Putting the Brakes on an IH

Cub Cadet Garden Tractor

Putting the Brakes on an IH

Cub Cadet Garden Tractor

If the information in this website have helped you in any way, please make a donation to the owner, Brian Miller, by clicking or tapping HERE. FYI - A-1 Miller's Performance Enterprises is a legal, legitimate, tax paying and reputable business. And as of 2024, A-1 Miller's Performance Enterprises is still in business and offering all parts and services listed in this website. Please click here to contact Brian Miller of A-1 Miller's Performance Enterprises to place an order, send your parts for repairing, if you need a part or parts, or service(s) performed that's not listed or mentioned in this website, and/or for FREE professional and honest technical customer service assistance and support and payment options. Who is Brian Miller anyway?

Putting the Brakes on an IH

Cub Cadet Garden Tractor

Putting the Brakes on an IH

Cub Cadet Garden Tractor

Nowadays, prices are subject to change without notice. (Click Refresh to see any changes or updates.) Optimized for 1024 x 768 computer screen resolution. To search for a word or phrase in any of my websites, press CTRL and F on your keyboard simultaneously to open the Find or Search dialog box in your web browser. Scroll down this website or click/tap the links below to jump down to...

Links to Other Brian Miller's Websites -

Links to Other Brian Miller's Websites -

Click or Tap Here to Visit the Missouri Mini Truck & Mini Rod Pullers Association Website |

Separate the Brake and Clutch Operations and Use a Hand-Operated Brake Instead of a Foot Brake -

Many professional Cub Cadet garden tractor competition pullers prefer to use a hand brake because they run an extremely stiff pressure spring on the driveshaft to prevent clutch slippage. When they depress the clutch/brake pedal to apply the brakes, the stiff spring must fully compress, which makes it very hard to easily apply the brakes. The hand brake makes it effortlessly and much safer to apply the brakes. It requires a lot less muscle (in the arm) to stop the tractor.

When safely rolling the tractor off a trailer, sometimes this requires great effort to depress the clutch/brake pedal to apply the brakes, especially by hand (and arm muscles). What can be done to change this is separate the brake(s) and the clutch operations by disconnecting the brake linkage from the clutch/brake pedal cross shaft, and fabricate a long upright lever (with an adjustable linkage) on the right side of the steering column support pedestal which can be easily and effortlessly pulled back (rearward) by hand to apply the brakes. The clutch/brake pedal will then become just the "clutch pedal," and the lever will be the "brake lever." This would also make it much safer and easier to fully stop or slow the tractor down a steep hill or when unloading the tractor down the ramp(s) of a utility trailer or platform work table. Also, a "parking brake" lock mechanism can be installed on the brake lever-to-tractor frame to securely lock the brakes in position to prevent the tractor from rolling or coasting when the tractor is out of gear and the engine running.

Cub Cadet garden tractors that have the brakes integrated with the clutch/brake pedal, when applying the brakes on a competition pulling tractor that has an extremely stiff clutch pressure spring (on the driveshaft), great effort is required (strong leg muscles) to overcome and compress the clutch spring before the brakes can be fully applied. I don't have any photos of the hand brake (yet), but to make it work, fabricate a 3/4" diameter cross-shaft next to the original clutch/brake cross-shaft, mount it between the tractor frame rails and allow it to rotate slightly. The brake lever is then positioned on the right side of the tractor (if you're right-handed), and it can be made to a comfortable length (height) and it's securely welded to the cross-shaft. Then a bellcrank or short lever is installed or welded to the cross-shaft with an adjustable link (turnbucket) which connects to the brake lever on the transaxle. The adjustable link is used to set the proper position of the lever. Install an extension spring to allow the pressure to be taken off the brakes when the lever is released.

If your IH Cub Cadet model

70,

72,

73,

100,

102,

122,

124,

582 (prior to serial # 719999),

682 (prior to serial # 719999),

782 (prior to serial # 719999),

784 (prior to serial # 719999), and the early

800,

1000 and

1200 models have an internal brake assembly like the one

shown to the right ->, the adjustment is easily made by loosening the

jam nut on the square-head bolt and rotating the bolt clockwise. Make the

adjustment when there's a slight drag on the brake pads and disc when the

clutch/brake pedal is about 3/4 depressed, then tighten the jam nut.

If your IH Cub Cadet model

70,

72,

73,

100,

102,

122,

124,

582 (prior to serial # 719999),

682 (prior to serial # 719999),

782 (prior to serial # 719999),

784 (prior to serial # 719999), and the early

800,

1000 and

1200 models have an internal brake assembly like the one

shown to the right ->, the adjustment is easily made by loosening the

jam nut on the square-head bolt and rotating the bolt clockwise. Make the

adjustment when there's a slight drag on the brake pads and disc when the

clutch/brake pedal is about 3/4 depressed, then tighten the jam nut.

If you can't get the brake to stop the tractor at all by tightening the square-head brake adjustment bolt, and you are sure that the adjustment bolt is pushing against the brake push rod firmly when the pedal is depressed, then the brake pad retainer (plunger) is obviously frozen/rusted in the reduction housing. This is common for tractors that was stored in a high humility environment or sat outside in damp weather for many years.

DO NOT ATTEMPT TO

DRIVE OUT THE PIN WITHOUT FIRST THOROUGHLY HEATING THE LEVER AND/OR YOKES

BECAUSE BEING THE YOKES ARE MADE OF BRITTLE CAST IRON, THIS WILL LIKELY CAUSE

ONE OR BOTH OF THEM TO BREAK OFF, then it/they would need to be welded back

on.

DO NOT ATTEMPT TO

DRIVE OUT THE PIN WITHOUT FIRST THOROUGHLY HEATING THE LEVER AND/OR YOKES

BECAUSE BEING THE YOKES ARE MADE OF BRITTLE CAST IRON, THIS WILL LIKELY CAUSE

ONE OR BOTH OF THEM TO BREAK OFF, then it/they would need to be welded back

on.

How to Free-Up a Frozen/Rusted-In Brake Pad Retainer (Plunger) -

This happens when a tractor is left outside in damp weather for many years, which causes the brake pad retainer (plunger) to get rusted in the bore. To free the plunger, remove the transaxle from the tractor, and from inside the reduction gear box housing, remove the large reduction gear, then use a large, flat cold chisel and big hammer between the plunger and brake disc to drive the plunger forward. Use Liquid Wrench to dissolve the rust around the retainer. The brake disc may get scored or scratched from use of the chisel, but this is the only way I know how to do this. Once the plunger is removed from the reduction housing, the scratches on the brake disc can be removed and smoothed over with a fine file. Before reinstalling the plunger, clean the rust from the plunger, install a new rubber O-ring and new brake pads if needed, and remove the rust from the plunger bore with a small, automotive wheel cylinder hone tool, then apply clean motor oil, gear oil or lubricating grease on the plunger and inside the bore so the brake will work flawlessly for many years.

To replace this type of brake, first remove the transaxle from the tractor. Then, remove the square head bolt, drive out the rocker shaft and remove the cast brake arm. Try tapping on the piston and use penetrating oil on it to free it. Often, the transaxle will have to be removed from the tractor and the reduction housing removed to drive the brake pad retainer out from inside and clean up the bore and retainer. If you go that far, replace both pads/pucks with new ones, they are cheap. On reassembly, coat the outside of the piston with a thin layer of motor oil.

If the brake pad retainer is rusted and stuck in place, here's how to fix this...

Parts for this job will involve a new "O" ring for the retainer that the cast rod and shaft pushes on, a reduction gear housing gasket or use clear RTV silicone adhesive sealant and 2 new brake pads/pucks. Use only OEM (Original Equipment Manufacturer) material when replacing the brake pads/pucks. FYI - I'm not an OEM (Original Equipment Manufacturer) Cub Cadet parts dealer. Cub Cadet won't let A-1 Miller's become a dealer because there's already one in my area. (It's another way how big businesses support other big businesses, or how the rich help the rich get richer.) Besides, competition from different dealers in the same area help keep prices low. I think this is unfair business practice because by allowing only one dealer in a wide-spread area can have them gouge (overcharge) unsuspecting customers on parts and/or repair costs. They probably laugh all the way to the bank after every sale, too.

The internal brake is preferred by most Cub Cadet owners and pullers over the external disc setup, and are normally almost totally trouble-free because the parts stay cleaner than the external brakes.

Only the early Cub Cadets (models

70,

72,

73,

100,

102,

122,

124,

582,

682,

782,

784 (prior to serial # 720000), and certain

800,

1000 and

1200's) were equipped with an internal brake. The Cub Cadet

engineers realized later that people were hauling heavy (fully loaded,

automotive-type) trailers around their property (farms) with these tractors,

and the small internal brake pads couldn't stop the tractor and trailer well,

especially when going down a steep hill. Nor does it have the ability to

"park" well (with a heavy trailer) downward or upward on a steep hillside.

That's why Cub Cadet converted to the external disc/axle brake system, as

described further down in this web page. External disc/axle brakes have more

contact area, permitting the external brakes to hold about 5 times better

than the internal brake.

Only the early Cub Cadets (models

70,

72,

73,

100,

102,

122,

124,

582,

682,

782,

784 (prior to serial # 720000), and certain

800,

1000 and

1200's) were equipped with an internal brake. The Cub Cadet

engineers realized later that people were hauling heavy (fully loaded,

automotive-type) trailers around their property (farms) with these tractors,

and the small internal brake pads couldn't stop the tractor and trailer well,

especially when going down a steep hill. Nor does it have the ability to

"park" well (with a heavy trailer) downward or upward on a steep hillside.

That's why Cub Cadet converted to the external disc/axle brake system, as

described further down in this web page. External disc/axle brakes have more

contact area, permitting the external brakes to hold about 5 times better

than the internal brake.

How to Replace the Internal (Wet) Brake Pads/Pucks in an IH Cub Cadet Garden Tractor Transaxle -

Acquire new brake pads from

A-1 Miller's Performance Enterprises or your

local Cub Cadet dealer.

Acquire new brake pads from

A-1 Miller's Performance Enterprises or your

local Cub Cadet dealer.

The external/axle disc brakes

on Cub Cadet models

86,

106,

107,

108,

109,

126,

127,

128,

129,

149, 784 w/serial number 720000 and up,

1250,

1450,

1650 and certain

800,

1000 and

1200's are much easier to service than the internal brake

models above. Unlike the internal brake, a piece of .125" thickness 6061

(medium hardness) aluminum will work. Use highly adhesive glue or countersink

some 3/16" aluminum rivets or flat-head brass bolts to fasten the aluminum

in place.

The external/axle disc brakes

on Cub Cadet models

86,

106,

107,

108,

109,

126,

127,

128,

129,

149, 784 w/serial number 720000 and up,

1250,

1450,

1650 and certain

800,

1000 and

1200's are much easier to service than the internal brake

models above. Unlike the internal brake, a piece of .125" thickness 6061

(medium hardness) aluminum will work. Use highly adhesive glue or countersink

some 3/16" aluminum rivets or flat-head brass bolts to fasten the aluminum

in place.

The front brake pads that's made for a 1998-2001 Chevrolet S10 2wd pickup can be used in place of the OEM (Original Equipment Manufacturer) pads for these type of brakes. This is the flat pad with slotted ends. They're available at virtually any auto parts store. The thickness of a new OEM Cub Cadet brake pad is .100". The automotive pads are thicker.

The automotive brake pads to use are the riveted-on type. Grind the backs off the rivets. The two top rivet holes should line up enough to get two screws through them. Then turn the pads over, and from the back side, use a drill bit to go through the Cub backing plate. Drill through the pad and turn it over. Counter sink the holes to install two more screws.

Also, I have no information on how to mount the S10 brake pads on a Cub Cadet. Somebody gave A-1 Miller's this information and I posted it here. Use the information here to the best of your knowledge.

Also, seasoned oak wood or 6061 aluminum can be used as external brake friction

material for a Cub Cadet. But only if the tractor doesn't go any faster

than factory gearing!  NEVER use wood or aluminum as brake friction

material in a high speed (above 20 mph) vehicle or in an automobile! The

reason being, due to severe friction, wood will burn and aluminum

will melt!

NEVER use wood or aluminum as brake friction

material in a high speed (above 20 mph) vehicle or in an automobile! The

reason being, due to severe friction, wood will burn and aluminum

will melt!

To adjust these type of brakes, there's an adjusting rod going forward from each axle end. You'll need to remove them, clean the dirt and paint from the threads with a threading die, a wire brush or a wire wheel, then reinstall them. Place the brake pedal with the hold down lever in place then adjust them to where each axle has the same amount of braking.

Advertisement: (Prices are subject to change without notice.)

| Click here to contact A-1 Miller's Performance Enterprises to place an order, send your parts for repairing, and/or for FREE professional and honest technical customer service assistance and support and payment options. Please contact A-1 Miller's if you need a part or parts, or service(s) performed that's not listed or mentioned in this website. | |

New Brake Band

w/Lining. Fits 1961, '62 and '63 IH Cub Cadet "Original" Garden Tractors

with 4-1/2" diameter brake drum. High quality aftermarket. Replaces discontinued

Cub Cadet part # IH-358753-R21. New Brake Band

w/Lining. Fits 1961, '62 and '63 IH Cub Cadet "Original" Garden Tractors

with 4-1/2" diameter brake drum. High quality aftermarket. Replaces discontinued

Cub Cadet part # IH-358753-R21.

|

|

Internal (Wet) Brake Pads/Pucks and Neoprene Rubber O-Ring

Seal. Fits Cub Cadet garden tractor models 70, 71, 72, 73, 100, 102, 104,

105, 122, 123, 124, 125, 580, 582, 680, 682, 782, 784, 800, 1000, 1200, 1210,

1250, 1282, 1450, 1604, 1606, 1650, 1710, 1711 and 1712. IMPORTANT: Before

installing any new oil seal, always apply oil or grease inside the seal and

on the shaft to keep the rubber seal lubricated and cool until internal oil

can reach it. With no prior lubrication, the dry rubber will wear away, causing

another oil leak. Do the job right the first time, and it won't have to be

done again. Internal (Wet) Brake Pads/Pucks and Neoprene Rubber O-Ring

Seal. Fits Cub Cadet garden tractor models 70, 71, 72, 73, 100, 102, 104,

105, 122, 123, 124, 125, 580, 582, 680, 682, 782, 784, 800, 1000, 1200, 1210,

1250, 1282, 1450, 1604, 1606, 1650, 1710, 1711 and 1712. IMPORTANT: Before

installing any new oil seal, always apply oil or grease inside the seal and

on the shaft to keep the rubber seal lubricated and cool until internal oil

can reach it. With no prior lubrication, the dry rubber will wear away, causing

another oil leak. Do the job right the first time, and it won't have to be

done again.

|

|

External/Axle Disc Brake Liner

Kit. Fits Cub Cadet garden tractor models 106, 107, 127 and 147 with H-H

Products type brake calipers. OEM Cub Cadet part # IH-544835-R91.

$251.85 per set (as shown), plus shipping & handling. External/Axle Disc Brake Liner

Kit. Fits Cub Cadet garden tractor models 106, 107, 127 and 147 with H-H

Products type brake calipers. OEM Cub Cadet part # IH-544835-R91.

$251.85 per set (as shown), plus shipping & handling. |

External/Axle Disc Brake

Pad. Fits IH Cub Cadet garden tractor models 86, 108, 109, 128, 129, 149,

169, 800, 1000, 1200, 1250, 1450 and 1650. NOTE: These are sold each,

and not sold in pairs. Because sometimes one pad on the same axle will wear

more than the other. OEM Cub Cadet part # IH-548122-R2. $75.00

each, plus shipping & handling. External/Axle Disc Brake

Pad. Fits IH Cub Cadet garden tractor models 86, 108, 109, 128, 129, 149,

169, 800, 1000, 1200, 1250, 1450 and 1650. NOTE: These are sold each,

and not sold in pairs. Because sometimes one pad on the same axle will wear

more than the other. OEM Cub Cadet part # IH-548122-R2. $75.00

each, plus shipping & handling. |

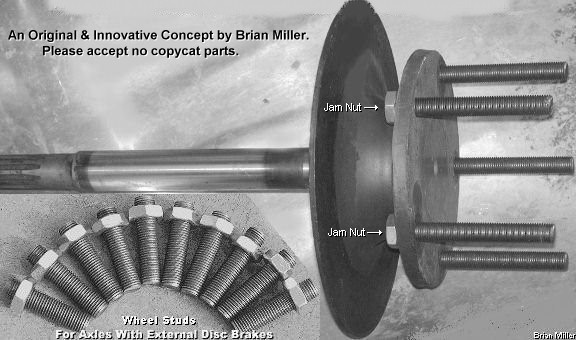

Wheel Stud Kits

for IH-built Cub Cadets with an internal (wet) brake or external

axle/disc brakes, but will work on other makes and models of garden tractors

as well. Along with wheel spacers, these are a must when wheels will not

clear the fenders and/or brake calipers. With lug nuts (below

Ê) installed, these make for easier mounting

of wheels with or without spacers on a garden tractor. Along with lug nuts

(below Ê), these make for easier mounting

of wheels with or without spacers on a garden tractor. Made of 125,000 PSI

hardened 7/16-20 UNF studs and secured from the backside in the wheel flanges

with jam nuts. Each set includes 10 studs and 10 jam nuts. Replaces Cub Cadet

part # 710-3027. An ingenious and innovative concept by Brian Miller.

Please accept no advertised copycat products of this kind. (But I do appreciate

them acknowledging my ingenuity and intelligence.) Wheel Stud Kits

for IH-built Cub Cadets with an internal (wet) brake or external

axle/disc brakes, but will work on other makes and models of garden tractors

as well. Along with wheel spacers, these are a must when wheels will not

clear the fenders and/or brake calipers. With lug nuts (below

Ê) installed, these make for easier mounting

of wheels with or without spacers on a garden tractor. Along with lug nuts

(below Ê), these make for easier mounting

of wheels with or without spacers on a garden tractor. Made of 125,000 PSI

hardened 7/16-20 UNF studs and secured from the backside in the wheel flanges

with jam nuts. Each set includes 10 studs and 10 jam nuts. Replaces Cub Cadet

part # 710-3027. An ingenious and innovative concept by Brian Miller.

Please accept no advertised copycat products of this kind. (But I do appreciate

them acknowledging my ingenuity and intelligence.)

|

|

Stainless Steel

Plain Nuts and Flat Washers for Mounting of Aluminum Wheels. 7/16-20 UNF

thread size. Will not rust. Along with studs (above

È), these make for easier mounting of

wheels on a garden tractor. The flat washers allow for equal load distribution

across the wheel for additional strength, and they prevent the socket from

marking the wheel. Torque to 50 ft. lbs. Stainless Steel

Plain Nuts and Flat Washers for Mounting of Aluminum Wheels. 7/16-20 UNF

thread size. Will not rust. Along with studs (above

È), these make for easier mounting of

wheels on a garden tractor. The flat washers allow for equal load distribution

across the wheel for additional strength, and they prevent the socket from

marking the wheel. Torque to 50 ft. lbs.

|

|

Zinc-Plated

Tapered Lug/Wheel Nuts for Mounting of Steel Wheels. 7/16-20 UNF thread size.

Along with studs (above È), these make

for easier mounting of wheels on a garden tractor. Torque to 50 ft. lbs.

NOTE: The mounting holes in steel garden tractor wheels will need to be

drilled (enlarged) to 21/32" to allow for these lug nuts to tighten properly

and keep the wheel centered with the axle. Zinc-Plated

Tapered Lug/Wheel Nuts for Mounting of Steel Wheels. 7/16-20 UNF thread size.

Along with studs (above È), these make

for easier mounting of wheels on a garden tractor. Torque to 50 ft. lbs.

NOTE: The mounting holes in steel garden tractor wheels will need to be

drilled (enlarged) to 21/32" to allow for these lug nuts to tighten properly

and keep the wheel centered with the axle.

|

|

Chrome Acorn

Closed-End Tapered Lug/Wheel Nuts for Mounting of Steel Wheels. 7/16-20 UNF

thread size. Along with studs (above È),

these make for easier mounting of wheels on a garden tractor. NOTE: The

mounting holes in steel garden tractor wheels will need to be drilled (enlarged)

to 21/32" to allow for these lug nuts to tighten properly and keep the wheel

centered with the axle. Torque to 50 ft. lbs. Chrome Acorn

Closed-End Tapered Lug/Wheel Nuts for Mounting of Steel Wheels. 7/16-20 UNF

thread size. Along with studs (above È),

these make for easier mounting of wheels on a garden tractor. NOTE: The

mounting holes in steel garden tractor wheels will need to be drilled (enlarged)

to 21/32" to allow for these lug nuts to tighten properly and keep the wheel

centered with the axle. Torque to 50 ft. lbs.

|

|

Internal Brake VS External Brake Transaxles -

Many professional pullers prefer to use the internal brake transaxle so the rear wheels can be set closer to the tractor frame, allowing for a narrower wheelbase. This require the driver to lean less when heading toward the boundary line, and the tractor can pull more straight down the track.

To convert a Cub Cadet external brake transaxle into an internal brake design, a front gear reduction housing, brake pad retainer, brake link, brake lever, push rod, pivot pin, brake pads, disc and the lower main shaft, off/out of an internal brake transaxle are required. The opposite will need to be done when converting a Cub Cadet internal brake transaxle into an external brake design. It's exactly easier (and less costly) to acquire an entire internal or external brake transaxle (in good condition, of course), install it, and fabricate or install the required brake linkage. All IH Cub Cadet tractor frames, except the "Original", are made for use with either transaxle.

Available Soon - Detailed Illustrated Plans on How to Construct a Professional Pull-Back Garden Tractor Pulling Sled and a Self-Propelled Garden Tractor/Small Wheel Mini Rod Pulling Sled (Weight Transfer Machines) - (Updated 7/16/24) [Top of Page]

FYI - I'm getting closer to

completing my sled plans. But being I have lots of work to do in my shop,

I work on designing my sled plans in my spare time. As soon as my plans with

an inventory list of parts to use and with illustrations are perfected, I'll

post the announcement in my websites. And as for prices of the pull-back

sled and self-propelled sled plans, I'm not sure yet. Make me an offer and

I'll consider it. And remember - Perfection takes time. If it's worth having,

it's worth waiting for. It'll be money well spent. - Brian Miller

If interested, please contact me below.

FYI - I'm getting closer to

completing my sled plans. But being I have lots of work to do in my shop,

I work on designing my sled plans in my spare time. As soon as my plans with

an inventory list of parts to use and with illustrations are perfected, I'll

post the announcement in my websites. And as for prices of the pull-back

sled and self-propelled sled plans, I'm not sure yet. Make me an offer and

I'll consider it. And remember - Perfection takes time. If it's worth having,

it's worth waiting for. It'll be money well spent. - Brian Miller

If interested, please contact me below.

Quality-Built and Nice-Appearing Garden Tractor & Mini Rod Self-Propelled Tractor Pulling Sleds (Weight Transfer Machines) For Sale - (Updated 8/17/24) [Top of Page]

Sleds will be built as orders are placed. A minimum 50% deposit

is required for all sled purchases. Buyer/purchaser can test sled with their

pulling tractors or vehicles on our 200 ft. dirt track, and then can tow

it on the road (like a trailer) or haul it on a large, sturdy trailer. Sleds

are designed with style and made beautiful to admire, and painted metallic

or color of your choice. Also, sleds are designed to start easy, pull smoothly

and sure to stop with grouser bar. They will also have a safety release lever

up front so when the weight box tops out and trips it, it will automatically

disengage the clutch to prevent major damage to the drive mechanism for the

weight box. And it will have another safety release lever at the rear in

case the clutch (for the weight box) is engaged when backing up the sled.

The self-propelled sleds will have a varible speed mechanical drive system

with hydraulics to lower the two front steering wheels/tires, and the bigger

sled will use hydraulics to bring the weight box back to its starting position.

By the way - the self-propelled garden tractor pulling sled that I built

in 1995 (and sold in 2021) is such an excellent design, I realized later

that I made something very special when other people copied it. It's still

in use today; click or tap photo of it to the right for a larger view.

Sleds will be built as orders are placed. A minimum 50% deposit

is required for all sled purchases. Buyer/purchaser can test sled with their

pulling tractors or vehicles on our 200 ft. dirt track, and then can tow

it on the road (like a trailer) or haul it on a large, sturdy trailer. Sleds

are designed with style and made beautiful to admire, and painted metallic

or color of your choice. Also, sleds are designed to start easy, pull smoothly

and sure to stop with grouser bar. They will also have a safety release lever

up front so when the weight box tops out and trips it, it will automatically

disengage the clutch to prevent major damage to the drive mechanism for the

weight box. And it will have another safety release lever at the rear in

case the clutch (for the weight box) is engaged when backing up the sled.

The self-propelled sleds will have a varible speed mechanical drive system

with hydraulics to lower the two front steering wheels/tires, and the bigger

sled will use hydraulics to bring the weight box back to its starting position.

By the way - the self-propelled garden tractor pulling sled that I built

in 1995 (and sold in 2021) is such an excellent design, I realized later

that I made something very special when other people copied it. It's still

in use today; click or tap photo of it to the right for a larger view.

Small size, pull-back

(non-motorized) sled with open cabin, comfortable swivel seat and controls

within easy reach for operator. For use with 1,050 lb. garden pulling tractors

and up to 1,500 lb. small wheel (26-12.00x12 tires) mini rod pulling tractors.

Length of sled: 12 ft. Total weight of sled fully loaded with weights:

approximately 4,000 lb. $6,000.00 each.

Small size, pull-back

(non-motorized) sled with open cabin, comfortable swivel seat and controls

within easy reach for operator. For use with 1,050 lb. garden pulling tractors

and up to 1,500 lb. small wheel (26-12.00x12 tires) mini rod pulling tractors.

Length of sled: 12 ft. Total weight of sled fully loaded with weights:

approximately 4,000 lb. $6,000.00 each.

To place an order, send your item(s) for repairing, and/or

for customer service assistance, and FREE honest and accurate technical

support, please contact: Brian Miller

of A-1 Miller's Performance Enterprises, 12091 N Route B, Hallsville, MO

(Missouri) 65255-9604 USA. Please call in your order or send an email with

a list parts you need and your contact information.

To place an order, send your item(s) for repairing, and/or

for customer service assistance, and FREE honest and accurate technical

support, please contact: Brian Miller

of A-1 Miller's Performance Enterprises, 12091 N Route B, Hallsville, MO

(Missouri) 65255-9604 USA. Please call in your order or send an email with

a list parts you need and your contact information.

Phone: 1-573-881-7229 (cell;

call, text or leave voicemail) or use

Whatsapp. Please call

Monday-Friday, 9am to 5pm, Central time zone, except holidays. If no answer,

please try again later. (When speaking with Brian on the phone, please

be patient and understanding because I stutter.)

Phone: 1-573-881-7229 (cell;

call, text or leave voicemail) or use

Whatsapp. Please call

Monday-Friday, 9am to 5pm, Central time zone, except holidays. If no answer,

please try again later. (When speaking with Brian on the phone, please

be patient and understanding because I stutter.)

E-mail:

pullingtractor@aol.com.

Payment Options. A-1 Miller's shop is open

to the public Monday-Friday, 9am to 5pm, Central time zone, with an appointment

on weekends, except holidays. If you're the kind of person who don't trust

delivery/shipping companies (mis)handling your high-dollar and fragile

merchandise, you can make the long drive to

A-1 Miller's new shop (click image

to the right) to personally purchase parts, or drop off and/or pick up your

carburetor, clutch assembly, engine and/or parts, etc., for repairing and/or

rebuilding. Or visit the address of our (old) shop mentioned above to drop

off your engine, transmission, transaxle, garden tractor, small motorized

vehicle, etc. We also custom build pulling tractors and other small vehicles.

Please contact me before coming so I'll be at my shop waiting for your arrival.

When you visit our shop, you will be dealing directly with the owner for

the best customer service.

12091 N Route B, Hallsville, MO - Google Maps "The road

to a [trusted] friend's house (or shop) is never long." Don't sacrifice quality

workmanship for distance. [Return

To Previous Paragraph, Section or Website]

E-mail:

pullingtractor@aol.com.

Payment Options. A-1 Miller's shop is open

to the public Monday-Friday, 9am to 5pm, Central time zone, with an appointment

on weekends, except holidays. If you're the kind of person who don't trust

delivery/shipping companies (mis)handling your high-dollar and fragile

merchandise, you can make the long drive to

A-1 Miller's new shop (click image

to the right) to personally purchase parts, or drop off and/or pick up your

carburetor, clutch assembly, engine and/or parts, etc., for repairing and/or

rebuilding. Or visit the address of our (old) shop mentioned above to drop

off your engine, transmission, transaxle, garden tractor, small motorized

vehicle, etc. We also custom build pulling tractors and other small vehicles.

Please contact me before coming so I'll be at my shop waiting for your arrival.

When you visit our shop, you will be dealing directly with the owner for

the best customer service.

12091 N Route B, Hallsville, MO - Google Maps "The road

to a [trusted] friend's house (or shop) is never long." Don't sacrifice quality

workmanship for distance. [Return

To Previous Paragraph, Section or Website]

By the way - As business is booming, we relocated our business at 12091 N. Route B, Hallsville, MO 65255 with a new, bigger, better, fully insulated, heated and air-conditioned building/shop (shouse) so we can provide many more professional services and high quality parts, and hire more reliable and knowledgeable help to have our customer's parts orders fulfilled sooner, parts repaired sooner and engine rebuilds performed promptly without a long delay. We will also offer custom welding fabrication jobs and other custom services. And we also provide pick up and delivery service and perform professional repairs for various small engines and lawn & garden equipment! Photos of our new building/shop are posted here! 12091 N Route B, Hallsville, MO - Google Maps

Payment Options, and We Ship to Canada and

Worldwide

Item(s) in a package or cushioned envelope weighing less than 1 lb. is sent

by US Postal Service Airmail Letter Post for a 4-7 days delivery. Packaged

item(s) weighing over 1 lb. and up to 66 lb. is sent by US Postal Service

Airmail Parcel Post for a 4-10 days delivery. I cannot use the US Postal

Services' Flat Rate Priority Mail envelopes and boxes to ship outside U.S.

territories. Item(s) weighing over 67 lbs. or more is sent by FedEx Ground

or equivalent services. We try to keep our shipping cost to customers within

reason. Therefore, we don't ship our products in a fancy-looking package

with our company name and/or logo on it because most customers will just

toss it in the trash after they remove the contents. And being there is no

USPS tracking number outside the US, all I can do is make sure I write your

address correctly on the customs form and on your package.

My websites are not set up to process orders and accept payments. Therefore, to place an order with me, please call either number above or send an email with a list of parts you need, with your name, complete and correct postal mailing address and phone number. For payment options, I accept cash (in person), USPS Postal Money Orders, cashier's checks, business checks, MasterCard, VISA, Discover, American Express (please add 2.5% to the total amount for the credit/debit card processor's surcharge). If paying with a credit/debit card, please call me at either number above. Or to make a payment to me through PayPal, please click this link: https://www.paypal.com. Or use Cash App (username: pullingtractor) or Venmo (username: Pullingtractor) to make a payment to me. And be sure to mention a description of what the payment is for with your full name, postal address, phone number and email address. I also accept payments through Western Union Money Transfer or MoneyGram Money Transfers. If sending a money order or cashier's check, please include a note in the envelope with your name, complete mailing address, phone number, email address and a description of what the payment is for. I'll make a note of your order when I have all your information, and I may have to order some of the parts on your list, which should take a few days to come in, but I will send everything to you as soon as I have the parts in stock after I receive your payment.

Return To Previous Website | Top of Page

Copyright © 1996-Present. This website created, designed and maintained by Brian Miller