed engine speed, and I have no idea why. I believe this is

why the 10 amp stator was a short-lived item that was discontinued from Kohler

and replaced with the more reliable 15 or 20 amp stator charging system,

which works much better and is still in use on many makes and models of small

engines today. So if your engine has the 10 amp charging system and it only

generates a few amps, it may need to be upgraded with the new-style 15 or

20 charging system.

|

|

|

|

1/4" Width Slide-On Brass

Spade Crimp Wire Connector with Locking Tab/Tang. Replace damaged brass

connector(s) to insure 100% electrical connections. Fits plastic housing

electrical connectors used on most Off-Ignition-Start key switches, voltage

rectifier/regulators, head lights, etc. FYI - Solder or use

terminal crimping pliers to secure new brass connector

on wire. To remove old slide-on brass connector from plastic housing, depress

locking tab/tang on connector from the wire end with a small flat blade

screwdriver, and pull connector out of housing. Before installing the new

connector, make sure locking tab/tang is slightly bent outward, and then

slide connector into plastic housing in the correct position until it locks/snaps

in place. This part was never available separately from Kohler.

$1.40 each, plus shipping & handling. 1/4" Width Slide-On Brass

Spade Crimp Wire Connector with Locking Tab/Tang. Replace damaged brass

connector(s) to insure 100% electrical connections. Fits plastic housing

electrical connectors used on most Off-Ignition-Start key switches, voltage

rectifier/regulators, head lights, etc. FYI - Solder or use

terminal crimping pliers to secure new brass connector

on wire. To remove old slide-on brass connector from plastic housing, depress

locking tab/tang on connector from the wire end with a small flat blade

screwdriver, and pull connector out of housing. Before installing the new

connector, make sure locking tab/tang is slightly bent outward, and then

slide connector into plastic housing in the correct position until it locks/snaps

in place. This part was never available separately from Kohler.

$1.40 each, plus shipping & handling. |

Plastic Housing Electrical

Connector. Fits old style 10 amp and new style 15/20 amp voltage

rectifier/regulators (listed below). Replace damaged/melted connector when

the brass slide-on spade crimp wire connectors are in good condition. Requires

1/4" width slide-on brass spade crimp wire connector with locking tab/tang.

OEM Kohler part # 25 155 41-S. $5.20 each, plus shipping & handling. Plastic Housing Electrical

Connector. Fits old style 10 amp and new style 15/20 amp voltage

rectifier/regulators (listed below). Replace damaged/melted connector when

the brass slide-on spade crimp wire connectors are in good condition. Requires

1/4" width slide-on brass spade crimp wire connector with locking tab/tang.

OEM Kohler part # 25 155 41-S. $5.20 each, plus shipping & handling. |

Electronic/Solid

State Voltage Rectifiers/Regulators for New-Style 12 Volt 15/20 Amp Output

Alternator/Stator Charging Stators (listed below). If the charging system

continues to charge with no gradual moving back of the needle to zero on

an analog ammeter/amp gauge (if installed) while the

engine is running, this will put too much voltage throughout the entire

electrical system, which could eventually burn up the ignition coil, battery,

burn out light bulbs, burn up the electric PTO clutch, burn up the electronic

ignition control module (crank trigger ignition)

and burn up the any other electrical components. Each listed below work the

same. These voltage rectifier/regulators are small, compact and have the

same mounting hole spacing, and fit many 8 thru 24hp Kohler engine models

with a 15 or 20 amp alternator/stator charging stator under the flywheel.

For various makes and models of small engines with a 30 amp stator, instead

of using a 30 amp NOS (and high dollar) replacement voltage rectifier/regulator

(discontinued Kohler part # 277063-S), two 15/20 amp voltage

rectifiers/regulators wired in parallel can be used. Each listed below mounts

in the rectangular hole in the Kohler flywheel shroud with ribs facing the

flywheel for better cooling of the unit. If it's mounted elsewhere with no

cool air blowing over it, it could overheat and prematurely burn up. These

can be substituted for use on virtually any 15 or 20 amp garden tractor,

motorcycle, etc., alternator/stator charging system. Orientation of terminals

are "three in a row" (AC - BAT+ - AC). NOTE: These cannot be substituted

for use with the starter/generator charging system. Electronic/Solid

State Voltage Rectifiers/Regulators for New-Style 12 Volt 15/20 Amp Output

Alternator/Stator Charging Stators (listed below). If the charging system

continues to charge with no gradual moving back of the needle to zero on

an analog ammeter/amp gauge (if installed) while the

engine is running, this will put too much voltage throughout the entire

electrical system, which could eventually burn up the ignition coil, battery,

burn out light bulbs, burn up the electric PTO clutch, burn up the electronic

ignition control module (crank trigger ignition)

and burn up the any other electrical components. Each listed below work the

same. These voltage rectifier/regulators are small, compact and have the

same mounting hole spacing, and fit many 8 thru 24hp Kohler engine models

with a 15 or 20 amp alternator/stator charging stator under the flywheel.

For various makes and models of small engines with a 30 amp stator, instead

of using a 30 amp NOS (and high dollar) replacement voltage rectifier/regulator

(discontinued Kohler part # 277063-S), two 15/20 amp voltage

rectifiers/regulators wired in parallel can be used. Each listed below mounts

in the rectangular hole in the Kohler flywheel shroud with ribs facing the

flywheel for better cooling of the unit. If it's mounted elsewhere with no

cool air blowing over it, it could overheat and prematurely burn up. These

can be substituted for use on virtually any 15 or 20 amp garden tractor,

motorcycle, etc., alternator/stator charging system. Orientation of terminals

are "three in a row" (AC - BAT+ - AC). NOTE: These cannot be substituted

for use with the starter/generator charging system.

|

|

Electronic/Solid

State Voltage Rectifiers/Regulators for New-Style 12 Volt 15/20 Amp Output

Alternator Charging Stators (listed below). If the charging system continues

to charge with no gradual moving back of the needle to zero on an analog

ammeter/amp gauge (if installed) while the engine

is running, this will put too much voltage throughout the entire electrical

system, which could eventually burn up the ignition coil, battery, burn out

light bulbs, burn up the electric PTO clutch, burn up the electronic ignition

control module (crank trigger ignition) and

burn up the any other electrical components. Each listed below work the same.

Each have same mounting holes and fit many 8 thru 24hp Kohler engines with

a 15 amp alternator charging stator under the flywheel. These can be substituted

for use on virtually any 15 or 20 amp garden tractor, motorcycle, etc.,

alternator/stator charging system. The "two over, one under offset" plastic

wiring connector no longer available from Kohler. NOTE: Cannot be substituted

for use with the starter/generator charging system. Electronic/Solid

State Voltage Rectifiers/Regulators for New-Style 12 Volt 15/20 Amp Output

Alternator Charging Stators (listed below). If the charging system continues

to charge with no gradual moving back of the needle to zero on an analog

ammeter/amp gauge (if installed) while the engine

is running, this will put too much voltage throughout the entire electrical

system, which could eventually burn up the ignition coil, battery, burn out

light bulbs, burn up the electric PTO clutch, burn up the electronic ignition

control module (crank trigger ignition) and

burn up the any other electrical components. Each listed below work the same.

Each have same mounting holes and fit many 8 thru 24hp Kohler engines with

a 15 amp alternator charging stator under the flywheel. These can be substituted

for use on virtually any 15 or 20 amp garden tractor, motorcycle, etc.,

alternator/stator charging system. The "two over, one under offset" plastic

wiring connector no longer available from Kohler. NOTE: Cannot be substituted

for use with the starter/generator charging system.

|

|

|

|

Internal Flywheel Charging Magnets - Click here to contact A-1 Miller's Performance Enterprises to place an order, send your parts for repairing, and/or for FREE professional and honest technical customer service assistance and support and payment options. Please contact A-1 Miller's if you need a part or parts, or service(s) performed that's not listed or mentioned in this website. [Top of Page]

Internal Flywheel Charging Magnets for 5-1/2" Diameter Alternator

Charging Systems. Fits aluminum and cast iron block single and twin cylinder

Kohler engine models K141, K161, K181, K241, K301, K321, K341, K361, KT17,

KT17 Series II, KT19, KT19 Series II, M8, M10, M12, M14, M16, MV16, M18,

MV18, M20, MV20, K482, K532, K582, CH1000, CH11-CH26, CH430, CH450, CH620-CH682,

CH730-CH752, CH940, CH980, CV1000, CV11-CV25, CV430-CV493, CV620-CV682, CV725,

CV730-CV940, CV960, CV980, ECV630-ECV680, ECV730-ECV749, ECV630-ECV680,

ECV730-ECV749, ECV850-ECV880, ECV940, ECV980, FCV740, KT610, KT620, KT715-KT745,

LH430, LH640-LH690, LH750, LH755, LV625-LV680, PCH680, PCH740, PCV680, PCV740,

PCV850, PCV860, SV470-SV480, SV530-SV590, SV600-SV620, SV710-SV740, SV810-SV840,

TH16, TH18, TH575, ZT710-ZT740, except various early John Deere with a single

cylinder Kohler engine with the 4-1/4"± charging stator, and larger

Tecumseh engines. Magnet(s) may come in 3/4" or 7/8" height, but will work

the same. Comes with magnetic poles identified. Not available separate from

Kohler or Tecumseh. All magnets are used and in excellent condition.

Click or tap here to

learn how to identify the magnetic pole positions and how to reinstall or

replace the charging magnets in a Kohler or Tecumseh flywheel. Internal Flywheel Charging Magnets for 5-1/2" Diameter Alternator

Charging Systems. Fits aluminum and cast iron block single and twin cylinder

Kohler engine models K141, K161, K181, K241, K301, K321, K341, K361, KT17,

KT17 Series II, KT19, KT19 Series II, M8, M10, M12, M14, M16, MV16, M18,

MV18, M20, MV20, K482, K532, K582, CH1000, CH11-CH26, CH430, CH450, CH620-CH682,

CH730-CH752, CH940, CH980, CV1000, CV11-CV25, CV430-CV493, CV620-CV682, CV725,

CV730-CV940, CV960, CV980, ECV630-ECV680, ECV730-ECV749, ECV630-ECV680,

ECV730-ECV749, ECV850-ECV880, ECV940, ECV980, FCV740, KT610, KT620, KT715-KT745,

LH430, LH640-LH690, LH750, LH755, LV625-LV680, PCH680, PCH740, PCV680, PCV740,

PCV850, PCV860, SV470-SV480, SV530-SV590, SV600-SV620, SV710-SV740, SV810-SV840,

TH16, TH18, TH575, ZT710-ZT740, except various early John Deere with a single

cylinder Kohler engine with the 4-1/4"± charging stator, and larger

Tecumseh engines. Magnet(s) may come in 3/4" or 7/8" height, but will work

the same. Comes with magnetic poles identified. Not available separate from

Kohler or Tecumseh. All magnets are used and in excellent condition.

Click or tap here to

learn how to identify the magnetic pole positions and how to reinstall or

replace the charging magnets in a Kohler or Tecumseh flywheel.

|

Available Soon - Detailed Illustrated Plans on How to Construct a Professional Pull-Back and Self-Propelled Garden Tractor/Small Wheel Mini Rod Pulling Sleds (Weight Transfer Machines) - [Top of Page]

FYI - I'm getting closer to

completing my sled plans. But being I have lots of work to do in my shop,

I work on designing my sled plans in my spare time. As soon as my plans with

an inventory list of parts to use and with illustrations are perfected, I'll

post the announcement in my websites. And as for prices of the pull-back

sled and self-propelled sled plans, I'm not sure yet. Make me an offer and

I'll consider it. And remember - Perfection takes time. If it's worth having,

it's worth waiting for. It'll be money well spent. Contact

information below.

FYI - I'm getting closer to

completing my sled plans. But being I have lots of work to do in my shop,

I work on designing my sled plans in my spare time. As soon as my plans with

an inventory list of parts to use and with illustrations are perfected, I'll

post the announcement in my websites. And as for prices of the pull-back

sled and self-propelled sled plans, I'm not sure yet. Make me an offer and

I'll consider it. And remember - Perfection takes time. If it's worth having,

it's worth waiting for. It'll be money well spent. Contact

information below.

Complete Narrowed Automotive Rear End/Differential for Use in Garden Tractor Pulling Sled - [Top of Page]

Details Include -

When connected to an automotive

3- or 4-speed manual transmission, this narrowed rear end controls the movement

of the weight box in a garden tractor pulling sled (weight transfer machine).

When connected to an automotive

3- or 4-speed manual transmission, this narrowed rear end controls the movement

of the weight box in a garden tractor pulling sled (weight transfer machine).

To place an order, send your item(s) for repairing, and/or

for customer service assistance, and FREE honest and accurate technical support,

please contact: A-1 Miller's Performance Enterprises, 12091 N Route B,

Hallsville, MO (Missouri) 65255-9604 USA. Please call in your order or send

an email with a list parts you need and your contact information.

To place an order, send your item(s) for repairing, and/or

for customer service assistance, and FREE honest and accurate technical support,

please contact: A-1 Miller's Performance Enterprises, 12091 N Route B,

Hallsville, MO (Missouri) 65255-9604 USA. Please call in your order or send

an email with a list parts you need and your contact information.

Phone: 1-573-881-7229 (cell;

call, text or leave voicemail). Please call Monday-Friday, 9am to 5pm, Central

time zone, except holidays. If no answer, please try again later.

Phone: 1-573-881-7229 (cell;

call, text or leave voicemail). Please call Monday-Friday, 9am to 5pm, Central

time zone, except holidays. If no answer, please try again later.

E-mail:

pullingtractor@aol.com. A-1 Miller's

shop is open to the public Monday-Friday, 9am to 5pm, Central time zone,

with an appointment on weekends, except holidays. If you're the kind of person

who don't trust delivery/shipping companies (mis)handling your high-dollar

and fragile merchandise, you can make the long drive to A-1 Miller's new

shop (click image to the right) to personally purchase parts, or drop off

and/or pick up your carburetor, clutch assembly, and/or other parts for repairing

and/or rebuilding. Or visit our new shop to drop off your parts. Please contact

us before coming so we'll be at our shop waiting for your arrival. When you

visit our shop, you will be dealing directly with the owner for the best

customer service. "The road to a [trusted] friend's house (or shop) is

never long." Don't sacrifice quality workmanship for distance.

Payment Options below.

Photos

of our new building/shop are posted here!

12091 N Route B, Hallsville, MO - Google Maps.

[Return To Previous Paragraph, Section

or Website]

E-mail:

pullingtractor@aol.com. A-1 Miller's

shop is open to the public Monday-Friday, 9am to 5pm, Central time zone,

with an appointment on weekends, except holidays. If you're the kind of person

who don't trust delivery/shipping companies (mis)handling your high-dollar

and fragile merchandise, you can make the long drive to A-1 Miller's new

shop (click image to the right) to personally purchase parts, or drop off

and/or pick up your carburetor, clutch assembly, and/or other parts for repairing

and/or rebuilding. Or visit our new shop to drop off your parts. Please contact

us before coming so we'll be at our shop waiting for your arrival. When you

visit our shop, you will be dealing directly with the owner for the best

customer service. "The road to a [trusted] friend's house (or shop) is

never long." Don't sacrifice quality workmanship for distance.

Payment Options below.

Photos

of our new building/shop are posted here!

12091 N Route B, Hallsville, MO - Google Maps.

[Return To Previous Paragraph, Section

or Website]

Payment Options, and We Ship to Canada and

Worldwide

Item(s) in a package or cushioned envelope weighing less than 1 lb. is sent

by US Postal Service Airmail Letter Post for a 4-7 days delivery. Packaged

item(s) weighing over 1 lb. and up to 66 lb. is sent by US Postal Service

Airmail Parcel Post for a 4-10 days delivery. I cannot use the US Postal

Services' Flat Rate Priority Mail envelopes and boxes to ship outside U.S.

territories. Item(s) weighing over 67 lbs. or more is sent by FedEx Ground

or equivalent services. We try to keep our shipping cost to customers within

reason. Therefore, we don't ship our products in a fancy-looking package

with our company name and/or logo on it because most customers will just

toss it in the trash after they remove the contents. And being there is no

USPS tracking number outside the US, all I can do is make sure I write your

address correctly on the customs form and on your package.

My websites are not set up to process orders and accept payments. Therefore, to place an order with me, please call either number above or send an email with a list of parts you need, with your name, complete and correct postal mailing address and phone number. For payment options, I accept cash (in person), USPS Postal Money Orders, cashier's checks, business checks, MasterCard, VISA, Discover, American Express (please add 2.5% to the total amount for the credit/debit card processor's surcharge). If paying with a credit/debit card, please call me at either number above. Or to make a payment to me through PayPal, please click this link: https://www.paypal.com. Or use Cash App (username: pullingtractor) or Venmo (username: Pullingtractor) to make a payment to me. And be sure to mention a description of what the payment is for with your full name, postal address, phone number and email address. If sending a money order or cashier's check, please include a note in the envelope with your name, complete mailing address, phone number, email address and a description of what the payment is for. I'll make a note of your order when I have all your information, and I may have to order some of the parts on your list, which should take a few days to come in, but I will send everything to you as soon as I have the parts in stock after I receive your payment.

Return To Previous Website | Top of Page | Copyright © 1996-Present. This website created, designed and maintained by A-1 Miller's Performance Enterprises